Thingiverse

Sprenger Spindle Prusa V3 - fully water cooled with full-color diamond nozzle by Sprenger

by Thingiverse

Last crawled date: 3 years, 1 month ago

Upgrade:

this project has been closed and will not supported:

The Reason:

look here: https://www.thingiverse.com/thing:3590034

Upgrade 03.05.18

This Project has been stopped temporarely, because I'll buy my own 3D CNC milling machine:https://www.cnc-step.de/cnc-fraese-high-z-s-1000t-kugelgewindetrieb-1000x600mm/

(the link shows only the basic model)

Then I'll be able to create all the water-cooling Elements I need!

V3:

V3 will be water-cooled.

I want to modify some wooden parrts, but Piquard can't do it for me.

So I need a new specialist with a good working CNC milling machine.

The 1.8A Nanotec stepper motors will heat up the RAPS128 too much. a 120mm cooler cools permanently the RADDS. The motors which turns the spindles with the zero-tolerance screws need power. They heat up, too.

When printing Inofill ERP-PET with 140mm and 3D honeycomb infill, the motors (with coolers and fan) go down or loose steps after a time

First I bought a water-cooling kit from youprintin3D.https://youprintin3d.de/hotendszubehoer/e3d/wasserkuehlung/834/water-cooling-kit.html?number=Water-Cooling-Kit

Warning!!!

Never more! It's a very cheap chinese kit.

As it has been filled with coolant, bubbles came up, burst at the surface and some grey fume came out of them. The clear coolant changed into a milky sludge.

As it has been connected to the 12V power supply, none of the electrical components were working.

youprintin3D was not willing to take it back. They told me, that I was not able to connect it correctly. The + and - should have been changed and the electrical components damaged by me.

A friend of mine disassembles it and will identify the truth. And it looks good for me and the company which paid for that trash!

Update: youprintin3d contacted me. I should delete the entry above.

I'll never delete my impression about that product, but I'll delete my words about youprintin3d when they are willing to give me back the money.

First Step:

-Building alls parts, which are needed for the diamond nozzle.

-Building the base for a circuit which cools all my 9 stepper-motors, the 9 RAPS128 and the diamond Nozzle

Bought things:

Aqua Computer Aquastream Ultimate pump with Aquainlet Pro reservoir.

(Hot parts. You're able to connect them to your PC via USB. With the software you're able to control your system. Fans, temperature and flow control sensors can be directly connected to the pump or the reservoir. There are a lot of more options. You're old enough to read it yourself at manufactors side).

Update: The Aquastream pump is great, but it has been developed for PC cooling.

Problems:

1) The controlling Software is only available for Windows

2) the USB wires are confected for Mainboards. I modified them to plug them into a USB A port.

3) All the other wires are too short. The power connector is a SATA connector

Aqua Computer Radiator 240mm

Plug&Cool tube system 6/8mm with different connectors

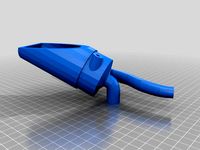

A Diamond Full-Color Nozzle water-cooled.

(It's fully assembled. That's a little bit tricky.

Problem to solve. The water connectors are too small for a full cirquit. The PUR tubes have 6mm ID. Other components 6-8mm ID. The connectors of the diamond nozzle has only 2 mm. The pressure rises. I'll solve the problem)

-BL-Touch smart height sensor for autobedleveling!

All parts for the diamond nozzle have been printed.

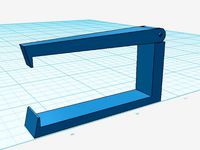

Spool holder

filament cleaner

holder for the stepper motors

the nozzle holder

All parts for the water pump have been printed.

Platform for the pump

Update: 25.03.2018:

The connectors for the 6/8mm tubes are implemented. Look at the photos.

The pressure for the pump has been decreased.

Now, I have to recreate the Holder!

Update: 17.04.18

After some testing, I decided to recreate the heatbreak system. The original heatbreaks are not really good.

When the printer retracts 2mm of one filament it cools down and clogs the heatbreak.

I'll test coated heatbreaks (from mapa-refining)

encapsulated with copper. The copper parts will be built into the cooling element.

