Thingiverse

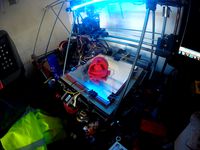

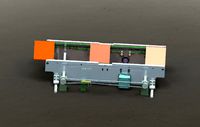

Steel Conveyor Belt for ABP (raftless) by Tunell

by Thingiverse

Last crawled date: 3 years ago

This is a semi-permanent belt for the ABP. It is a derivative of http://www.thingiverse.com/thing:7460 by tmartin. Tmartin uses titanium, which would be preferable, but is not widely available in the dimensions needed.

Use steel foil measuring 12" width by .002" thick, you'll need to cut the roll at the final belt width.

I used some steel foil from the local electronics store (Elliots in tucson) where they charged me $1/ft, but this stuff is available from many locations:

http://www.mcmaster.com/#stainless-steel-foil/=cntox8http://cgi.ebay.com/NEW-K-S-Stainless-Steel-002-Foil-6030-NIB-/290545521747?pt=Radio_Control_Parts_Accessories&hash=item43a5dcd453#ht_739wt_905http://www.quickshipmetals.com/foils/stainless-foil-00212.html

Apparently this foil is used for "tool-wrapping" whatever that is...

Steel is a great belt medium because: (borrowed from tmartin)

1) Unlike aluminum foil and paper, it does not normally crinkle and maintains a smooth flat shiny surface unless deliberately creased. It it actually somewhat springy.

2) It is flexible like a sheet of paper and rolls smoothly through the mechanism

3) The coefficient of thermal expansion is much lower than plastic over the temperature ranges used, therefore although the plastic will adhere nicely when hot, when both are cooled the plastic shrinks more than the surface beneath it and pops right off.

4) It is physically extremely tough and will survive a lot of abuse.

5) Not damaged by build platform temperatures.

6) Inexpensive.

7) Great for raftless printing

8) Excellent thermal conductivity, gets hot all over.

Disadvantages:

1) It is NOT chemically inert and will not withstand solvent attack.

2) There will be a seam on the belt which will occasionally leave a (small) line on the bottom of a print

3) Poor adhesion to ABS, must be coated with Kapton tape. Sanding doesn't help.

4) Steel may crease if you are not careful when making the belt.

5) Cannot run the ABP conveyor backwards (as if you would want to)

6) Steel may swell when heated causing a loss of belt tension.

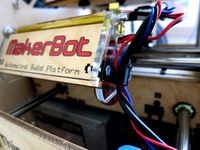

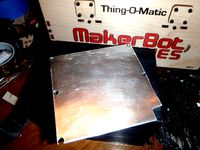

Note: I noticed that the belt works even better and stays even flatter when I added the new countersunk plate to my ABP. This provides just a bit of an edge that the belt must wrap over on the front and back. Plus no more bolt interference. See the pic!

Use steel foil measuring 12" width by .002" thick, you'll need to cut the roll at the final belt width.

I used some steel foil from the local electronics store (Elliots in tucson) where they charged me $1/ft, but this stuff is available from many locations:

http://www.mcmaster.com/#stainless-steel-foil/=cntox8http://cgi.ebay.com/NEW-K-S-Stainless-Steel-002-Foil-6030-NIB-/290545521747?pt=Radio_Control_Parts_Accessories&hash=item43a5dcd453#ht_739wt_905http://www.quickshipmetals.com/foils/stainless-foil-00212.html

Apparently this foil is used for "tool-wrapping" whatever that is...

Steel is a great belt medium because: (borrowed from tmartin)

1) Unlike aluminum foil and paper, it does not normally crinkle and maintains a smooth flat shiny surface unless deliberately creased. It it actually somewhat springy.

2) It is flexible like a sheet of paper and rolls smoothly through the mechanism

3) The coefficient of thermal expansion is much lower than plastic over the temperature ranges used, therefore although the plastic will adhere nicely when hot, when both are cooled the plastic shrinks more than the surface beneath it and pops right off.

4) It is physically extremely tough and will survive a lot of abuse.

5) Not damaged by build platform temperatures.

6) Inexpensive.

7) Great for raftless printing

8) Excellent thermal conductivity, gets hot all over.

Disadvantages:

1) It is NOT chemically inert and will not withstand solvent attack.

2) There will be a seam on the belt which will occasionally leave a (small) line on the bottom of a print

3) Poor adhesion to ABS, must be coated with Kapton tape. Sanding doesn't help.

4) Steel may crease if you are not careful when making the belt.

5) Cannot run the ABP conveyor backwards (as if you would want to)

6) Steel may swell when heated causing a loss of belt tension.

Note: I noticed that the belt works even better and stays even flatter when I added the new countersunk plate to my ABP. This provides just a bit of an edge that the belt must wrap over on the front and back. Plus no more bolt interference. See the pic!

