Thingiverse

TronXY P802MA Modular frame braces by AAZeroThree4

by Thingiverse

Last crawled date: 3 years, 5 months ago

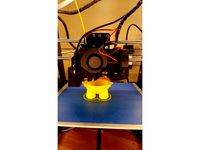

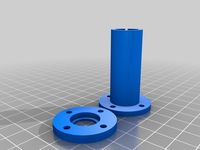

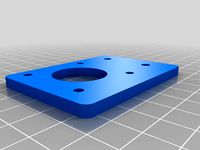

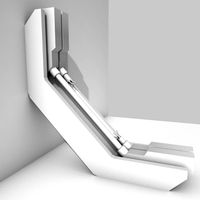

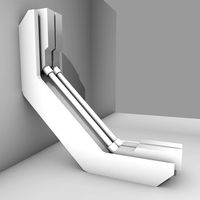

I printed some modular vertical frame braces to reduce wobble in the z-x plane to less than 0.1mm relative movement at the top of the z axis. Note this was crudely measured.

At this stability it is an angular error of 0.026 degrees and the deviation in mm in the plane vertical alignment is equal to:

the z axis printing height x 0.000454.

The multiplier comes from the tangent of the angular error.

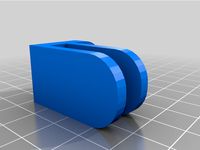

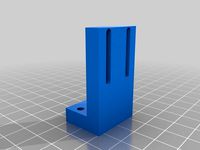

The braces fit together with dowels that are friction fit. They fit between the horizontal surfaces of the acrylic frame.

There is some movement along the rod, you can try different infill patterns or increase the diameter to get more rigidty but make sure they don't get in the way of the carriages or anything else.

Scad files included for customisation.

You need two frame braces and two dowels and one rod for each side. It might be easier to print two sets of the above all together so you have a complete brace for each side.

If you need to make slight adjustments, you can print a washer to put between the brace sections and the rod. If the dowels are tight don't force them, lightly sand them. A friction fit doesn't matter much here as the part is in compression. Don't bend the rods sideways or they will break!.

You might experiment with a different cross section to get more rigid rods. This is left as an exercise for the reader LOL.

Actually the braces can be printed alone and the rod replaced with copper pipe or tubing 15mm outside diameter (OD). The base of the brace is 16mm OD and the shaft is 12mm OD. Copper pipe is very strong and rigid and cheap. Again fine adjustments can be made with a 0.2mm high printed washer at the base of the pipe. You might have a piece laying around.

At this stability it is an angular error of 0.026 degrees and the deviation in mm in the plane vertical alignment is equal to:

the z axis printing height x 0.000454.

The multiplier comes from the tangent of the angular error.

The braces fit together with dowels that are friction fit. They fit between the horizontal surfaces of the acrylic frame.

There is some movement along the rod, you can try different infill patterns or increase the diameter to get more rigidty but make sure they don't get in the way of the carriages or anything else.

Scad files included for customisation.

You need two frame braces and two dowels and one rod for each side. It might be easier to print two sets of the above all together so you have a complete brace for each side.

If you need to make slight adjustments, you can print a washer to put between the brace sections and the rod. If the dowels are tight don't force them, lightly sand them. A friction fit doesn't matter much here as the part is in compression. Don't bend the rods sideways or they will break!.

You might experiment with a different cross section to get more rigid rods. This is left as an exercise for the reader LOL.

Actually the braces can be printed alone and the rod replaced with copper pipe or tubing 15mm outside diameter (OD). The base of the brace is 16mm OD and the shaft is 12mm OD. Copper pipe is very strong and rigid and cheap. Again fine adjustments can be made with a 0.2mm high printed washer at the base of the pipe. You might have a piece laying around.

Similar models

thingiverse

free

Z brace using 1/2 inch wooden dowel by emaglott

...le to lock the dowel to the bracket at each end. the wood is very strong in tension and compression so makes a very rigid brace.

thingiverse

free

CR-10 Z-Axis Brace by DrSteve42

...h can help improve the quality of taller prints.

the upper brackets have been designed so that there is no loss of z-axis height.

thingiverse

free

anet a8 frame brace back y axis by nclsdf

...d two m8 washers.

front brace versions : http://www.thingiverse.com/thing:1844448

and : http://www.thingiverse.com/thing:1860060

thingiverse

free

Robo3D Z-axis Rod Brace by odie_wan

...securing with two m3 screws and includes a drill template, but you can just glue them in place with ca.

just print at 10% infill.

thingiverse

free

Z-Axis Double Rod Stabilizer for Printrbot by wersy

...more stiffness you will reach with two rods. in combination with a additional clamp between the rods will generate a rigid frame.

thingiverse

free

Qidi Tech Z-Axis 8mm Rod Brace by KludgeGuru

...ods by adding more support around the bottom.

