Thingiverse

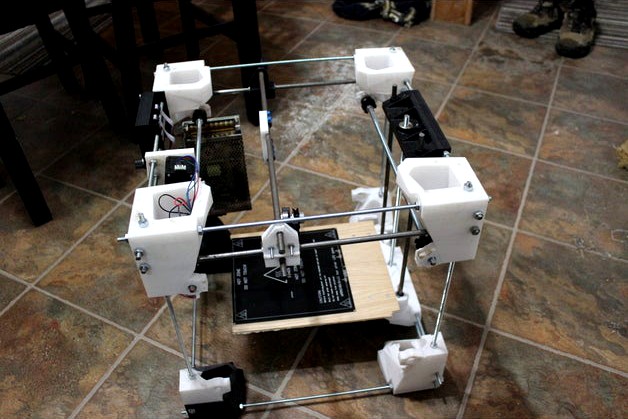

The RepRap "Cubit" New Printer by netpipe

by Thingiverse

Last crawled date: 3 years ago

Please wait before printing one of these it is still a WIP - pictures soon. all the holes seem to line up so it looks ok to print now, seems sturdy enough to handle the quick movements. (use remote extruder to keep it light). has only 8 1/2 inches of build height so if you want more cut your threadrod longer than 18" i would suggest for the z to use 20" or 26+" if you want to print larger tslot

the z carrage is so tight you dont need screws to secure them just hammer in.

print 4 of each block v10 , takes about 4 hours to print each block, can be done without supports.

prices in cdn

72 - 1/4 inch nuts - $10

15 - 5/16 inch nuts - $3

2 6' 1/4" peices of thread rod - $16 iirc

3 3' 8mm peices of smoothrod - $18

2 3' peices of 5/16 threadrod - $12

1 - 1 1/2 long 5/16 bolt with smooth part

2 1kg rolls of pla - $40

ballchain $10

6 z608 bearings $10

11 lm8uu bearings for the slides $10

parts cost about $90, $130 with PLA

electronics

ramps 1.4 - $6

lcd $10

arduino mega $6

steppers 11 dollars each x 3 so $33

5 x stepsticks the red ones $10

heatbed and glass - $20

PSU $20

$105 dollars total cost

20 hours to print at 50 watts is still less than 5 dollars so i wont factor that in.

230 total cost unless you want to print a larger 3' version then its going to be about 260 dollars.

the top z608 bearings need a bit of cleanup on the tops where the print sagged, use a dremmel with carbide tip or a drum sander attachment.

print of the 516 dual ballchain gears and one single for the x axis, even if only using one peice of ballchain double nut the sides where the nut insert is to prevent loosening. also print 2 nema 17 dual ballchain

was thinking shrink sleve and a peice of wire around it might work to secure the y axis dual ballchain or maybe just a short peice of ss wire

where the non motor side bearing is 1/2" bolt bolt head will have to be ground down for clearence on the xaxis its really close to the smoothrod and has to spin still also you might need to make a drill hole into where it touches the block OR cut the bolt end off and shave a nut down. could even go the full 3' or weld 2 together to make a 6' version if you attach it to a wall.

if you are using it for engraving there is 14 inches wide cleaence if you leave one of the bearings out on the x slide where the shaved bolt is.

also you need a drill and a peice of quarter inch smoothrod to make a short reamer tool for the vertical holes in the blocks for a tight fit.

the x axis peaks need to be grinded down 2mm to because they rub on the threadrod. use 1/8 x 1 1/2 " bolts to fasten the mount on. also you will have to drill the 2 bottom holes out to fit the bolts, existing holes are there already and the hook on top keeps it secure.

cut heatbed base board 11.5(could be 12") x 9" 1/4 inch thick fasten with 1/8" x 3/4 bolts the package says metal on them from home hardware clear package with white with blue label.

im going to be using a cyclops hotend converted into chimera for dual extrusion, plus it fits well inside the cube blocks.

i decided to go with 4.4 mm ballchainhttps://www.thingiverse.com/thing:2971750

https://www.thingiverse.com/thing:1589653 hotend mount

the blocks print standing up without supports on my printer.

my next version of cubit will be using 2020 or 3030 printed tslot 3d hopefully more efficient use of plastic and time, if all goes well with the strength tests, gluing threadrod in place as joiners also do a melt in the middle with 2 peices.

