Thingiverse

Tevo Tarantula Resized by rich4rdmacwan

by Thingiverse

Last crawled date: 4 years, 2 months ago

Tarantula Resized

Overview

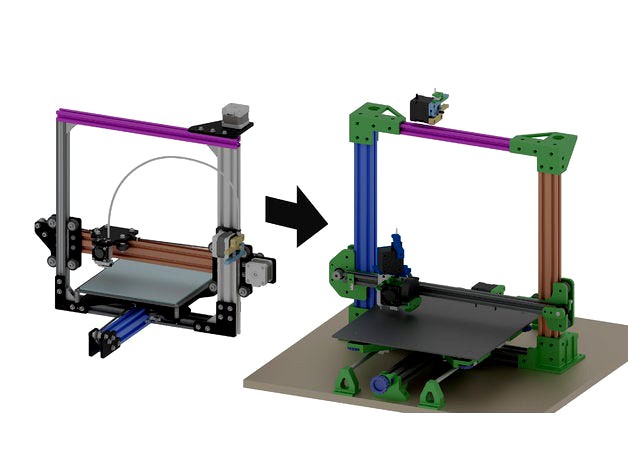

This is a redesign of the OG Tevo Tarantula (purchased second hand) to support a larger bed (310x310mm), as well as to incorporate the new model changes inspired from Tevo's new rebranded models as Homers. It is loosely inspired, and remixed from the project CARL https://www.thingiverse.com/thing:3226089. For the larger bed, I needed to change the length of some aluminum extrusions. Needless to say, the brackets are independent of the length of the extrusions and should work for you if you don't opt to enlarge your setup. I am providing the original fbx file along with the stls. You can adjust these to your needs in your favorite cad software.

Finally, I know this is a long read, but I tried to provide as much details as possible. In my experience, when looking at others' designs and trying to reuse/modify them, I felt the description lacking many a times. So I have tried to be as comprehensive as possible.

Along the way, I made quite a few improvements to the X and Y frame, added a second Z axis, added a filament runout sensor, and modified the X carriage to accommodate chimera and microswiss hotends. This work has been remixed and inspired from several others, which I will cite where used. However, since this has been done over a long period of time, if you find a design resembling your part and I haven't given you credit, do let me know and I shall cite your work as well.

IMPORTANT: To complete this setup, at the most 5 parts are needed from the CARL project. More details in the print settings.

Notes

There are parts, the XCarriageHotendMount for instance, where I have used M2 (or M3 in certain others) inserts to shave off space. If you don't have inserts, you'll have to modify these holes (as well as the design to accomodate nuts). See the image XCarriageAssemblyChimera.png for these holes. I recommend using inserts however, as it makes for a more elegant and compact structure.

Although this goes without saying, make sure your frame is completely square. Mine had somehow drifted over time due to loose screws, because of which I wasted some time in understanding why my X carriage didn't move freely and was wobbling a bit. After meticulously squaring the frame, the problem was resolved.

Mandatory disclaimer

I am uploading this a few weeks after I have mounted everything and tested that it works. However, the measurements are fine-tuned for my printer, so if it doesn't fit right away on your setup, you might have to fine tune the measurements a bit. To be on the safe side, verify the measurements before printing if you know your printer is not up to mark.

Detailed description

The X Carriage

Parts needed: X carriage from Creality/Ender 3 series such as this one https://fr.aliexpress.com/item/32956134101.html.

The CR10XCarriageMount part is a modular part and can accommodate an allmetal microswiss (or creality's stock hotend) as well as chimera single and dual hotends. For using the chimera hotends, you'll need to print the chimerahotend.microswissadapter (or chimerahotend.dual.microswissadapter) part. Recommend to print it in PETG, since it is near the hotend and PLA might go soft if ever your fan stops working. It has happened to me once ;)

To use a microswiss hotend, the 40x40 fan can be inserted in the groove in the front of the part as visible in the images. A 20x20 fan should also work, although you'll have to shrink the groove a bit, and rearrange the screw holes. But I am not too sure about its cooling capacity. I recommend a 40x40 fan.

