GrabCAD

The ABC Face Shield

by GrabCAD

Last crawled date: 2 years ago

Atlanta Beats Covid (ABC) has been working with Atlanta Shield Makers to come up with a face shield to protect healthcare workers. There are countless variants out there, but ours has been developed with a particular emphasis toward 3D printing a master mold, then using that to cast plastic parts. The goal was to come up with a design that was:

- Beginner friendly for new plastic casters

- Able to use a wide variety of three-hole-punched visor materials

- Optimized for minimal silicone usage

- Easy to demold

- Easy to scale up to larger production quantities

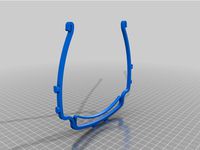

To meet these requirements, we present a remixed Prusa (US) that incorporates a browshield and a host of small geometry changes to make it molding-friendly. File _0_ is the Solidworks part file that contains all the geometry for each of the subsequent parts - this is where you should go to have the best results remixing.

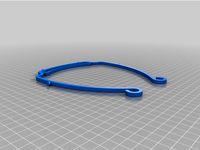

It is possible to 3D print the ABC face shield frame directly, where you simply download and slice file _1_. We have had great results with a really coarse 0.35mm layer-height PLA print taking around 2 hours.

For molding and casting we provide two STL files ready to use. File _2_ is simply the frame geometry from _1_ but with an additional flat plinth that provides a crisp edge when molding. For the best results this file should be printed in a high-resolution printer such as SLA or Polyjet, or post-processed. We have had great success with SLA, Polyjet, and acetone-smoothed ABS. File _3_ is merely a mold box that provides a 0.5" border around the outside of the part to contain the silicone rubber. It fits snugly around the plinth, with hot glue or tape being used to create the final master pattern ready for pouring. We use Smooth-On MoldStar 16 for this (around 22floz per mold), but many other silicone rubber options exist.

The final part to be made is the strap clip which hooks over the rear-most pegs on the frame and incorporates a tension adjustment. File _4a_ provides the DXF of this part for laser cutting, where we use 0.100" acrylic with good success. File _4b_ is the 3D version of this part in case you wanted to 3D print it.

For the visor material, we have proven our frame with the following options:

- Overhead transparency acetate with three-hole-punched holes

- Binder covers with three-hole-punched holes

- 34mil PET sheet CNCed or laser cut according to the original Prusa geometry, found here: https://www.prusaprinters.org/prints/27950-prusa-face-shield-us-version

Finally, we finish the assembly with the following:

- 12mm self-adhesive foam cut into 9"x0.75" strips, such as what can be found at https://tntcosplaysupply.com/product/eva-foam-sheets/

- 0.5" knitted elastic such as what is found at https://tntcosplaysupply.com/product/eva-foam-sheets/

Note: It goes without saying that this design or variants similar to it are free to use. Please share it far and wide, and we'd love to hear your feedback or remixes.

- Beginner friendly for new plastic casters

- Able to use a wide variety of three-hole-punched visor materials

- Optimized for minimal silicone usage

- Easy to demold

- Easy to scale up to larger production quantities

To meet these requirements, we present a remixed Prusa (US) that incorporates a browshield and a host of small geometry changes to make it molding-friendly. File _0_ is the Solidworks part file that contains all the geometry for each of the subsequent parts - this is where you should go to have the best results remixing.

It is possible to 3D print the ABC face shield frame directly, where you simply download and slice file _1_. We have had great results with a really coarse 0.35mm layer-height PLA print taking around 2 hours.

For molding and casting we provide two STL files ready to use. File _2_ is simply the frame geometry from _1_ but with an additional flat plinth that provides a crisp edge when molding. For the best results this file should be printed in a high-resolution printer such as SLA or Polyjet, or post-processed. We have had great success with SLA, Polyjet, and acetone-smoothed ABS. File _3_ is merely a mold box that provides a 0.5" border around the outside of the part to contain the silicone rubber. It fits snugly around the plinth, with hot glue or tape being used to create the final master pattern ready for pouring. We use Smooth-On MoldStar 16 for this (around 22floz per mold), but many other silicone rubber options exist.

The final part to be made is the strap clip which hooks over the rear-most pegs on the frame and incorporates a tension adjustment. File _4a_ provides the DXF of this part for laser cutting, where we use 0.100" acrylic with good success. File _4b_ is the 3D version of this part in case you wanted to 3D print it.

For the visor material, we have proven our frame with the following options:

- Overhead transparency acetate with three-hole-punched holes

- Binder covers with three-hole-punched holes

- 34mil PET sheet CNCed or laser cut according to the original Prusa geometry, found here: https://www.prusaprinters.org/prints/27950-prusa-face-shield-us-version

Finally, we finish the assembly with the following:

- 12mm self-adhesive foam cut into 9"x0.75" strips, such as what can be found at https://tntcosplaysupply.com/product/eva-foam-sheets/

- 0.5" knitted elastic such as what is found at https://tntcosplaysupply.com/product/eva-foam-sheets/

Note: It goes without saying that this design or variants similar to it are free to use. Please share it far and wide, and we'd love to hear your feedback or remixes.

