Thingiverse

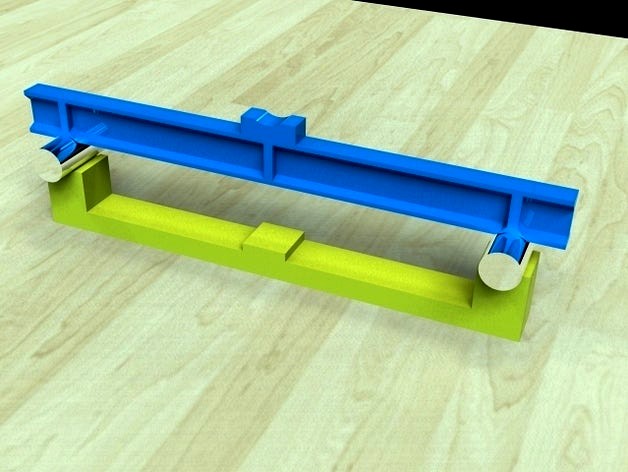

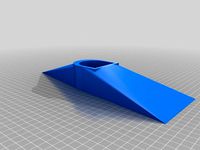

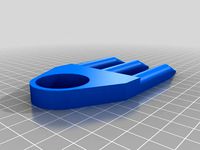

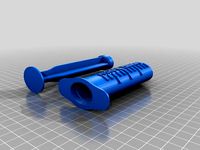

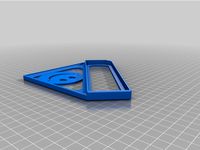

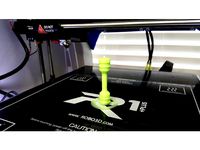

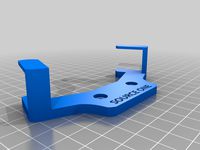

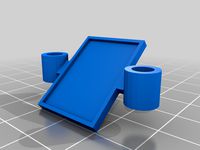

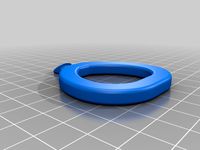

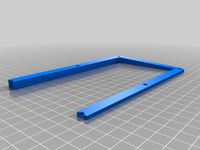

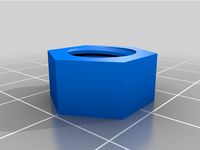

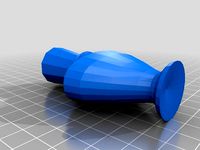

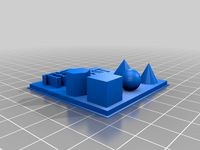

Strength Test Facility for Open Source Appropriate Technology (OSAT) 3D Printing by julianh72

by Thingiverse

Last crawled date: 3 years ago

A Test Bed and sample Test Pieces for strength / stiffness testing of 3D Printed parts

(See attached Word document for a detailed description)

I am recording my development process and experiments in more detail on my blog: http://julianh72.blogspot.com/ I will continue to post relevant files here on Thingiverse, but I will have more space for discussion and debate on my blog. The first entry is here: http://julianh72.blogspot.com/2011/11/testing-strength-of-reprap-printed.html but there will be more discussion on later posts.

EDIT 02 December 2011 - Modified parts (Mk II) uploaded, to make the test assembly more stable.

The strength and stiffness of components manufactured using RepRap and other 3D Printing technologies are affected by a number of independent and inter-dependent parameters, including:

a) the generic stock material used (e.g. PLA, ABS, PE, etc)

b) the actual source and condition of the stock material; e.g. it has been reported that PLA filament will absorb atmospheric humidity over time, and this affects its condition when placed using RepRap-type fabrication; it has also been reported that different coloured batches of otherwise nominally identical filament from the same source can exhibit significantly different fabrication properties, and therefore presumably different mechanical properties

c) the tool-path and build parameters which are used to fabricate the component (e.g. filament diameter, layer thickness, number of layers in the surface “shellâ€, % solid fill vs. % voids used in the core fill, etc)

d) the orientation of the part during printing (filaments parallel or perpendicular to the main load paths, etc)

e) the attributes of the actual printer (print head speed, precision / repeatability of placing the print head, backlash, etc)

When manufacturing components which are intended to have mechanical strength and function, it is necessary to be able to measure the actual strength of materials which can be printed with a particular machine, using a particular set of printing parameters, so that the strength and service life of the component can be predicted, and to assist in the design of new components which will be subjected to loads whose magnitude can be predicted or estimated.

