Thingiverse

Stepper motor tune-up aid by jpnurro

by Thingiverse

Last crawled date: 3 years ago

I ran in to the issue with 3DBenchy. The cabin walls got the diagonal stripes with 0.1 &0.05 mm accuracy. (You'll find the phenomenon called as 'Zebra stripes' or 'Moire')

The reason is that our stepper motors aren't rotating full steps but electronically created fraction of the steps, (microsteps) e.g. 1/16. These are not accurate especially near the motor's full step area. Holding in to those depends about the current feeding in to the motor.

The phenomenon is visible when motor needs to do micro movements. The surface is on the low angel '__----' towards axis so these steps comes visible.

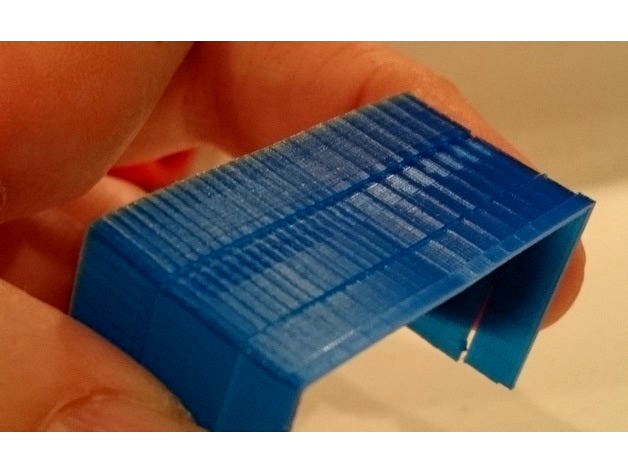

Here is the test piece I made. X-axis (ends) & Y-axis (middle two) surfaces are 5 & 10 degree off the angels. (In the picture on the front 10 degree and back 5 degree Y-axis off-set angle)

During the printing I tuned up the motor drivers current to find out the optimum settings for the both axis. (There are small trimmers on the motor drivers e.g. in A4988 Stepper Motor Driver)

On the left the my original setting and right end the optimized result. (when the current goes too low or high the steps are missed - gaps in the picture)

I DO RECOMMEND TO USE CAUTION WHEN TOUCHING THE LIVE ELECTRONICS !!!

Use non-conductive screwdriver with tuning the trimmers (or very steady hand :-)

Avoid static electricity, don't use synthetic clothing. Earth yourself e.g. touching the water tab before the work.

The Z-axis shouldn't be the issue. E.g M8 tread has 1.25mm progress/rotation (pitch). The Nima17 motor has 200 steps/rotation -> 0.2 layer the motor turns 32 full step and 0.5 gives 8 steps, these are good, no microstepping.

If you'd like to use e.g. 1/100in layer height you'd get the rotation 6 1/4 steps, in this case you might have a issue.

The reason is that our stepper motors aren't rotating full steps but electronically created fraction of the steps, (microsteps) e.g. 1/16. These are not accurate especially near the motor's full step area. Holding in to those depends about the current feeding in to the motor.

The phenomenon is visible when motor needs to do micro movements. The surface is on the low angel '__----' towards axis so these steps comes visible.

Here is the test piece I made. X-axis (ends) & Y-axis (middle two) surfaces are 5 & 10 degree off the angels. (In the picture on the front 10 degree and back 5 degree Y-axis off-set angle)

During the printing I tuned up the motor drivers current to find out the optimum settings for the both axis. (There are small trimmers on the motor drivers e.g. in A4988 Stepper Motor Driver)

On the left the my original setting and right end the optimized result. (when the current goes too low or high the steps are missed - gaps in the picture)

I DO RECOMMEND TO USE CAUTION WHEN TOUCHING THE LIVE ELECTRONICS !!!

Use non-conductive screwdriver with tuning the trimmers (or very steady hand :-)

Avoid static electricity, don't use synthetic clothing. Earth yourself e.g. touching the water tab before the work.

