Thingiverse

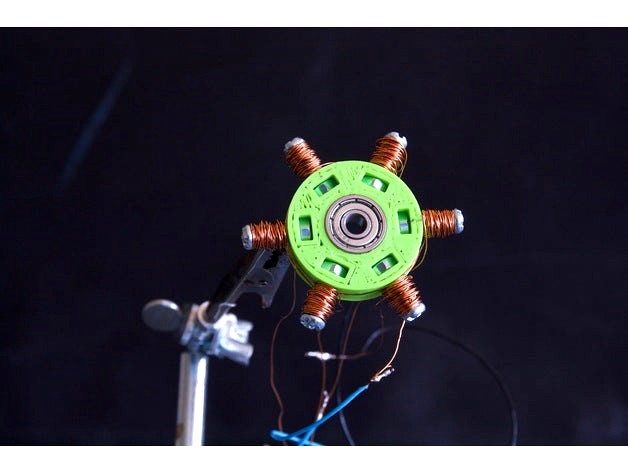

The Electric motor challenge! by linusjarbo

by Thingiverse

Last crawled date: 3 years, 1 month ago

Please don't try to use this motor for anything practical! It is really weak :D

You are hearby challenged to make an electric motor! :D

https://youtu.be/nSAchBjz5uI

https://youtu.be/jgRP5jPOVO0

UPDATE: I added a inner core without any iron for the electromagnet, there is no point to use a metalcore if the electromagnet cant overcome the attraction anyway. For an electromagnet with air core, the internet suggests a tall and thin windig of the wire since the "magnetic field" cant travel along the length of an air core. Thas why I have a very thin gap for the wire. This setup actually used a bit less power. 0.6- 0.8A instead of 0.9A. The air-core electcromagnets truly is very weak, so be sure to make a close design for your parts.

Motive

As a kid, I discovered an electric motor entirely made in acrylic glass, It was on display on a small table in a closed room in a friends family house. It was a large transparent disk with metalfoil attached to it - wires here and there. This must have been around 1975-1980, I was probably 7 years old? My family spent a short holiday in Norway, Oslo, and the motor I saw must have been made by Nils Berner for a class, if I remember correctly? (Nils later became an inventor)

I was so impressed, acrylic glass, this was the future. Totally awesome.

Ever since I saw that acrylic-glas-motor I wanted to make an electric motor myself. So now I finally made it. It was surprisingly easy.

Some info on the AIR-core - construction:

-insulated copperwire, 0.25mm, 30 turns on each

-1 bearing, 13mm x 4mm ( outer x inner)

Some info on the METAL-core - construction:

-insulated copperwire, 0.25mm, 100 turns on each bolt (could probably be thicker wire and fewer turns?)

-6 bolts and nuts. 3M(mm) 16mm long (could try to anneal the metal?)

-1 bearing, 13mm x 4mm ( outer x inner)

Some info on the Outer-ring construction:

-10 neodynium magnets, cylindrical 5mmx5mm

-1 long bolt 4M, 38mm long, 1 nut to adjust height of the outer ring of magnets.

Some info on control

-arduino uno

-adafruit motorshield (4 h-bridges)

-1 trimpot 10K

I ran the motor with 7 volt and 0.9 A (x 3). (The adafruit motorshield cant handle more than 3A in total, and the wires got really hot if I used any more power)

Arduino code

The Arduino code for the Adafruit motorshield v2.0 is found here.https://github.com/LinusJarbo/Arduino/blob/master/ElectricMotor/ElectricMotor.ino

You are hearby challenged to make an electric motor! :D

https://youtu.be/nSAchBjz5uI

https://youtu.be/jgRP5jPOVO0

UPDATE: I added a inner core without any iron for the electromagnet, there is no point to use a metalcore if the electromagnet cant overcome the attraction anyway. For an electromagnet with air core, the internet suggests a tall and thin windig of the wire since the "magnetic field" cant travel along the length of an air core. Thas why I have a very thin gap for the wire. This setup actually used a bit less power. 0.6- 0.8A instead of 0.9A. The air-core electcromagnets truly is very weak, so be sure to make a close design for your parts.

