Thingiverse

Tailgator Blender Base by Who_Knew

by Thingiverse

Last crawled date: 3 years ago

Tailgator was a brand of cordless blenders used for making mixed drinks at tailgating events, backyard parties, etc. It's a blender powered by a Weed Eater brand 2-stroke internal combustion engine. Fun!

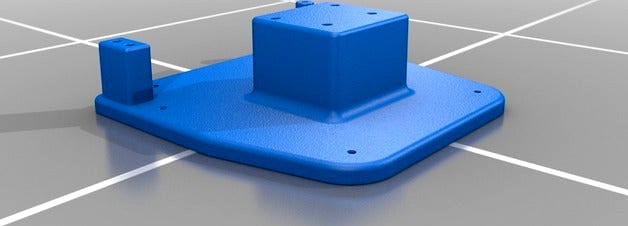

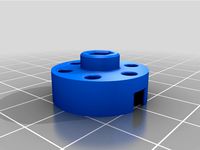

I repaired a blender like this for a friend, and the base was missing. I drew this in Fusion 360. It uses 6 of these feet from McMaster Carr. https://www.mcmaster.com/#9541k3

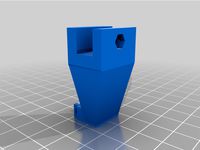

The engine's lower plastic shroud also acts as a crank case cover and is sealed to the crank case with a gasket and 4 bolts. This seal is important to maintain, otherwise the engine will run rough and have poor power. I believe Weed Eater (Poulan) originally secured this with 4 10-24 thread forming screws. The people who made Tailgator removed two of these screws and installed/secured a base that holds the engine's crank vertically so it can be used to power a blender.

When I took the engine apart to repair it, I replaced the screws with studs and put a new gasket on on. Thin nuts now hold the lower shroud in place (recommend use Loc-Tite). This base/stand mounts on the same studs and is held in place by 4 nylock nuts. I figured doing it this way, the lower shroud/gasket remains undisturbed if the base is removed and replaced. Also, the base is now held by 4 fasteners to a larger surface of the shroud, should be less likely to break, as it appears the original one did.

Unfortunately, the thickness of the plastic shroud varies from screw hole to screw hole, which prevents the thin nuts from going completely into the shroud's countersinks. With some of the nuts standing proud, this base wants to be crooked. I tuned the base "straightness" with flat washers so that with the base fastened to the engine and the whole thing is on a level table, the blender jar is level.

A future version of this base could include counter bores to clear the thin nuts, so the base rests only on the shroud surfaces, and not on the shroud nuts, which tend to vary in height as previously mentioned. AAMOF, a future version could allow the use of flanged nylock nuts, which would work better with the lower shroud.

A future version of this might include a few extra feet mounted centrally, and enough clearance to be able to add a spring clamp or some such, so the blender can be clamped to the table (picnic bench). As it is, the blender cannot be run without someone keeping their hand on it. Otherwise, it vibrates so much that it tends to move around on the table quite a bit.

I repaired a blender like this for a friend, and the base was missing. I drew this in Fusion 360. It uses 6 of these feet from McMaster Carr. https://www.mcmaster.com/#9541k3

The engine's lower plastic shroud also acts as a crank case cover and is sealed to the crank case with a gasket and 4 bolts. This seal is important to maintain, otherwise the engine will run rough and have poor power. I believe Weed Eater (Poulan) originally secured this with 4 10-24 thread forming screws. The people who made Tailgator removed two of these screws and installed/secured a base that holds the engine's crank vertically so it can be used to power a blender.

When I took the engine apart to repair it, I replaced the screws with studs and put a new gasket on on. Thin nuts now hold the lower shroud in place (recommend use Loc-Tite). This base/stand mounts on the same studs and is held in place by 4 nylock nuts. I figured doing it this way, the lower shroud/gasket remains undisturbed if the base is removed and replaced. Also, the base is now held by 4 fasteners to a larger surface of the shroud, should be less likely to break, as it appears the original one did.

Unfortunately, the thickness of the plastic shroud varies from screw hole to screw hole, which prevents the thin nuts from going completely into the shroud's countersinks. With some of the nuts standing proud, this base wants to be crooked. I tuned the base "straightness" with flat washers so that with the base fastened to the engine and the whole thing is on a level table, the blender jar is level.

A future version of this base could include counter bores to clear the thin nuts, so the base rests only on the shroud surfaces, and not on the shroud nuts, which tend to vary in height as previously mentioned. AAMOF, a future version could allow the use of flanged nylock nuts, which would work better with the lower shroud.

