Thingiverse

The All You Can Feed Buffet v1.3 :-) by mnis

by Thingiverse

Last crawled date: 2 years, 12 months ago

!!! Currently under construction (...PAUSED for an unspecified period...). Content might be faulty and incomplete. This package will be gradually expanded to include additional content. If interested, please check regularly back here.!!!

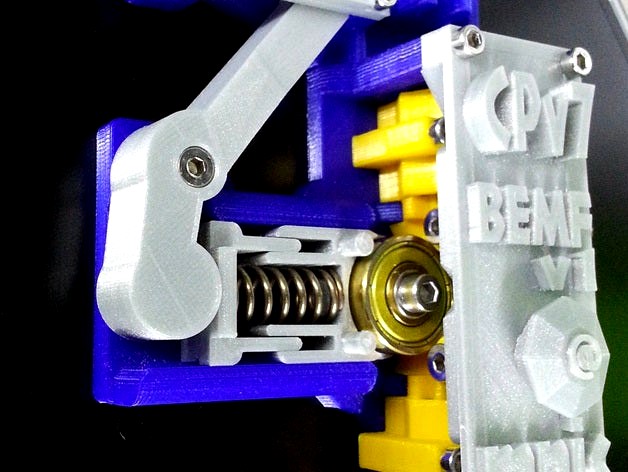

• This is "CPv7-BEMF" - UNIVERSAL (Bowden Extruder-Material-Feeder). To have the BEST, maybe NO. But to have the MOST UNIVERSAL, maybe YES :-) :-) :-)

• This ELEVEN -parts object is one component of my One Man - *Co.Me.Do.ONE - project. CP-v7 (Co.Me.Do. - Part No: 7). To use this printable object, additional components are required.

• Description #1

• The All You Can Feed Buffet...

• MENU 1: The complete CPv7 Download Package for 3mm and 2.85mm Filament (Already available).

• MENU 1.1: !!! Great stability improvements to the feeder base (Today: 2014-12-16) !!!

• The basic design has been completely revised again ... BEMF - Reloaded :-)

• Significantly lower breakage / will bend Risk of all static elements, with the use of possibly substandard filaments for the construction of the feeder.

• The Bowden guide on the base now allow easier insertion and removal of the standard Bowden tubing OD: 6 / ID: 4mm.

• The two stabilizing bridges were revised slightly.

• MENU 1.3: !!! Stability improvements to the feeder base (Today: 2015-12-22) !!!

• MENU 1.5: Carriages for alternative couplings eg. UM - Tube collet (Will be soon available).

• MENU 2: The complete CPv7 Download package for 3mm, 2.85mm and 1.75mm Filament (Will soon be available).

• MENU 3: SketchUp source files (Will soon be available).

• Description #2:

• The CPv7-BEMF-v1 basic design has completed over 750 hours of operation successful.

• Universal "Bowden-Extruder - Material-Feeder", suitable for filaments with a diameter of 3mm, 2.85mm, and later 1.75mm.

• Based on the conventional unicycle-principle: Suitable for a variety of knurled and hobbed drive wheels.

• Finely adjustable uniform pressure, and the lowest possible friction: A large counterpressure roller (608ZZ-Bearing), and two limiting rollers (624ZZ-Bearing), can reliably carry material through the couplings in the Bowden.

• One hundred percent compatible with the Ultimaker 2 machine, Software and firmware adjustments are NOT required. But fully universally applicable.

• Modular feeder structure: Adjustable guide slides available for different hard and thick filaments: Even flexible filaments, for example Ninja Flex (Layer: 0.1mm / speed. 20-25mm/s.) can be printed with CPv7. But tests with very soft filaments are currently not yet completed.

• Depending on the selected guide slides, an almost trouble-free material change is possible: it needs a little force for inserting new material, it must be straightened slightly only in the initial region. The adjustment of the spring tensioning lever can be moved temporarily close to zero, this allows an added locking lever.

• A very reliable and almost wear-free operation is possible depending on the correct implementation. A simple work for a 3D printer, and a not too complicated work for the user. All optional components are relatively cheap to buy. You need for a successful reproduction a generally functioning 3D printer. Unfortunately, a whole long printing time is expected. Ask at best an experienced friend or colleague to accompanying Support.

