Thingiverse

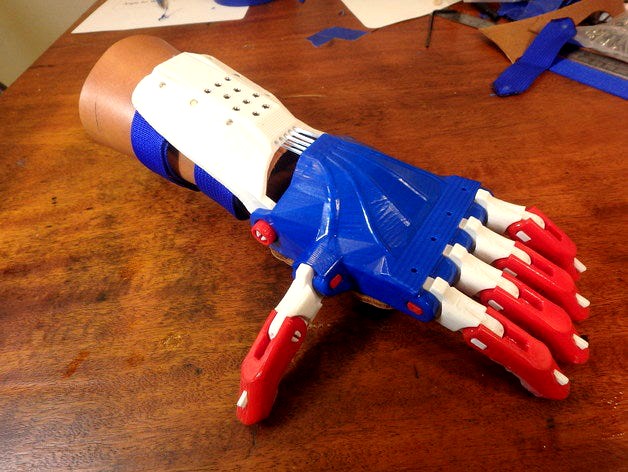

The Osprey Hand by Alderhand and e-Nable by profbink

by Thingiverse

Last crawled date: 3 years, 1 month ago

The Osprey Hand is a wrist-powered mechanical prosthetic that was built in Blender based on the low-poly interior and robust components of the original Raptor Hand, but now sporting an attractive fairing and a very durable and comfortable low-profile universal-fit bracer.

The Osprey is optimized for the use of heavy gauge nylon monofilament, which resists linear compression and generates little friction, so has excellent Bowden properties; the cables are pulled to provide flexion and pushed to provide extension. This device requires neither elastics nor springs nor any mechanical extension system.

Heavy gauge nylon monofilament is generally inexpensive, and available as landscapers' trimmer line, nylon or Bridge nylon 3d printer filament, and as deep sea fishing leader line. I suggest fishing line, since it is available in a variety of thicknesses. Running through joints, the monofilament doesn't abrade at all, so there's no "sawing" of printed plastic.

Elastic resistance is a major drawback to many assistive devices, because resistance reduces a device's grip strength. Furthermore, as an elastic-extended device approaches full actuation, resistance from elastics increases, so that it may be quite difficult for a user to grasp small objects. Also, most elastic materials degrade quickly. Designs which reduce or eliminate elastic resistance are a welcome development.

Pay particular attention to the new bill of materials. The Cyborg Beast, the original Raptor and the Raptor Reloaded hardware kits are not compatible with the Osprey. However, the Osprey does use the same hardware as the Gamma Raptor. Materials kits and tool kits should be available in the near future, so stay tuned.

In this version:

Pin-and-Proximal sets with varying tolerances ("A" is loosest; "D" is tightest) Make it easy to compensate for differences in print scale, extrusion settings, and thermal expansion. Learn about Peregrine's ABCD Key in the instructions document !

Update 2015-7-14

Palm v.2.1 The thumb has been rotated to better oppose the fingers. This affected the palm stencil, which was also updated.

Update 2015-8-26

Support material was removed from proximal phalanges. Let me know if you miss it. The hinge on the distals was bulked up, since it was a common point of failure under heavy lifting.

Update 2015-9-16

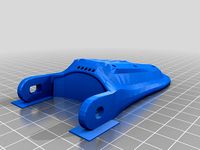

I added a new bracer/gauntlet. This fits the Osprey aesthetic better, and it has easier-to-remove support material. The old bracer will probably become part of the Gamma Raptor design.

Update 2015-11-23

Updated bracer and palm, and removed the old versions. Added 3/4" triglide buckle. Added proximal "key" to help determine which proximal tolerance best fits in the palm.

Update 2016-6-16 Instructions have improved a lot, so please have a look.

Replaced proximal and distal phalanges: improved mechanical performance.

Update 2017-10-19

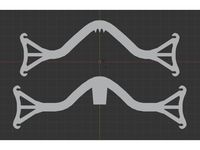

Added a printable bracer stencil that will fit most clients just fine. After fitting, any overlapping leather can be trimmed if needed, but on most clients that won't be necessary.

