Thingiverse

TTT - Titan Take Three by thsturgill

by Thingiverse

Last crawled date: 3 years, 1 month ago

TTT - Titan Take Three

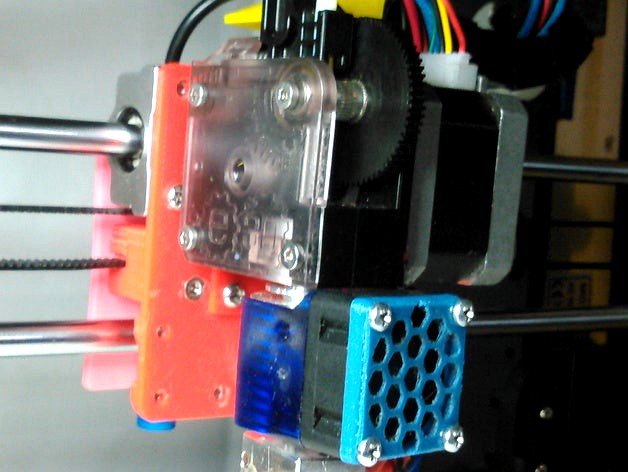

E3D Titan mount for the ANET A8 and other Prusa i3 clones using bearing blocks on the X-Axis. OpenSCAD code included so that you can modify as needed. Two parts, base plate and mount, are required and five; fan mount, captured fan nozzle, sensor mount, and cable chain ends are optional. The parts are designed separately to allow printing with mimimal supports.

1) The base plate or carrier, which can be printed with or without the integrated belt attachments. The belt attachment can also be printed separately using the SCAD file to generate the STL by changing variables. Nut catches are provided for the front mount fan and sensor mounts and for the rear mount sensor mount. Thickness of the plate and mount have been kept to a minimum to allow re-use of the original screws to attach to the bearing blocks.

2) The extruder mount, which includes a tab for either cable restraint or mounting a cable chain. The extruder mount design allows full access to the Titan's features. I use a shorter motor (34mm vs 40mm which fine with the gearing advantage of the Titan, and also serves to lighten the assembly. The original motor can be used with this assembly. The mount uses the same holes as the bearings, so leave out the top screws on all three bearings when mounting the base plate to the bearings. You will add them when you install the mount bracket.

3a) OPTIONAL: Side fan mount which allows the stock ANET fan to be rotated so that the air intake faces the extruder. Includes a hook at the top to keep the wires away from the X-axis switch. This assembly could be replaced with thing:1354526 by 3DIYOriginal which would also replace the stock E3D fan. There are also several other options available.

3b) OPTIONAL: Captured fan nozzle replaces the original nozzle with one that will not droop or come off.

4a) OPTIONAL: The rear sensor mount, which mounts from the back and uses holes for the belt attachment. This works with either my plate or the original ANET hot-end/extruder. Optionally, use the ANET sensor and plate if you have them. This is set for 12mm diameter sensors, but the SCAD file will allow easy modification.

4b) OPTIONAL: Front sensor mount places the sensor in front of the motor. While closer to the nozzle, I did not like this position personally as it is off the build plate when the nozzle is homed.

5a&b) OPTIONAL: Cable Chain mounts. One screws to the top of the extruder mount and the other simply clamps on top of the x-motor mount. Standard chain should work well.

STL files have been included for each option, based on a 34mm motor length. You can use the OpenScad files to create your own STL files. The fan mount, plate, rear sensor mount, and extruder mount are in a separate files. The 'rounded_cube.scad' is a routine that I use anytime I need a cube with rounded edges and is used as an include by the other programs, so simply place it in the same directory.

Thom Sturgill

9/27/16 fixed issue with side fan catching on X-limit switch and added optional cable chain attachments. Modified Rear Sensor so that it prints flat and lightened it.

9/28/16 re-enforce joints on mount.

9/30/16 Uploaded tweaked side fan mount and captured fan nozzle. Uploaded pictures.