To use chimera hotends, you'll need to screw the 40x40 fan in front of the part. Again, I recommend a 40x40 fan. For a 20x20 fan, you'll need to adjust the part accordingly.

I use a BLtouch clone, for which I reused the bracket from https://www.thingiverse.com/thing:3092044 by kelokera, refining it a bit, making it less bulky. If you use another bed level sensor, kelokera has parts for various bed level sensors.

I use a 50x15 blower fan for which I upgraded the mount from kelokera, again refining and reducing the bulk. I decided to go for a modular design, which is screwed on to the CR10-XCarriageHotendMount using M2 screws and inserts. If you choose to use inserts, you'll need two, which can be press fit on the inside of the right wall of CR10-XCarriageHotendMount using a soldering iron. If you dont have inserts, you can use simple nuts. It would be better then, to resize the holes to a 2.1 mm diameter throughout on the right wall of CR10-XCarriageHotendMount accordingly.

I have also designed compact oldham couplers which take up less place. They aren't perfect, but work quite well when the frame is perfectly square.

The Y Carriage

Parts needed if you upgrade to a 310x310mm heated bed with dual rails: Two steel rods of 8mm diameter, 500 mm length, SC8UU linear bearings.

The previous owner of my tarantula had used dual Y rails to stabilize the Y carriage. I rebuilt my upgrade around the same idea, adding longer rails to accommodate my larger bed. Everything is screwed on to a wooden board to have a fixed frame. If you decide to use this upgrade, you will need to be really careful in screwing down the Y rail holders such that the 8mm rods are parallel. If you don't want to bother about this, you can use a single bracket that holds the two rails together such as this one https://www.thingiverse.com/thing:1828362. I did not use this because these parts are huge and my printer wasn't reliable enough to print it out, additionally using up quite a bit of material.

If you choose not to upgrade to a larger bed, and/or not use the dual Y rails, you can use the Y carriage from the "Tarantula Reframed CARL project". I recommend the Y rails though for added stability.

You will also need the X-Y-belt-tensioner-inner.stl part from the CARL project. The accompanying nut, X-Y-belt-tensioner-nut.stl was a bit too tight for my printer's liking. So I have uploaded a relaxed version of it here.

Enlarging the frame to accommodate a larger bed

This part is optional if you do not want to upgrade to a larger bed. I followed the reframing strategy according the project CARL, where the aluminum extrusions are rearranged to have a more solid structure. I additionally added slightly larger extrusions of 20x20x450mm for the X axis and 20x40x450mm for the Y axis to accommodate a new 310x310 Aluminum bed, with a silicon AC heated bed. I followed the instructable at https://www.instructables.com/Upgrade-3D-Printer-Heated-Bed-to-110V/, adapting it to my needs for a 220V bed. AC is dangerous, so do read the article carefully and follow all safety instructions related to the Solid-State-Relay and the relevant thermal fuses.

Dual Z. If you opt for a larger frame like I did, the T8 lead screws might be slightly smaller and won't reach the top corner brackets where the 608zz bearings are inserted. To avoid reprinting, I just hot glued the 608zz on the underside of the hole. I have since redesigned the T8 lead screw corner bracket(parts TopBracketLeft.stl and TopBracketRight.stl), but do verify that it works with your T8 lead screw, since it hasn't been tested.

You'll also need to print the Oldham couplers twice (obviously!) for the two Z axes.

Miscellaneous parts

Filament runout sensor. A dead simple filament runout sensor. I have also uploaded it separately (here). More details there. I have a bowden setup for which I have tested the sensor, it works. I have also designed one for the Tevo stock direct extruder, but haven't tested it. https://www.thingiverse.com/thing:4857712

Direct Extruder mount for the tevo stock direct extruder. Again, untested, but you're welcome to try and accommodate it to your needs. I designed the part for uniform distribution of the weight, where the motor is at a 45° angle from the horizontal. This is untested do. Do let me know if you try it.