Added sets of snap pins that are more compatible with PLA. The original pins were calculated for ABS, which is softer. So they were pretty difficult to insert in PLA builds. These PLA pins have longer tines that bend better.

Added D-Ring buckle. This is a good secure closure for the loose-weave nylon webbing.

2017-10-23

Added pin tongs and a pin pusher, to help with the insertion and removal of snap pins.

The Osprey is optimized for the use of heavy gauge nylon monofilament, which resists linear compression and generates little friction, so has excellent Bowden properties; the cables are pulled to provide flexion and pushed to provide extension. This device requires neither elastics nor springs nor any mechanical extension system.

Heavy gauge nylon monofilament is generally inexpensive, and available as landscapers' trimmer line, nylon or Bridge nylon 3d printer filament, and as deep sea fishing leader line. I suggest fishing line, since it is available in a variety of thicknesses. Running through joints, the monofilament doesn't abrade at all, so there's no "sawing" of printed plastic.

Elastic resistance is a major drawback to many assistive devices, because resistance reduces a device's grip strength. Furthermore, as an elastic-extended device approaches full actuation, resistance from elastics increases, so that it may be quite difficult for a user to grasp small objects. Also, most elastic materials degrade quickly. Designs which reduce or eliminate elastic resistance are a welcome development.

Pay particular attention to the new bill of materials. The Cyborg Beast, the original Raptor and the Raptor Reloaded hardware kits are not compatible with the Osprey. However, the Osprey does use the same hardware as the Gamma Raptor. Materials kits and tool kits should be available in the near future, so stay tuned.

In this version:

Pin-and-Proximal sets with varying tolerances ("A" is loosest; "D" is tightest) Make it easy to compensate for differences in print scale, extrusion settings, and thermal expansion. Learn about Peregrine's ABCD Key in the instructions document !

Update 2015-7-14

Palm v.2.1 The thumb has been rotated to better oppose the fingers. This affected the palm stencil, which was also updated.

Update 2015-8-26

Support material was removed from proximal phalanges. Let me know if you miss it. The hinge on the distals was bulked up, since it was a common point of failure under heavy lifting.

Update 2015-9-16

I added a new bracer/gauntlet. This fits the Osprey aesthetic better, and it has easier-to-remove support material. The old bracer will probably become part of the Gamma Raptor design.

Update 2015-11-23

Updated bracer and palm, and removed the old versions. Added 3/4" triglide buckle. Added proximal "key" to help determine which proximal tolerance best fits in the palm.

Update 2016-6-16 Instructions have improved a lot, so please have a look.

Replaced proximal and distal phalanges: improved mechanical performance.

Update 2017-10-19

Added a printable bracer stencil that will fit most clients just fine. After fitting, any overlapping leather can be trimmed if needed, but on most clients that won't be necessary.

Added sets of snap pins that are more compatible with PLA. The original pins were calculated for ABS, which is softer. So they were pretty difficult to insert in PLA builds. These PLA pins have longer tines that bend better.

Added D-Ring buckle. This is a good secure closure for the loose-weave nylon webbing.

2017-10-23

Added pin tongs and a pin pusher, to help with the insertion and removal of snap pins.

Similar models

thingiverse

free

Cathy's Lucky Fin V3 by Rhadamanthys76

... using this option), fingertips mould, gauntlet and tensioner

i used pla+, printed with 0.15 resolution, 25% infill and 2 shells

thingiverse

free

The Raptor Hand by e-NABLE by e-NABLE

...102497715636887179986

for more information and stories:http://enablingthefuture.orghttps://www.facebook.com/enableorganization

thingiverse

free

Ody Hand 2.1 by profbink

...e abs) and/or underextruding printers. i also widened the cable channels in the fingers so it's easier to install the cables.

thingiverse

free

Splint for immobilising injured finger customizable V1.0 by srakovec

...teral deviation

trigger finger

https://youtu.be/zfqqdyhkza8https://youtu.be/uvacw1byksg

use at your own risk.

happy printing!