Motive

As a kid, I discovered an electric motor entirely made in acrylic glass, It was on display on a small table in a closed room in a friends family house. It was a large transparent disk with metalfoil attached to it - wires here and there. This must have been around 1975-1980, I was probably 7 years old? My family spent a short holiday in Norway, Oslo, and the motor I saw must have been made by Nils Berner for a class, if I remember correctly? (Nils later became an inventor)

I was so impressed, acrylic glass, this was the future. Totally awesome.

Ever since I saw that acrylic-glas-motor I wanted to make an electric motor myself. So now I finally made it. It was surprisingly easy.

Some info on the AIR-core - construction:

-insulated copperwire, 0.25mm, 30 turns on each

-1 bearing, 13mm x 4mm ( outer x inner)

Some info on the METAL-core - construction:

-insulated copperwire, 0.25mm, 100 turns on each bolt (could probably be thicker wire and fewer turns?)

-6 bolts and nuts. 3M(mm) 16mm long (could try to anneal the metal?)

-1 bearing, 13mm x 4mm ( outer x inner)

Some info on the Outer-ring construction:

-10 neodynium magnets, cylindrical 5mmx5mm

-1 long bolt 4M, 38mm long, 1 nut to adjust height of the outer ring of magnets.

Some info on control

-arduino uno

-adafruit motorshield (4 h-bridges)

-1 trimpot 10K

I ran the motor with 7 volt and 0.9 A (x 3). (The adafruit motorshield cant handle more than 3A in total, and the wires got really hot if I used any more power)

Arduino code

The Arduino code for the Adafruit motorshield v2.0 is found here.https://github.com/LinusJarbo/Arduino/blob/master/ElectricMotor/ElectricMotor.ino

Similar models

3dwarehouse

free

Electromagnetic Propulsor( Magnetless)

...ctromagnets, which are included in series in circuit: inner electromagnet – iron core – outer electromagnet. #internal_propulsion

thingiverse

free

Enclosure - Arduino with Shield and wires/buttons/leds by captainmojojojo

...or 4 buttons with and 4 leds

-moved the power led to the top center

-left room for several wires to go out the side to the motors

3dwarehouse

free

Electric Motor 600 Brushed

...ectric motor. separable electromagnets and brushes. #600 #brushes #electric #electric_motor #electromagnet #engine #magnet #motor

thingiverse

free

Turn Table - photo movie image sequencer by linusjarbo

...) threaded rod (1) + nuts

2mmx2cm(2m) + nuts (this is to fasten small spur gear to stepper motor)

3mm (3m) for the stepper mount.

thingiverse

free

electric motor by trzeci

...etween electromagnets

works with 1.5v battery.

https://drive.google.com/file/d/1scbs2pjx53npgtvbjqb69dys9npy3ev9/view?usp=sharing

sketchfab

$17

Magnetization by Coli

...rators, inductors, electromagnets, transformers, and sensor coils. - magnetization by coli - buy royalty free 3d model by arloopa

grabcad

free

DC Motor

... parts of the dc motor. a tutorial to it from the youtube channel, solidworks tutorials is also added if you want to recreate it.

grabcad

free

Mobility Aid With Electromagnet System

...e very useful because you can turn the magnets on and off by controlling the circuit.

may be useful

thank you

regards,

chaniago

thingiverse

free

Automatic Fish Feeder neat solution. by Steve5092

... bolts m4 x 20mm screws x 2

n20 dc gear motor miniature high torque electric gear box motor x 1

arduino nano x 1

oneway relay x 1

grabcad

free

Rotor(Coil wiring)

...es for its 3-phase windings which are evenly spaced at 120 electrical degrees apart and connected in a 'y' configuration.