• Very stable Bowden guide (Bowden Fix) at the top outlet: The lower material supply can be easily implemented by means of a short length Bowden. An almost free of play support for the Bowden tube in direct interaction with the presented powerful pneumatic couplings, shorter retractions are possible, and a sudden grip loss is almost unthinkable. But there will be later carriages for alternative couplings.

• Integrated cable Management.

• There are different covers to choose from: The installation of a neutral variant is easy to implement.

• Versions for left and right rear panel mounting available. Note for Ultimaker 2 users: Please use the right version. The left version is currently not optimized for extruder 2 operation, and does not fit on the rear Panel.

• Information regarding enhancements and bug fixes you will find in the "Comment" section. Photos with the already assembled object does not show the latest design.

• Again and again: My work for you lives solely by your feedback. If something is wrong or useless in my designs, I need more information from you so that I can ever change anything. Suggestions to improve or simplify my designs and descriptions are highly desirable. So if you use my designs and parts thereof, please take a few moments to convey a little feedback.

• This is "CPv7-BEMF" - UNIVERSAL (Bowden Extruder-Material-Feeder). To have the BEST, maybe NO. But to have the MOST UNIVERSAL, maybe YES :-) :-) :-)

• This ELEVEN -parts object is one component of my One Man - *Co.Me.Do.ONE - project. CP-v7 (Co.Me.Do. - Part No: 7). To use this printable object, additional components are required.

• Description #1

• The All You Can Feed Buffet...

• MENU 1: The complete CPv7 Download Package for 3mm and 2.85mm Filament (Already available).

• MENU 1.1: !!! Great stability improvements to the feeder base (Today: 2014-12-16) !!!

• The basic design has been completely revised again ... BEMF - Reloaded :-)

• Significantly lower breakage / will bend Risk of all static elements, with the use of possibly substandard filaments for the construction of the feeder.

• The Bowden guide on the base now allow easier insertion and removal of the standard Bowden tubing OD: 6 / ID: 4mm.

• The two stabilizing bridges were revised slightly.

• MENU 1.3: !!! Stability improvements to the feeder base (Today: 2015-12-22) !!!

• MENU 1.5: Carriages for alternative couplings eg. UM - Tube collet (Will be soon available).

• MENU 2: The complete CPv7 Download package for 3mm, 2.85mm and 1.75mm Filament (Will soon be available).

• MENU 3: SketchUp source files (Will soon be available).

• Description #2:

• The CPv7-BEMF-v1 basic design has completed over 750 hours of operation successful.

• Universal "Bowden-Extruder - Material-Feeder", suitable for filaments with a diameter of 3mm, 2.85mm, and later 1.75mm.

• Based on the conventional unicycle-principle: Suitable for a variety of knurled and hobbed drive wheels.

• Finely adjustable uniform pressure, and the lowest possible friction: A large counterpressure roller (608ZZ-Bearing), and two limiting rollers (624ZZ-Bearing), can reliably carry material through the couplings in the Bowden.

• One hundred percent compatible with the Ultimaker 2 machine, Software and firmware adjustments are NOT required. But fully universally applicable.

• Modular feeder structure: Adjustable guide slides available for different hard and thick filaments: Even flexible filaments, for example Ninja Flex (Layer: 0.1mm / speed. 20-25mm/s.) can be printed with CPv7. But tests with very soft filaments are currently not yet completed.

• Depending on the selected guide slides, an almost trouble-free material change is possible: it needs a little force for inserting new material, it must be straightened slightly only in the initial region. The adjustment of the spring tensioning lever can be moved temporarily close to zero, this allows an added locking lever.

• A very reliable and almost wear-free operation is possible depending on the correct implementation. A simple work for a 3D printer, and a not too complicated work for the user. All optional components are relatively cheap to buy. You need for a successful reproduction a generally functioning 3D printer. Unfortunately, a whole long printing time is expected. Ask at best an experienced friend or colleague to accompanying Support.

• Very stable Bowden guide (Bowden Fix) at the top outlet: The lower material supply can be easily implemented by means of a short length Bowden. An almost free of play support for the Bowden tube in direct interaction with the presented powerful pneumatic couplings, shorter retractions are possible, and a sudden grip loss is almost unthinkable. But there will be later carriages for alternative couplings.