The Z-axis shouldn't be the issue. E.g M8 tread has 1.25mm progress/rotation (pitch). The Nima17 motor has 200 steps/rotation -> 0.2 layer the motor turns 32 full step and 0.5 gives 8 steps, these are good, no microstepping.

If you'd like to use e.g. 1/100in layer height you'd get the rotation 6 1/4 steps, in this case you might have a issue.

Similar models

3dwarehouse

free

CW230 Stepper Driver

...se

this is a stepper motor driver model cw230 capable of microstepping 1/64 #controller #cw230 #driver #motor #stepper #stepping

grabcad

free

DRIVER A4988

...oximately 1 a per phase without a heat sink or forced air flow (it is rated for 2 a per coil with sufficient additional cooling).

grabcad

free

PoStep60-256 Stepper Motor Driver

...decay modes, including an auto-mixed decay mode, are available in the settings. thus ultra-smooth motion profile can be achieved.

thingiverse

free

Stepper Motor V1.1 by ProtoG

...per motors work. this is specifically a permanent magnet stepper motor capable of 15 degree full steps and 7.5 degree half steps.

thingiverse

free

Stepper to Camera - Universal mounting plates by limeyrock

...otation. if this still proves to be too jerky a geared down stepper motor could easily be adapted (and provide even more torque).

thingiverse

free

Stepper Motor Driver v3.3 by MakerBot

... feeling adventurous, the chip can handle up to 35v for the drive voltage. you'll have to wire up your own connector though.

grabcad

free

Stepper Motor

...stepper motor

grabcad

a stepper motor is a motor that drives a full rotation into a number of equal steps .

grabcad

free

3 Axis Stepper Motor Driver

...3 axis stepper motor driver

grabcad

3 axis stepper motor driver

grabcad

free

5th axis table for a CNC machine that I am designing

...0 steps but the other 3 need to be 360 steps be cus a 200 step motor is a 1.8 degree rotation uvw need to be a 1 degree rotation

grabcad

free

Stepper Motor

...nown as step motor or stepping motor, is a brushless dc electric motor that divides a full rotation into a number of equal steps.

Jpnurro

thingiverse

free

Eastern Egg container by jpnurro

...eastern egg container by jpnurro

thingiverse

and maybe a bit of paint...

thingiverse

free

M10 cap nut by jpnurro

...m10 cap nut by jpnurro

thingiverse

cap nut for m10 tread row. the depth 11mm

thingiverse

free

Picture table stand by jpnurro

...tand by jpnurro

thingiverse

the table stand for the canvas frame. the stand length is 165mm but you can zoom it with the slicer.

thingiverse

free

Spinner bearing by jpnurro

...ww.thingiverse.com/thing:2067794)

add a bit lubricant and the spinner rotates reasonable well.

print 1 bearing and 2 cap pieces.

thingiverse

free

PSVR Stand, no screws needed by jpnurro

...psvr stand, no screws needed by jpnurro

thingiverse

i modified the top & bottom part fastening setup so that no hw needed.

thingiverse

free

CTC i3 MK8 extruder_right_lever_semi_Bowden by jpnurro

...en by jpnurro

thingiverse

the bowden type filament guide to avoid filament jams for the http://www.thingiverse.com/thing:2203796

thingiverse

free

Bed surface holder by jpnurro

...ace holder for 330x330 heated aluminum bed e.g. x5s series. protects the bed bottom surface for the scratching by the spring ends

thingiverse

free

glass plate holder by jpnurro

...prings to bind the glass plate in to one corner.

the holders are designed for the mk2 heat bed with 213x200x3.5 (mm) glass plate.

thingiverse

free

Powerfix Water Pipe Pliers' jaw covers by jpnurro

...powerfix water pipe pliers' jaw covers by jpnurro

thingiverse

the covers for the pliers jaw.

thingiverse

free

Sharpening aid cone by jpnurro

...aid for the dremel multi-tool to help keep 22.5 degree angle. the length of the cone 73mm. you might make it shorter down to 50mm