this is made for the qidi printers with 8mm z-axis rods.

design in solidworks 2016.

thingiverse

free

Malyan M150 Z Brace by nullandvoid

...e stable.

square up your z axis, adjust the brace ends til all the holes line up (this might take some grunting) and screw it on.

thingiverse

free

Robo3D Z-Axis Slide Rod Brace by odie_wan

...mplate at no extra charge!!! :)

this design doesn't require any support and can be printed without a raft, even. 10% is fine.

thingiverse

free

Ender 3 Cable Chain Z-Axis Connector by Sevary

...can be used to zip-tie the cables.

because there's a slight left-shift, you'll need the new included frame connector too.

thingiverse

free

Y-Axis Rod Alignment Jig for Wanhao Di3v2.1 (for use with Z-brace mod) by Drake_Richards

...ww.thingiverse.com/thing:921948

if your z-braces are on felt feet or if you don't have the z-brace then these won't work.

Aazerothree4

thingiverse

free

Z sensor mount locators for TronXY P802MA by AAZeroThree4

...ery light sanding. i like a perfect fit, so i printed at 100% scale.

you will need to recalibrate your offsets after doing this.

thingiverse

free

Y axis rear motor mount with sound dampeners for TronXY P802MA by AAZeroThree4

...one acoustic washers for silencing pcs. 2.5mm inside diameter and 2mm thickness. the nubs are for the washers to be located on.

thingiverse

free

TronXY P802MA Warped Carriage Levelling Washers M3 by AAZeroThree4

...n place because that nut should be a permanent part of the carriage.

it's customisable, the code is included as an scad file.

thingiverse

free

TronXY P802 PSUCover switch, no socket. by AAZeroThree4

...le using a cad program of your choice.

the stock psu is not made perfectly square in my case so there is a tiny gap when mounted.

thingiverse

free

Y axis pulley bushes for TronXY P802MA by AAZeroThree4

... don't let the bed cool properly the part will deform. you can re-form it by placing it on a heated bed.

enjoy the silence!!

thingiverse

free

Belt clip clamp removeable for GT2-6 toothed belt zip tie alternative by AAZeroThree4

...oth at a time. it's hard to get really high tension this way but it's working for my purposes.

i included the scad file.

thingiverse

free

Sound dampening bush for use with acoustic washers to make printer quiet. by AAZeroThree4

... smooth rod spacers to place at the top or bottom of the smooth rods to account for the thickness of the sound dampening washers.

P802Ma

thingiverse

free

Tronxy P802MA sensor mount by Chrysroy

...tronxy p802ma sensor mount by chrysroy

thingiverse

tronxy p802ma sensor mount with one screw adjustment

thingiverse

free

P802MA Marlin 1.1.8 by fregoe85

...verse

marlin 1.1.8 for tronxy p802ma. will need an arduino uno to update boot loader. use arduino 1.8.5

upgraded to marlin 1.1.9

thingiverse

free

P802MA LCD backplate by Lowich

...ted just on the right side, it should be fine, becouse that's where the button is.

also check if your cables are long enough.

thingiverse

free

Filament Guide for Tronxy P802ma by egerry905

...de created for my tronxy p802ma 3d printer. clips on the top acrylic piece next to the lcd display.

nothing fancy, but it works.

thingiverse

free

Hotbed wire holder for Tronxy p802ma by Atiesh

...e holder for tronxy p802ma by atiesh

thingiverse

hotbet wire holder for tronxy p802ma 3d printer.

help not drop wires to y motor

thingiverse

free

TronXY P802MA Part Cooling Fan Duct by DJ_Foot

...tronxy p802ma part cooling fan duct by dj_foot

thingiverse

part cooling fan duct upgrade for the tronxy p802ma printer

thingiverse

free

Double Fan Mount for Tronxy P802MA by Chriskelly

...mount for tronxy p802ma by chriskelly

thingiverse

tronxy p802ma double fan mount! i have now added the fan ducts aswell!! enjoy!

thingiverse

free

P802ma Table Mount

...es with the rubber mat used for toolbox drawers to reduce vibration noise transfer. this is for the tronxy p802ma, anet a8 clone.

thingiverse

free

BL Touch mount for p802ma by richardcampbell1976

...bl touch mount for p802ma by richardcampbell1976

thingiverse

mount to replace z stop with bl touch on 802ma

thingiverse

free

Reinforcement T corner for Tronxy P802MA by auger

...reinforcement t corner for tronxy p802ma by auger

thingiverse

reinceforcement for t corner

Tronxy

thingiverse

free

LMF8LUU for tronxy x5s

...lmf8luu for tronxy x5s

thingiverse

lmf8luu for tronxy x5s

thingiverse

free

TRONXY XY2PRO by MaiMaiFACTORY

...tronxy xy2pro by maimaifactory

thingiverse

tronxy xy2-pro

sadebox

thingiverse

free

Power_supply_cover for TRONXY by Karollo

...power_supply_cover for tronxy by karollo

thingiverse

power supply cover for tronxy.

