Thingiverse

Tank3d printer by silyavski

by Thingiverse

Last crawled date: 3 years ago

Still in Alpha stage. Will be posting element by element and link here, so please subscribe, so you keep in touch with the latest development and updates

Join the new Support forum to discuss the printer in details and Tank3d Facebook Group for the latest news and quick Q&A

HI,

My name is Boyan. Here i present you a printer which i call Tank3d due to its shape and robustness. The printer design is a result of extensive research + my experience as a DIY machine builder and each element is designed from scratch by me exactly to serve its integral purpose in an optimal manner. The aim is to be the best performing Cartesian 3d printer while maintaining absolute simplicity and easy to DIY build

The main Purpose:

3d printer build from 20x20 aluminum extrusion that is fully scalable to at least 600x600x600mm without any further change than using longer rails and longer profiles for the frame.

The printer to be able to achieve real life 150mm/sec printing speeds with acceleration at least 1500mm/s2, while producing high quality prints at that settings.

A real production machine to be able to work non stop 24h for at least 5 years, minimum maintenance and no further adjustments, high precision and repeatability during its life cycle.

4.Not exactly cheap to build but Best Bang For The Buck

Additional Purpose

While the ideal candidate for custom size order printer for you or your client, if by any reason you dont like the design, the elements can be used to make any printer, printer enclosures filament boxes, etc.

Design Details:

There is not a specific order of importance as all is equally important for a perfect final result. The whole is as strong as its weakest spot

Working area is X440 x Y220 x Z200mm .Outside enclosure dimensiones ~630x430x410 mm. Probably one of the best ratio of working area to oustide dimensions. Compromise between size, $$, ability to do very small parts precisely and at the same time have large volume area.

Parts are designed as much as printable as possible. Material could be PLA for most parts except for parts around heated bed, provided that if when enclosed you monitor temperature and do not permit enclosure to heat more than 45C. ABS, Hi temp PLA, PTEG are other options.

Parts are designed so that printer could be put together precisely square and all elements aligned extremely fast and easy. So an accurate machine could be build just using a simple square and digital caliper.

All elements are housed inside the frame so an enclosure could be formed by just fitting panels outside

Bed is heated aluminum plate 6mm 500w/230VAC

Linear movement is HIWIN MGN12H on all axis. Belt is 10mm GT2 belt, puleys are 20T. Motors are low induction high power Wantai 10PCS Nema17 Step Motor 42BYGHW811 4800g.cm 2.5A 2Ph

Motion control is Duet WIFi as at the moment is the only controller that could push reliably the motors to specified speeds and acceleration

to continue....

Join the new Support forum to discuss the printer in details and Tank3d Facebook Group for the latest news and quick Q&A

HI,

My name is Boyan. Here i present you a printer which i call Tank3d due to its shape and robustness. The printer design is a result of extensive research + my experience as a DIY machine builder and each element is designed from scratch by me exactly to serve its integral purpose in an optimal manner. The aim is to be the best performing Cartesian 3d printer while maintaining absolute simplicity and easy to DIY build

The main Purpose:

3d printer build from 20x20 aluminum extrusion that is fully scalable to at least 600x600x600mm without any further change than using longer rails and longer profiles for the frame.

The printer to be able to achieve real life 150mm/sec printing speeds with acceleration at least 1500mm/s2, while producing high quality prints at that settings.

A real production machine to be able to work non stop 24h for at least 5 years, minimum maintenance and no further adjustments, high precision and repeatability during its life cycle.

4.Not exactly cheap to build but Best Bang For The Buck

Additional Purpose

While the ideal candidate for custom size order printer for you or your client, if by any reason you dont like the design, the elements can be used to make any printer, printer enclosures filament boxes, etc.

Design Details:

There is not a specific order of importance as all is equally important for a perfect final result. The whole is as strong as its weakest spot

Working area is X440 x Y220 x Z200mm .Outside enclosure dimensiones ~630x430x410 mm. Probably one of the best ratio of working area to oustide dimensions. Compromise between size, $$, ability to do very small parts precisely and at the same time have large volume area.