• Integrated cable Management.

• There are different covers to choose from: The installation of a neutral variant is easy to implement.

• Versions for left and right rear panel mounting available. Note for Ultimaker 2 users: Please use the right version. The left version is currently not optimized for extruder 2 operation, and does not fit on the rear Panel.

• Information regarding enhancements and bug fixes you will find in the "Comment" section. Photos with the already assembled object does not show the latest design.

• Again and again: My work for you lives solely by your feedback. If something is wrong or useless in my designs, I need more information from you so that I can ever change anything. Suggestions to improve or simplify my designs and descriptions are highly desirable. So if you use my designs and parts thereof, please take a few moments to convey a little feedback.

Similar models

thingiverse

free

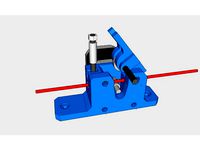

Vslot Bowden Feeder 3mm filament for CoreXY by bondtje

...ced anywhere on the frame right side model.

for left side model you can simply mirror the desgin (feeder and lever)

used with mk8

thingiverse

free

Yet Another Ultimaker 2 Feeder - robspin by sheldonr

.../thing:1147029

but you can't use both.

note: the "no_print" parts are used by openscad to construct the stl models.

thingiverse

free

Kuro´s Compact Extruder for the Diamond Hotend by snipermand

...

i have provided the scad files for others to remix.

complete kit can be bought here:http://reprap.me/geared-extruder-kit.html

thingiverse

free

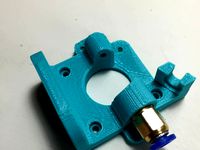

Extruder / Bowden - 3mm filament by dinizhobby

...zhobby

thingiverse

extruder for bowden filament 3mm

you need mk8 driver gear and one bearing 6x13x5 and shaft 6mm with screw m4

thingiverse

free

Improved Snap On Guide for "|Robert|'s Alternative UM2 Feeder V2" by alex9779

...e a bit. so i changed the round hole to long holes because only the position of the filament centered on the wheels is important.

thingiverse

free

Bowden tube feeder with filament release mechanism by 2by2

...m m4 bolds should be 50mm)

also included is a filament spool holder for extrusion bars

if you use it, please share a picture!

thingiverse

free

Manual Filament Feeder Bowden Extruder by Kaya3D

...manual filament feeder bowden extruder by kaya3d

thingiverse

helps you to improve and remove the filement

thingiverse

free

Cr6 Top Mounted Filament Guide and extruder guide in one. by MB_AUZ

...ruder guide for 1 simple print.

also changed the bowden end that can be tapped in with a bowden metal connection.

happy printing

thingiverse

free

Bowden extruder - Filament Suport for prusa i3 steel by Juan_Ursic

...bowden extruder - filament suport for prusa i3 steel by juan_ursic

thingiverse

bowden extruder, it guides the filament properly.

thingiverse

free

Bowden extruder for 1.75mm filament and 1/8" push fit coupling (used for 4mm OD tubing) by sheffdog

...fit coupling, it now screws in perfectly straight off the printer, i also tapered the filament entrance to the push fit coupling.

Mnis

thingiverse

free

Mni Blaster by LethalTeaspoon

...mni blaster by lethalteaspoon

thingiverse

a mini blaster sci-fi type gun, its very small about 90mm long. enjoy.

thingiverse

free

Galaxy S5 Stand by mnis

...galaxy s5 stand by mnis

thingiverse

an easy-to-print smartphone stand for the samsung galaxy s5.

thingiverse

free

Universal Hooks by mnis

...ption:

scale the s-hooks to a desired size or use the sizes available.

use single hooks. or use double hooks (... male / female).

thingiverse

free

Ring for GU10 to E27 Adapter by mnis

...ring for gu10 to e27 adapter by mnis

thingiverse

note:

please read the description in the attached picture.

thingiverse

free

UDB (Universal Device Base) by mnis

...universal device base) by mnis

thingiverse

description:

universally usable device feet (...to alleviate vibration and slippage).

thingiverse

free

LiteOn eSAU208 ODD Enclosure by mnis

...liteon esau208 odd enclosure by mnis

thingiverse

a completely new housing for the liteon optical disc drive esau208.

thingiverse

free

LED-Remote-Holder by mnis

...e

three simple variants of remote control holders.