Aid

3ddd

$1

Kitchen Aid

...kitchen aid

3ddd

чайник

kitchen aid

3ddd

$1

First aid box

...first aid box

3ddd

аптечка

decorative first aid box, with band aids, bottle of anticeptic fluid, a pair of siccors and gauze.

turbosquid

$30

KItchen Aid

...e 3d model kitchen aid for download as c4d, 3ds, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1589732)

turbosquid

$165

aids b.max

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$3

first aid

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$3

First Aid

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

First Aid

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Hearing aid

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

first aid kit

...first aid kit

3dexport

low poly game model of a first aid kit, for sterilized games

3d_export

$5

First aid kit

...first aid kit

3dexport

first aid kit props +texture<br>format fbx

Stepper

turbosquid

$85

Stepper

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_ocean

$22

Mini Stepper

...gymnastic indoor legs machine mini silver sport stepper trainer workout

3d model of silver and black mini stepper with a counter.

turbosquid

$3

stepper deluxe

...osquid

royalty free 3d model stepper deluxe for download as on turbosquid: 3d models for games, architecture, videos. (1284335)

turbosquid

$49

Stepper Motor

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$5

Fitness Stepper

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$1

stepper motor driver

...stepper motor driver for download as , fbx, dae, obj, and stl on turbosquid: 3d models for games, architecture, videos. (1688860)

turbosquid

$1

Stepper motor driver

... model stepper motor driver for download as obj, stl, and ige on turbosquid: 3d models for games, architecture, videos. (1577811)

3d_export

$5

Stepper motor Nema17 17HS4401

...stepper motor nema17 17hs4401

3dexport

turbosquid

$1

Nema 17 Stepper motor

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$1

Nema 17 Stepper Motor 59Nm

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Tune

3ddd

$1

Tune VWS - TERMA

...tune vws - terma

3ddd

terma , полотенцесушитель

tune vws - terma radiator

turbosquid

$70

tuning car

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$50

tuning auto

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$7

Tuning wheel

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$55

toyota cresta jts tuning

...toyota cresta jts tuning

3dexport

toyota cresta jts tuning

3d_export

$10

Dodge SRT4 ACR tuning

...dodge srt4 acr tuning

3dexport

dodge srt4 acr tuning

3d_export

$60

Ford GT tuned 3D Model

...ford gt tuned 3d model

3dexport

ford gt tuned tuning

ford gt tuned 3d model godzik 4370 3dexport

cg_studio

$50

Tuned Skyline3d model

...ed skyline3d model

cgstudio

.3ds .max - tuned skyline 3d model, royalty free license available, instant download after purchase.

turbosquid

$50

datsun 510 tuning

...

royalty free 3d model datsun 510 tuning for download as max on turbosquid: 3d models for games, architecture, videos. (1510050)

3d_export

$20

Audi a5 tuning 3D Model

...audi a5 tuning 3d model

3dexport

car tuning

audi a5 tuning 3d model lino 71952 3dexport

Motor

archibase_planet

free

Motor

...base planet

motor motor engine engine electric motor

motor wagner n250213 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Motor

...motor

archibase planet

motor motor engine engine

motor n151112 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Motor

...motor

archibase planet

motor motor engine engine

motor n150615 - 3d model (*.gsm+*.3ds+*.max) for interior 3d visualization.

turbosquid

$15

Motor

...otor

turbosquid

royalty free 3d model motor for download as on turbosquid: 3d models for games, architecture, videos. (1639404)

3d_ocean

$5

Electric motor

...electric motor

3docean

car electric engine industry motor phase train vehicle

an electric motor enjoy!

3d_ocean

$18

Electric Motor

...electric motor

3docean

electric motor engine machine mover parts

3d model electric motor for hoist crane

turbosquid

$29

Motor

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$5

Motor

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

electric motor

...electric motor

3dexport

electric motor use for industrial purposes

3d_export

$5

servo motor

...tor

3dexport

it's a simple part of servo motor 0.75kw for used in machines assembly to show specified motor in own project.