Thingiverse

Tevo Titan upgraded filament guide by Robko

by Thingiverse

Last crawled date: 3 years ago

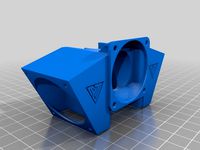

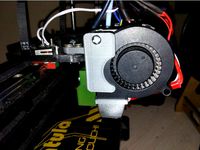

This is an upgraded filament guide for TEVO Titan extruder. I am not sure whether this fits original e3d Titan.

This solves problems with extruding flexible filament.

What is different:

The original guide has a 5mm diameter conical entrance for the filament, which is some 7mm deep and then meets your PTF bowden. This is a perfect place for your filament to curl up and get stuck. My upgraded version is designed so that your bowden gets all the way through the guide and meets drive nut and guide pulley. As soon as the filament leaves the drive nut, it is trapped in a tight bowden tube, which is perfectly smooth all the way to the hotend.

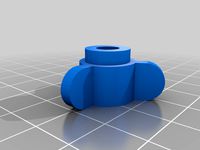

The filament guide in my Titan extruder was originally not in a perfect line with the guide pulley. To solve this, I made the new one slightly off-set. You can see the difference in the photo (the photo is showing a prototype which was misaligned slightly too much).

Notes:

There are two versions, the difference is the hole diameter. If your printer prints holes smaller, the 4,1mm will probably need drilling. The 4,5mm should be fine right away.

After getting the bowden through, trim it as seen in the photo.

For easy installation, load the bowden with both the guide and the "one-way lock nut (or what you call the part)" into the extruder body from a side, while the transparent extruder part is still off.

The spring that pushes the guide pulley likes to shoot out while the extruder body is open, so get it out at the begining of the installation and put it back right before you screw the transparent part back on.

Reloading a filament gets a little bit more difficult as the entrance is now much smaller than before, but it was not a big issue for me.

EDIT: I updated the design for even better fit. I uploaded two versions, one with 4,1mm hole which will probably need drilling if your printer prints holes smaller and a 4,5mm one, which should be usable right away, even if your printer makes holes smaller.

This version is also longer than the previous one, the gap between the pulley and drive wheels is now less than 0,5mm.

The new version is slightly off-perpendicular to the print bed, which is made on purpose for a better alignment (the original TEVO was also not perpendicular).

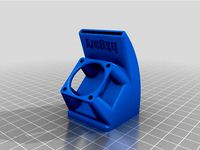

In one picture, I highlighted a bolt which is not originally in the TEVO extruder. I added it because I found out that the release arm of the extruder has a really bad wobble to it, due to the fact that its axis is plastic and only attached on one side, which causes it to bend. First, you have to drill the hole in that axis a bit bigger for the bolt to fit freely (but without wobble). If the bolt goes in tightly, it stretches the whole plastic axis and prevents the release arm from moving freely. The bolt head then fits exactly into a mould which is in the translucent part of the extruder and stiffens the axis. This also allows you to tighten the tension spring of the release arm, so you get better grip of the filament.

Please, let me know how it works for you, this is my first upload and any feedback will encourage me to make more useful things.

This solves problems with extruding flexible filament.

What is different:

The original guide has a 5mm diameter conical entrance for the filament, which is some 7mm deep and then meets your PTF bowden. This is a perfect place for your filament to curl up and get stuck. My upgraded version is designed so that your bowden gets all the way through the guide and meets drive nut and guide pulley. As soon as the filament leaves the drive nut, it is trapped in a tight bowden tube, which is perfectly smooth all the way to the hotend.

The filament guide in my Titan extruder was originally not in a perfect line with the guide pulley. To solve this, I made the new one slightly off-set. You can see the difference in the photo (the photo is showing a prototype which was misaligned slightly too much).

Notes:

There are two versions, the difference is the hole diameter. If your printer prints holes smaller, the 4,1mm will probably need drilling. The 4,5mm should be fine right away.