10/5/16 modified rear sensor mount to include nut capture for top nut.

E3D Titan mount for the ANET A8 and other Prusa i3 clones using bearing blocks on the X-Axis. OpenSCAD code included so that you can modify as needed. Two parts, base plate and mount, are required and five; fan mount, captured fan nozzle, sensor mount, and cable chain ends are optional. The parts are designed separately to allow printing with mimimal supports.

1) The base plate or carrier, which can be printed with or without the integrated belt attachments. The belt attachment can also be printed separately using the SCAD file to generate the STL by changing variables. Nut catches are provided for the front mount fan and sensor mounts and for the rear mount sensor mount. Thickness of the plate and mount have been kept to a minimum to allow re-use of the original screws to attach to the bearing blocks.

2) The extruder mount, which includes a tab for either cable restraint or mounting a cable chain. The extruder mount design allows full access to the Titan's features. I use a shorter motor (34mm vs 40mm which fine with the gearing advantage of the Titan, and also serves to lighten the assembly. The original motor can be used with this assembly. The mount uses the same holes as the bearings, so leave out the top screws on all three bearings when mounting the base plate to the bearings. You will add them when you install the mount bracket.

3a) OPTIONAL: Side fan mount which allows the stock ANET fan to be rotated so that the air intake faces the extruder. Includes a hook at the top to keep the wires away from the X-axis switch. This assembly could be replaced with thing:1354526 by 3DIYOriginal which would also replace the stock E3D fan. There are also several other options available.

3b) OPTIONAL: Captured fan nozzle replaces the original nozzle with one that will not droop or come off.

4a) OPTIONAL: The rear sensor mount, which mounts from the back and uses holes for the belt attachment. This works with either my plate or the original ANET hot-end/extruder. Optionally, use the ANET sensor and plate if you have them. This is set for 12mm diameter sensors, but the SCAD file will allow easy modification.

4b) OPTIONAL: Front sensor mount places the sensor in front of the motor. While closer to the nozzle, I did not like this position personally as it is off the build plate when the nozzle is homed.

5a&b) OPTIONAL: Cable Chain mounts. One screws to the top of the extruder mount and the other simply clamps on top of the x-motor mount. Standard chain should work well.

STL files have been included for each option, based on a 34mm motor length. You can use the OpenScad files to create your own STL files. The fan mount, plate, rear sensor mount, and extruder mount are in a separate files. The 'rounded_cube.scad' is a routine that I use anytime I need a cube with rounded edges and is used as an include by the other programs, so simply place it in the same directory.

Thom Sturgill

9/27/16 fixed issue with side fan catching on X-limit switch and added optional cable chain attachments. Modified Rear Sensor so that it prints flat and lightened it.

9/28/16 re-enforce joints on mount.

9/30/16 Uploaded tweaked side fan mount and captured fan nozzle. Uploaded pictures.

10/5/16 modified rear sensor mount to include nut capture for top nut.

Similar models

thingiverse

free

i3 Titan mount system by thsturgill

...not hit the upper bearing case. i used phillips head screws which have a flatter head than allen head.

scad files are provided.

thingiverse

free

Anet A8 3 Bearing X Carriage With CableChain by werddomain

... light cable chain as they move more easily.

when i have flashed the frimware, i will post all the settings for the bltouch here.

thingiverse

free

Anet A8 E3D Stock with Cable Chain Mount by TatoTot

...e a8 with a cable chain attached. the mount for the extruder is offset so the nozzle is centered. hope someone finds it usefull.

thingiverse

free

Anet A6 integrated autolevel, extruder chain cable and detachable fan by lupus00

... into one:

autolevel mount,

extruder chain cable

detachable extruder fan.

sketchup file included for anyone customization needs.

thingiverse

free

Anet A8 X axis Cable chain mounts

...anet a8 x axis cable chain mounts

thingiverse

x motor and extruder mount for installing a cable chain on the anet a8.

