Thingiverse

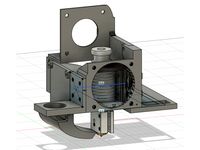

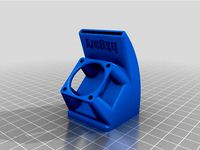

The Monolith 50mm E3D V6 Shroud Fanduct by PokeyDoggo

by Thingiverse

Last crawled date: 3 years ago

EDIT: 21-02-2019

I'm busy with a COREXY version. I kinda.. well I did make a volcano version and tested them, but they sucked, my bad. I'm not a great designer.

This thing has worked for me and served me for the last few years, eventhough without any cooling the two ducts started melting and I'm clumsy. Nothing a bit of kapton tape could not solve.

A link to download the fusion360 files, which can be downloaded as all kinds of 3d files.https://a360.co/2DZDqSc

EDIT: 26-04-2018

Hey, seems like a lot of people like this. Uhm I kinda said I'd make a volcano version..

a year ago.

I was busy with college and what not with life. But the Volcano version will come.

This cooler shroud served me for over a year with clean ABS printing.

It did had some issues. Actually it had none, only though a problem of way to much filament clogging up at the hotend which I tried to remove and then I twisted the hotend against the side of the fanduct and it melted a little bit. Which I could easily scrape off with a knife and it still functioned perfectly. and the e3d cooler fanduct melted a little bit.

But I used this a few times with 100% fan speed for both 50mm fans, and it cooled the printed part so much that the layer adhesion was.. well it did adhere, but it was a weak connection. I could bridge stuff so easily and make 75+ degree angles but yeah cooling molten plastic too much, especially ABS is not a good idea.

But the main problem was, I couldn't see what it was printing directly.

So, I'll make a new version! It's almost done. The first will be a way too large Volcano one.

Which I then improve.

And a standalone 50mm e3d V6 cooler version which you can snap on like the original 30mm one.

Then a duct like this one, but it only two 50mm fans, for the normal heatingblock and the volcano to reduce mass and the size.

Maybe I'll figure out how to fit a 60mm fan.

Might just remake the 50mm version for a 40mm one.

Actually I also have a 2x mk7 hobbed bolt extuder idea, for bowder and direct drive. But I'll focus on the fanducts first.

Stay tuned, they will be up in a week or so.

I'll make a E3D V6 Volcano version soon and both V5 versions. Since I also have such a hotend and heatsink laying around. But I'll redesign it from scratch, because my old fusion 360 file takes way too long to load because it had too many additions and extrusion. But I keep learning new things.

I also printed quite a bit with this new shroud, and it works fine at 150mm/s setting in cura, eventhough the anet cannot reach those speeds. And nothing has melted yet at 270 degrees.

Edit: Set your fan speed to 100% if you need to bridge.

Assembly:

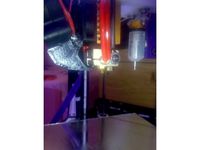

The E3D V6 heatsink might have a very tight fit or it does not fit at first. You need to push it into the plastic pretty hard. I took the direct dimensions with a caliper, and even removed 0.01mm here and there. But I also wanted to prevent resonance so it’s a very tight fit.

This shroud should fit on any groovemount if there is enough room at the front. I kept about 1mm of space between the back of the plastic and the back of the heatsink. So there would always be 1 mm free space for the hot air to espace and to solve any mounting issues.

When you want to screw this shroud to the groovemount, you might need drill out the holes at the top. I made these to be 3.0mm, the diameter of a M3 screw, but I had some filament in between so I had to drill it out very slightly. These groovemount screwholes should give no resistance.

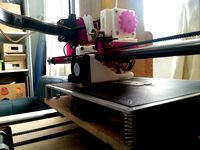

On my own AnetA8 I could remove the extra X-stop and I now use the default X-stop location. Because this shroud is (surprisingly) not as wide as I initially thought.

When I mounted this to my own X-carriage (which is very butchered) I had to screw it together with quite some force but not too much force to get everything to fit tightly. But it won’t go anywhere now.

For reference of the width of the screw holes that I used, I used these groovemount X-carriage for the Prusa i3 and AnetA8:

https://www.thingiverse.com/thing:2099577 ANET A8 | Customizable E3D v6 Carriage / Bowden mount by TNS, published Feb 12, 2017

https://www.thingiverse.com/thing:1632847 E3Dv6 Bowden X-carriage mount v2 for Prusa i3 by Tech2C, published Jun 18, 2016

I kept this thing as a whole block due to mounting weight and the lack of space for a mounting block.