Similar models

thingiverse

free

Paper/Kapton ABP Conveyor Belt by mraiser

...er/kapton abp conveyor belt by mraiser

thingiverse

i used a sharpie to darken the edges of the plastic belt and then scanned it.

thingiverse

free

Titanium Conveyor For Makerbot ABP and raftless printing by tmartin

...metal foils like zirconium or tungsten would probably work similary. it seems to last nearly forever too, i've run...

thingiverse

free

Paper/Kapton ABP Conveyor Belt by AVataRR

...ake's abp v1.0 and on the thing-o-matic's abp (although you quickly get wrinkles in the middle because of the roller gap)

grabcad

free

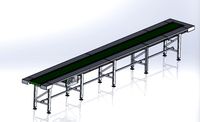

Stainless Steel Belt Conveyor

...stainless steel belt conveyor

grabcad

stainless steel belt conveyor

grabcad

free

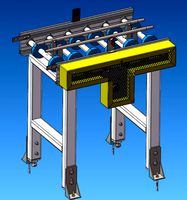

STAINLESS STEEL ROLL CONVEYOR

...stainless steel roll conveyor

grabcad

general propose stainless steel roll conveyor

grabcad

free

Conveyor Belt, 25-Meter - Aluminum Profiles and Stainless-Steel chassis

...- with an inverter - ( please leave me a comment if you have any suggestion to modify this design ) , solidworks 2018 or step.

grabcad

free

Umbra U7 Paper towel Dispenser

...is integrated with the snap-fit, twist remove cap for easy installation of the paper roll. can be used vertically or horizontally

grabcad

free

Steel Conveyor

...steel conveyor

grabcad

steel conveyor belt used to load biochar with a temperature resistance of 500-700 degrees celsius

thingiverse

free

Foil, Paper, Plastic-Wrap Shelf by BetterHalf

...trip "refills".

any standard double-sided tape.

drill holes for any hardware of your choice for a permanent mount.

cg_trader

$12

Roller Conveyor

...rconveyor stainless industry technology design belt driven business equipment industrial machine industrial machine conveyor belt

Raftless

thingiverse

free

Skeinforge 006 + Raftless by AntonioSantos

... tell the feedrate and flowrate for the remaining 1

layer, other then the first perimeter only...

let me know if you tested it...

thingiverse

free

Autobot Icon - Raftless by MrJohn

...ce. should print nicely.

updated aug 14, added sketch up! file.

someone please print and share, i'm away from my bot for now.

thingiverse

free

MBot Raftless Spool Holder by Bob_East

...he original took a long time printing support material, so i trimmed one side flat so it can be printed without support material.

thingiverse

free

Up Mini Adjustable Bed Mod for Raftless Printing by Woodlake

... print area.

i am using a print bed comprised of 0.03" pei laminated to 3mm borosilicate glass with 3m 468mp adhesive sheet.

thingiverse

free

Large print bed tester by josefprusa

...(i use custom modified raftless plugin originaly by zaggo http://pleasantsoftware.com/developer/3d/2009/12/05/raftless ). flat consistent surface is key for...

thingiverse

free

Mouse Eared Rocket Fincan by tbuser

...the fins to help prevent warping on this difficult raftless ...

thingiverse

free

Butterfly Ornament by bpijls

...bpijls thingiverse i used this butterfly model to test raftless printing of complex outlines using my heated build platform:...

thingiverse

free

Titanium Conveyor For Makerbot ABP and raftless printing by tmartin

...t. as far as i know this is still the only metal build surface that rotates and functions like the original conveyor belt though.

thingiverse

free

Motu MK828 MkII 19 by simongeist

...and iii as well. i printed it standard 0.3mm, raftless works...

Abp

3dfindit

free

ABP

...abp

3dfind.it

catalog: festo

3dfindit

free

ABP

...abp

3dfind.it

catalog: festo

thingiverse

free

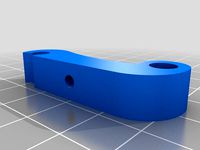

ABP belt tensioner arm for removable ABP mod by MarcusWolschon

...se

designed a shorter arm for the

abp belt tensioner, so it fits the different bolt-location when the removable abp mod is used.

3dfindit

free

SP10-ABP

...sp10-abp

3dfind.it

catalog: weidemann hydraulik

thingiverse

free

TOM ABP Side Replacement by skywurz

...tom abp side replacement by skywurz

thingiverse

tom (thing-o-matic) abp (automated build platform) replacement side

thingiverse

free

Paper bag catcher for makerbot ABP by natko

...paper bag catcher for makerbot abp by natko

thingiverse

its a paper bag catcher for abp

thingiverse

free

ABP wire clip by tomlombardi

...ep the abp wiring harness from flailing around. this thing allows you to quickly secure or remove the wiring harness to your abp.

thingiverse

free

Veruca ABP Modification by WiggyG

...at a time

-requires the use of acetone; you must use proper ventilation/safety precautions with acetone to prevent fire/explosion

thingiverse

free

Smykke med bogstaver ABP by Stolpepost

...smykke med bogstaver abp by stolpepost

thingiverse

mange seje tin xd

thingiverse

free

Thing-O-Matic ABP Bushing Holder by niloc

...ic abp bushing holder by niloc

thingiverse

i broke this piece on my abp for my thing-o-matic while trying to remove the bushing.