After getting the bowden through, trim it as seen in the photo.

For easy installation, load the bowden with both the guide and the "one-way lock nut (or what you call the part)" into the extruder body from a side, while the transparent extruder part is still off.

The spring that pushes the guide pulley likes to shoot out while the extruder body is open, so get it out at the begining of the installation and put it back right before you screw the transparent part back on.

Reloading a filament gets a little bit more difficult as the entrance is now much smaller than before, but it was not a big issue for me.

EDIT: I updated the design for even better fit. I uploaded two versions, one with 4,1mm hole which will probably need drilling if your printer prints holes smaller and a 4,5mm one, which should be usable right away, even if your printer makes holes smaller.

This version is also longer than the previous one, the gap between the pulley and drive wheels is now less than 0,5mm.

The new version is slightly off-perpendicular to the print bed, which is made on purpose for a better alignment (the original TEVO was also not perpendicular).

In one picture, I highlighted a bolt which is not originally in the TEVO extruder. I added it because I found out that the release arm of the extruder has a really bad wobble to it, due to the fact that its axis is plastic and only attached on one side, which causes it to bend. First, you have to drill the hole in that axis a bit bigger for the bolt to fit freely (but without wobble). If the bolt goes in tightly, it stretches the whole plastic axis and prevents the release arm from moving freely. The bolt head then fits exactly into a mould which is in the translucent part of the extruder and stiffens the axis. This also allows you to tighten the tension spring of the release arm, so you get better grip of the filament.

Please, let me know how it works for you, this is my first upload and any feedback will encourage me to make more useful things.

Similar models

thingiverse

free

Tevo Titan upgraded filament guide remix by dark_matterFPV

...ound this remixed version to locate the bowden tube better than the original, and i like that it requires no post-print drilling.

thingiverse

free

Tevo Titan Extruder Filament Sensor And Guide by sopak

...

roll sensor and guide for a filament.

it is designed for tevo titan extruder and tevo tornado.

the sensor is omron v-156-1c25.

thingiverse

free

Titan Extruder internal filament guide by rudemutant

...er off the extruder, remove the guide and housing for the bolt, insert the piece into the bolt housing, and put it back together.

thingiverse

free

Bowden Filament Guide For E3D Titan Extruder by MikeNzl

...gh it for clearance again if you want one with a different size just ask. to fit you will need 2 m4 csk screws and 2 m4 tee nuts.

thingiverse

free

Bowden Adapter fuer Tevo Titan Extruder by reinhard_gervelmeyer

...er tevo titan extruder by reinhard_gervelmeyer

thingiverse

adapter fuer den original titan extruder und den tevo titan extruder.

thingiverse

free

![Ender3 filament guide from extruder construction into bowden [1.75mm] by ZeroCZ](/t/8158318.jpg)

Ender3 filament guide from extruder construction into bowden [1.75mm] by ZeroCZ

...ole might need to be finished by drilling with 2mm drill bit.

update: v2 version with 3mm hole for better extraction of filament.

thingiverse

free

Compact Bowden Extruder flex by 3D_Ice

... i drilled the holes whit a 4mm drill.

changes:

added a reinforced idler that also can increase force on filament labeled as v2.

thingiverse

free

Tevo Titan Extruder Upgrade

...de by misterguru. i modified for the tevo titan extruder. will be using this on my tevo flash and add updates if they are needed.

thingiverse

free

Direct Drive Bowden Extruder; MK8 version by cfeniak

...e to motor base to reduce cantilevered load on motor shaft

-tensioning bolt catch is slotted to allow quick release functionality

thingiverse

free

Tevo Titan Extruder Entrance Safety Attachment by mike4u

... insert it into the entrance of tevo titan extruder and attach this clip to keep that piece in place. see pictures to understand.