grabcad

free

Distal Phalange Tip

...distal phalange tip

grabcad

distal phalange tip surface achieved through projected curves and boundary surface

thingiverse

free

Osprey Hand Chaos Cog Bracer by GentlemanFaun

...or the cables, so extra care must be taken while wiring up the hand, but for me, the aesthetic appeal was worth the extra effort.

thingiverse

free

Finger prosthesis by xibalbawax

...o scale this for a good fit. see fitting instructions by viewing my instructable "thumb prosthesis" @ instructables.com

thingiverse

free

Osprey Hand Distal Fingers with Claws by GentlemanFaun

...ned the claws to make the fingers more useful, and removed the built in support, to accommodate more advanced support generation.

thingiverse

free

Joint Pins for Prosthetic Hand by Caboose

...use. these snap into place and won't fall out.

i'll do thumb pins when i'm finished printing the rest of the hand.

thingiverse

free

Raptor Reloaded by e-NABLE by e-NABLE

...dded fingertip with finger nail that can be painted, added link to detailed print and assembly instructions on instructables. ab

Profbink

thingiverse

free

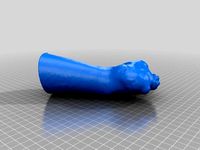

Peregrine's forearm by profbink

...39;s forearm by profbink

thingiverse

this is a model i made in blender, based on photos of a casting of peregrine's forearm.

thingiverse

free

Peregrine's left hand by profbink

...thingiverse

this is a scan of a casting of peregrine's hand, using a makerbot digitizer. i smoothed the model using blender.

thingiverse

free

Cozy Enclosure for Solidoodle 3 by profbink

...ozy enclosure for solidoodle 3 by profbink

thingiverse

i wanted to strengthen my abs prints, so decided to make an acrylic case.

thingiverse

free

Ear Savers (Ear relief for mask wearing) by profbink

... that slips behind the sweatband of the hat to hold it up.

prints quickly flat on the print bed. scale if you like. share freely.

thingiverse

free

Talon Flextensor 1.0 by profbink

...tensor relies on both the user's wrist flexor and extensor muscles, which should be preferable from a therapeutic standpoint.

thingiverse

free

Talon Hand 3.0 by profbink

...t cables:https://www.youtube.com/watch?v=rtojln_bhts

for more information or to get involved, visit http://enablingthefuture.org/

thingiverse

free

Ody Hand 2.1 by profbink

...e abs) and/or underextruding printers. i also widened the cable channels in the fingers so it's easier to install the cables.

thingiverse

free

Dual Action Cable Anchor (Flextender) by profbink

...jg&feature=youtu.be

for more information or to get involved, visit http://enablingthefuture.org/

files updated march 31, 2014

thingiverse

free

e-Nable Device Sizing Blender file by profbink

...with the scaling process. please follow the youtube video tutorial series in the instructions to learn the image scaling process.

thingiverse

free

Ultimaker 2, 2+, Extended spool holder for really big spools by profbink

...eft. it works great. and the printer didn't even tip over from all the weight in the back! ;)

my tweaks were done in blender.

Nable

3ddd

$1

Mangrove - Roche Bobois

...95 x h. 170 x p. 46 cm. mangrove nable l. 90 x h. 90 x p. 45 cm....

thingiverse

free

Bracelets e-nable

...bracelets e-nable

thingiverse

bracelet association e-nable

thingiverse

free

Jeton Caddie E-Nable

...jeton caddie e-nable

thingiverse

jeton de caddie association e-nable

thingiverse

free

e-Nable Bookmark by Greg76

...e-nable bookmark by greg76

thingiverse

bookmark with e-nable theme.

easy to print and resizable.

thingiverse

free

e-NABLE paperclip by JohnDiamond

...e-nable paperclip by johndiamond

thingiverse

paperclip featuring one of the logos used by the e-nable community

thingiverse

free

Pencil e-nable attachment by Gtrautman1

...n1

thingiverse

this is for the e-nable c.r.e.a.t.e t.i.m.e january 2016 challenge. it is an attachment for the e-nable hand....

thingiverse

free

e-NABLE keychain by JohnDiamond

...hand finger with "e-nable" embossed on both sides of the fingertip. this is intended as a giveaway trinket at an event.