and many types of plastic cards (credit cards, etc.) fit in these holders :-)

thingiverse

free

Soken RK1 01 Rocker by mnis

...en rk1 01 rocker by mnis

thingiverse

this object replaces a defective on / off rocker of the switch with the name: soken rk1 01.

thingiverse

free

Door Lock by mnis

...n windows or maintenance flaps.

door thickness max: 3mm

thickness of the frame max: 6mm

note: all parts have not been tested yet.

thingiverse

free

Gunpla aftermarket mni gatling gun by Mokanaman

...gunpla aftermarket mni gatling gun by mokanaman

thingiverse

aftermarket part to customize your gundam models.

Feed

3d_export

$10

Feed chang

...feed chang

3dexport

turbosquid

$10

Feed-Pump

...lty free 3d model feed-pump for download as 3ds, obj, and c4d on turbosquid: 3d models for games, architecture, videos. (1456492)

3d_export

$10

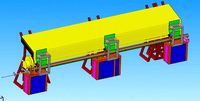

Hydraulic in-feed out-feed support roller

...s at adjustable height, while machining such as cutting, drilling and etc. it is operated by hydraulic and modeled in nx siemens.

turbosquid

$5

Feeding Troughs and Buckets

...free 3d model feeding troughs and buckets for download as fbx on turbosquid: 3d models for games, architecture, videos. (1582798)

3d_export

$180

Boiler Feed Unit 3D Model

...boiler feed unit 3d model

3dexport

boiler feed unit

boiler feed unit 3d model briancrosdale 76895 3dexport

turbosquid

$6

Bird Feed House

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$7

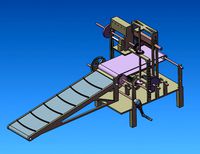

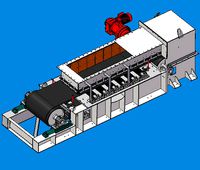

Conveyor belt feeding punching machine

...conveyor belt feeding punching machine

3dexport

conveyor belt feeding punching machine

3d_export

$6

automatic feeding and pipe cutting machine

...automatic feeding and pipe cutting machine

3dexport

automatic feeding and pipe cutting machine

3d_export

$6

ore feeding equipment mining machinery

...ore feeding equipment mining machinery

3dexport

ore feeding equipment mining machinery

3d_export

$5

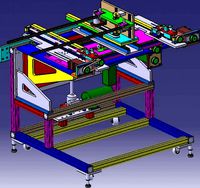

feed system

...omponent and the executive element constitute the mechanical transmission system, the detection element and the feedback circuit.

Buffet

turbosquid

$2

D3.C3.08 Buffet table-Buffet Mesa de Buffet

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$2

Buffet

...buffet

turbosquid

free 3d model buffet for download as blend on turbosquid: 3d models for games, architecture, videos. (1637473)

3ddd

$1

chopfer Buffet

...chopfer buffet

3ddd

modern chopfer buffet

turbosquid

$10

Buffet

...uid

royalty free 3d model buffet for download as max and fbx on turbosquid: 3d models for games, architecture, videos. (1221460)

turbosquid

$10

BUFFET

...uid

royalty free 3d model buffet for download as c4d and max on turbosquid: 3d models for games, architecture, videos. (1687005)

turbosquid

$1

Buffet

...d

royalty free 3d model buffet for download as blend and fbx on turbosquid: 3d models for games, architecture, videos. (1656773)

turbosquid

$19

Buffet

...oyalty free 3d model buffet for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1231613)

turbosquid

$9

Buffet

...oyalty free 3d model buffet for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1380331)

3d_ocean

$3

Buffet Table

...odel 3ds buffet buffet table max meal restaurant table

3d buffet table model. use for any your needs. thanks for your attention:)

turbosquid

$35

Buffet

...y free 3d model buffet for download as 3ds, obj, c4d, and fbx on turbosquid: 3d models for games, architecture, videos. (1439411)