Similar models

thingiverse

free

Face Shield Frame by TRAVIS_D

...frame by travis_d

thingiverse

face shield frame: use plastic sheets or laminate sheets, paper punch 3 holes and attach to frame.

thingiverse

free

Reusable Face Shield Frame by CMPresby

....5"x11", the center post is offset, this is normal and the design intent so the transparency sits even across the face.

thingiverse

free

3DVERKSTAN Face Shield remix - Euro 4Hole by TryHard105

...verkstan one, so follow their print guide for best settings.

https://3dverkstan.se/protective-visor/protective-visor-print-guide/

thingiverse

free

Hole punch guide for Prusa medical face shield by Yayyohh

... shield, but have to source an alternative material for the shield part, use this hole guide to quickly mark your hole placement.

thingiverse

free

Face shield visor Prusa compatible and stackable by jjmouris

...he middle section and 79-80mm again. can do this with a simple 80mm hole punch.

they are all 5.2mm high so 10 pieces is 52mm etc.

thingiverse

free

Protective visor (face shield) for health proffesionals fighting Coronavirus by joseamirandavelez

...to fit in a prusa i3 printer and other similary sized...

thingiverse

free

3 Holes visor shield (US binder size) by Piper3D

...eld (no laser cutting). this is improved version of visor from: https://3dverkstan.se/protective-visor/protective-visor-versions/

thingiverse

free

Covid-19 Face Shield by davidzacher

...anged to improve spring and printing speed

earpiece hooks grab a cut rubber band to secure the face shield

prints in about 1 hour

thingiverse

free

Hido Face Shield by 3DVolunteer

... clear pvc 8 1/2" x 11" cover sheet.

use a 3 hole punch to make mounting holes.

use elastic string or band for strap.

thingiverse

free

Covid19 Face Shield Hole Punch V1.1 by ScienceofOM88

... https://www.prusaprinters.org/prints/25857-protective-face-shield-rc1#_ga=2.125524866.925504750.1584670323-1236707100.1584648344

Shield

3d_export

$5

shield

...shield

3dexport

shield

3d_export

$5

Shield

...shield

3dexport

shield and a spear

3d_ocean

$6

Shield

...shield

3docean

game shield low polygon mei evil shild old shield shield

2048 texture obj,fbx,blend game ready.

3d_export

$5

Shield

...shield

3dexport

a shield that hasn't been made of materials will be available to everyone

3d_ocean

$4

Round Shield

...round shield

3docean

ancient battle fantasy knight medieval shield shields warrior

nice model of round shield.

3d_export

free

metal shield

...metal shield

3dexport

russian metal shield - anti-riot shield.

3d_export

$5

shield

...shield

3dexport

old shield, damaged and covered in mold. every file have a zip folder in with textures.

turbosquid

free

Shield

...shield

turbosquid

free 3d model shield for download as c4d on turbosquid: 3d models for games, architecture, videos. (1164800)

3d_export

$5

fire shield

...fire shield

3dexport

fire shield

turbosquid

$10

SHIELD

...

turbosquid

royalty free 3d model shield for download as obj on turbosquid: 3d models for games, architecture, videos. (1273553)

Abc

3ddd

$1

ABC

...abc

3ddd

living divani

abc armchair

living divanihttp://www.livingdivani.it/en/products/armchairs_and_chairs/abc.aspx

turbosquid

$20

ABC

...

royalty free 3d model abc for download as max, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1579168)

turbosquid

$9

ABC

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

Rabalux Abc 4608

..., люстра

светильник потолочный, фирмы rabalux . модель - abc. номер по каталогу - 4608

turbosquid

$5

ABC Cubes

...lty free 3d model abc cubes for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1500480)

turbosquid

$10

Abc stove

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$15

ABC armchair 3D Model

...abc armchair 3d model

3dexport

abc armchair flexform

abc armchair 3d model boroda 12629 3dexport

3d_export

$15

ABC sofa 3D Model

...abc sofa 3d model

3dexport

abc sofa flexform

abc sofa 3d model boroda 12630 3dexport

3d_export

$15

ABC sofa 3D Model

...abc sofa 3d model

3dexport

abc sofa flexform

abc sofa 3d model boroda 12631 3dexport

cg_studio

$10

ABC Armchair3d model

...abc armchair3d model

cgstudio

.max - abc armchair 3d model, royalty free license available, instant download after purchase.

Face

turbosquid

$100

face a face

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$6

Face To Face Swing

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

Almerich Face to Face

... гибкостью материала, прозрачностью и тактом, чтобы создавать игры со светом и тенью.

размеры: 48 x 48 x 155 см

полигоны: 39 376

design_connected

$11

Face

...face

designconnected

montis face chairs computer generated 3d model. designed by gerard van den berg.

turbosquid

$15

Face

...ce

turbosquid

royalty free 3d model face for download as mud on turbosquid: 3d models for games, architecture, videos. (1178369)

turbosquid

$6

Face

...ce

turbosquid

royalty free 3d model face for download as max on turbosquid: 3d models for games, architecture, videos. (1409756)

turbosquid

$1

Face

...uid

royalty free 3d model face for download as obj and blend on turbosquid: 3d models for games, architecture, videos. (1288500)

turbosquid

$150

Face

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$50

face

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$15

Face

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.