I did kept in account that screw heads are about 4.7mm in diameter so I made the grooves to be 5mm.

For mounting the fans I used M3 screws, and made the holes to be 2.9mm so it grips on the plastic when you screw it in. The screwholes for the fans are 6mm deep into the plastic. I used 20mm screws myself for these fans. The screwhole walls are 1mm or more so it should not break easily.

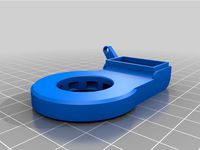

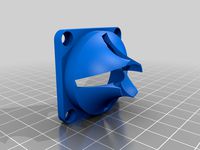

There should be around 2 to 3mm of space between the lowest part of the fanduct and the tip of the E3D nozzle. These fanducts blow directly and a bit below the nozzle. Atleast I hope that it does that, I’m not a wind engineer. But you can inspect the STL file if it’s to your liking. I test printed some frogs which had an overhand at their chin and belly and that worked out very well, with 35% fan speed.

I printed this with 2 walls and 15% infill. Use whatever setting you like but so note that the mounting pressing for the heatsink to fit onto the plastic is pretty high.

Extra information and reasoning:

This is a triple 50mm fan shroud that I made for 2 purposes:

Actually fit on the X-carriage groove mount for E3D heatsinks.

To be able to use 50mm silent fans.

[3. To not resonate when I’m printing fast]

It’s a large block, but surprisingly not as wide as the other shrouds that I printed from other people. Multiple plastic parts that are held down with bolts can have small gaps and can resonate at high print speeds (60+ mm/s). I also kept about 7mm of space in between the heatingblock and the plastic shroud so the plastic does not soften when I print at 270 degrees Celsius or hotter. (for stronger layer adhesion as the filament melts into the previous layers. Skynet3D has a safety shut down at 275 degrees, but I’ll be using a pt100 thermocouple soon to print POM or PETG)

For me there is enough space in between the heating block and the plastic shroud; I use Chinese clone parts to tinker around.

I made this fan shroud in fusion 360, with too much effort by only using the model tools. So I used a lot of sketches and extrusions. I should have used the sculpt tools instead.

I used these fans:

Gelid Solutions Silent 5

Size: 50 mm

Noise: 23 dB

Airflow: 21,94 m³/h

Airflow: 12,91 cf/m

Max RPM: 4.000rpm

These cost me about 5 euro’s a piece. And they are pretty silent, as they do make noise but at a lower frequency pitch. It's more like a blowing noise instead of a tearing noise that'll hear on turbine fans. But due to my design faults, it can cause turbulence which makes the fans a bit louder than when you do not mount them. And these fans pull/suck a lot of air in. I might put a tachometer in between so I can regulate the fan speed for the heatsink. The filament coolers can be controlled by the board/slicer software. But at the moment my anet a8 frame is squeaking louder than the noise of the fans.

Apparently if You write here your token expires and you'll loose all your text.

Should have know that, as for my previous experiences with writing on thingyverse.

As you can read here:https://www.thingiverse.com/PokeyDoggo/collections/anet-a8-early-upgradeshttps://www.thingiverse.com/PokeyDoggo/collections/e3d-v6-hotend-filament-coolers

So there goes half an hour of typing and getting the right data and pictures.

I'll update this with a proper description if I feel like it.

Yes I have multiple heatsinks and heaterblocks. One used, one not yet used.

I'm busy with a COREXY version. I kinda.. well I did make a volcano version and tested them, but they sucked, my bad. I'm not a great designer.

This thing has worked for me and served me for the last few years, eventhough without any cooling the two ducts started melting and I'm clumsy. Nothing a bit of kapton tape could not solve.

A link to download the fusion360 files, which can be downloaded as all kinds of 3d files.https://a360.co/2DZDqSc

EDIT: 26-04-2018

Hey, seems like a lot of people like this. Uhm I kinda said I'd make a volcano version..

a year ago.

I was busy with college and what not with life. But the Volcano version will come.

This cooler shroud served me for over a year with clean ABS printing.

It did had some issues. Actually it had none, only though a problem of way to much filament clogging up at the hotend which I tried to remove and then I twisted the hotend against the side of the fanduct and it melted a little bit. Which I could easily scrape off with a knife and it still functioned perfectly. and the e3d cooler fanduct melted a little bit.