https://www.thingiverse.com/thing:2541291 3030 slot

new style of reprap using 3'x6' 4 peices of 1/4 inch threadrod - 12 x 18" pieces of 1/4 inch threadrod you can get 6' lengths at homehardware for 5 dollars each. going for a nice ultimaker / davinci style clone.

borrowed a few parts from https://www.thingiverse.com/thing:2260317

the z carrage is so tight you dont need screws to secure them just hammer in.

print 4 of each block v10 , takes about 4 hours to print each block, can be done without supports.

prices in cdn

72 - 1/4 inch nuts - $10

15 - 5/16 inch nuts - $3

2 6' 1/4" peices of thread rod - $16 iirc

3 3' 8mm peices of smoothrod - $18

2 3' peices of 5/16 threadrod - $12

1 - 1 1/2 long 5/16 bolt with smooth part

2 1kg rolls of pla - $40

ballchain $10

6 z608 bearings $10

11 lm8uu bearings for the slides $10

parts cost about $90, $130 with PLA

electronics

ramps 1.4 - $6

lcd $10

arduino mega $6

steppers 11 dollars each x 3 so $33

5 x stepsticks the red ones $10

heatbed and glass - $20

PSU $20

$105 dollars total cost

20 hours to print at 50 watts is still less than 5 dollars so i wont factor that in.

230 total cost unless you want to print a larger 3' version then its going to be about 260 dollars.

the top z608 bearings need a bit of cleanup on the tops where the print sagged, use a dremmel with carbide tip or a drum sander attachment.

print of the 516 dual ballchain gears and one single for the x axis, even if only using one peice of ballchain double nut the sides where the nut insert is to prevent loosening. also print 2 nema 17 dual ballchain

was thinking shrink sleve and a peice of wire around it might work to secure the y axis dual ballchain or maybe just a short peice of ss wire

where the non motor side bearing is 1/2" bolt bolt head will have to be ground down for clearence on the xaxis its really close to the smoothrod and has to spin still also you might need to make a drill hole into where it touches the block OR cut the bolt end off and shave a nut down. could even go the full 3' or weld 2 together to make a 6' version if you attach it to a wall.

if you are using it for engraving there is 14 inches wide cleaence if you leave one of the bearings out on the x slide where the shaved bolt is.

also you need a drill and a peice of quarter inch smoothrod to make a short reamer tool for the vertical holes in the blocks for a tight fit.

the x axis peaks need to be grinded down 2mm to because they rub on the threadrod. use 1/8 x 1 1/2 " bolts to fasten the mount on. also you will have to drill the 2 bottom holes out to fit the bolts, existing holes are there already and the hook on top keeps it secure.

cut heatbed base board 11.5(could be 12") x 9" 1/4 inch thick fasten with 1/8" x 3/4 bolts the package says metal on them from home hardware clear package with white with blue label.

im going to be using a cyclops hotend converted into chimera for dual extrusion, plus it fits well inside the cube blocks.

i decided to go with 4.4 mm ballchainhttps://www.thingiverse.com/thing:2971750

https://www.thingiverse.com/thing:1589653 hotend mount

the blocks print standing up without supports on my printer.

my next version of cubit will be using 2020 or 3030 printed tslot 3d hopefully more efficient use of plastic and time, if all goes well with the strength tests, gluing threadrod in place as joiners also do a melt in the middle with 2 peices.

https://www.thingiverse.com/thing:2541291 3030 slot

new style of reprap using 3'x6' 4 peices of 1/4 inch threadrod - 12 x 18" pieces of 1/4 inch threadrod you can get 6' lengths at homehardware for 5 dollars each. going for a nice ultimaker / davinci style clone.

borrowed a few parts from https://www.thingiverse.com/thing:2260317

Similar models

thingiverse

free

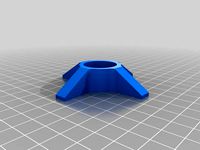

2020 Spool Holder by crankylinuxuser

...rint 2 of these. mirror 1 of them.

