Thingiverse

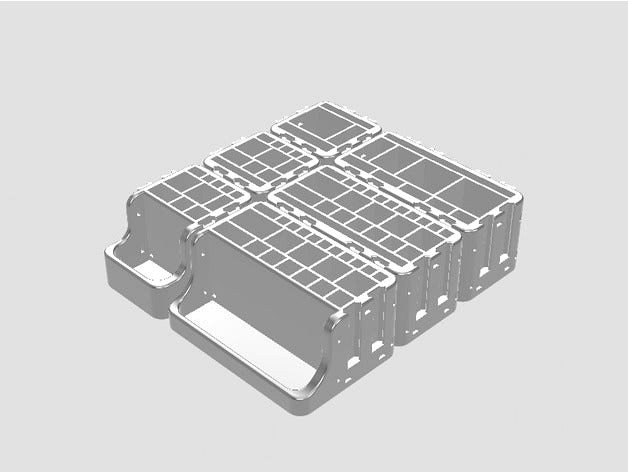

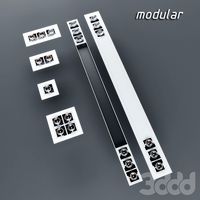

tool- and penholder - deskorganizer - modular - boxes by AzurOne

by Thingiverse

Last crawled date: 3 years ago

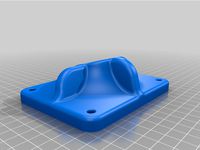

the holes / guides / tunnels are designed for cable ties.

for none needed holes = > i leave support

Printed with a Prusa Style 3DPrinter

I am printing nearly everything sucessfully in high definition

(layer height 0,05mm-0,2mm) with these types of filament:

White PLA Filament 1,75 mm:

3 spool pack (nicest price)1 spool pack

Black PLA Filament 1,75 mm:

3 spool pack (nicest price)1 spool pack

!!!NOW THIS IS SUPER HOT!!!

MECHANICAL HIGHLY DURABLE - NICEST SURFACES DUE TO TRANSPARENT NONE PIGMENTED PETG FILAMENT

TRANSPARENT PETG Filament1 spool pack

Print Settings:

Layer:

height:0,2

perimeters: 3

solid layers: top4 bottom4

Infill: 10%

Support:yes

Advanced:

extrusion width:

default: 0,45

first layer: 0,45

perimeter: 0,45

external perimeter: 0,45

infill: 0,4

solid infill: 0,7

top solid infill: 0,45

support material: 0,35

Infill perimeter overlap: 30%

Bridge Flow: 0,95

For support:

< Shirts, Hoodies, Stickers, Mugs >

PAYPALME

Thank you, have a nice day, n cya o/

Update:

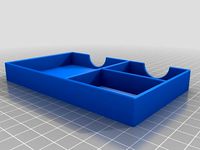

added an inlays for the x1 and x2 frontpart to organize:

usb-sticks

sd-cards in several formats

usb-adapters

other stuff

added a easy-to-print version of the things by simplifying the rails. https://www.thingiverse.com/thing:2924654

note: I still prefer to print the version with the complex rails - as its a nice benchmark for me o/

I always print these parts with 8-10% infill, how much i used for this print i'm not aware anymore.

The inlay was definitely an 8% infill print.

the numerous walls contribute to the stability of parts.

Print settings:

Filament:

PETG:

diameter 1.75mm

extrusion mulktiplier: 1 (depends on your filament)

density:1.29g/cm³ (depends on your filament)

cost: too much money/kg

temperature (°C)

extruder first layer: 230 other layers: 240 (depends on your filament)

bed: first layer:85 other layers: 90 (depends on your filament)

Layers and Perimeters:

layer height 0.2

perimeters 2

horizontal shells: solid layers: top 3, bottom 3

ensure vertical shell thickness: enabled

detect bridging perimeters: enabled

Infill:

8% Infill

fill pattern: grid

top/bottom fill pattern: rectilinear

combine infill every 1 layers

only infill where needed: disabled

(causes the infill to not get parallel to the perimeter lines and within this to get rarely connected/melted to the perimeters. please let this deactivated)

solid infill every: "0" layers

fill angle: 45°

solid infill threshold area: 0 mm²

bridging angle: 0°

only retract when crossing perimeters: disabled

infill before perimeters: disabled (i think if the perimeters are printed first and have time to cool down, they are building a smoother object surface)

skirt and brim

loops: 1

distance from object: 2mm

skirt height: 2 layer

minimum extrusion length: 4mm

brim width:0mm

Support Material:

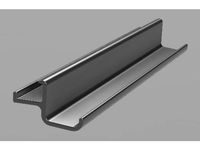

generate support material: enabled (its only for the rails)

overhang threshold: 45°

enforce support for the first: "0" layers

raft layer: "0" layer

options for support material and raft

contact z distance: "0.2" (detachable)

patter: rectilinear

support sheath around the support: disabled

pattern spacing: 2 mm

pattern angle: 0°

interface layers: "2" layers

interface pattern spacing: 0.2 mm

interface loops: disabled

support on build plate only: enabled (so the support will only get generated for the rails, the print of the cable-tie-tunnels works great with bridging)

xy separation between an object and its suport: 0.4 mm

don't support bridges: enabled

synchronize with object layers: disabled

speed:

perimeters 45mm/s

small perimeters: 25mm/s

external perimeters:35mm/s

infill: 170mm/s

solid infill: 170mm/s

top solid infill: 50mm/s

support material: 50mm/s

support material interface:100%

bridges: 30mm/s

gap fill: 40mm/s

speed for non-print moves

travel: 180mm/s

modifiers

first layer speed: 30mm/s

acceleration control

perimeters 800mm/s²

infill: 1500mm/s²

bridge: 1000mm/s²

first layer: 1000mm/s²

default: 1000mm/s²

autospeed:

max print speed: 170mm/s

max volumetric speed: 0 mm³/s

max volumetric slope positive: 0 mm³s/s²

max volumetric slope negative: 0 mm³s/s²

Advanced:

default extrusion width: 0.45mm

first layer: 0.6mm (the first layer is on the printbed and with good calibration and configs it gets perfectly smooth - I print it with a wide layer so that it goes a little faster)

perimeters: 0.45 mm

external perimeters: 0.45 mm

infill: 0.4 mm (with this setting, my infill layer lines are still very stable)

solid infill: 0.7 mm (This does not affect the upper layer and the plains fill up well and quickly)

top solid infill: 0.45 mm (my config for a smooth surface)

support material: 0.35 mm

overlap:

infill/perimeter overlap: 30% (so that infill and perimeter are well glued together)

bridge flow ratio: 0.95

other

clip multi-part objects: enabled

elefant foot compensation: 0mm

xy size compensation: 0mm

resolution 0mm

for none needed holes = > i leave support

Printed with a Prusa Style 3DPrinter

I am printing nearly everything sucessfully in high definition

(layer height 0,05mm-0,2mm) with these types of filament:

White PLA Filament 1,75 mm:

3 spool pack (nicest price)1 spool pack

Black PLA Filament 1,75 mm:

3 spool pack (nicest price)1 spool pack

!!!NOW THIS IS SUPER HOT!!!

MECHANICAL HIGHLY DURABLE - NICEST SURFACES DUE TO TRANSPARENT NONE PIGMENTED PETG FILAMENT

TRANSPARENT PETG Filament1 spool pack

Print Settings:

Layer:

height:0,2

perimeters: 3

solid layers: top4 bottom4

Infill: 10%

Support:yes

Advanced:

extrusion width:

default: 0,45

first layer: 0,45

perimeter: 0,45

external perimeter: 0,45

infill: 0,4

solid infill: 0,7

top solid infill: 0,45

support material: 0,35

Infill perimeter overlap: 30%

Bridge Flow: 0,95

For support:

< Shirts, Hoodies, Stickers, Mugs >

PAYPALME

Thank you, have a nice day, n cya o/

Update:

added an inlays for the x1 and x2 frontpart to organize:

usb-sticks

sd-cards in several formats

usb-adapters

other stuff

added a easy-to-print version of the things by simplifying the rails. https://www.thingiverse.com/thing:2924654

note: I still prefer to print the version with the complex rails - as its a nice benchmark for me o/

I always print these parts with 8-10% infill, how much i used for this print i'm not aware anymore.

The inlay was definitely an 8% infill print.

the numerous walls contribute to the stability of parts.