But I used this a few times with 100% fan speed for both 50mm fans, and it cooled the printed part so much that the layer adhesion was.. well it did adhere, but it was a weak connection. I could bridge stuff so easily and make 75+ degree angles but yeah cooling molten plastic too much, especially ABS is not a good idea.

But the main problem was, I couldn't see what it was printing directly.

So, I'll make a new version! It's almost done. The first will be a way too large Volcano one.

Which I then improve.

And a standalone 50mm e3d V6 cooler version which you can snap on like the original 30mm one.

Then a duct like this one, but it only two 50mm fans, for the normal heatingblock and the volcano to reduce mass and the size.

Maybe I'll figure out how to fit a 60mm fan.

Might just remake the 50mm version for a 40mm one.

Actually I also have a 2x mk7 hobbed bolt extuder idea, for bowder and direct drive. But I'll focus on the fanducts first.

Stay tuned, they will be up in a week or so.

I'll make a E3D V6 Volcano version soon and both V5 versions. Since I also have such a hotend and heatsink laying around. But I'll redesign it from scratch, because my old fusion 360 file takes way too long to load because it had too many additions and extrusion. But I keep learning new things.

I also printed quite a bit with this new shroud, and it works fine at 150mm/s setting in cura, eventhough the anet cannot reach those speeds. And nothing has melted yet at 270 degrees.

Edit: Set your fan speed to 100% if you need to bridge.

Assembly:

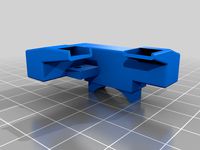

The E3D V6 heatsink might have a very tight fit or it does not fit at first. You need to push it into the plastic pretty hard. I took the direct dimensions with a caliper, and even removed 0.01mm here and there. But I also wanted to prevent resonance so it’s a very tight fit.

This shroud should fit on any groovemount if there is enough room at the front. I kept about 1mm of space between the back of the plastic and the back of the heatsink. So there would always be 1 mm free space for the hot air to espace and to solve any mounting issues.

When you want to screw this shroud to the groovemount, you might need drill out the holes at the top. I made these to be 3.0mm, the diameter of a M3 screw, but I had some filament in between so I had to drill it out very slightly. These groovemount screwholes should give no resistance.

On my own AnetA8 I could remove the extra X-stop and I now use the default X-stop location. Because this shroud is (surprisingly) not as wide as I initially thought.

When I mounted this to my own X-carriage (which is very butchered) I had to screw it together with quite some force but not too much force to get everything to fit tightly. But it won’t go anywhere now.

For reference of the width of the screw holes that I used, I used these groovemount X-carriage for the Prusa i3 and AnetA8:

https://www.thingiverse.com/thing:2099577 ANET A8 | Customizable E3D v6 Carriage / Bowden mount by TNS, published Feb 12, 2017

https://www.thingiverse.com/thing:1632847 E3Dv6 Bowden X-carriage mount v2 for Prusa i3 by Tech2C, published Jun 18, 2016

I kept this thing as a whole block due to mounting weight and the lack of space for a mounting block.

I did kept in account that screw heads are about 4.7mm in diameter so I made the grooves to be 5mm.

For mounting the fans I used M3 screws, and made the holes to be 2.9mm so it grips on the plastic when you screw it in. The screwholes for the fans are 6mm deep into the plastic. I used 20mm screws myself for these fans. The screwhole walls are 1mm or more so it should not break easily.

There should be around 2 to 3mm of space between the lowest part of the fanduct and the tip of the E3D nozzle. These fanducts blow directly and a bit below the nozzle. Atleast I hope that it does that, I’m not a wind engineer. But you can inspect the STL file if it’s to your liking. I test printed some frogs which had an overhand at their chin and belly and that worked out very well, with 35% fan speed.

I printed this with 2 walls and 15% infill. Use whatever setting you like but so note that the mounting pressing for the heatsink to fit onto the plastic is pretty high.

Extra information and reasoning:

This is a triple 50mm fan shroud that I made for 2 purposes:

Actually fit on the X-carriage groove mount for E3D heatsinks.

To be able to use 50mm silent fans.