A future version of this might include a few extra feet mounted centrally, and enough clearance to be able to add a spring clamp or some such, so the blender can be clamped to the table (picnic bench). As it is, the blender cannot be run without someone keeping their hand on it. Otherwise, it vibrates so much that it tends to move around on the table quite a bit.

Similar models

thingiverse

free

Printrbot PLUS Z-axis Set Screw Tensioner by Jerrill

... held in position to provide tension on the screw so i didn't have to loosen and tighten nuts against the screw all the time.

thingiverse

free

weed eater tri blade part one by tommy2toes

...t there are no replacement blades to buy so i made my own. your welcome to use them they work best at 100% infill for durability.

3dwarehouse

free

KpilotRC's 2- and 4-cycle engine repair

...engine #fix #gas #glow #lawn #log #maintain #mower #phone #plane #rc #repair #room #saw #sell #storage #trade #tree #weed #window

3dwarehouse

free

Weed eater

...weed eater

3dwarehouse

gas weed eater

thingiverse

free

REV / FTC 11717 Ultra thin drivetrain sprocket hub and ultraplanetary spacer by FTC11717

...nylock nuts to hold the sprocket to the hub, and 2-4 flathead screws and nylock nuts to hold the wheel to the hub & sprocket.

3dwarehouse

free

feather lite weed eater

...feather lite weed eater

3dwarehouse

weed eater

3dwarehouse

free

Weed eater

...weed eater

3dwarehouse

weed eater or line trimmer

thingiverse

free

Weed Eater Throttle

...is is a throttle trigger for a weed eater i had. i'm not positive of the model of the one i have but it seems fairly generic.

thingiverse

free

Strain relief reworked with a nylock nut by brotherchris

... by brotherchris

thingiverse

i reworked this part so it would use a nylock nut with a through hole, also made the wires run out.

thingiverse

free

Weed/Yard trimmer attachment hanger by Steverino

...at came with one of the attachments, so i used that as inspiration to create one that would print on my printer with no supports.

Tailgator

3d_ocean

$4

Super Tailgate Cinema 4D 3D Text File

...ean, it can be used for design projects for club parties, tailgates, sport events, etc or to create animations. in this packag...

3d_export

$45

Cornhole Game 3D Model

...odel

3dexport

cornhole corn hole bag game throw toss skill tailgate party beanbag

cornhole game 3d model plutonius 33485 3dexport

3d_ocean

$4

Game Day Cinema 4D 3D Text File

...t is editable and can be can be used for design and animation projects for club parties, tailgates, sport events, etc. in this...

3d_export

$60

Zil-4334 Wagon

...ows and tarpaulin. this military truck has a payload capacity of 3 750 kg. in troop carrier configuration it can carry 24 troops.

3d_ocean

$9

3D Typography Cinema 4D Bundle-Vol 001

...an, it can be used for creating animations or to enhance your graphic design projects. change the text for whatever event you ...

3d_export

$26

F-Series F-800 CrewCab Customized Pickup Truck 1985

...other items. i can give lower price if you will buy few models. p.s.: ask for custom parts or versions ot this model if you need.

3d_ocean

$9

3D Typography Cinema 4D Bundle-Vol 002

...an, it can be used for creating animations or to enhance your graphic design projects. change the text for whatever event you ...

3d_export

$40

truck with sides and stands

...ixed_ao,<br>heigt,<br>metallic,<br>roughness,<br>coat_opacity,<br>normal_opengl,<br>emissive.

3d_export

$39

wt-9000 grain truck 1974

...ms. i can give lower price if you will buy few models.<br>p.s.: ask for custom parts or versions ot this model if you need.

3d_export

$39

wt-9000 grain truck 1972

...ms. i can give lower price if you will buy few models.<br>p.s.: ask for custom parts or versions ot this model if you need.

Knew

3d_export

$12

anubis

...the greek version of his name; the ancient egyptians knew him as anpu (or inpu). anubis was an extremely...

3d_export

$499

s of perfume bottles set

...set 3dexport available 3d model format:<br>.max (autodesk 3ds max)<br>everybody knew that woman love good perfumes. and i knew that...

3d_export

$20

T 80

...team trying to fix the problems with t-70. they knew that they needed to improve combat performance, because the...