V1

turbosquid

$35

v1

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$10

street tree v1

...street tree v1

3dexport

street tree v1

3d_export

$5

potato v1

...potato v1

3dexport

turbosquid

$20

Kitchen V1

...bosquid

royalty free 3d model kitchen v1 for download as max on turbosquid: 3d models for games, architecture, videos. (1153622)

turbosquid

$12

sofa v1

...turbosquid

royalty free 3d model sofa v1 for download as max on turbosquid: 3d models for games, architecture, videos. (1283267)

turbosquid

$3

Chair V1

...urbosquid

royalty free 3d model chair v1 for download as fbx on turbosquid: 3d models for games, architecture, videos. (1486093)

turbosquid

$15

Cupboard v1

...royalty free 3d model cupboard v1 for download as max and fbx on turbosquid: 3d models for games, architecture, videos. (1444568)

3d_export

$5

tram v1

...tram v1

3dexport

3d_export

$8

lumber car v1

...lumber car v1

3dexport

lumber car v1 printable, low poly model.

turbosquid

$20

DELTALIGHT v1

...free 3d model deltalight v1 for download as max, max, and obj on turbosquid: 3d models for games, architecture, videos. (1630928)

3

turbosquid

$10

Mountain Bike 3 -3 of 3

...model mountain bike 3 (#3 of 3) for download as fbx and blend on turbosquid: 3d models for games, architecture, videos. (1438752)

turbosquid

$6

Rock 3-3

...urbosquid

royalty free 3d model rock 3-3 for download as obj on turbosquid: 3d models for games, architecture, videos. (1628065)

turbosquid

$3

Genesis 3 Clothing 3

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

hinge 3

...hinge 3

3dexport

hinge 3

3ddd

$1

Розетка 3

...розетка 3

3ddd

розетка

розетка 3

turbosquid

$50

is-3

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

Mountain Bike 3 -2 of 3

...model mountain bike 3 (#2 of 3) for download as fbx and blend on turbosquid: 3d models for games, architecture, videos. (1438750)

turbosquid

$10

Mountain Bike 1 -3 of 3

...model mountain bike 1 (#3 of 3) for download as fbx and blend on turbosquid: 3d models for games, architecture, videos. (1438743)

3d_export

$5

3 CATS

...3 cats

3dexport

3 cats pen holder

3ddd

free

3 Буфета

...3 буфета

3ddd

буфет , кантри

3 буфета

All

turbosquid

$20

all

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$5

all

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

design_connected

$29

All-Two

...all-two

designconnected

bonaldo all-two computer generated 3d model. designed by bicego, sergio.

design_connected

$29

All-One

...all-one

designconnected

bonaldo all-one computer generated 3d model. designed by bicego, sergio.

design_connected

$16

Holly All

...holly all

designconnected

serralunga holly all computer generated 3d model. designed by starck, philippe.

3d_export

$15

all terrain

...all terrain

3dexport

turbosquid

$29

Holly All

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$19

Fireplace (All)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$19

Fireplace (All)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$19

Fireplace (All)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Can

design_connected

$13

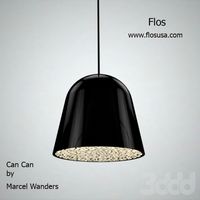

Can Can

...can can

designconnected

flos can can pendant lights computer generated 3d model. designed by marcel wanders.

3ddd

$1

Flos / Can Can

...

3ddd

can can , flos

подвесной светильник can can фабрики flos. дизайнер marcel wanders.

3d_ocean

$6

Cans

...cans

3docean

aluminium cans blender can cans food metal

set of cans (with label and without label). enjoy!

3ddd

$1

Flos Can Can

...для детской или гостиной.

основные технические характеристики:

высота (мм) 360 мм

диаметр (мм) 347 мм

категория ламп 150w e27

3ddd

$1

Can Can by Flos

...can can by flos

3ddd

flos

cancan byflos

3d_export

$5

Can

...can

3dexport

3d modeling of a beverage can. lies once in an obj. file and a stl. file.

3d_export

free

can

...can

3dexport

turbosquid

$15

Can

...can

turbosquid

royalty free 3d model can for download as max on turbosquid: 3d models for games, architecture, videos. (1260283)

turbosquid

$2

Can

...can

turbosquid

royalty free 3d model can for download as fbx on turbosquid: 3d models for games, architecture, videos. (1709812)

turbosquid

$44

Can

...osquid

royalty free 3d model can for download as c4d and obj on turbosquid: 3d models for games, architecture, videos. (1464835)