[3. To not resonate when I’m printing fast]

It’s a large block, but surprisingly not as wide as the other shrouds that I printed from other people. Multiple plastic parts that are held down with bolts can have small gaps and can resonate at high print speeds (60+ mm/s). I also kept about 7mm of space in between the heatingblock and the plastic shroud so the plastic does not soften when I print at 270 degrees Celsius or hotter. (for stronger layer adhesion as the filament melts into the previous layers. Skynet3D has a safety shut down at 275 degrees, but I’ll be using a pt100 thermocouple soon to print POM or PETG)

For me there is enough space in between the heating block and the plastic shroud; I use Chinese clone parts to tinker around.

I made this fan shroud in fusion 360, with too much effort by only using the model tools. So I used a lot of sketches and extrusions. I should have used the sculpt tools instead.

I used these fans:

Gelid Solutions Silent 5

Size: 50 mm

Noise: 23 dB

Airflow: 21,94 m³/h

Airflow: 12,91 cf/m

Max RPM: 4.000rpm

These cost me about 5 euro’s a piece. And they are pretty silent, as they do make noise but at a lower frequency pitch. It's more like a blowing noise instead of a tearing noise that'll hear on turbine fans. But due to my design faults, it can cause turbulence which makes the fans a bit louder than when you do not mount them. And these fans pull/suck a lot of air in. I might put a tachometer in between so I can regulate the fan speed for the heatsink. The filament coolers can be controlled by the board/slicer software. But at the moment my anet a8 frame is squeaking louder than the noise of the fans.

Apparently if You write here your token expires and you'll loose all your text.

Should have know that, as for my previous experiences with writing on thingyverse.

As you can read here:https://www.thingiverse.com/PokeyDoggo/collections/anet-a8-early-upgradeshttps://www.thingiverse.com/PokeyDoggo/collections/e3d-v6-hotend-filament-coolers

So there goes half an hour of typing and getting the right data and pictures.

I'll update this with a proper description if I feel like it.

Yes I have multiple heatsinks and heaterblocks. One used, one not yet used.

Similar models

thingiverse

free

E3D V6 Volcano clone (Haldis) part cooler fan 3010-blower air guide by cancermann

...other high temp melting point plastic so you don't melt your air guides when printing asa, abs etc with high temp and fan 0%.

thingiverse

free

Sunhokey 50mm fan shroud by Toxiccrisco

...original spot with same screws you just need 4 fan screws

printed in pla i made it so not touching the heatsink so pla works fine

thingiverse

free

E3D V6 Volcano 40mm Fanduct by Zloy_Glide

...e3d v6 volcano 40mm fanduct by zloy_glide

thingiverse

40 mm fan duct for e3d v6 volcano minimal mount.

thingiverse

free

K8200 E3D v6 Mount with integrated fan and fan shrouds by Joey_3D

... so that my bolts would reach the nuts. bouth fan shrouds are mounted with regular bolts and nuts. i also used some lock washers.

thingiverse

free

TronXY X5SA Pro V6 Hotend Mount by k0dyn

...he v6 is taller than the stock hotend, so you'll need to lower your abl mount. i made an adapter to lower the stock one here:

thingiverse

free

30 mm E3D-v6 Shroud for PLA by blakefobrien

... to the heatsink. this means that it is necessary to use a zip tie to mount the shroud.

find me here: http://progressbychance.com

thingiverse

free

E3D V6 30mm heatsink fan 30mm volcano Fan Ducts by zerosl

...s by zerosl

thingiverse

i designed a 30mm fan duct for my volcano nozzle. it attaches to the existing v6 heatsink fan

print with

thingiverse

free

MGN9H BMG Volcano V6 mount with level sensor by jatson

....

the fanduct not held by screws, you will need to stick it in position according to your setup.

i'm using it for my anet e10

thingiverse

free

E3D Volcano Triple fan mount (+Voxelab Aquila Bracket) by Breadycorn

... and remixed it to add a little bit of clearance so that my own fanduct fits and has a little bit of clearance to the x carriage.

thingiverse

free

5015 E3DV6 Heatsink Cooler by jjman6

...ecure w/ an m3 or m4 screw.

and you'll need longer m4's to mount the e3d w/ fang. i'll try to add more photos later.

Fanduct

thingiverse

free

jgmaker magic fanduct

...jgmaker magic fanduct

thingiverse

jgmaker magic fanduct

thingiverse

free

Ultimaker fanduct by Gijs

...ultimaker fanduct by gijs

thingiverse

replacement fanduct for ultimaker stock fan.

thingiverse

free

50mm Fanduct by NitroXpress

...50mm fanduct by nitroxpress

thingiverse

fanduct for 50mm fan.