Second Step:

develope and connect waterblocks for the RAPS128 and NEMA 17 stepper motors

(will follow)

this project has been closed and will not supported:

The Reason:

look here: https://www.thingiverse.com/thing:3590034

Upgrade 03.05.18

This Project has been stopped temporarely, because I'll buy my own 3D CNC milling machine:https://www.cnc-step.de/cnc-fraese-high-z-s-1000t-kugelgewindetrieb-1000x600mm/

(the link shows only the basic model)

Then I'll be able to create all the water-cooling Elements I need!

V3:

V3 will be water-cooled.

I want to modify some wooden parrts, but Piquard can't do it for me.

So I need a new specialist with a good working CNC milling machine.

The 1.8A Nanotec stepper motors will heat up the RAPS128 too much. a 120mm cooler cools permanently the RADDS. The motors which turns the spindles with the zero-tolerance screws need power. They heat up, too.

When printing Inofill ERP-PET with 140mm and 3D honeycomb infill, the motors (with coolers and fan) go down or loose steps after a time

First I bought a water-cooling kit from youprintin3D.https://youprintin3d.de/hotendszubehoer/e3d/wasserkuehlung/834/water-cooling-kit.html?number=Water-Cooling-Kit

Warning!!!

Never more! It's a very cheap chinese kit.

As it has been filled with coolant, bubbles came up, burst at the surface and some grey fume came out of them. The clear coolant changed into a milky sludge.

As it has been connected to the 12V power supply, none of the electrical components were working.

youprintin3D was not willing to take it back. They told me, that I was not able to connect it correctly. The + and - should have been changed and the electrical components damaged by me.

A friend of mine disassembles it and will identify the truth. And it looks good for me and the company which paid for that trash!

Update: youprintin3d contacted me. I should delete the entry above.

I'll never delete my impression about that product, but I'll delete my words about youprintin3d when they are willing to give me back the money.

First Step:

-Building alls parts, which are needed for the diamond nozzle.

-Building the base for a circuit which cools all my 9 stepper-motors, the 9 RAPS128 and the diamond Nozzle

Bought things:

Aqua Computer Aquastream Ultimate pump with Aquainlet Pro reservoir.

(Hot parts. You're able to connect them to your PC via USB. With the software you're able to control your system. Fans, temperature and flow control sensors can be directly connected to the pump or the reservoir. There are a lot of more options. You're old enough to read it yourself at manufactors side).

Update: The Aquastream pump is great, but it has been developed for PC cooling.

Problems:

1) The controlling Software is only available for Windows

2) the USB wires are confected for Mainboards. I modified them to plug them into a USB A port.

3) All the other wires are too short. The power connector is a SATA connector

Aqua Computer Radiator 240mm

Plug&Cool tube system 6/8mm with different connectors

A Diamond Full-Color Nozzle water-cooled.

(It's fully assembled. That's a little bit tricky.

Problem to solve. The water connectors are too small for a full cirquit. The PUR tubes have 6mm ID. Other components 6-8mm ID. The connectors of the diamond nozzle has only 2 mm. The pressure rises. I'll solve the problem)

-BL-Touch smart height sensor for autobedleveling!

All parts for the diamond nozzle have been printed.

Spool holder

filament cleaner

holder for the stepper motors

the nozzle holder

All parts for the water pump have been printed.

Platform for the pump

Update: 25.03.2018:

The connectors for the 6/8mm tubes are implemented. Look at the photos.

The pressure for the pump has been decreased.

Now, I have to recreate the Holder!

Update: 17.04.18

After some testing, I decided to recreate the heatbreak system. The original heatbreaks are not really good.

When the printer retracts 2mm of one filament it cools down and clogs the heatbreak.

I'll test coated heatbreaks (from mapa-refining)

encapsulated with copper. The copper parts will be built into the cooling element.

Second Step:

develope and connect waterblocks for the RAPS128 and NEMA 17 stepper motors

(will follow)

Similar models

3d_export

$15

Aquacomputer Aquastream XT USB 12V Pump 3D Model

...

water cooling pomp aquacomputer aquastream xt computer

aquacomputer aquastream xt usb 12v pump 3d model mackandco 37582 3dexport

thingiverse

free

Distillation coolant pump by svid123

...h 8v supply).

pump motor is over the ice water and it does not heat water coolant, which is important for effective water cooling

thingiverse

free

Jet propulsion pump by toto45

...3mm then it will be a watertight fit over the motorhousing.

the motor i use is a 4074 type.

this one here is not fully completed,

thingiverse

free

Centrifugal Water Pump for The Catfish/550 motor by hyperplanemike

...is for priming the pump and water cooling the motor.

update 7/16/15:

all new files - entire_thing.stl is now for reference only

thingiverse

free

Nema 17 Water Cooling by benzapprentice

...to a radiator, fan and water pump of your choice.

i uploaded the solidworks files to be able to rotate the models for your needs.

grabcad

free

Nozzle cooling water pump

...nozzle cooling water pump

grabcad

centrifugal pump for nozzle cooling of a ship engine

grabcad

free

Coolant Pipe | Length 300mm | Inlet 8mm dia | Outlet 6mm dia

...s needed, please let me know through the comments.

any new design needed, please comment that too. i'm always happy to help.