This project came about partly because I am an engineer, and I “need to know†these sorts of things, but was also spurred on by reading an paper on “3-D Printing of Open Source Appropriate Technologies for Self-Directed Sustainable Development†by Pearce, Blair, Laciak, Andrews, Nosrat & Zelenika-Zovko.

[Ref: www.ccsenet.org/jsd “Journal of Sustainable Development†Vol. 3, No. 4; December 2010 http://www.ccsenet.org/journal/index.php/jsd/article/view/6984/6385 ]

(See attached Word document for a detailed description)

I am recording my development process and experiments in more detail on my blog: http://julianh72.blogspot.com/ I will continue to post relevant files here on Thingiverse, but I will have more space for discussion and debate on my blog. The first entry is here: http://julianh72.blogspot.com/2011/11/testing-strength-of-reprap-printed.html but there will be more discussion on later posts.

EDIT 02 December 2011 - Modified parts (Mk II) uploaded, to make the test assembly more stable.

The strength and stiffness of components manufactured using RepRap and other 3D Printing technologies are affected by a number of independent and inter-dependent parameters, including:

a) the generic stock material used (e.g. PLA, ABS, PE, etc)

b) the actual source and condition of the stock material; e.g. it has been reported that PLA filament will absorb atmospheric humidity over time, and this affects its condition when placed using RepRap-type fabrication; it has also been reported that different coloured batches of otherwise nominally identical filament from the same source can exhibit significantly different fabrication properties, and therefore presumably different mechanical properties

c) the tool-path and build parameters which are used to fabricate the component (e.g. filament diameter, layer thickness, number of layers in the surface “shellâ€, % solid fill vs. % voids used in the core fill, etc)

d) the orientation of the part during printing (filaments parallel or perpendicular to the main load paths, etc)

e) the attributes of the actual printer (print head speed, precision / repeatability of placing the print head, backlash, etc)

When manufacturing components which are intended to have mechanical strength and function, it is necessary to be able to measure the actual strength of materials which can be printed with a particular machine, using a particular set of printing parameters, so that the strength and service life of the component can be predicted, and to assist in the design of new components which will be subjected to loads whose magnitude can be predicted or estimated.

This project came about partly because I am an engineer, and I “need to know†these sorts of things, but was also spurred on by reading an paper on “3-D Printing of Open Source Appropriate Technologies for Self-Directed Sustainable Development†by Pearce, Blair, Laciak, Andrews, Nosrat & Zelenika-Zovko.

[Ref: www.ccsenet.org/jsd “Journal of Sustainable Development†Vol. 3, No. 4; December 2010 http://www.ccsenet.org/journal/index.php/jsd/article/view/6984/6385 ]

Similar models

thingiverse

free

Food Scraper by jpearce

...customizable food scraper. print 100% infill with polycarbonate or similar on a reprap for cleaning dishes etc. this component...

thingiverse

free

Viking Shelf Holder by jpearce

...the michigan tech's open sustainability technology research group. for similar see the open-source lab how to build your own...

thingiverse

free

Libre Pickaxe by jpearce

...an tech in open sustainability technology research group. to make open source appropriate technology for sustainable development.

thingiverse

free

Libre Rake by jpearce

...an tech in open sustainability technology research group. to make open source appropriate technology for sustainable development.

thingiverse

free

Libre simple chisel by jpearce

... tech in open sustainability technology research group. to make open source appropriate technologies for sustainable development.

thingiverse

free

Libre Hoe by jpearce

...an tech in open sustainability technology research group. to make open source appropriate technology for sustainable development.

thingiverse

free

Parametric simple lamp shade by jpearce

...in transparent or translucent filament with a reprap or similar fff 3-d printer. please note all changes to variables...

thingiverse

free

Libre Scorp by jpearce

...an tech in open sustainability technology research group. to make open source appropriate technology for sustainable development.

thingiverse

free

Libre Thin Axe v2 by jpearce

... tech in open sustainability technology research group. to make open source appropriate technologies for sustainable development.

thingiverse

free

PASCO Test Coupon by mfarson

...ge. data on tensile strength of differing filaments printed with a variety of slicing parameters was obtained using this coupon.