4-6 m5x8 socket head bolts

4-6 hammer-in m5 tnuts

2 628 bearings

m8 threadrod or 8mm smoothrod

grabcad

free

1/4" x 3/4"

...1/4" x 3/4"

grabcad

bolt & nut ( inch )

1/4" x length 3/4"

grabcad

free

1/4" x 2"

...1/4" x 2"

grabcad

bolt & nut (inch)

1/4" x length 2"

grabcad

free

1/4" x 1/2"

...1/4" x 1/2"

grabcad

bolt & nut (inch)

1/4" x length 1/2"

grabcad

free

1/4" x 1 1/2"

...1/4" x 1 1/2"

grabcad

bolt & nut (inch)

1/4" x 1 1/2"

thingiverse

free

Router Lift by edlsmith

...s.

no supports required

if you found this useful, please consider donating to my paypal.me. help cover the time of design.

thanks

grabcad

free

Bolt and Nut Chess set

...bolt and nut chess set

grabcad

using 1/4" x 1 1/4" bolts and 1/2" and 1/4" nuts

3dwarehouse

free

1/2' x 6' Carriage Bolt + Washer + Nut

...1/2' x 6' carriage bolt + washer + nut

3dwarehouse

1/2-inch x 6-inch carriage bolt + washer + nut

grabcad

free

U-bolt 6 3/4" x 8 3/8" x 1/2"

...ot; x 1/2"

grabcad

u-bolt for use with 6" pipe, 6 3/4" wide, 8 3/8" tall, 1/2" dia. full thread profile

thingiverse

free

Tommy's Tripod for Astronomical Equipment (TT-2) by tommyent

... latitude wedge without the tripod, see https://www.thingiverse.com/thing:4776560

build instructions and metric version to follow

Netpipe

thingiverse

free

one handed keyboard by netpipe

...obably needs to be customized to your numberpad also needs smoothr hand cup

its to size but needs customizing and finishing still

thingiverse

free

Cocker Cookie Cutter by netpipe

...cocker cookie cutter by netpipe

thingiverse

cookie cutter shaped like cocker spaniel

thingiverse

free

WACOM tablet wall mount by netpipe

...wacom tablet wall mount by netpipe

thingiverse

wacom tablet wall mount

fits 18 mm tablet

thingiverse

free

Laminar Flow Nozzle For Gardenhose by netpipe

...denhose by netpipe

thingiverse

laminar flow nozzle for gardenhose. i have not printed this but it should print without supports.

thingiverse

free

window opener by netpipe

...les to get a more uniform layout for mass prints.

https://www.thingiverse.com/thing:3642542 see here for more pictures

wip still.

thingiverse

free

E3D hotend holder for Prusa i3 by netpipe

... i3 by netpipe

thingiverse

easier to print with abs version of hotend holder.

squish hotend and both halfs together with a vice.

thingiverse

free

Bird feeder by netpipe

...leaning up still but it should print for you with repetier also i should slant it away from the feeder more for rain drain guides

thingiverse

free

firing pin plastic spring suspension by netpipe

...ipe

thingiverse

3d printed firing pin plastic spring

could be for pinball or something

might work good for rc vehicle suspension

thingiverse

free

quarter inch t-slot by netpipe

...g quarter inch rod. im not sure brackets fit inside it for bolts anymore though.

3030 has room for extra threadrod in the corners

thingiverse

free

5mm coupler by netpipe

...tight or more sticks out to cut off).

version 2 works great with 1/8 x 1/2" bolts (no dremmeling or drilling the holes out).

Cubit

turbosquid

$8

CUBIT BOOK SHELF

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$13

the ark of the covenant

...carried by its staves by the levites approximately 2,000 cubit (approximately 800 meters or 2,600 feet) in advance of...

unity_asset_store

$10

Cubits Dogos

...te your workflow with the cubits dogos asset from rem storms. find this & other animals options on the unity asset store.

