Thingiverse

The PrintBone: a fully printable playable trombone by pieterbos82

by Thingiverse

Last crawled date: 3 years ago

A 3d printable trombone. Fully parameterized in OpenSCAD, see https://github.com/pieterbos/PrintBone and check the wiki there for instructions on creating your own trombone design.

See http://www.thingiverse.com/thing:2252952 for an updated version that prints and looks better. Soundwise it's the same.

The bell correspond to a large bore 8.5 inch symphonic bell. Fits a Bach 42 or Bach 50 slide, or a yamaha slide - possibly more brands.

The slide is a PVC slide. It can be done with any kind of tubes by editing the .scad file you can find on github. Fits the printed bell or a bach 42b.

The OpenSCAD file also works to create very nice working carbon fiber outer slides for different trombones, if you can find the correct tube diameter. A bach 42B inner slide fits widely available 15mm diameter tubes, but 14.9mm would be better. See github for improved designs for that purpose, that print without any support.

See https://soundcloud.com/pieter-bos-2013025 for a recording of both a regular brass bell and this bell. Can you guess which one is which?

It also has a recording of the pla slide, work in progress with still a leak somewhere and it will sound better later.

Printing instructions for the bell

I printed it in PLA on an original Prusa I3 MK2 with 0.2mm layer height. Choose whatever infill you like. Print time somewhere between 25-30 hours, but you can probably do a lot faster with a 0.6 or 0.8mm nozzle and a faster printer.

The bell flare is cut for an at least 21x22x20 printer. If you have a smaller printer, you will have to adjust those two files.

Print the tuning slide with the pegs upward, and support enabled. The two small midair rafts will be supported and make for a much more stable part. They can be easily broken off later.

A two piece bell flare that can be more easily printed without support is available as a setting in the OpenSCAD file, it has not yet been tested.

Printing the slide parts

add lots of infill or even solid for the inner handslide brace because it needs to be stiff!

The rest, just print whatever is the most airtight.

I printed the leadpipe in spiral vase mode with a 0.3mm nozzle and 0.37mm wall thickness, 0.1mm layer height.

The leadpipe is relatively bright. If you don't like it, increase the venturi diameter in the openscad file a bit.

See http://www.thingiverse.com/thing:2252952 for an updated version that prints and looks better. Soundwise it's the same.

The bell correspond to a large bore 8.5 inch symphonic bell. Fits a Bach 42 or Bach 50 slide, or a yamaha slide - possibly more brands.

The slide is a PVC slide. It can be done with any kind of tubes by editing the .scad file you can find on github. Fits the printed bell or a bach 42b.

The OpenSCAD file also works to create very nice working carbon fiber outer slides for different trombones, if you can find the correct tube diameter. A bach 42B inner slide fits widely available 15mm diameter tubes, but 14.9mm would be better. See github for improved designs for that purpose, that print without any support.

See https://soundcloud.com/pieter-bos-2013025 for a recording of both a regular brass bell and this bell. Can you guess which one is which?

It also has a recording of the pla slide, work in progress with still a leak somewhere and it will sound better later.

Printing instructions for the bell

I printed it in PLA on an original Prusa I3 MK2 with 0.2mm layer height. Choose whatever infill you like. Print time somewhere between 25-30 hours, but you can probably do a lot faster with a 0.6 or 0.8mm nozzle and a faster printer.

The bell flare is cut for an at least 21x22x20 printer. If you have a smaller printer, you will have to adjust those two files.

Print the tuning slide with the pegs upward, and support enabled. The two small midair rafts will be supported and make for a much more stable part. They can be easily broken off later.

A two piece bell flare that can be more easily printed without support is available as a setting in the OpenSCAD file, it has not yet been tested.

Printing the slide parts

add lots of infill or even solid for the inner handslide brace because it needs to be stiff!

The rest, just print whatever is the most airtight.

I printed the leadpipe in spiral vase mode with a 0.3mm nozzle and 0.37mm wall thickness, 0.1mm layer height.

The leadpipe is relatively bright. If you don't like it, increase the venturi diameter in the openscad file a bit.

Similar models

thingiverse

free

The PrintBone v1.1: a fully printable playable trombone by pieterbos82

... with the correct amount of friction. use tuning slide grease.

sand all the joints a bit. glue the parts together. happy playing!

thingiverse

free

iPhone 6 trombone bell amplifier - Bach 42/50, customizable by pieterbos82

...irtightness which will have an effect on acoustics, but with 2 perimeters it worked well. might even be better with slight leaks.

thingiverse

free

PrintBone small - 7 inch bell trombone by pieterbos82

... than the regular slide on a 48h/6h.

the bell fits a conn 48h/6h slide, but you will need to extend the tuning slide quite a bit.

thingiverse

free

Trombone Wall Hanger by Kyerohtaron

... part for you!

this bracket screws into the wall and supports the trombone at the slide brace (with the bell pointing downwards).

thingiverse

free

PrintBone practice mute for Trumpet, (Bass) Trombone and Flugelhorn - customizable! by pieterbos82

