Thingiverse

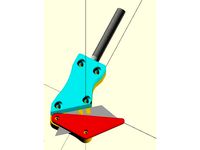

Tangential Oscillating Cutting Knife by luben111

by Thingiverse

Last crawled date: 3 years, 1 month ago

The tangential oscillating cutting knifes (TOCK) are used for cutting cardboard, rubber, plastic films, etc. They use a sharp edge knife which is moving (oscillating) in vertical direction and in the same time can be rotated to follow the tangent of the curve.

The oscillation of the knife up/down is done through a DC motor from some old ink jet printer, the rotation of the knife is done through stepper motor.

Normally the price of the TOCK is exceeding 1200 EUR and here you can make fully functional TOCK for less than 80 EUR on your 3D printer.

You'll need a CNC machine or router to connect the TOCK head, also one additional axis to control the rotation.

Here you can find a complete documentation how to build such TOCK by using 3D printer.

Video in YouTune showing how TOCK works on cardboard for making boxes (notice the smooth cutting of rounded shapes)https://www.youtube.com/watch?v=9aJhzyOltiY

Attached is also the program which takes PLT and converts it into GCode with the following features:

if the angle of the segment is bigger than some threshold - lifts the head. rotates it to the new angle and bring it back. This improves significantly the cutting quality of sharp edges

the program optimizes the order of cutting segments to minimize the head lift

the program makes possible to do the creasing without changing the tool (the knife was moved down partially and rotated by 45 deg to make semi cut). Lines in PLT file with red color are treated as creasing lines.

The program can also take GCode and add tangential commands

The generated GCode can be executed on Mach3

Oil less bushes are from RS components:http://export.rsdelivers.com/product/rs-pro/ob5812/oil-less-bush-8mm-od-x-5mm-id-x-12mm-l/5217758.aspx

The shaft is calibrated 5mm steel, if using hardened steel shaft it will be more difficult to drill the holes (you'll need carbide drills).

The stepper motor is standard Nema17 42x42x38 or 42x42x48 with 200 steps per turn. technically you can use motor with more or less steps - it's possible to adjust this in Mach3http://www.amazon.co.uk/3D-Printer-NEMA17-Stepper-Motors/dp/B00KS6I58A

I'll add in the next few days more info about some details (like stepper motor, shafts, oil less bushes, etc.), images of the working head and links to video on YouTube - stay tuned!

Adde IGES model of the design in case you can't open the SolidWorks files.

04/10/2016 - Increased limits of feed rate in Software

The oscillation of the knife up/down is done through a DC motor from some old ink jet printer, the rotation of the knife is done through stepper motor.

Normally the price of the TOCK is exceeding 1200 EUR and here you can make fully functional TOCK for less than 80 EUR on your 3D printer.

You'll need a CNC machine or router to connect the TOCK head, also one additional axis to control the rotation.

Here you can find a complete documentation how to build such TOCK by using 3D printer.

Video in YouTune showing how TOCK works on cardboard for making boxes (notice the smooth cutting of rounded shapes)https://www.youtube.com/watch?v=9aJhzyOltiY

Attached is also the program which takes PLT and converts it into GCode with the following features:

if the angle of the segment is bigger than some threshold - lifts the head. rotates it to the new angle and bring it back. This improves significantly the cutting quality of sharp edges

the program optimizes the order of cutting segments to minimize the head lift

the program makes possible to do the creasing without changing the tool (the knife was moved down partially and rotated by 45 deg to make semi cut). Lines in PLT file with red color are treated as creasing lines.

The program can also take GCode and add tangential commands

The generated GCode can be executed on Mach3

Oil less bushes are from RS components:http://export.rsdelivers.com/product/rs-pro/ob5812/oil-less-bush-8mm-od-x-5mm-id-x-12mm-l/5217758.aspx

The shaft is calibrated 5mm steel, if using hardened steel shaft it will be more difficult to drill the holes (you'll need carbide drills).

The stepper motor is standard Nema17 42x42x38 or 42x42x48 with 200 steps per turn. technically you can use motor with more or less steps - it's possible to adjust this in Mach3http://www.amazon.co.uk/3D-Printer-NEMA17-Stepper-Motors/dp/B00KS6I58A

I'll add in the next few days more info about some details (like stepper motor, shafts, oil less bushes, etc.), images of the working head and links to video on YouTube - stay tuned!

Adde IGES model of the design in case you can't open the SolidWorks files.

04/10/2016 - Increased limits of feed rate in Software

Similar models

thingiverse

free

Nema17 stepper motor by BigRedButton

...7 stepper motor by bigredbutton

thingiverse

a nema17 stepper motor mock-up with a rotating shaft and face mounting capabilities.

thingiverse

free

CERAMBOT Pro kit-Stepper motor bushing by CERAMBOT

...mm.

you can modify the internal control and outer diameter of the stepper motor bushing according to the accuracy of your printer

grabcad

free

Stepper motor

...grabcad

a stepper motor is a brush less, synchronous electric motor that converts digital pulses into mechanical shaft rotation.