85mm long

print without support.

thingiverse

free

Minimalist Fanduct

...esigned this new fanduct to be more minimalist.

also i'm using this fanguard:https://www.thingiverse.com/thing:1691426

thanks

thingiverse

free

BigBooster FanDuct by PHROZENOne

...bigbooster fanduct by phrozenone

thingiverse

big booster fanduct for 35x35 radial part fans and 40x40 hotendfan

thingiverse

free

Fanduct for chimera by StikkaDesign

...thingiverse

a simply fanduct for chimera (configuration with the rotating heating blocks - resistance and thermistor in lateral)

thingiverse

free

Geeetech A10 Fanduct by stefan177gr

...geeetech a10 fanduct by stefan177gr

thingiverse

fanduct for geeetech a10

thingiverse

free

Tevo Tarantula FanDuct by hkgary_g

...tevo tarantula fanduct by hkgary_g

thingiverse

fanduct for tevo tarantula

thingiverse

free

Mendel90 40mm Fanduct by sivar2311

...mendel90 40mm fanduct by sivar2311

thingiverse

40mm fanduct for mendel90.

thingiverse

free

Artillery Genius Hotend Fanduct

...artillery genius hotend fanduct

thingiverse

it is a fanduct for the artillery genius.

Monolith

design_connected

$11

Monolithic

...monolithic

designconnected

dennis miller monolithic computer generated 3d model.

turbosquid

free

Monolith

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

Ditreitalia monolith

...oyalty free 3d model ditreitalia monolith for download as max on turbosquid: 3d models for games, architecture, videos. (1702137)

3ddd

free

electric monolith skateboard

...electric monolith skateboardhttp://www.designboom.com/technology/electric-monolith-skateboard-motors-wheels-03-09-2015/

3d_export

$10

Monolithic multi-storey building

...monolithic multi-storey building

3dexport

monolithic, six-story house with balconies and a common entrance

turbosquid

$9

Monolith black coin

...royalty free 3d model monolith black coin for download as max on turbosquid: 3d models for games, architecture, videos. (1498952)

turbosquid

$9

Monolith gold coin

...

royalty free 3d model monolith gold coin for download as max on turbosquid: 3d models for games, architecture, videos. (1498948)

3d_export

$5

Ditre Italia - Monolith

...ditre italia - monolith

3dexport

turbosquid

$28

Monolith Bed by Ditre Italia

...ree 3d model monolith bed by ditre italia for download as max on turbosquid: 3d models for games, architecture, videos. (1490271)

turbosquid

$12

Ditre Italia Monolith Bed

...l ditre italia monolith bed for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1241129)

Shroud

3d_export

$500

Centrifugal pump volute casing with impeller

...casing with impeller 3dexport volute casing with impeller and shroud ...

3d_export

$35

The Holy Face base relief 3D Model

...the holy face base relief 3d model 3dexport shroud turin veronica veronica's veil gospel ikon jesus holy face...

3d_export

$20

present car cloth presentation transport transportation shape concepts show celebration cover showro

...transportation shape concepts show celebration cover showroom covered revealin shroudd cover covering tarp draped fabric cloth showroom reveal revealing...

3d_export

$5

Lockheed F-117 Nighthawk lowpoly stealth bomber

...initial operating capability status in 1983. the aircraft was shroudd in secrecy until it was revealed to the public...

3d_export

$49

kriss vector gen 2 sub-d

...rear flip sight.<br>- vector ejection port.<br>- vector crb square shroud / 16"" sliencer.<br>- ds150 stock.<br>- .ma (maya 2020 ascii)<br>-...

3d_export

$10

vichy dining table

...in oak, sycamore and walnut marquetry.<br>even if the restaurant shroud the vichy in a long table cloth, two slender...