Tunell

3d_export

$4

metro tunel

...metro tunel

3dexport

metro tunel

turbosquid

free

Tunel

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$30

barchelona wall tunel

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

free3d

free

Tunel

...tunel

free3d

tunel with texture, low poly

thingiverse

free

Tunel NATM by thespot

...tunel natm by thespot

thingiverse

tunel con metodo constructivo natm.

modelo simple un frente.

thingiverse

free

Different fan tunel :) by yoyoek1

...different fan tunel :) by yoyoek1

thingiverse

two variation of fan tunel.

sketchfab

$13

Tunel, underground passage.

... an approximately horizontal gallery or corridor in a mine - tunel, underground passage. - buy royalty free 3d model by libanciel

thingiverse

free

Tunel LUME 3D printer by Nikusv13

...tunel lume 3d printer by nikusv13

thingiverse

cooling tunel for lume 3d printer

thingiverse

free

30mm tunel new by jaxda1

...30mm tunel new by jaxda1

thingiverse

new 30mm tunnel .

thingiverse

free

Star Cookie Cutter by Tunell

...star cookie cutter by tunell

thingiverse

this is a star cookie cutter, folks.

Conveyor

3d_export

$5

Conveyor

...conveyor

3dexport

conveyor

3d_export

$10

Conveyor

...conveyor

3dexport

conveyor flow

3d_export

$6

roller conveyor lineturning conveyor line

...roller conveyor lineturning conveyor line

3dexport

roller conveyor line(turning conveyor line)

3d_export

$7

Electric Conveyor

...electric conveyor

3dexport

electric conveyor

3d_export

$5

Belt conveyor

...belt conveyor

3dexport

belt conveyor

turbosquid

$35

conveyor

...d

royalty free 3d model conveyor for download as 3ds and c4d on turbosquid: 3d models for games, architecture, videos. (1255579)

3d_export

$5

conveyor belt

...conveyor belt

3dexport

conveyor for mine. 24 meters length.

3d_export

$10

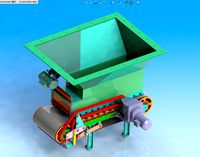

concrete mixing conveyor

...concrete mixing conveyor

3dexport

concrete mixing conveyor

3d_export

$10

conveyor-belt-for-dewatering

...conveyor-belt-for-dewatering

3dexport

conveyor-belt-for-dewatering

3d_export

$6

hopper roller conveyor

...hopper roller conveyor

3dexport

hopper roller conveyor

Belt

turbosquid

$9

Belt conveyor belt

...t conveyor belt for download as 3ds, ige, obj, stl, and sldas on turbosquid: 3d models for games, architecture, videos. (1226546)

3d_export

$6

belt

...d then comes off and fastens at the front of the seat. version: 2015 units: millimetres x-form: yes polys: 120 950 verts: 163 944

3d_export

$7

belt grinder

...belt grinder

3dexport

belt grinder

3d_export

$5

Belt conveyor

...belt conveyor

3dexport

belt conveyor

3ddd

$1

column belt

...column belt

3ddd

колонна

column belt

turbosquid

$5

Belt

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_ocean

$5

Leather Belt

...ather belt is created in 3dsmax 2011 and rendered with vray 1.5 and it has all the texture included with the multiple obj format.

3d_ocean

$5

Belt Ring

...belt ring

3docean

belt jewelry ring

belt ring 3d model. total weight 3.5 gram & 1.1 stone size. 3dm and obj file format.

design_connected

$11

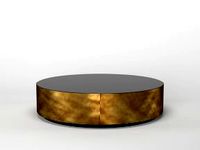

Belt Round

...belt round

designconnected

meridiani belt round computer generated 3d model. designed by parisio, andrea.

design_connected

$11

Belt Oval

...belt oval

designconnected

meridiani belt oval computer generated 3d model. designed by parisio, andrea.

Steel

3d_export

$10

Mask steel

...mask steel

3dexport

mask steel

turbosquid

$35

steel

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_ocean

$19

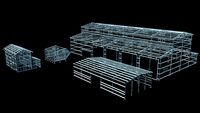

Steel Construction

...steel construction

3docean

construction frame h-beam house steel

4 models of steel construction. maya, obj, fbx

3ddd

$1

steel door

...steel door

3ddd

двери

steel door with black paint

archibase_planet

free

Steel Post

...steel post

archibase planet

fence balustrade

balustrade steel post

3d_export

$5

steel chair

...el chair

3dexport

a steel chair with leather and steel materials. 555.41 x 490.11 x 794 yes contains 4 leather materials 4.2

3d_export

$7

steel teapot

...steel teapot

3dexport

simple steel teapot. physical render. 28k polygons

3d_export

$25

tower steel

...tower steel

3dexport

steel tower 200 meters hight. autodesk revit 2019.2

3d_ocean

$4

Steel Tap

...athroom faucet green tiles shining faucet steel tap wall mounted silver tap

steel faucet mounted on green tiled wall of bathroom.

3d_export

$9

Steel Barrel

...steel barrel

3dexport

steel barrel - includes new and aged version - 4k png textures