Parts are designed as much as printable as possible. Material could be PLA for most parts except for parts around heated bed, provided that if when enclosed you monitor temperature and do not permit enclosure to heat more than 45C. ABS, Hi temp PLA, PTEG are other options.

Parts are designed so that printer could be put together precisely square and all elements aligned extremely fast and easy. So an accurate machine could be build just using a simple square and digital caliper.

All elements are housed inside the frame so an enclosure could be formed by just fitting panels outside

Bed is heated aluminum plate 6mm 500w/230VAC

Linear movement is HIWIN MGN12H on all axis. Belt is 10mm GT2 belt, puleys are 20T. Motors are low induction high power Wantai 10PCS Nema17 Step Motor 42BYGHW811 4800g.cm 2.5A 2Ph

Motion control is Duet WIFi as at the moment is the only controller that could push reliably the motors to specified speeds and acceleration

to continue....

Similar models

grabcad

free

CNC Router Machine

...presentation purpose .

all the nut bolts bearings have been generated using the design accelerator feature of autodesk inventor.

thingiverse

free

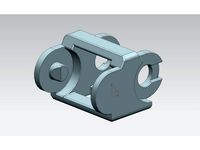

Tank3D Drag Cable Chain by silyavski

...qq

join me on facebook so you get first the updated files for tank3d printerhttps://www.facebook.com/groups/tank3d

thanks!

boyan

cg_trader

$2

Stepper motor holder NEMA 17

...older is on preview picture. cnc 3dprinter construction diy aluminium stepper motor part industrial industrial part stepper motor

thingiverse

free

Tank3d Simple Corner 20x20 aluminum extrusion by silyavski

...printer , many more things there, take a look. similar to tank3d t corner a and b 20x20 aluminum...

thingiverse

free

Heatsink Motor Fan Cage for Hot Racing Clip-On Two-Piece Motor Heat Sink with fan by luisfjdesigner3d

...nstalling the

heat sink motor fan cage. and then the photos should give you an idea how to

install it. so enjoy this new upgrade.

grabcad

free

Chineese Electric Motor

...ts not exactly as the actual motor but the specs are in the limit. (i use in the design of machine that uses a grinding compound)

thingiverse

free

Recirculating air filter by Manxian

...inatly safe its best not to take chances with you or your families health this is designed to help maintain heat in the enclosure

thingiverse

free

Tank3D Triple corner 20x20 aluminum extrusion by silyavski

...ible as it is designed to have same thickness as neighbor aluminum profile.

use it on your printer or enclosure for your printer

thingiverse

free

Heated Enclosure External Mount of LCD screen for Prusa i3 MK3 by Blargedy

...sa i3 mk3 underneath a flat surface. the intended purpose is to be able to control the printer while it is in a closed enclosure.

grabcad

free

Cetus 3D Printer heated bed electronics enclosure

...s 3d printer. see the link below for more detials.

https://capolight.wordpress.com/2018/08/02/diy-heated-bed-for-cetus-3d-printer

Silyavski

thingiverse

free

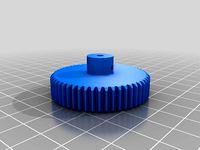

Follow focus gear 0.8 MOD for seamless lens rings by silyavski

...cus http://www.thingiverse.com/thing:565421 work with the seamless 0.8 mod lens rings http://www.thingiverse.com/thing:1060283

thingiverse

free

Tank3D Triple corner 20x20 aluminum extrusion by silyavski

...ible as it is designed to have same thickness as neighbor aluminum profile.

use it on your printer or enclosure for your printer

thingiverse

free

Tank3d Simple Corner 20x20 aluminum extrusion by silyavski

...assemblies.

very strong, at the same time almost invisible as it is designed to have same thickness as neighbor aluminum profile.

thingiverse

free

Tank3D T corner A and B 20x20 aluminum profile by silyavski

... 2 profiles

very strong, at the same time almost invisible as it is designed to have same thickness as neighbor aluminum profile.

thingiverse

free

Coin print support - anti lifting and warping for complicated objects by silyavski

...ayed quite some time to find the minimum size and thickness that works well, so thats it.

works with any normal printer setting.