...mk2 in 2-6 hours, depending on the quality you want. tested to work in abs, pla, ngen and petg. ngen and petg seem to sound best.

thingiverse

free

Bach Trombone Slide End Bumper by hazalu

...bach trombone slide end bumper by hazalu

thingiverse

printed in ninjaflex. temp: 230c speed: 30mm/s

3dwarehouse

free

Trombone

... better than i hoped for, please rate. #band #bell #brass #instrument #mouthpiece #music #orchestra #play #rough #slide #trombone

3dwarehouse

free

Trombone

... 2, i hope hope it looks better, froggy. #bell #brass #mouth #music #piece #position #slide #spit #three #trombone #update #valve

thingiverse

free

Cardboard Tube Spool Holder (Parametric) by aitherios

...spool_holder.scad file is to be used in openscad where you can change the diameters and generate a version suited for your needs.

cults

$1

Christmas decoration bells

...support turn the files so that you can print a bottom and no top. now you can print the hollow versions and assemble it together

Printbone

thingiverse

free

The PrintBone v1.1: a fully printable playable trombone by pieterbos82

... with the correct amount of friction. use tuning slide grease.

sand all the joints a bit. glue the parts together. happy playing!

thingiverse

free

PrintBone practice mute for Trumpet, (Bass) Trombone and Flugelhorn - customizable! by pieterbos82

...mk2 in 2-6 hours, depending on the quality you want. tested to work in abs, pla, ngen and petg. ngen and petg seem to sound best.

thingiverse

free

PrintBone small - 7 inch bell trombone by pieterbos82

... than the regular slide on a 48h/6h.

the bell fits a conn 48h/6h slide, but you will need to extend the tuning slide quite a bit.

thingiverse

free

iPhone 6 trombone bell amplifier - Bach 42/50, customizable by pieterbos82

...shows it attached to a bach 42b and a printbone bell. it fits a regular brass bach 42 or...

Pieterbos82

thingiverse

free

Two tuba mouthpieces by pieterbos82

...r.

the -no-support versions are without support, for example if you want to print on something else than extruder-based printers.

thingiverse

free

improved trombone mouthpiece customizer by pieterbos82

...see photso for a test print at 0.15mm layer thickness. i hope to do a much higher resolution print soon for a very smooth result.

thingiverse

free

trombone mouthpiece with small shank by rjhaines99

...thingiverse modification of trombone mouthpiece posted to thingiverse by pieterbos82 i modified the scad file for a smaller shank...

thingiverse

free

Ipad reverser for K&M holder/music stand by pieterbos82

... ipad holder with your printed part, and you're done! if this isn't clear, see the photos below for further instructions.

thingiverse

free

The PrintBone v1.1: a fully printable playable trombone by pieterbos82

... with the correct amount of friction. use tuning slide grease.

sand all the joints a bit. glue the parts together. happy playing!

thingiverse

free

iPhone 6 trombone bell amplifier - Bach 42/50, customizable by pieterbos82

...irtightness which will have an effect on acoustics, but with 2 perimeters it worked well. might even be better with slight leaks.

thingiverse

free

HifiBerry DAC+ ADC (Pro) case for RPi 4 by pieterbos82

...ive soon.

make the xlr version screw together with more neutrik a-screws, since you're likely to order more than four anyway.

thingiverse

free

PrintBone practice mute for Trumpet, (Bass) Trombone and Flugelhorn - customizable! by pieterbos82

...mk2 in 2-6 hours, depending on the quality you want. tested to work in abs, pla, ngen and petg. ngen and petg seem to sound best.

thingiverse

free

PrintBone small - 7 inch bell trombone by pieterbos82

... than the regular slide on a 48h/6h.

the bell fits a conn 48h/6h slide, but you will need to extend the tuning slide quite a bit.

Trombone

turbosquid

$50

Trombone

...alty free 3d model trombone for download as 3ds, max, and obj on turbosquid: 3d models for games, architecture, videos. (1297778)

3d_ocean

$9

Brass Trombone

...brass trombone

3docean

band brass concert instrument jazz music orchestra ska trombone wind

this is a model of brass trombone.

turbosquid

$39

Trombone

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$30

Trombone

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$30

Trombone

...l trombone for download as 3ds, max, obj, fbx, blend, and dae on turbosquid: 3d models for games, architecture, videos. (1393300)

turbosquid

$25

Trombone 003

...royalty free 3d model trombone 003 for download as ma and fbx on turbosquid: 3d models for games, architecture, videos. (1516900)

turbosquid

$25

Trombone 002

...royalty free 3d model trombone 002 for download as ma and fbx on turbosquid: 3d models for games, architecture, videos. (1516899)

turbosquid

$25

Trombone 001

...royalty free 3d model trombone 001 for download as ma and fbx on turbosquid: 3d models for games, architecture, videos. (1516898)

turbosquid

$8

Classical Trombone

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$6

Cartoon Trombone

...n trombone for download as 3ds, obj, fbx, blend, dae, and stl on turbosquid: 3d models for games, architecture, videos. (1506746)

Playable

3d_export

$10

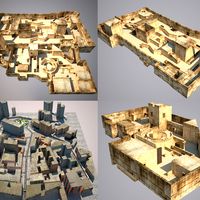

Eagle Eye View Map Bundle

...this collection of crazy rides maps items includes various map-playable items. this set of crazy rides maps items include...