Print settings:

Filament:

PETG:

diameter 1.75mm

extrusion mulktiplier: 1 (depends on your filament)

density:1.29g/cm³ (depends on your filament)

cost: too much money/kg

temperature (°C)

extruder first layer: 230 other layers: 240 (depends on your filament)

bed: first layer:85 other layers: 90 (depends on your filament)

Layers and Perimeters:

layer height 0.2

perimeters 2

horizontal shells: solid layers: top 3, bottom 3

ensure vertical shell thickness: enabled

detect bridging perimeters: enabled

Infill:

8% Infill

fill pattern: grid

top/bottom fill pattern: rectilinear

combine infill every 1 layers

only infill where needed: disabled

(causes the infill to not get parallel to the perimeter lines and within this to get rarely connected/melted to the perimeters. please let this deactivated)

solid infill every: "0" layers

fill angle: 45°

solid infill threshold area: 0 mm²

bridging angle: 0°

only retract when crossing perimeters: disabled

infill before perimeters: disabled (i think if the perimeters are printed first and have time to cool down, they are building a smoother object surface)

skirt and brim

loops: 1

distance from object: 2mm

skirt height: 2 layer

minimum extrusion length: 4mm

brim width:0mm

Support Material:

generate support material: enabled (its only for the rails)

overhang threshold: 45°

enforce support for the first: "0" layers

raft layer: "0" layer

options for support material and raft

contact z distance: "0.2" (detachable)

patter: rectilinear

support sheath around the support: disabled

pattern spacing: 2 mm

pattern angle: 0°

interface layers: "2" layers

interface pattern spacing: 0.2 mm

interface loops: disabled

support on build plate only: enabled (so the support will only get generated for the rails, the print of the cable-tie-tunnels works great with bridging)

xy separation between an object and its suport: 0.4 mm

don't support bridges: enabled

synchronize with object layers: disabled

speed:

perimeters 45mm/s

small perimeters: 25mm/s

external perimeters:35mm/s

infill: 170mm/s

solid infill: 170mm/s

top solid infill: 50mm/s

support material: 50mm/s

support material interface:100%

bridges: 30mm/s

gap fill: 40mm/s

speed for non-print moves

travel: 180mm/s

modifiers

first layer speed: 30mm/s

acceleration control

perimeters 800mm/s²

infill: 1500mm/s²

bridge: 1000mm/s²

first layer: 1000mm/s²

default: 1000mm/s²

autospeed:

max print speed: 170mm/s

max volumetric speed: 0 mm³/s

max volumetric slope positive: 0 mm³s/s²

max volumetric slope negative: 0 mm³s/s²

Advanced:

default extrusion width: 0.45mm

first layer: 0.6mm (the first layer is on the printbed and with good calibration and configs it gets perfectly smooth - I print it with a wide layer so that it goes a little faster)

perimeters: 0.45 mm

external perimeters: 0.45 mm

infill: 0.4 mm (with this setting, my infill layer lines are still very stable)

solid infill: 0.7 mm (This does not affect the upper layer and the plains fill up well and quickly)

top solid infill: 0.45 mm (my config for a smooth surface)

support material: 0.35 mm

overlap:

infill/perimeter overlap: 30% (so that infill and perimeter are well glued together)

bridge flow ratio: 0.95

other

clip multi-part objects: enabled

elefant foot compensation: 0mm

xy size compensation: 0mm

resolution 0mm

Similar models

thingiverse

free

tool- and penholder - deskorganizer - modular - boxes - easy to print version by AzurOne

...e flow ratio: 0.95

other

clip multi-part objects: enabled

elefant foot compensation: 0mm

xy size compensation: 0mm

resolution 0mm

thingiverse

free

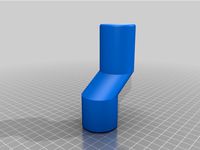

Grip Cap for ... Something by AzurOne

... 30%

bridge flow: 0,95

for support:

< shirts, hoodies, stickers, mugs >

paypalme

thank you, have a nice day, n cya o/

thingiverse

free

testtower with overhangs by AzurOne

... 30%

bridge flow: 0,95

for support:

< shirts, hoodies, stickers, mugs >

paypalme

thank you, have a nice day, n cya o/

thingiverse

free

calibration cube by AzurOne

... 30%

bridge flow: 0,95

for support:

< shirts, hoodies, stickers, mugs >

paypalme

thank you, have a nice day, n cya o/

thingiverse

free

e-step calibration by AzurOne

... 30%

bridge flow: 0,95

for support:

< shirts, hoodies, stickers, mugs >

paypalme

thank you, have a nice day, n cya o/

thingiverse

free

calibration tower by AzurOne

... 30%

bridge flow: 0,95

for support:

< shirts, hoodies, stickers, mugs >

paypalme

thank you, have a nice day, n cya o/

thingiverse

free

calibration cube - xyz by AzurOne

... 30%

bridge flow: 0,95

for support:

< shirts, hoodies, stickers, mugs >

paypalme

thank you, have a nice day, n cya o/

thingiverse

free

MOLLE - fast attachment clip by AzurOne

... 30%

bridge flow: 0,95

for support:

< shirts, hoodies, stickers, mugs >

paypalme

thank you, have a nice day, n cya o/

thingiverse

free

flashlight mounting part for #Bike Handy Mount by AzurOne

... 30%

bridge flow: 0,95

for support:

< shirts, hoodies, stickers, mugs >

paypalme

thank you, have a nice day, n cya o/

thingiverse

free

basket for 4 glasses - or for almost everything by AzurOne

... 30%

bridge flow: 0,95

for support:

< shirts, hoodies, stickers, mugs >

paypalme

thank you, have a nice day, n cya o/

Deskorganizer

thingiverse

free

DeskOrganizer by Nevitt

...deskorganizer by nevitt

thingiverse

modified desk organizer.

thingiverse

free

deskorganizer by DanielCamp

...deskorganizer by danielcamp

thingiverse

this is for the contest going on. it is a desk organizer.

thingiverse

free

deskOrganizer by Elward

...deskorganizer by elward

thingiverse

a desktop organizer for pens, pencils and so

thingiverse

free

Deskorganizer "twisted square" by Renngarage

...deskorganizer "twisted square" by renngarage

thingiverse

deskorganizer for business cards, pens, notes...

thingiverse

free

Deskorganizer V2 by seaspotter

...d the stl a bit from what i originaly designed because made 2 small mistakes, so these are fixed with the actual versin.

have fun

thingiverse

free

Penholder / Deskorganizer for Pencils / Screw and Wing Nut by maroth2

...rhülle 2

screw and nut with m50x4 tread. you can easy print without support structure. i used pla,

infill 15%, contour envelope 2

thingiverse

free

Penholder / Deskorganizer / Organizer for Pencils / Screw and Nut by maroth2

...hüllen 2

screw and nut with m50x4 tread. you can easy print without support structure. i used pla,

infill 15%, contour envelope 2

thingiverse

free

Post it Organizer by MaZ_T3

...post it organizer by maz_t3 thingiverse this is a deskorganizer i made for normal and small post-it, and also...

thingiverse

free

tool- and pen, -cil stand/holder - deskorganizer - simple by AzurOne

... 30%

bridge flow: 0,95

for support:

< shirts, hoodies, stickers, mugs >

paypalme

thank you, have a nice day, n cya o/

thingiverse

free

tool- and pen, -cil stand/holder - simple - deskorganizer by AzurOne

... 30%

bridge flow: 0,95

for support:

< shirts, hoodies, stickers, mugs >

paypalme

thank you, have a nice day, n cya o/

Azurone

thingiverse

free

Shower Cabin Hook by AzurOne

...shower cabin hook by azurone

thingiverse

shower cabin hook

thingiverse

free

shower-cabin-hook by AzurOne

...shower-cabin-hook by azurone

thingiverse

shower-cabin-hook

thingiverse

free

JD Bot - Torso by AzurOne

...jd bot - torso by azurone

thingiverse

jd bot - torso

thingiverse

free

Yamaha DTX Drums - Mount by AzurOne

...yamaha dtx drums - mount by azurone

thingiverse

yamaha dtx drums - mount

thingiverse

free

Mini Cam - Tripod Mount by AzurOne

...mini cam - tripod mount by azurone

thingiverse

mini cam - tripod mount

thingiverse

free

Drum Hardware - Tubular Frame - Shifted by AzurOne

...drum hardware - tubular frame - shifted by azurone

thingiverse

drum hardware - tubular frame - shifted

thingiverse

free

Monitor Ledge - Benq/Zowie XL 2546 by AzurOne

...monitor ledge - benq/zowie xl 2546 by azurone

thingiverse

monitor ledge - benq/zowie xl 2546

thingiverse

free

Drum Hardware - Tubular Frame - Shifted - fillets by AzurOne

...drum hardware - tubular frame - shifted - fillets by azurone

thingiverse

drum hardware - tubular frame - shifted - fillets

thingiverse

free

Yamaha DTX Drums - Mount - 15 deg slant by AzurOne

...yamaha dtx drums - mount - 15 deg slant by azurone

thingiverse

yamaha dtx drums - mount - 15 deg slant

thingiverse

free

wall mount - waterbed heater touch control - calesco by AzurOne

...wall mount - waterbed heater touch control - calesco by azurone

thingiverse

wall mount - waterbed heater touch control - calesco

Penholder

turbosquid

$30

penHolder

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Penholder

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$39

Penholder With Pencils

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

free

Download free Svin King penholder 3D Model

...penholder free

svin king penholder 3d model download free .c4d .max .obj .fbx .ma .lwo .3ds .3dm .stl hiropraktic 105576 3dexport

3d_ocean

$5

Penholder Concept Piri Reis

...created for a design competition about piri reis. all questions about my models and designs will be answered lightning fast. p...