3dwarehouse

free

Coolant Pumps Unit N°2

...coolant pumps unit n°2

3dwarehouse

condenser coolant pumps nº2 #coolant #pump #unit #water

3dwarehouse

free

Coolant Pumps Unit N°1

...coolant pumps unit n°1

3dwarehouse

condenser coolant pumps nº1 #coolant #pump #unit #water

3dwarehouse

free

Coolant Pumps Unit N°3

...coolant pumps unit n°3

3dwarehouse

condenser coolant pumps nº3 #coolant #pump #unit #water

Sprenger

3d_export

$14

houseplants in a flowerpot for the interior 1025

...pots. houseplants exotic plants tropical plants reed, reed, grass sprenger#39;s asparagus aethiopicus...

thingiverse

free

Filament Guide and Cleaner for Filament Spool Floor Mount by Sprenger

...pool floor mount by sprenger

thingiverse

a remix for my remix filament spool floor mounthttp://www.thingiverse.com/thing:1625898

thingiverse

free

Filament Floor Mount by Sprenger

...as not mannifold!

try my remix:

filament guide and cleaner for filament spool floor mounthttp://www.thingiverse.com/thing:1625868

thingiverse

free

Ramps 1.4 enclosure by Sprenger

...he photos hasn't been used, because i bought a radds 1.5.

so it contains none of the two 50mm fans and nealy all the support!

thingiverse

free

18mm Capacitive/inductive sensor holder for Geeetech Prusa i3x by Sprenger

...uctive sensors (diameter).

the autolevelholder_3a.stl contains a little hole for the hotend cables,

the autolevelholder_3.stl not

thingiverse

free

Stepperdriver demount Tool for RADDS (and others) V1/V2 by Sprenger

... damage the electronical parts.

so i redesigned it. v2 print it with 0..2/ better 0.1mm

it's your choice which you'll use

thingiverse

free

Sprenger Spindle Prusa V1/V2 by Sprenger

...9;ll develope a totally new concept. tho most things are in my head. i'll try to find some sponsors to help me developing it.

thingiverse

free

e-cig stand for Provari 3 and other 23mm battery carrier by Sprenger

...y in a faster way.

if you don't like it, wait some time, take some abrasive paper or a dremel to widen the hole some microns.

thingiverse

free

Prusa i3 Dual MK8 X Carriage with capacitive/inductive sensor 12/18mm by Sprenger

... printing size is not affected!

the belt holder for this carriage can be downloaded here:http://www.thingiverse.com/thing:1003604

thingiverse

free

Hall-E - height adjustable endstop holder for Hall-E-Endstops by Sprenger

...an the real one. after that you have set g29)

i developed it for my spindel prusa, but you can easilly adapt it to other systems!

Spindle

3d_export

$5

simple spindle

...simple spindle

3dexport

simple spindle

design_connected

$7

Spindle shade

...spindle shade

designconnected

rothschild&bickers spindle shade computer generated 3d model.

design_connected

$9

Spindle Table

...spindle table

designconnected

ligne roset spindle table computer generated 3d model. designed by ascalon, brad.

design_connected

free

Spindle Clock

...spindle clock

designconnected

vitra spindle clock free models computer generated 3d model. designed by george nelson.

turbosquid

$10

Spindle Table

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$9

Spindle-chair

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$9

DVD Spindle

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$15

Spike Spindle 3D Model

...s procession spindled spindling spiking spearing spear document bill hole paperwork

spike spindle 3d model firdz3d 90192 3dexport

turbosquid

$15

Nelson Spindle Clock

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$2

Vitra Spindle Clock

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

V3

3d_export

$5

Poison-v3

...poison-v3

3dexport

poison-v3

3ddd

$1

Curtain v3

...curtain v3

3ddd

полупрозрачная штора v3

turbosquid

free

v3

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

potato v3

...potato v3

3dexport

turbosquid

$69

Skeletor v3

...royalty free 3d model skeletor v3 for download as ztl and obj on turbosquid: 3d models for games, architecture, videos. (1712713)

turbosquid

$49

Zombie v3

...