3d_ocean

$49

4 Different Low Poly Maps

...2755 faces each objects are separated (not attached eachothers) playable ...

3d_export

$20

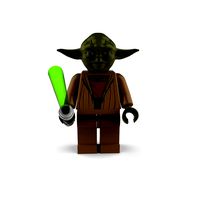

yoda

...the years in eight different sets and is a playable character in all four lego star wars video games...

3d_export

$15

samantha maxis death bride

...ops until the map moon, where she becomes a playable character during richtofen's grand scheme. in call of duty:...

3d_export

$60

Vampire Cyborg

...a different number of polygons, the minimum for a playable character is<br>faces - 14 902<br>triangles - 29 061<br>maximum is<br>faces...

3d_export

$45

EMMy GIRL CHARACTER RIGGED ANIMATED 99 ANIMATIONS INCLUDED

...fantasy vii remake.<br>update 4/9/2022: new ue4 template project with playable blueprint and hair/cloth/body physic<br>+low poly, game ready, rigged, pbr...

3d_export

$90

Azura Cyber Girl Constructor

...a different number of tris, the minimum for a playable character is 23 164, maximum - 67 394 with...

unity_asset_store

$35

Hero Playable Character

...ith the hero playable character asset from mister necturus. find this & other humanoids options on the unity asset store.

unity_asset_store

$25

Warlock Playable Character

... the warlock playable character asset from mister necturus. find this & other humanoids options on the unity asset store.

unity_asset_store

free

Low Poly Playable Vehicles

... with the low poly playable vehicles asset from odd stone games. find this & other land options on the unity asset store.

Fully

turbosquid

$50

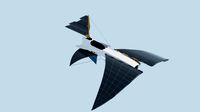

Drone fully rigged

...

royalty free 3d model drone fully rigged for download as max on turbosquid: 3d models for games, architecture, videos. (1282280)

turbosquid

$12

FULLY PARAMETRIC CHAIR

...alty free 3d model fully parametric chair for download as rvt on turbosquid: 3d models for games, architecture, videos. (1280209)

turbosquid

$10

firetruck-fully-rigged

...yalty free 3d model firetruck-fully-rigged for download as ma on turbosquid: 3d models for games, architecture, videos. (1653811)

turbosquid

$6

Fully rigged character

...ty free 3d model fully rigged character for download as blend on turbosquid: 3d models for games, architecture, videos. (1486076)

turbosquid

$3

Fully Rigged shark

...ee 3d model fully rigged 3d shark model for download as blend on turbosquid: 3d models for games, architecture, videos. (1517695)

turbosquid

$75

Fully Customizable Hospital

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Fully Rigged Link

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

design_connected

$16

Troy W Fully Covered

...troy w fully covered

designconnected

magis troy w fully covered computer generated 3d model. designed by wanders, marcel.

cg_studio

$99

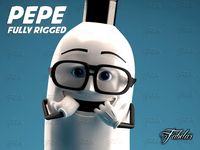

Pepe fully rigged3d model

...ully rigged3d model

cgstudio

.max - pepe fully rigged 3d model, royalty free license available, instant download after purchase.

3d_export

$60

Ankylosaur 8K - fully animated

...ankylosaur 8k - fully animated

3dexport

Printable

turbosquid

$5

printable giraffe

...uid

royalty free 3d model printable giraffe for download as on turbosquid: 3d models for games, architecture, videos. (1504825)

turbosquid

$49

Longhorn Printable

...

royalty free 3d model longhorn printable for download as stl on turbosquid: 3d models for games, architecture, videos. (1712930)

3d_export

$2

printable audi car

...printable audi car

3dexport

printable audi car

turbosquid

$40

Fox printable

...lty free 3d model fox printable for download as blend and stl on turbosquid: 3d models for games, architecture, videos. (1507558)

turbosquid

$23

Printable Statue

...ty free 3d model printable statue for download as obj and stl on turbosquid: 3d models for games, architecture, videos. (1415137)

turbosquid

$3

Ear Printable

...yalty free 3d model ear printable for download as obj and stl on turbosquid: 3d models for games, architecture, videos. (1671689)

turbosquid

$1

heart printable

...y free 3d model heart printable for download as stl and sldpr on turbosquid: 3d models for games, architecture, videos. (1209566)

turbosquid

$1

Printable Hook

...

royalty free 3d model 3d printable hook for download as stl on turbosquid: 3d models for games, architecture, videos. (1413683)

turbosquid

$30

Printable support

... model 3d printable support for download as max, 3ds, and stl on turbosquid: 3d models for games, architecture, videos. (1689342)

turbosquid

$24

Printable Dolphin

...el printable dolphin for download as , dae, fbx, obj, and stl on turbosquid: 3d models for games, architecture, videos. (1602353)