Julianh72

thingiverse

free

Visual Illusion by julianh72

...iece should give the illusion that all 4 ramps slope up to the middle platform. viewing from any other angle gives the game away!

thingiverse

free

Battleshots by julianh72

...lass small aircraft carrier is there because – well, every navy has to have at least one aircraft carrier (to be the flagship!)

thingiverse

free

Celestron 5SE Dust Cap by julianh72

...el is "shared" publicly in my onspace account - search https://www.onshape.com/ for "celestron 5se dust cap".

thingiverse

free

Just another M3 Thumbwheel! by julianh72

...design for other applications; sorry, no openscad files, but it shouldn’t be too hard to design something similar in openscad!)

thingiverse

free

Solar Finder-Scope by julianh72

...ot;solar finder mk 3".

you may need to ream out the pinhole with a drill bit to get a nice clean sun image on the target.

thingiverse

free

Tripod Spreader for Celestron NexStar 4SE by julianh72

...cked into position.

to fold away the tripod, wind back on the knob, and then the spokes can be folded up between the tripod legs.

thingiverse

free

2 mm Allen Key Extension Handle by julianh72

...eeded a 2.5 mm allen key holder as well, so i have added the file for it, and both designs have the size embossed onto the handle

thingiverse

free

3 mm Spanner for Bed Levelling Screws by julianh72

...uploaded the alibre model file for those with alibre pe who may want to modify the design; otherwise, just download the stl file.

thingiverse

free

Camera-Mount Base for Orion Mini 50 mm Guide Scope by julianh72

...20 thread) salvaged from another camera mount and "welded" it in with a soldering iron to melt the surrounding plastic.

Osat

thingiverse

free

Pin Box Occupational Therapy Toy OSAT

...sat

thingiverse

this is an osat project that fulfills the need of a toy to help patients build their dexterity while in therapy.

thingiverse

free

OSAT Planter with reusable water collection point. by TubaTom

...conjunction with a pot/bottle bottom set inside of this, which then allows water to be drained into a central location for reuse.

thingiverse

free

Twisted Tent Stakes by Azw

...course at michigan technological university. for more information on osat please see...

thingiverse

free

Geared clamping system by dchopp

...by dchopp thingiverse a geared clamping system design for osat more documentation...

thingiverse

free

Spoon Fork Knife Combo by atketter

...fork knife combo by atketter thingiverse this is an osat project for michigan tech's my4777. it is a spoon...

thingiverse

free

Carpenter's Hammer - 16 ounce by cjkmiec

...- 16 ounce by cjkmiec thingiverse hammer made for osat project at michigan tech use a 3/4" x 3.5"...

thingiverse

free

3d Printable Bike Grip by swallen

...is a 3d printable bike handle designed for the osat project for mtu's my4777 class. it features an ergonomic...

thingiverse

free

Parametric Pulley Assembly by lwilder

...this is a fully parametric pulley designed for the osat assignment for ee 4777 @ michigan technological university. please...

thingiverse

free

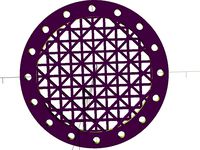

Variable Sifter by AdamPringle

...variable sifter by adampringle thingiverse this osat project is meant to provide utility in sifting for...

Facility

thingiverse

free

Homeless Facility by mondesirSTEAM

...lity by mondesirsteam

thingiverse

lillie and vivianna made a prototype of a homeless facility for their inventure prize project.

thingiverse

free

TBMM facility by oraltosun

...to stl.

below is the original file link:

https://3dwarehouse.sketchup.com/model.html?id=uece319d4-fd6e-4281-8e9b-64fca96faded

thingiverse

free

T gauge locomotive facility by Carter1970

...omotive facility. it is designed to fit in 3 tracks and i have the roof separate to either fit in leds and to help print quality.

thingiverse

free

MARS MANUFACTURING FACILITY by MarjorieOszman

... reduces the radiation.

the power system is two mini sodium-based nuclear reactors with a estimated life-span of thirty years.

thingiverse

free

HO Scale Container and Truck Loading Facility by kabrumble

...ity uses actual ho rails and wheels and moves smoothly. it has lots of variations.

tips are not necessary...but they are fun.

kim

thingiverse

free

HO Scale Fuel Distribution Facility by kabrumble

...ho scale fuel distribution facility by kabrumble

thingiverse

this is my version of a fuel distribution center.

thingiverse

free

Pandemic Research Facility Upgrade

...ease pieces: https://www.thingiverse.com/thing:4140664

both of these together really make the game a more fun visual experience.

thingiverse

free

support ventilateur facile a enlever by bender57

... assez de devoir deviser les supports de ventilateurs pour regler ma hauteur de de buse, avec ce remix c'est bien plus simple

thingiverse

free

Lego Mindstorms parking facility by zouzou21

...once. no mess with the cables. all pieces have numbers, so you know how many of them you have to cut.

6 mm mdf board is perfect.

thingiverse

free

Balls porte clé impression facile by Thib54

...lat.

print, paste ... done!

to be scaled for your needs, realized in the range pla peau from arianeplast for more realism.

enjoy!