3d_export

$5

Knoll High Sticking Chair

...from function.<br>w d h seat h 17.87520.125 43.37517.875<br>neither party knew what lay ahead when frank gehry came to knoll...

thingiverse

free

"WHO KNEW?" refrigerator magnet (with a heart) by costmo

...ike to stick on the fridge - ultrasound pictures, wedding announcements, a good report card(!), etc. it's just cute, darn it!

thingiverse

free

Gansta Christ... Because, you knew somebody would do it. by 80am33

...ons...

if you print this... you are going to hell.

i guess i will see you guys there.

https://www.youtube.com/watch?v=cyq8xu-7gnw

thingiverse

free

Soapy A thing you never knew you needed by Bobobrazil

... edges so you can actually use it like a bar of soap. v1 had sharp edges making shower time a little dangerous. save the soap!!

thingiverse

free

Calc curve by lee7670

...curve by lee7670 thingiverse a calc curve no one knew how to...

thingiverse

free

Very sus keycap! by rickynof

...sus keycap! by rickynof thingiverse very sus keycap! i knew it was...

3d_sky

free

Wardrobe

...wardrobe cabinet modelils? on photography, so that the company knew nothing. textures with customized materials in the...

Who

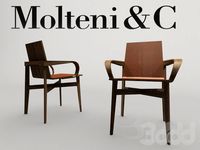

design_connected

$16

Who armchair

...who armchair

designconnected

molteni & c who armchair computer generated 3d model. designed by dordoni, rodolfo.

design_connected

$13

Who chair

...who chair

designconnected

molteni & c who chair computer generated 3d model. designed by dordoni, rodolfo.

3ddd

free

molteni who

...molteni who

3ddd

molteni

molteni chair whit textures

3d_export

$5

dalek doktor who

...dalek doktor who

3dexport

turbosquid

$2

TARDIS - Doctor Who

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

cg_studio

$50

Dr Who SpiderBot3d model

...ho spiderbot3d model

cgstudio

.lwo - dr who spiderbot 3d model, royalty free license available, instant download after purchase.

3d_export

$10

Tardis by Doctor who 3D Model

...rdis doctor who

tardis by doctor who 3d model download .c4d .max .obj .fbx .ma .lwo .3ds .3dm .stl miqayel7255451 112732 3dexport

3d_export

$10

Dalic be Doctor who 3D Model

...dalek doctor who

dalic be doctor who 3d model download .c4d .max .obj .fbx .ma .lwo .3ds .3dm .stl miqayel7255451 112729 3dexport

3d_export

$12

Batman Who Laughs Earth 22

...batman who laughs earth 22

3dexport

earth 22 batman who laughs batman character 3d design

turbosquid

$18

CURB SOFA by SAYS WHO

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Blender

3d_export

$10

Blender

...blender

3dexport

blender 3d modelling fusion360<br>sat , 3dobjeckt

turbosquid

$10

BLENDER

...turbosquid

royalty free 3d model blender for download as max on turbosquid: 3d models for games, architecture, videos. (1201811)

turbosquid

$5

Blender

...rbosquid

royalty free 3d model blender for download as blend on turbosquid: 3d models for games, architecture, videos. (1459008)

3d_export

$5

blender

...blender

3dexport

кружка для кофе

turbosquid

$5

Blender

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$5

Blender

... 3d model blender for download as max, 3ds, stl, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1651551)

turbosquid

$1

Blender

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Blender

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Blender

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$8

Blender robot

...blender robot

3dexport

blender robbot

Base

archibase_planet

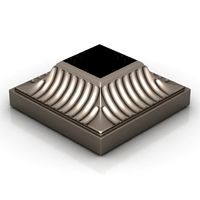

free

Base

...base

archibase planet

base column column base

base 1 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

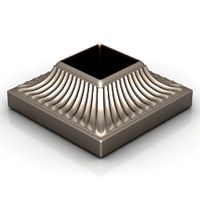

archibase_planet

free

Base

...base

archibase planet

base column base column

base 5 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

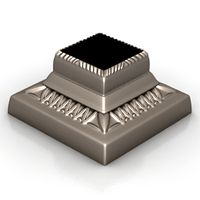

archibase_planet

free

Base

...base

archibase planet

base column column base

base 7 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Base

...base

archibase planet

base column column base

base 2 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Base

...base

archibase planet

base column column base

base 3 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Base

...base

archibase planet

base column column base

base 4 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Base

...base

archibase planet

base column base column

base 6 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Base

...base

archibase planet

foundation base

column base ionic - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Base

...base

archibase planet

foundation base

column base tuscan - 3d model (*.gsm+*.3ds) for interior 3d visualization.

design_connected

$18

Base

...base

designconnected

tom dixon base computer generated 3d model. designed by dixon, tom.