Linusjarbo

thingiverse

free

Bat Listener case by linusjarbo

... i could have the listener in a bag.

electronics can be found here.https://www.tindie.com/products/curiouselectric/bat-listener/

thingiverse

free

Remix of Acupuncture/ massage buttons by linusjarbo

...two spikes after some brutal handling but overall they seem pretty sturdy.

i hotglued them to a small carpet. see provided image.

thingiverse

free

Turn Table - photo movie image sequencer by linusjarbo

...) threaded rod (1) + nuts

2mmx2cm(2m) + nuts (this is to fasten small spur gear to stepper motor)

3mm (3m) for the stepper mount.

thingiverse

free

Relief Printing Tutorial, 3D printed by linusjarbo

...based etching ink and not the water soluble. (i'll see if i make any testing with the water soluble, it might work once dry?)

Challenge

turbosquid

$120

Challenger 2 and challenger 2 TES

...e 3d model challenger 2 and challenger 2 tes for download as on turbosquid: 3d models for games, architecture, videos. (1430319)

3d_export

$59

dodge challenger srt8

...dodge challenger srt8

3dexport

dodge challenger srt8

3d_export

$20

dodge challenger 1970

...dodge challenger 1970

3dexport

dodge challenger 1970

3d_export

$15

Dodge Challenger Hellcat

...dodge challenger hellcat

3dexport

dodge challenger hellcat

turbosquid

$80

challenger-2

...rbosquid

royalty free 3d model challenger-2 for download as on turbosquid: 3d models for games, architecture, videos. (1498848)

3d_export

$5

dodge challenger car

...dodge challenger car

3dexport

3d model dodge challenger!

turbosquid

$99

Dodge Challenger

...

royalty free 3d model dodge challenger for download as blend on turbosquid: 3d models for games, architecture, videos. (1489358)

turbosquid

$49

Dodge Challenger

...

royalty free 3d model dodge challenger for download as blend on turbosquid: 3d models for games, architecture, videos. (1698375)

turbosquid

$10

dodge challenger

...

royalty free 3d model dodge challenger for download as blend on turbosquid: 3d models for games, architecture, videos. (1405948)

3d_export

free

dodge challenger srt8

...dodge challenger srt8

3dexport

dodge challenger srt8 free model

Electric

3d_export

$5

Electric pole

...electric pole

3dexport

electric pole for street, electricity line

3ddd

$1

electric mixer

...electric mixer

3ddd

electric mixer , миксер

electric mixer

3ddd

$1

electrical installation

...electrical installation

3ddd

electrical installation , розетка

electrical installation

turbosquid

$19

The electric water heater electric

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Electrical Outlet electric splitter

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_ocean

$20

Electric Guitar

...electric guitar

3docean

electric electric guitar guitar music music instrument

model of a electric guitar created in maya.

3d_ocean

$12

Electric Shaver

...electric shaver

3docean

electric electric shaver hair removal personal care shaver shaving

electric shaver created in 3ds max.

3ddd

$1

electrical switch

...h

3ddd

electrical , розетка

electrical switch from bticino company

series livinglight

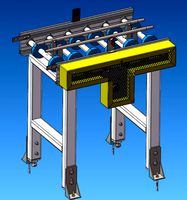

3d_export

$7

Electric Conveyor

...electric conveyor

3dexport

electric conveyor

3d_export

$5

electric drums

...electric drums

3dexport

electric drums

Motor

archibase_planet

free

Motor

...base planet

motor motor engine engine electric motor

motor wagner n250213 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Motor

...motor

archibase planet

motor motor engine engine

motor n151112 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Motor

...motor

archibase planet

motor motor engine engine

motor n150615 - 3d model (*.gsm+*.3ds+*.max) for interior 3d visualization.

turbosquid

$15

Motor

...otor

turbosquid

royalty free 3d model motor for download as on turbosquid: 3d models for games, architecture, videos. (1639404)

3d_ocean

$5

Electric motor

...electric motor

3docean

car electric engine industry motor phase train vehicle

an electric motor enjoy!

3d_ocean

$18

Electric Motor

...electric motor

3docean

electric motor engine machine mover parts

3d model electric motor for hoist crane

turbosquid

$29

Motor

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$5

Motor

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

electric motor

...electric motor

3dexport

electric motor use for industrial purposes

3d_export

$5

servo motor

...tor

3dexport

it's a simple part of servo motor 0.75kw for used in machines assembly to show specified motor in own project.