3dwarehouse

free

NEMA17 Stepper motor 49mm

...nema17 stepper motor 49mm

3dwarehouse

nema17 stepper motor 49mm long plus shaft with flat. pin connector

grabcad

free

Solid aluminium coupling

...

5mm motor shaft to 8mm shaft. (ender coupling)

usage: nema17 stepper motor shaft to 8mm lead screw mostly on hobby 3d printers.

grabcad

free

Harmonic drive reducer with stepper motor or BLDC motor

...3 stepper motor with harmonic drive reducer for compact application where a hollow shaft stepper motor's torque can not meet.

grabcad

free

NEMA17 Stepper Motor

...nema17 stepper motor

grabcad

3d model of nema17 stepper motor used in 3d printers, pick and place devices, etc.

grabcad

free

Nema17 mount

...nema17 mount

grabcad

here you can find a mount for the nema17 stepper motor.

thingiverse

free

Mock NEMA17 Stepper Motor by PeteJM

...mock nema17 stepper motor by petejm

thingiverse

this is a mock up stepper motor for fitment in most 3d modeling programs.

grabcad

free

NEMA17 (SY42STH47-1684B double shaft) stepper motor

...or, more information on:

https://blog.poscope.com/stepper-motor-driver/

https://www.poscope.com/product-category/cnc-controllers/

Luben111

thingiverse

free

ER20 Collet holder by luben111

...t holder - place 9 er20 collets with labels

put your er20 collets into nice and slim holder - easy access and requires less space

thingiverse

free

Air valve by luben111

...ep model of the engine.

a short video showing how the engine works is on the following link:https://youtu.be/09nnfs2ehyo

thanks.

thingiverse

free

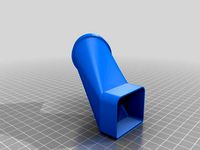

CNC Sieg KX1 vacuum suction by luben111

...ing detail and sucks all the particles created from the milling process. use m3 screw to tide the suction collet on spindle base.

thingiverse

free

Sieg KX1 vacuum suction by luben111

...le detail exceeds the makerbot replicator 2 3d printing area so it was split into two details.

solidworks files also included.

thingiverse

free

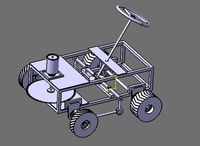

Small XY servo movement by luben111

...erppezxvq-a

converting the rotation angle of the servos into cartesian coordinate system requires some trigonometry calculations.

thingiverse

free

Kleenex 6340 adapter for Cien HandWash by luben111

...16150/

the adapter was printed and tested into real kimberly-clark hand wash unit and works flawlessly (0.2 mm layers, 20% fill).

thingiverse

free

Touch probe by luben111

...rinting the components (0.1mm layers 50%) and assembling the unit the sensitivity is excellent.

more text will be added soon.....

thingiverse

free

Oscilloscope probe holder by luben111

...the first design which is not perfect for 3d printing, i'll post soon another version which is more friendly for 3d printing.

thingiverse

free

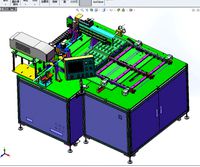

Test jig (clamp) by luben111

.../www.youtube.com/watch?v=cmesfn8o52q

attached is the complete design in solidworks 2016 (zip file) and the iges for the assembly.

thingiverse

free

Fast fixture by luben111

...e fixture.

unfortunately the working prototype was lost long time ago but the design remains and i'm pleased to share it now.

Tangential

3dfindit

free

Tangential Air Separators

...tangential air separators

3dfind.it

catalog: wheatley hvac

thingiverse

free

MPCNC Universal mount for Tangential Knife by yvesvlb

...ial knife by yvesvlb

thingiverse

i quickly adapted the mount of the tangential knife so that i can use it in my universal mount.

thingiverse

free

Geeetech Prusa I3B 18mm Inductor and tangential fan support by mava70

...nd tangential fan support by mava70

thingiverse

support for a 18mm sensor on a geeetech i3 pro b and a tangential fan deployable

thingiverse

free

Tangential fan support for hot-end IEC 4.0 by Graziano

...ngiverse

tangential fan support for hot-end iec 4.0

link iec 4.0 manufacturer :

http://www.immaginaecreashop.it/hot-end-iec.html

thingiverse

free

E3DV6 tangential fan + hot-end fan 40 MM by Graziano

...

thingiverse

e3dv6 support for extruded material cooled, using the 50 mm tangential fan and body cooling hot-end with fan 40 mm.