thingiverse

free

5mm Tslot printed nut M4 and M3 for 20x20 aluminum profile by silyavski

...t then screw and it will hold same as metal screw forever.

as you see on last pictures petg part will rather break than the nuts.

thingiverse

free

Tank3d Bottom triple corner L+R 20x20 aluminum extrusion by silyavski

...sible as it is designed to have same thickness as neighbor aluminum profile.

use it on your printer or enclosure for your printer

thingiverse

free

Ultimate Spinner Button Cap Low Profile Rounded by silyavski

...rted properly with high detail so it does not look edgy

all, even edge blends are made for beautifull print with standard nozzle

thingiverse

free

VW Volkswagen Polo Gear Shift Knob 12mm shaft by silyavski

... the shaft. no need to print all object

3.there is smaller version, which is normal sized for me. there is a bigger version also.

Tank3D

3d_export

$3

tank3d

...tank3d

3dexport

tank 3d model in ptc creo parametric.

cg_studio

$20

Tank3d model

...tank3d model

cgstudio

.3ds .c4d .obj - tank 3d model, royalty free license available, instant download after purchase.

cg_studio

$35

M1 Tank3d model

...m1 tank3d model

cgstudio

.max - m1 tank 3d model, royalty free license available, instant download after purchase.

cg_studio

$110

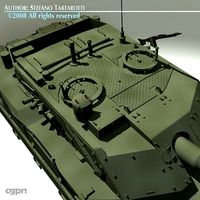

Ariete tank3d model

...te tank3d model

cgstudio

.3ds .c4d .obj - ariete tank 3d model, royalty free license available, instant download after purchase.

cg_studio

$45

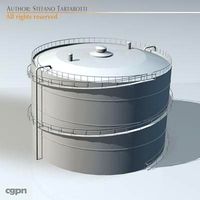

Propane Tank3d model

...k3d model

cgstudio

.3ds .max .obj .wrl - propane tank 3d model, royalty free license available, instant download after purchase.

cg_studio

$24

Gas tank3d model

... tank3d model

cgstudio

.3ds .c4d .dxf .obj - gas tank 3d model, royalty free license available, instant download after purchase.

cg_studio

$45

T-40 tank3d model

...t-40 tank3d model

cgstudio

.max - t-40 tank 3d model, royalty free license available, instant download after purchase.

cg_studio

$69

Panther 'A' Tank3d model

...c4d .lwo .ma .max .obj .xsi - panther 'a' tank 3d model, royalty free license available, instant download after purchase.

cg_studio

$59

Leopard 2 Tank3d model

...tank3d model

cgstudio

.fbx .max .obj - leopard 2 tank 3d model, royalty free license available, instant download after purchase.

cg_studio

$30

Electronic war Tank3d model

...d model

cgstudio

.3ds .c4d .obj - electronic war tank 3d model, royalty free license available, instant download after purchase.

Printer

archibase_planet

free

Printer

...inter

archibase planet

printer laser printer pc equipment

printer n120614 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Printer

...rchibase planet

laser printer office equipment computer equipment

printer - 3d model (*.gsm+*.3ds) for interior 3d visualization.

turbosquid

$100

Printer

...er

turbosquid

royalty free 3d model printer for download as on turbosquid: 3d models for games, architecture, videos. (1487819)

turbosquid

$3

Printer

...turbosquid

royalty free 3d model printer for download as max on turbosquid: 3d models for games, architecture, videos. (1670230)

turbosquid

$1

printer

...turbosquid

royalty free 3d model printer for download as max on turbosquid: 3d models for games, architecture, videos. (1595546)

turbosquid

$1

printer

...turbosquid

royalty free 3d model printer for download as max on turbosquid: 3d models for games, architecture, videos. (1595105)

turbosquid

$10

Printer

...id

royalty free 3d model printer for download as max and 3dm on turbosquid: 3d models for games, architecture, videos. (1607146)

turbosquid

$7

Printer

...royalty free 3d model printer for download as ma, ma, and obj on turbosquid: 3d models for games, architecture, videos. (1644580)

turbosquid

$30

Printer

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

Printer

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.