thingiverse

free

TronXY X5S Titan Aero Mount by kyrixa10

...the heads of the m5 bolts. the cutouts are 10mm diameter and are 5mm deep.

print 3 of the 6mm spacers and 2 of the 20mm spacers.

thingiverse

free

Anet A8 Titan Extruder & 3D Touch mount by devatu

...ce that one with the e3d titan extruder & e3d v6 hotend since it is a remix, i think it will fit without any problems though.

thingiverse

free

40x40 dual fan mount by FoxyHox

...erse

40x40 dual fan mount

used to cool down nozzles and extruder motor

temporaily attachable to plates within thickness of 1.5cm

thingiverse

free

Anet A8 Titan Extruder mount

...anet a8 titan extruder mount

thingiverse

titan extruder mount for the anet a8. mounts at the top center using two screws.

thingiverse

free

E3D Titan Extruder Inductive Sensor Mount by zenstorm

... you use an inductive sensor with your new titan extruder. :) zip ties work best for securing the mount. i printed with supports.

Thsturgill

thingiverse

free

MK2 filament holder & guide by thsturgill

...e reason or another - too tall or too wide... openscad files included so you can tweak. print the filament holder with support.

thingiverse

free

Bondhous Metric Driver holder by thsturgill

...my enclosure. i printed 3 perimeters, 10% gyroid infill. and attched using 3m command strips. screw holes provided for 6 mm dia.

thingiverse

free

Raspberry PI case for Prusa Mini base by thsturgill

...h a rpi b+ case for octoprint integration. screws needed for case and fan. snaps into new version psu case from prusa mini base.

thingiverse

free

XBOX controller wall bracket by thsturgill

...rounded_cube.scad" is a library file used to parametrically create cubes with rounded sides and is used by the primary file.

thingiverse

free

Raspberry Pi case for Prusa MK2(s) with header access by thsturgill

... to header, recess for screw head inside case. scad file allows choice of which item to render, original files slightly renamed.

thingiverse

free

YACO - Yet another Christmas Ornament by thsturgill

...ave also printed in pla. use zero infill to create a light ornament and glue the three parts together.

openscad source included.

thingiverse

free

Prusa Mini Base leg extension by thsturgill

... https://www.thingiverse.com/thing:495821 (shown).

three heights: 7mm, 15mm, and 25mm all but shortest have insets on the bottom.

thingiverse

free

YAPB (Yet Another PokeBall) by thsturgill

...ring so that there are two pieces of filament holding them so they can not rotate. ball can be completely assembled without glue.

thingiverse

free

YAFR - Yet Another Filament Reel (Parametric) by thsturgill

...nge 200mm hub 55 mm by 60mm wide to match hatchbox reels and 120mm flange with 60mm hub 30mm wide for small remnants or samples.

thingiverse

free

MK2 Frame upgrade by thsturgill

...extrusions. hole sizes are 3.1mm (1/8") and 5.1mm (3/16"). https://github.com/prusa3d/original-prusa-i3/tree/mk3/frame

Ttt

thingiverse

free

Bomb from Pavlov VR (TTT) by narwhal11

...bomb from pavlov vr (ttt) by narwhal11

thingiverse

a printable model of the bomb from ttt mode in pavlov

thingiverse

free

Heattower - Temperature Test Tower - TTT by Z3ALT

...om 126: 230°c

from 151: 235°c

from 176: 240°c

from 201: 245°c

from 226: 250°c

please comment, if you need some improvements.

thingiverse

free

type something by Icanthinkofanid

...type something by icanthinkofanid thingiverse ttt ...

thingiverse

free

Foot Extension Makerbot Replicator 2 62mm TTT by Masterteeko

...m/small-clear-cabinet-furniture-bumpers/dp/b005s1tjlc/ref=sr_1_4?ie=utf8&qid=1394569835&sr=8-4&keywords=drawer+bumper

thingiverse

free

80mm Computer Hole Cover by Masterteeko

...a way to block some ports for airflow management. ttttrue, tried and tested) installed 3 in my computer works...

thingiverse

free

Toy-Brick Tensile Tester by SoftMatterPhysics

...common and available from large distributors in total the ttt can be built for around 700 eur – significantly...

grabcad

free

ttt

...ttt

grabcad

ttt

grabcad

free

ttt

...ttt

grabcad

ttt

grabcad

free

ttt

...ttt

grabcad

ttt

Titan

design_connected

$18

Titan

...titan

designconnected

original btc titan computer generated 3d model.