thingiverse

free

12° angle block for making a tangential toolholder by stmorgan

...compound angle for the tool bit slot.

plans can be found on www.gadgetbuilder.com on the "tangential toolholder" page.

thingiverse

free

N-Tangential Rotated Rods by ProcerSapientiae

... questions, i'll be posting more now that i finally made an account. i've got a back log of beautiful geometry to upload.

thingiverse

free

MPCNC Tangential Knife by jamesd256

...code directly.

thanks to all over at the vicious1 forums, especially alted

alted i borrowed your pineapple. hope that's ok

thingiverse

free

Remix of MPCNC Tangential Knife by GeoDave

...d to a value from 0 to 20.

see the original design: https://www.thingiverse.com/thing:2624654 for further details on this design.

Oscillating

turbosquid

$1

Oscillating Fan

... model oscillating fan for download as obj, c4d, fbx, and dae on turbosquid: 3d models for games, architecture, videos. (1391574)

turbosquid

$55

Oscillating Fan

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

Crystal Oscillator

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$10

Oscillating Fan 3D Model

...oscillating fan 3d model

3dexport

fan electric oscillating desk table cooling air

oscillating fan 3d model lama 28686 3dexport

turbosquid

$10

Oscillator with 2K PBR textures

...r with 2k pbr textures for download as c4d, 3ds, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1609586)

turbosquid

$5

16MHz Quartz Crystal Oscillator

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$5

Oscillating Pedestal Fan 3D Model

...oscillating pedestal fan 3d model for download as max and fbx on turbosquid: 3d models for games, architecture, videos. (1337610)

turbosquid

$19

Karcher Oscillating Sprinkler OS 3.220

...prinkler os 3.220 for download as 3ds, max, obj, fbx, and dwg on turbosquid: 3d models for games, architecture, videos. (1453338)

3d_export

$45

Oscillating Fire Fighting Monitor 3D Model

...n tanker industrial equipment power station flames field

oscillating fire fighting monitor 3d model 3dillustration 23977 3dexport

3d_ocean

$5

Ventilator

...air appliance blower desk detailed electric electro fan hvac oscillating realistic table ventilator high poly, very detailed...

Knife

archibase_planet

free

Knifes

...knifes

archibase planet

knifes kitchen knife case-knifes

knifes - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Knife

...knife

archibase planet

knife kitchen-knife carving-knife

knife - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Knife

...knife

archibase planet

knife kitchen knife carving knife

knife - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Knifes

...knifes

archibase planet

kitchen-knifes knife carving-knifes

knifes - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Knife

...knife

archibase planet

knife kitchen-knife carving-knife

knife n211207 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Knife

...knife

archibase planet

kitchen-knife knife carving-knife

knife n010808 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Knife

...knife

archibase planet

knife bread knife kitchen knife

knife n040212 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Knife

...fe

archibase planet

knife penknife pocket knife clasp-knife

knife n300715 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Knife

...e

archibase planet

knife kitchen knife kitchen ware kitchen-knife

knife n090212 - 3d model (*.3ds) for interior 3d visualization.

archibase_planet

free

Knife

...knife

archibase planet

knife kitchen knife

knife n220807 - 3d model for interior 3d visualization.

Cutting

design_connected

$11

e15 Cut Cutting Boards

...e15 cut cutting boards

designconnected

e15 cut cutting boards computer generated 3d model.

design_connected

$16

Cut

...cut

designconnected

lapalma cut computer generated 3d model. designed by rota, francesco.

3d_export

$5

cutting machine

...cutting machine

3dexport

crop cutting machine

3d_export

$5

cutting board

...cutting board

3dexport

12 models for cutting boards

3d_export

$20

wire laser cutting peeling cutting machine ffc cutting machine

...and receiving machine, with the structure of this drawing, you don't need to draw by yourself, welcome to collect, thank you.

3ddd

$1

Lapalma CUT

... cut

фабрика: lapalma

коллекция: cut

размер:↑ 74 cm, ↔ 55 см.

описание: стул, ткань, кожа, дерево.

сайт: www.lapalma.it

3ddd

$1

стул lapalma cut

...стул lapalma cut

3ddd

lapalma , cut

стул lapalma cut

3ddd

$1

Lapalma CUT

...

коллекция: cut

размер:↑ 74 cm, ↔ 55 см.

описание: стул, порошковое покрытие, черный, белый, ткань, пластик.

сайт: www.lapalma.it

design_connected

$16

Hi Cut

...hi cut

designconnected

kartell hi cut computer generated 3d model. designed by starck, philippe.

3ddd

$1

Vorwerk Cut

...vorwerk cut

3ddd

ковер

vorwerk cut

прямоугольный:

размеры : 2400mm x 3200mm

круглый:

размеры : 2400mm