Robko

thingiverse

free

Tevo Tarantula Bed Support V2 with integrated belt tensioners by Robko

... belt tensioners. you will have to cut a thread into the holes and use m3 screws. wings are the same as original (v2!!!) version.

thingiverse

free

Cornelius keg portable tap by Robko

...ed

edit: i removed the non-reinforced version as it was not stiff enough. the reinforced three-piece design should be far enough.

thingiverse

free

Xiaomi Scooter Pro U-Lock Mount (Decathlon' s BTWIN 900 mini) by Robko

... filament, i used carbon fiber pla (perfect color match). all should be printable without supports, depends on your settings tho.

Tevo

thingiverse

free

TEVO Logo by limwenyao

...verse

tevo logo - for customizing your builds to look cooler with the tevo logo! pdf version is editable with adobe illustrator.

thingiverse

free

Tevo Tornado e3d Tevo Flash Style fan Mount by DemolitionX

...an mount by demolitionx

thingiverse

just messing around and made a tevo flash style fan mount for the e3d v6 on the tevo tornado

thingiverse

free

BODEN TUBE CLAMP FOR TEVO TARANTULA PRO AND TEVO TORNADO

... and tevo tornado

thingiverse

bodwen tube clamp. printable adjustable tension clamp for tevo tarantula pro and tornado extruder.

thingiverse

free

TEVO Tornado Model by JMDesigns

...tevo tornado model by jmdesigns

thingiverse

tevo tornado model

thingiverse

free

Tevo Tarantula FanDuct by hkgary_g

...tevo tarantula fanduct by hkgary_g

thingiverse

fanduct for tevo tarantula

thingiverse

free

FAN TEVO TARANTULA by llprokall

...fan tevo tarantula by llprokall

thingiverse

fan tevo tarantula

thingiverse

free

Tevo Tarantula filament by Xbertus

...tevo tarantula filament by xbertus

thingiverse

suport for filamente tevo tarantula

thingiverse

free

TEVO Top Brackets by _Godoy_

...tevo top brackets by _godoy_

thingiverse

top brackets for tevo tarantula

thingiverse

free

Tevo Tarantula Spool Holder

...tevo tarantula spool holder

thingiverse

strong spool holder for tevo tarantula

thingiverse

free

tevo tarantula spacer by poundskinnyboy

...tevo tarantula spacer by poundskinnyboy

thingiverse

it's a tevo tarantula spacer

Titan

design_connected

$18

Titan

...titan

designconnected

original btc titan computer generated 3d model.

3d_ocean

$25

RMS Titanic

...rms titanic

3docean

ship steamer titanic

3d model of the rms titanic

turbosquid

$49

Titan

...quid

royalty free 3d model titan for download as obj and ztl on turbosquid: 3d models for games, architecture, videos. (1314276)

turbosquid

$8

Titan

...d

royalty free 3d model titan for download as , fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1545505)

3d_export

$15

eren yeager titan from attack on titan

...eren yeager titan from attack on titan

3dexport

3d model of eren titan

3d_export

$5

titanic new

...titanic new

3dexport

titanic 3d model normal quality for animation

3d_export

$100

Titan 3D Model

...titan 3d model

3dexport

silo launcher rocket titan

titan 3d model acquarius 37854 3dexport

3d_ocean

$25

Titan

...nfs nfshs one ps ps1 psone rod speed sports stakes titan transport vehicle

quality exterior and low polygon interior concept car.

3ddd

$1

Titanic Lamp(table)

...titanic lamp(table)

3ddd

titanic lamp(table)

turbosquid

$10

Titan chair

...osquid

royalty free 3d model titan chair for download as max on turbosquid: 3d models for games, architecture, videos. (1301533)

Upgraded

turbosquid

$15

Upgraded Glock

...e 3d model upgraded glock for download as obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1185950)