Technology

thingiverse

free

Technology by mhkac

...technology by mhkac

thingiverse

turkish ipad

thingiverse

free

mushroom by TechnologyEd

...mushroom by technologyed

thingiverse

mushroom -zoe williams

thingiverse

free

mushroom by TechnologyEd

...mushroom by technologyed

thingiverse

mushroom -zoe williams

thingiverse

free

Technology College logo

...technology college logo

thingiverse

logo of the technology college in which i studied.

thingiverse

free

Fairphone Technology Case by Fairphone

...fairphone technology case by fairphone

thingiverse

fairphone technology case

thingiverse

free

Wentworth Institute of Technology by ndisalvo

... the wentworth institute of technology mascot. the mascot is on the top and it says wentworth institute of technology on the back

thingiverse

free

Technology: Savior and Destroyer by ryanmorrissey1997

...technology: savior and destroyer by ryanmorrissey1997

thingiverse

art300 technology as both savior and destroyer

thingiverse

free

SMART Technologies Logo by JbaileyHTHS

...smart technologies logo by jbaileyhths

thingiverse

this is my smart technologies logo (c)

thingiverse

free

YIF Technologies Logo by gopalsuresh74

...yif technologies logo by gopalsuresh74

thingiverse

yif technologies private limited logo

thingiverse

free

Meadowbrook Technology Logo by schmidjon

...meadowbrook technology logo by schmidjon

thingiverse

the meadowbrook school of weston technology logo, 3d!

Appropriate

thingiverse

free

microwave oven by Gallmix

...microwave oven by gallmix thingiverse appropriate dimensions...

thingiverse

free

RPG Army units by Dirsh

...rpg army units by dirsh thingiverse scale to the appropriate ...

thingiverse

free

Mouse Coaster by BlackConcept

...blackconcept thingiverse a coaster... be sure to scale it appropriatey ...

thingiverse

free

Rook

...rook thingiverse rook chess piece, should be scaled appropriatey. ...

thingiverse

free

Bonewood Ranger

...bonewood ranger thingiverse bonewood ranger appropriate for 18mm or 15mm...

thingiverse

free

Phone Stand by chandlersupple

...phone stand by chandlersupple thingiverse a phone stand with appropriate holes for a charging...

thingiverse

free

Forest Witch

...forest witch thingiverse forest witch miniature appropriate for 18mm or 15mm...

thingiverse

free

Behringer TD-3 Smiley Stand by Lizard_Wizard

...td-3 smiley stand by lizard_wizard thingiverse a smiley stand appropriate for this machine...

thingiverse

free

Slowbro Buddha by Fisk400

...thingiverse i think this is one of the more appropriate buddha remixes out...

Strength

thingiverse

free

strength test by AGcenturion47

...strength test by agcenturion47

thingiverse

thingiverse

free

Strength test by DoktorSylesej

...al design for a strength test, it is expected to break at around 40kg using abs.

the specimen should break at the middle section.

thingiverse

free

Strength Tester by jarred1997

... print. the concept of this rectangular shape is to test your plastic strength. simply print it and see how strong this piece is.

thingiverse

free

Strength Rune by ChezWaldo

...mark gives the angelic warrior a short but intense burst of increased physical strength.

taken straight from shadowhunters wiki

thingiverse

free

Strength/weakness key chain by CHIEF83620

...strength/weakness key chain by chief83620

thingiverse

key chain that is an ambigram of strength/weakness.

thingiverse

free

Project: Strength of Materials by insane66

...h break test and a compression strength break test. in this project we will do some material testing.https://youtu.be/4dgdbdbmbte

thingiverse

free

Strength Tester for Kids by WillemvD

... you hit, the faster the wheel starts rotating.https://youtu.be/um4qe2jxuyu

better print it with 50% infill for strength reasons.

thingiverse

free

Filament strength test "HOOK" by Gam017

...filament strength test "hook" by gam017

thingiverse

with this test you can check the strength of any filament.

thingiverse

free

Box Holder Wood Plank (More Strength)

...box holder wood plank (more strength)

thingiverse

(more strength)

thingiverse

free

Filament Strength Test Specimens by flyingaz

...- horizontal

bending - horizontal

bending - vertical

fracture toughness

hardness

compressive strength

burning

thermal deformation

Source

thingiverse

free

Source One - wall mount

...source one - wall mount

thingiverse

wall mount for tbs source one

thingiverse

free

HomePod Source by MadeByNozzle

...ing some marks on wooden furniture due to the rubber that apple is using. this homepod source gets ride of this problem entirely.