3dbaza

$2

Nable Table Lamp (338771)

...nable table lamp (338771)

3dbaza

nable table lamp 3d model<br>l 700mmv250mmh1000mm

thingiverse

free

Phone support E-nable by Tarin67

...phone support e-nable by tarin67

thingiverse

support phone logo e-nable

thingiverse

free

e-NABLE Keyring by franklima260

...ngiverse

a simple keyring for e-nable outreach giveaways.

this is a remix of this thing: http://www.thingiverse.com/thing:808889

Osprey

turbosquid

$60

OSPREY

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$99

V22 Osprey

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$59

Osprey V22

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

V22 OSPREY

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

Animated Osprey Helicopter

...odel osprey helicopter for download as max, 3ds, fbx, and stl on turbosquid: 3d models for games, architecture, videos. (1594424)

3d_export

$17

Bell Boeing V-22 Osprey

...bell boeing v-22 osprey

3dexport

bell boeing v-22 osprey

3d_export

$140

V22 Osprey IAF 3D Model

... osprey tiltrotor helicopter assault troop carrier iaf transport israeli air force

v22 osprey iaf 3d model tartino 69705 3dexport

turbosquid

$20

TURBOSPAIN BOEING V22 OSPREY

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$150

3D Models V22 Osprey USAF 3D Model

... mv22 mv22b osprey tiltrotor helicopter assault troop carrier transport

3d models v22 osprey usaf 3d model tartino 69387 3dexport

cg_studio

$140

V-22 Osprey USAF3d model

...udio

.3ds .c4d .dae .dxf .fbx .obj - v-22 osprey usaf 3d model, royalty free license available, instant download after purchase.

Hand

3d_export

$8

hand

...hand

3dexport

fantasy hand

3d_export

$5

hand

...hand

3dexport

male hand

3d_export

$5

hand

...hand

3dexport

realistic male hand

3d_export

$5

hand

...hand

3dexport

hand with nails and structure

archibase_planet

free

Hand

...hand

archibase planet

hand

hand n190111 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3ddd

$1

Hand

...hand

3ddd

hand

модель руки будды

3d_export

$5

hand

...hand

3dexport

it is my wrist of hand and this is on 3d sculpt

3d_export

$5

hand

...hand

3dexport

realistic male hand obj file

3d_export

$7

hand-006 rigged hand

...hand-006 rigged hand

3dexport

rigged right hand 3d model additional textures for pbr rendering included

3d_ocean

$6

Hand

...

this 3d models of the hands, made in 3ds max, has textures(.jpg), materials(.mat), rigged, the models in .max, fbx, obj format.

E

3ddd

$1

WALL-E

...wall-e

3ddd

wall-e , робот

wall-e

3d_export

$100

e-rickshaw

...e-rickshaw

3dexport

e-rickshaw- it have 3d model of passenger e-rickshaw

3d_ocean

$12

Wall E

...wall e

3docean

character robot wall e

its a 3d model of wall e….

turbosquid

$68

Model-E Droids 2-E Q-E Star Wars

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

cg_studio

$45

Model-E Droids 2-E Q-E Star Wars3d model

....3ds .c4d .obj .vue - model-e droids 2-e q-e star wars 3d model, royalty free license available, instant download after purchase.

3d_export

$100

e-rickshaw

...e-rickshaw

3dexport

e-rickshaw design for passenger it have all mechanical component

design_connected

$7

Cone E

...cone e

designconnected

bonaldo cone e computer generated 3d model. designed by pasini, ennio.

3ddd

$1

Wall-E NEW

...wall-e new

3ddd

wall-e , робот

wall-e

design_connected

$29

Extrasoft E

...extrasoft e

designconnected

living divani extrasoft e computer generated 3d model. designed by lissoni, piero.

3ddd

$1

E-Turn

... скамейка

современная скамейка фирмы kundalini.

модель e-turn.

дизайнер brodie neil.

размеры: h 42 cm l 185 cm w 54 cm