3ddd

$1

Calligaris / UPGRADE

...calligaris / upgrade

3ddd

calligaris

c материалом

3d_export

free

cz upgrade

...cz upgrade

3dexport

https://www.buymeacoffee.com/mestrezen3d https://linktr.ee/mestrezen3

turbosquid

$80

Custer Tank upgrade

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$39

Domestos 1 upgrade

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$10

Upgraded tea cup

...upgraded tea cup

3dexport

a cup with an unusual design and a unique shape for a more enjoyable tea experience

3d_export

$8

dixy outlander classic style upgraded poplar wood lounge chair

...utlander classic style upgraded poplar wood lounge chair

3dexport

dixy outlander classic style upgraded poplar wood lounge chair

turbosquid

free

AK-12 + Upgrades low-poly 3D model

...ow-poly 3d model for download as fbx, blend, and unitypackage on turbosquid: 3d models for games, architecture, videos. (1501145)

evermotion

$700

Upgrade from V-ray 1.5 to 3.5 for 3ds max

...here is no need to purchase a new dongle - your current dongles will be reprogrammed to carry v-ray 3. evermotion 3d models shop.

evermotion

$300

Upgrade from V-Ray 2.0 to V-ray 3.5 for 3ds Max

... interface (gui) for editing settings on one machine and one render node for rendering on one machine. evermotion 3d models shop.

Guide

turbosquid

$15

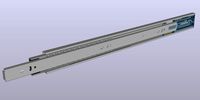

Guide drawer

...squid

royalty free 3d model guide drawer for download as dwg on turbosquid: 3d models for games, architecture, videos. (1261387)

turbosquid

$1

Road Guide

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

archive3d

free

Guide-board 3D Model

...ion sign guide sign

guide-board n170112 - 3d model (*.gsm+*.3ds) for exterior 3d visualization.

turbosquid

$2

soap cutter guide

...

royalty free 3d model soap cutter guide for download as stl on turbosquid: 3d models for games, architecture, videos. (1694030)

turbosquid

$15

Blind Guiding tiles

...free 3d model blind guiding tiles for download as 3dm and dae on turbosquid: 3d models for games, architecture, videos. (1156598)

turbosquid

$69

Japanese Tour Guide

...d model japanese tour guide for download as max, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1614288)

turbosquid

$10

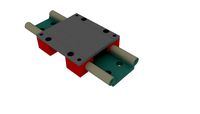

CNC Linear Guide

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$1

Tank Model Guide

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$1

Road Guide 2

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_ocean

$9

Guide Books 3

...sformed separately and each have unique texture map on front and back cover. to make your work easier this model comes in thre...

Filament

3ddd

$1

Filament Cage

...filament cage

3ddd

лофт , filament cage

модель бра, делалась по фото!

turbosquid

$3

FILAMENT COUNTER

...d

royalty free 3d model filament counter for download as stl on turbosquid: 3d models for games, architecture, videos. (1563049)

3d_export

$5

Filament lamp 3D Model

...filament lamp 3d model

3dexport

filament lamp 3d model kevin 54161 3dexport

3d_export

$5

Filament bulb candle 3D Model

...filament bulb candle 3d model

3dexport

filament bulb-candle

filament bulb candle 3d model kevin 54163 3dexport

3d_export

$5

Filament led light bulb

...filament led light bulb

3dexport

realistic 3d model of filament light bulb with v-ray materials.

3d_export

$5

Filament led light bulb

...filament led light bulb

3dexport

realistic 3d model of filament light bulb with v-ray materials.

3d_export

$5

Filament led light bulb

...filament led light bulb

3dexport

realistic 3d model of filament light bulb with v-ray materials.

3d_export

$5

Filament led light bulb

...filament led light bulb

3dexport

realistic 3d model of filament light bulb with v-ray materials.

3d_export

$5

Filament led light bulb

...filament led light bulb

3dexport

realistic 3d model of filament light bulb with v-ray materials.

3ddd

$1

Factory filament metal shade

...factory filament metal shade

3ddd

restoration hardware

restoration hardware. 20th c. factory filament metal shade.