thingiverse

free

source one socks by Dutzisphere

...source one socks by dutzisphere

thingiverse

another take on tpu socks for source one

thingiverse

free

Radioactive source holder by poblockim

...radioactive source holder by poblockim

thingiverse

this is radioactive source holder for the a-level required practical.

thingiverse

free

TBS Source One Protection Kit

...ource one arm bumpers/skids

source one soft motor mount pad

source one front bumper

source one rear unify/crossfire antenna mount

thingiverse

free

TBS Source One Accessories

...tbs source one accessories

thingiverse

a couple accessories for the tbs source one frame. should work with all versions.

thingiverse

free

source one camera mount by ninnux

...source one camera mount by ninnux

thingiverse

source one camera mount

is there 10,15,20,25 grades mount and freecad source

thingiverse

free

Arm bumper source one by jydotix

...arm bumper source one by jydotix

thingiverse

source one bumper

thingiverse

free

tbs source one toothgrinder by n2tat2ng

...tbs source one toothgrinder by n2tat2ng

thingiverse

toothgrinder source one skid

thingiverse

free

Source One Cap Holder by ikuiku

...source one cap holder by ikuiku

thingiverse

cap holder for the source one

Open

thingiverse

free

Opener

...opener

thingiverse

beer opener for dad

thingiverse

free

Bottle Opener & Can Opener

... be a good idiea.

like the original project this opener not have a big life opening bottles, but you can open hundreds of cans...

thingiverse

free

Package opener

...package opener

thingiverse

tool to open packages.

thingiverse

free

Opened half-open box by Kzivi

...opened half-open box by kzivi

thingiverse

openable container. i use it to keep garbage bags under the sink in the kitchen.

thingiverse

free

Open

...7 wheels and falken tires.

will fit open rc truggy

ref: https://www.thingiverse.com/thing:42198

wheel dia 98.4mm

tire dia 122.4mm

thingiverse

free

Beer opener aka Bottle opener by jega

...beer opener aka bottle opener by jega

thingiverse

this is remix of bottle opener

thingiverse

free

Decola Opener

...iverse

parametric decola paints opener. there are three different models, the third one (decola-opener-3.stl) is the most handy.

thingiverse

free

Softdrink Opener

...softdrink opener

thingiverse

can opener for hand function weakness with disiblity...

thingiverse

free

Bottle Opener

...bottle opener

thingiverse

the best freaking bottle opener you can print!https://youtu.be/nfh9eeinmzs

thingiverse

free

Jar Opener

...jar opener

thingiverse

jar opener- fasten to cupboard upper

~d mcg 19/03/2020

Test

thingiverse

free

TEST test

...test test

thingiverse

test

thingiverse

free

test test by discount

...test test by discount

thingiverse

test

thingiverse

free

test by test-it-free

...test by test-it-free

thingiverse

test

thingiverse

free

test

...test

thingiverse

test

thingiverse

free

Test

...test

thingiverse

test

thingiverse

free

Test

...test

thingiverse

test

thingiverse

free

Test

...test

thingiverse

test

thingiverse

free

test

...test

thingiverse

test

thingiverse

free

test

...test

thingiverse

test

thingiverse

free

test

...test

thingiverse

test

Printing

thingiverse

free

for print by Kieran20

...for print by kieran20 thingiverse for printing ...

thingiverse

free

Test Print - Calibration Print by fischer99

...nt settings. includes bridge, overhang, square walls and round walls.

i print with 20% infill, 3 shells, skirt only, no support.

thingiverse

free

Printing by munchanc

...printing by munchanc

thingiverse

things to print

thingiverse

free

Test Print

...test print thingiverse much fun by printing ...

thingiverse

free

Print test

...print test

thingiverse

i use it to test print parameters for new materials

thingiverse

free

PRINTED by t_kondo

...printed by t_kondo thingiverse it's just a 3d printing typeface...

thingiverse

free

3D Printed ball (Print Your own) by 001002003004

...3004

thingiverse

print your own ball

steps

download the size you want to print

double click on the file

click print

thingiverse

free

3d Printing Support Test Print

...can learn more about using supports in cura on the drvax youtube channel and by watching this video:

https://youtu.be/qko_ayibp8k

thingiverse

free

Print on Fabric - small test print by OeG3D

...ingiverse

we tried to print on fabric as shown in https://www.thingiverse.com/thing:2787803

use the link above for instructions.

thingiverse

free

Print Scoop by Gibson1990

...print scoop by gibson1990

thingiverse

scoop for lifting 3d prints off the print bed