3d_ocean

$25

RMS Titanic

...rms titanic

3docean

ship steamer titanic

3d model of the rms titanic

turbosquid

$49

Titan

...quid

royalty free 3d model titan for download as obj and ztl on turbosquid: 3d models for games, architecture, videos. (1314276)

turbosquid

$8

Titan

...d

royalty free 3d model titan for download as , fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1545505)

3d_export

$15

eren yeager titan from attack on titan

...eren yeager titan from attack on titan

3dexport

3d model of eren titan

3d_export

$5

titanic new

...titanic new

3dexport

titanic 3d model normal quality for animation

3d_export

$100

Titan 3D Model

...titan 3d model

3dexport

silo launcher rocket titan

titan 3d model acquarius 37854 3dexport

3d_ocean

$25

Titan

...nfs nfshs one ps ps1 psone rod speed sports stakes titan transport vehicle

quality exterior and low polygon interior concept car.

3ddd

$1

Titanic Lamp(table)

...titanic lamp(table)

3ddd

titanic lamp(table)

turbosquid

$10

Titan chair

...osquid

royalty free 3d model titan chair for download as max on turbosquid: 3d models for games, architecture, videos. (1301533)

Three

turbosquid

$5

three

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

three tiger

...three tiger

3dexport

three tank tiger move in attack.

3d_export

$5

three trees

...three trees

3dexport

three trees tri dereva vegetation

design_connected

$16

Three Skin

...three skin

designconnected

moroso three skin computer generated 3d model. designed by arad, ron.

turbosquid

$1

Three vases

...s

turbosquid

free 3d model three vases for download as blend on turbosquid: 3d models for games, architecture, videos. (1214567)

turbosquid

$2

three candlesticks

...

royalty free 3d model three candlesticks for download as dwg on turbosquid: 3d models for games, architecture, videos. (1479291)

turbosquid

$2

three rings

...quid

royalty free 3d model three rings for download as blend on turbosquid: 3d models for games, architecture, videos. (1327579)

3d_export

free

Three free cans

...three free cans

3dexport

three free cans

turbosquid

$10

Satsumas three

...ree 3d model satsumas three for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1378138)

turbosquid

$3

Three trees

...y free 3d model three trees for download as c4d, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1709095)

Take

design_connected

$9

Take

...take

designconnected

kartell take computer generated 3d model. designed by laviani, ferruccio.

3d_export

free

Takes

...takes

3dexport

this model can be used in further visualization and rendering.

3d_ocean

$18

Kartell Take

...tylish

high quality model of take lamp by kartell. pack containts: – highly detailed model of take lamp – realistic v-ray shaders

3d_export

$65

hostage taking

...hostage taking

3dexport

simple rendering of the scene file

3d_export

$65

hostage taking

...hostage taking

3dexport

simple rendering of the scene file

3ddd

$2

busnelli / take it easy

...busnelli / take it easy

3ddd

busnelli

диван фабрики"busnelli",модель"take it easy"

design_connected

$16

Take a line for a walk

...for a walk

designconnected

moroso take a line for a walk lounge chairs computer generated 3d model. designed by alfredo häberli.

turbosquid

$12

Take Away Cup

...yalty free 3d model take away cup for download as 3ds and obj on turbosquid: 3d models for games, architecture, videos. (1324337)

turbosquid

$3

Kartell Take Lamp

... 3d model kartell take lamp for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1218111)

turbosquid

$30

Take-a-Line-For-a-Walk

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.