thingiverse

free

Tronxy support by d3m1sf

...tronxy support by d3m1sf

thingiverse

soporte para impresora tronxy x3.

thingiverse

free

Tronxy 13mm wrench

...tronxy 13mm wrench

thingiverse

13mm wrench for hotend fitting on tronxy x1...

thingiverse

free

Tronxy x5s by alex190074

...tronxy x5s by alex190074

thingiverse

tronxy x5s cart x fully adjustable only !!

thingiverse

free

Tronxy Logo

...tronxy logo

thingiverse

made this logo

thingiverse

free

Patas TronXY X3 - Vitofeli - TronXY Legs by Todopic

...todopic

thingiverse

patas separadoras para la tronxy x3, permite colocar la caja de control debajo y aprovechas mejor el espacio

thingiverse

free

TRONXY X5S EXTRUDER by ADAM98

...tronxy x5s extruder by adam98

thingiverse

tronxy x5s extruder

thingiverse

free

Belt tensioner Tronxy by jpalianak

...belt tensioner tronxy by jpalianak

thingiverse

belt tensioner tronxy

Braces

archive3d

free

Bracing 3D Model

...

holder bracing strengthening

bracing 4 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archive3d

free

Bracing 3D Model

...

bracing strengthening holder

bracing 2 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

turbosquid

$5

brace PARIS

...osquid

royalty free 3d model brace paris for download as max on turbosquid: 3d models for games, architecture, videos. (1284415)

archive3d

free

Bracing 3D Model

...older fastening strengthening

bracing 1 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archive3d

free

Bracing 3D Model

...older fastening strengthening

bracing 3 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

turbosquid

$20

Corner Brace Bracket

...oyalty free 3d model corner brace bracket for download as stl on turbosquid: 3d models for games, architecture, videos. (1322777)

turbosquid

$10

Craftsman Handtools - Brace

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$2

Degree Brace 4

...el degree brace 4 for download as 3ds, max, obj, c4d, and fbx on turbosquid: 3d models for games, architecture, videos. (1205705)

turbosquid

$1

Degree Brace 3

...el degree brace 3 for download as 3ds, max, obj, c4d, and fbx on turbosquid: 3d models for games, architecture, videos. (1205719)

turbosquid

$1

Degree Brace 2

...el degree brace 2 for download as 3ds, max, obj, c4d, and fbx on turbosquid: 3d models for games, architecture, videos. (1205714)

Modular

3ddd

$1

MODULAR

...modular

3ddd

modular , врезной свет

modular потолочные светильники

3ddd

$1

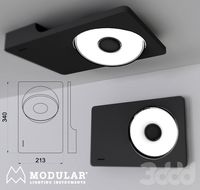

Modular Spock

...modular spock

3ddd

modular

modular spock

3ddd

$1

MODULAR / Spock

...modular / spock

3ddd

modular

modular/spock

design_connected

$7

Modular

...modular

designconnected

emmemobili modular shelves and storage computer generated 3d model. designed by ferruccio laviani.

3ddd

$1

Modular spock

...modular spock

3ddd

modular

spock wall led

turbosquid

$25

Modular sofa Angelo Cappellini Modular

...a angelo cappellini modular for download as max, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1570923)

turbosquid

$15

Modular sofa Angelo Cappellini Modular

...a angelo cappellini modular for download as max, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1570304)

3ddd

$1

Modular 2FLAT2C

...modular 2flat2c

3ddd

modular

modularhttp://www.supermodular.com/

3d_export

free

Modular walls

...modular walls

3dexport

modular walls for playing without materials and textures

3ddd

$1

Modular / Lighting Juliette

...modular / lighting juliette

3ddd

modular

modular lighting juliette

Frame

archibase_planet

free

Frame

...frame

archibase planet

frame photo frame

frame n190813 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Frame

...frame

archibase planet

frame photo frame

frame n071113 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3ddd

$1

Frame

...frame

3ddd

frame

3ddd

free

Frame

...frame

3ddd

frame

archibase_planet

free

Frame

...frame

archibase planet

frame mirror frame ornament

frame n260113 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Frame

...frame

archibase planet

frame photo frame

frame photo n190813 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Frame

...frame

archibase planet

frame window window frame

frame 1 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Frame

...frame

archibase planet

frame window frame window

frame 3 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Frame

...frame

archibase planet

frame wall frame decoration

frame 1 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Frame

...frame

archibase planet

frame window window frame

frame 2 - 3d model (*.gsm+*.3ds) for interior 3d visualization.