3d_export

$500

us navy pcu sterett ddg-104 arleigh burke class destroyer flight iia max

...the position has been shifted.<br>q. where are the exhaust shroud for the stacks?<br>a. since ddg-89, the exhaust system was...

thingiverse

free

shroud by samshay317

...shroud by samshay317

thingiverse

shroud

thingiverse

free

Fan Shroud

...fan shroud

thingiverse

this is a fan shroud for a 140mm fan

thingiverse

free

40mm fan shroud

...40mm fan shroud

thingiverse

40mm fan shroud

E3D

turbosquid

$23

E3D - Google Home

... 3d model e3d - google home for download as max, obj, and c4d on turbosquid: 3d models for games, architecture, videos. (1192509)

cg_studio

free

e3d model

...e3d model

cgstudio

- e 3d model, royalty free license available, instant download after purchase.

turbosquid

$2

Syringe C4D (E3D Ready)

...lty free 3d model syringe c4d (e3d ready) for download as c4d on turbosquid: 3d models for games, architecture, videos. (1336720)

turbosquid

$12

Microphone USB E3D and C4D

...ree 3d model microphone usb e3d & c4d for download as c4d on turbosquid: 3d models for games, architecture, videos. (1568216)

turbosquid

$29

E3D - OnePlus 6 Black

...model e3d - oneplus 6 black for download as max, obj, and c4d on turbosquid: 3d models for games, architecture, videos. (1358534)

turbosquid

$29

E3D - Motorola One 2018

...del e3d - motorola one 2018 for download as max, obj, and c4d on turbosquid: 3d models for games, architecture, videos. (1358533)

turbosquid

$29

E3D - Disney MagicBands 2

...l e3d - disney magicbands 2 for download as max, obj, and c4d on turbosquid: 3d models for games, architecture, videos. (1355515)

turbosquid

$29

E3D - Samsung Z4 Smartphone

...e3d - samsung z4 smartphone for download as max, obj, and c4d on turbosquid: 3d models for games, architecture, videos. (1182179)

turbosquid

$23

E3D - Razer Phone model

...del e3d - razer phone model for download as max, obj, and c4d on turbosquid: 3d models for games, architecture, videos. (1231207)

turbosquid

$23

E3D - Alcatel Idol 5

... model e3d - alcatel idol 5 for download as max, obj, and c4d on turbosquid: 3d models for games, architecture, videos. (1212799)

V6

3d_export

$100

v6 engine

...engine

3dexport

complete v6 engine modeled on solidworks 2017 along with .stl, .sldprt and .sldasm of all th parts and assembly.

3d_export

$10

V6 engine

... the first v6 engines were designed and produced independently by marmon motor car company, deutz gasmotoren fabrik and delahaye.

3d_export

$35

v6 engine

...s a complete model of a v6 engine containing over 400 components. you can contact me for a video of all the components assembling

3d_export

$10

v6 engine

...v6 engine

3dexport

turbosquid

$25

Bed1001-v6

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$22

Chair2-v6

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

V6.mb

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$20

V6 engine

...rovided in this package is all the parts in sldprt format and assembly in sldasm format. i can also convert the format on demand.

3ddd

$1

Стол V6

...6" в стиле дизельпанк изготовлен из блока двигателя, 4х поршней и 4х шатунов.

столешница изготовлена из стекла толщиной 8мм.

cg_studio

$199

V6 VVTi3d model

...v6 vvti3d model

cgstudio

.3ds - v6 vvti 3d model, royalty free license available, instant download after purchase.

50Mm

3d_ocean

$9

50mm Canon lens

...50mm canon lens

3docean

50mm canon foto lens photo

canon lens 50mm 1.8 the most practical affordable lens to start with

3d_export

$20

50mm cal 3D Model

...50mm cal 3d model

3dexport

50mm cal bullet ammo

50mm cal 3d model archer 23592 3dexport

turbosquid

$39

50mm Prime Lens

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$1

Base insert - Stone&Wood 50mm

...e 3d model base insert - stone&wood 50mm for download as on turbosquid: 3d models for games, architecture, videos. (1325614)

turbosquid

$7

Grenade Launcher Ammo Type 91 50mm

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$19

Lensbaby Composer Double Glass 50mm lens

...lass 50mm lens for download as ma, max, ma, dae, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1523910)

3ddd

$1

объектив Canon EF 50mm f-1.2L USM

... canon

объектив canon ef 50mm f-1.2l usmhttp://market.yandex.ru/model.xml?modelid=988322&hid;=90613

turbosquid

$5

SOCKET HEAD CAP SCREW M7 LENGTH-50mm

...screw m7 length-50mm for download as sldpr, sldpr, stl, and x on turbosquid: 3d models for games, architecture, videos. (1677023)

turbosquid

$19

Lens Sigma 17-50mm F2.8 EX OS

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$12

nissan skyline r33 50mm over fenders

...late gtr width<br>model format ready obj, fbx, 3ds, 3ds max 2015-2018<br>poly's - 8790<br>vert's - 7578