Finally, happy tinkering!

References

Dual Z design inspired from https://www.thingiverse.com/thing:2334406

Hotbed carriage inspired from https://www.thingiverse.com/thing:2572598

Y tensioner, Y motor bracket, frame center bracket, and others inspired from https://www.thingiverse.com/thing:3226089

X carriage and fan duct inspired from https://www.thingiverse.com/thing:3092044

Overview

This is a redesign of the OG Tevo Tarantula (purchased second hand) to support a larger bed (310x310mm), as well as to incorporate the new model changes inspired from Tevo's new rebranded models as Homers. It is loosely inspired, and remixed from the project CARL https://www.thingiverse.com/thing:3226089. For the larger bed, I needed to change the length of some aluminum extrusions. Needless to say, the brackets are independent of the length of the extrusions and should work for you if you don't opt to enlarge your setup. I am providing the original fbx file along with the stls. You can adjust these to your needs in your favorite cad software.

Finally, I know this is a long read, but I tried to provide as much details as possible. In my experience, when looking at others' designs and trying to reuse/modify them, I felt the description lacking many a times. So I have tried to be as comprehensive as possible.

Along the way, I made quite a few improvements to the X and Y frame, added a second Z axis, added a filament runout sensor, and modified the X carriage to accommodate chimera and microswiss hotends. This work has been remixed and inspired from several others, which I will cite where used. However, since this has been done over a long period of time, if you find a design resembling your part and I haven't given you credit, do let me know and I shall cite your work as well.

IMPORTANT: To complete this setup, at the most 5 parts are needed from the CARL project. More details in the print settings.

Notes

There are parts, the XCarriageHotendMount for instance, where I have used M2 (or M3 in certain others) inserts to shave off space. If you don't have inserts, you'll have to modify these holes (as well as the design to accomodate nuts). See the image XCarriageAssemblyChimera.png for these holes. I recommend using inserts however, as it makes for a more elegant and compact structure.

Although this goes without saying, make sure your frame is completely square. Mine had somehow drifted over time due to loose screws, because of which I wasted some time in understanding why my X carriage didn't move freely and was wobbling a bit. After meticulously squaring the frame, the problem was resolved.

Mandatory disclaimer

I am uploading this a few weeks after I have mounted everything and tested that it works. However, the measurements are fine-tuned for my printer, so if it doesn't fit right away on your setup, you might have to fine tune the measurements a bit. To be on the safe side, verify the measurements before printing if you know your printer is not up to mark.

Detailed description

The X Carriage

Parts needed: X carriage from Creality/Ender 3 series such as this one https://fr.aliexpress.com/item/32956134101.html.

The CR10XCarriageMount part is a modular part and can accommodate an allmetal microswiss (or creality's stock hotend) as well as chimera single and dual hotends. For using the chimera hotends, you'll need to print the chimerahotend.microswissadapter (or chimerahotend.dual.microswissadapter) part. Recommend to print it in PETG, since it is near the hotend and PLA might go soft if ever your fan stops working. It has happened to me once ;)

To use a microswiss hotend, the 40x40 fan can be inserted in the groove in the front of the part as visible in the images. A 20x20 fan should also work, although you'll have to shrink the groove a bit, and rearrange the screw holes. But I am not too sure about its cooling capacity. I recommend a 40x40 fan.

To use chimera hotends, you'll need to screw the 40x40 fan in front of the part. Again, I recommend a 40x40 fan. For a 20x20 fan, you'll need to adjust the part accordingly.

I use a BLtouch clone, for which I reused the bracket from https://www.thingiverse.com/thing:3092044 by kelokera, refining it a bit, making it less bulky. If you use another bed level sensor, kelokera has parts for various bed level sensors.