3dbaza

$3

CUBIT 3D SUPERMATTE WALL FLATS (125797)

...cubit 3d supermatte wall flats (125797)

3dbaza

cubit 3d supermatte wall flats 3d model.

unity_asset_store

$5

Low Poly Warrior (Cubits Warrior)

...rom rem storms and speed up your game development process. find this & other characters options on the unity asset store.

thingiverse

free

Cubit Charm by Bip_40

...ed after i was inspired through an image search of sacred geometry. have not printed so i can offer no help. thanks for looking!

thingiverse

free

Body Centered Cubit Unit Cell by ajw05001

...body centered cubit unit cell by ajw05001

thingiverse

model of atomic lattice structure

unity_asset_store

$5

Cute Low Poly Zombie ( Cubits Zombie )

...rom rem storms and speed up your game development process. find this & other characters options on the unity asset store.

thingiverse

free

Cyberpunk 2077 / Johnny Silverhand / Cubit by Otonasi

...cyberpunk 2077 / johnny silverhand / cubit by otonasi

thingiverse

johnny silverhand character elbow joint for cosplay

unity_asset_store

$15

Low Poly People Pack #2 (Cubits #2 Ver. 2.0)

...people pack #2 (cubits #2 ver. 2.0) asset from rem storms. find this & other characters options on the unity asset store.

Reprap

turbosquid

$1

Go Pro Balance Hand Wand Reprap

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

thingiverse

free

Reprap keychain by AndreasD

...reprap keychain by andreasd

thingiverse

a simple reprap logo keychain for the reprap lovers like me!

thingiverse

free

REPRAP CHASSIS by leonk

...reprap chassis by leonk

thingiverse

reprap chassis

thingiverse

free

COUPLER RepRap by leonk

...coupler reprap by leonk

thingiverse

coupler reprap

thingiverse

free

RepRap Switch by n3opl4n

...reprap switch by n3opl4n

thingiverse

switch for reprap prusa i2.

p-space hackerspace logo.

thingiverse

free

Reprap pendulum by mr_seeker

...ap pendulum by mr_seeker

thingiverse

its a pendulum in the shape of the reprap logo. it has a 1mm hole for putting a wire in it.

thingiverse

free

RepRap Ornament by redskinsjbs

...reprap ornament by redskinsjbs

thingiverse

i tried to make a teardrop shape ornament for the holiday season in honor of reprap

thingiverse

free

Spool holder reprap by mdnm

...spool holder reprap by mdnm

thingiverse

this is spool holder for reprap.

thingiverse

free

RepRap logo keyring by mrjohnc

...reprap logo keyring by mrjohnc

thingiverse

reprap logo keyring

thingiverse

free

REPRAP LEON K by leonk

...reprap leon k by leonk

thingiverse

reprap leon k

Printer

archibase_planet

free

Printer

...inter

archibase planet

printer laser printer pc equipment

printer n120614 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Printer

...rchibase planet

laser printer office equipment computer equipment

printer - 3d model (*.gsm+*.3ds) for interior 3d visualization.

turbosquid

$100

Printer

...er

turbosquid

royalty free 3d model printer for download as on turbosquid: 3d models for games, architecture, videos. (1487819)

turbosquid

$3

Printer

...turbosquid

royalty free 3d model printer for download as max on turbosquid: 3d models for games, architecture, videos. (1670230)

turbosquid

$1

printer

...turbosquid

royalty free 3d model printer for download as max on turbosquid: 3d models for games, architecture, videos. (1595546)

turbosquid

$1

printer

...turbosquid

royalty free 3d model printer for download as max on turbosquid: 3d models for games, architecture, videos. (1595105)

turbosquid

$7

Printer

...royalty free 3d model printer for download as ma, ma, and obj on turbosquid: 3d models for games, architecture, videos. (1644580)

turbosquid

$30

Printer

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

Printer

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$18

printer

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

New

turbosquid

$119

New New Beetle

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

New-feather

...new-feather

3dexport

new-feather

3d_export

$6

new style

...new style

3dexport

new style room

3ddd

free

New Items

...ew items

3ddd

new items , барный

барный стул от китайского производителя фирмы new items

3d_export

$6

Logo new

...logo new

3dexport

new american style logo

3d_export

$10

New jersey

...new jersey

3dexport

new jersey stp and stl format

design_connected

$20

New Deal

...new deal

designconnected

new deal computer generated 3d model.

3d_ocean

$15

New bed

... for this bed all this file format include in zip file 3ds,obj,max,zip file change material and re-size very easy very for render

3ddd

free

Sofa-New Classic

...sofa-new classic

3ddd

new classic

sofa,new classic

design_connected

$13

New Antiques

...new antiques

designconnected

cappellini new antiques computer generated 3d model. designed by wanders, marcel.