3d_ocean

$5

Penholder Concept Piri Reis 2

...created for a design competition about piri reis. all questions about my models and designs will be answered lightning fast. p...

3d_export

$29

mesh penholder

...count: 9<br>- xform: no<br>- boxtrick: yes<br>textures:<br>pbr metallic / roughnes textures 4096x4096 png

archive3d

free

Pen 3D Model

...pen 3d model archive3d pen penholder pen 1 - 3d model for interior 3d...

archive3d

free

Accessories 3D Model

...accessories 3d model archive3d pens penholder office accessories accessories - 3d model for interior 3d...

archive3d

free

Pen 3D Model

...pen 3d model archive3d pens penholder writing materials pen n160808 - 3d model (*.gsm+*.3ds) for...

Modular

3ddd

$1

MODULAR

...modular

3ddd

modular , врезной свет

modular потолочные светильники

3ddd

$1

Modular Spock

...modular spock

3ddd

modular

modular spock

3ddd

$1

MODULAR / Spock

...modular / spock

3ddd

modular

modular/spock

design_connected

$7

Modular

...modular

designconnected

emmemobili modular shelves and storage computer generated 3d model. designed by ferruccio laviani.

3ddd

$1

Modular spock

...modular spock

3ddd

modular

spock wall led

turbosquid

$25

Modular sofa Angelo Cappellini Modular

...a angelo cappellini modular for download as max, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1570923)

turbosquid

$15

Modular sofa Angelo Cappellini Modular

...a angelo cappellini modular for download as max, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1570304)

3ddd

$1

Modular 2FLAT2C

...modular 2flat2c

3ddd

modular

modularhttp://www.supermodular.com/

3d_export

free

Modular walls

...modular walls

3dexport

modular walls for playing without materials and textures

3ddd

$1

Modular / Lighting Juliette

...modular / lighting juliette

3ddd

modular

modular lighting juliette

Tool

turbosquid

$21

Tool box with tools

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

archibase_planet

free

Tools

...tools

archibase planet

tools instruments implements

tools n070114 - 3d model (*.gsm+*.3ds+*.max) for interior 3d visualization.

3d_ocean

$12

Tools

...tools

3docean

hammer metal old screw tools wrench

maya

turbosquid

$6

Tool Cart / Tool Box

...

royalty free 3d model tool cart / tool box for download as on turbosquid: 3d models for games, architecture, videos. (1241859)

3d_ocean

$15

crimp tool

... tool copper cutter crimp crimp tool electrical electrical tools press tools pressing tool tools wire cutter

created in maya 2013

3d_ocean

$5

Tools

...tools

3docean

3d models paint tools work

3d,models,works,paint,art,create,working,

3d_export

free

tools

...tools

3dexport

coldsteel

turbosquid

$15

Tools

...turbosquid

royalty free 3d model tools for download as blend on turbosquid: 3d models for games, architecture, videos. (1331352)

3ddd

$1

bar tool

...bar tool

3ddd

барный

bar tool

turbosquid

$35

tools

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Boxes

archibase_planet

free

Box

...box

archibase planet

box carton cardboard box

box 2 - 3d model (*.3ds) for interior 3d visualization.

archibase_planet

free

Box

...box

archibase planet

carton cardboard box box

box 1 - 3d model (*.3ds) for interior 3d visualization.

3d_export

$6

box

...box

3dexport

box

3d_export

$5

Box

...box

3dexport

box

3d_export

$5

box

...box

3dexport

box

3d_export

$5

box

...box

3dexport

box

archibase_planet

free

Box

...box

archibase planet

box box for paper notebook pencil

box - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Box

...box

archibase planet

box carton cardboard box

box n170111 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Box

...box

archibase planet

box carton cardboard box

box n050411 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Boxes

...boxes

archibase planet

boxes box case bin

boxes n281213 - 3d model (*.gsm+*.3ds+*.max) for interior 3d visualization.