I use a 50x15 blower fan for which I upgraded the mount from kelokera, again refining and reducing the bulk. I decided to go for a modular design, which is screwed on to the CR10-XCarriageHotendMount using M2 screws and inserts. If you choose to use inserts, you'll need two, which can be press fit on the inside of the right wall of CR10-XCarriageHotendMount using a soldering iron. If you dont have inserts, you can use simple nuts. It would be better then, to resize the holes to a 2.1 mm diameter throughout on the right wall of CR10-XCarriageHotendMount accordingly.

I have also designed compact oldham couplers which take up less place. They aren't perfect, but work quite well when the frame is perfectly square.

The Y Carriage

Parts needed if you upgrade to a 310x310mm heated bed with dual rails: Two steel rods of 8mm diameter, 500 mm length, SC8UU linear bearings.

The previous owner of my tarantula had used dual Y rails to stabilize the Y carriage. I rebuilt my upgrade around the same idea, adding longer rails to accommodate my larger bed. Everything is screwed on to a wooden board to have a fixed frame. If you decide to use this upgrade, you will need to be really careful in screwing down the Y rail holders such that the 8mm rods are parallel. If you don't want to bother about this, you can use a single bracket that holds the two rails together such as this one https://www.thingiverse.com/thing:1828362. I did not use this because these parts are huge and my printer wasn't reliable enough to print it out, additionally using up quite a bit of material.

If you choose not to upgrade to a larger bed, and/or not use the dual Y rails, you can use the Y carriage from the "Tarantula Reframed CARL project". I recommend the Y rails though for added stability.

You will also need the X-Y-belt-tensioner-inner.stl part from the CARL project. The accompanying nut, X-Y-belt-tensioner-nut.stl was a bit too tight for my printer's liking. So I have uploaded a relaxed version of it here.

Enlarging the frame to accommodate a larger bed

This part is optional if you do not want to upgrade to a larger bed. I followed the reframing strategy according the project CARL, where the aluminum extrusions are rearranged to have a more solid structure. I additionally added slightly larger extrusions of 20x20x450mm for the X axis and 20x40x450mm for the Y axis to accommodate a new 310x310 Aluminum bed, with a silicon AC heated bed. I followed the instructable at https://www.instructables.com/Upgrade-3D-Printer-Heated-Bed-to-110V/, adapting it to my needs for a 220V bed. AC is dangerous, so do read the article carefully and follow all safety instructions related to the Solid-State-Relay and the relevant thermal fuses.

Dual Z. If you opt for a larger frame like I did, the T8 lead screws might be slightly smaller and won't reach the top corner brackets where the 608zz bearings are inserted. To avoid reprinting, I just hot glued the 608zz on the underside of the hole. I have since redesigned the T8 lead screw corner bracket(parts TopBracketLeft.stl and TopBracketRight.stl), but do verify that it works with your T8 lead screw, since it hasn't been tested.

You'll also need to print the Oldham couplers twice (obviously!) for the two Z axes.

Miscellaneous parts

Filament runout sensor. A dead simple filament runout sensor. I have also uploaded it separately (here). More details there. I have a bowden setup for which I have tested the sensor, it works. I have also designed one for the Tevo stock direct extruder, but haven't tested it. https://www.thingiverse.com/thing:4857712

Direct Extruder mount for the tevo stock direct extruder. Again, untested, but you're welcome to try and accommodate it to your needs. I designed the part for uniform distribution of the weight, where the motor is at a 45° angle from the horizontal. This is untested do. Do let me know if you try it.

Finally, happy tinkering!

References

Dual Z design inspired from https://www.thingiverse.com/thing:2334406

Hotbed carriage inspired from https://www.thingiverse.com/thing:2572598

Y tensioner, Y motor bracket, frame center bracket, and others inspired from https://www.thingiverse.com/thing:3226089

X carriage and fan duct inspired from https://www.thingiverse.com/thing:3092044