royalty free 3d model zombie v3 for download as obj and ztl on turbosquid: 3d models for games, architecture, videos. (1342458)

turbosquid

$2

Bitcoin v3

...

royalty free 3d model bitcoin v3 for download as c4d and prj on turbosquid: 3d models for games, architecture, videos. (1182845)

turbosquid

$29

Turret V3

...alty free 3d model turret v3 for download as ma, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1217498)

turbosquid

$20

Radiators v3

... free 3d model radiators v3 for download as max, max, and obj on turbosquid: 3d models for games, architecture, videos. (1607437)

turbosquid

$10

Wheel V3S

...e 3d model wheel v3s for download as 3ds, obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1344250)

Prusa

turbosquid

$2

Frame Filament Guide Clip-On for Prusa Mk3

...rame filament guide clip-on for prusa mk3 for download as stl on turbosquid: 3d models for games, architecture, videos. (1634730)

3d_export

free

prusa i3 mk3s laser mount for opt lasers

...to learn more about the blue laser technology that conceived the cutting and engraving laser heads from opt lasers, please visit:

turbosquid

free

Prusa small printer adapter holder

...er for download as ipt, skp, dwg, dxf, fbx, ige, obj, and stl on turbosquid: 3d models for games, architecture, videos. (1642936)

3d_export

$30

geisha by jonathan adler

...** i did a 3d printing test in the prusa software, you can find it among the attached images.<br>exchange:<br>.blend...

thingiverse

free

Prusa without Prusa (rc2) by madless

...prusa without prusa (rc2) by madless

thingiverse

just the main part of prusa rc2 faceshield, without writing.

enjoy :)

thingiverse

free

Prusa by acejbc

...prusa by acejbc

thingiverse

prusa knob info

m3 8mm screw

thingiverse

free

Prusa house

...prusa house

thingiverse

how prusa house could look like...

thingiverse

free

Prusa Mk2 "Fake Prusa" LCD cover by anraf1001

...r by anraf1001

thingiverse

version of prusa's lcd cover with "fake prusa" instead of "original prusa"

thingiverse

free

Prusa stabilizator by gutiueugen

...prusa stabilizator by gutiueugen

thingiverse

prusa stabilizator

thingiverse

free

Keychain Prusa by rbarbalho

...keychain prusa by rbarbalho

thingiverse

keychain with text prusa.

Nozzle

3d_export

$5

nozzle

...nozzle

3dexport

3d_export

$49

fuel nozzles

...fuel nozzles

3dexport

fuel nozzles 3d model. include max, obj, fbx files.

archive3d

free

Nozzle 3D Model

...archive3d

nozzle hair-drier ware

nozzle - 3d model (*.gsm+*.3ds) for interior 3d visualization.

turbosquid

$25

Pirouette Nozzle

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

Fuel Nozzle

...model fuel nozzle for download as c4d, fbx, obj, 3ds, and stl on turbosquid: 3d models for games, architecture, videos. (1672732)

turbosquid

$8

Aeration Nozzles

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$10

laval airjet nozzle

...laval airjet nozzle

3dexport

a simple modified laval nozzle (airjet shooter) for sorting purposes.

3d_export

$36

Gas nozzle 3D Model

... 3d model

3dexport

gas pump nozzle dispenser filling station petrol fuel spout tank gun

gas nozzle 3d model tartino 1945 3dexport

turbosquid

$10

Diecast Jet nozzle

... free 3d model diecast jet nozzle for download as obj and stl on turbosquid: 3d models for games, architecture, videos. (1425990)

turbosquid

$39

Rocket nozzle, supressor.

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Fully

turbosquid

$50

Drone fully rigged

...

royalty free 3d model drone fully rigged for download as max on turbosquid: 3d models for games, architecture, videos. (1282280)

turbosquid

$12

FULLY PARAMETRIC CHAIR

...alty free 3d model fully parametric chair for download as rvt on turbosquid: 3d models for games, architecture, videos. (1280209)

turbosquid

$10

firetruck-fully-rigged

...yalty free 3d model firetruck-fully-rigged for download as ma on turbosquid: 3d models for games, architecture, videos. (1653811)

turbosquid

$6

Fully rigged character

...ty free 3d model fully rigged character for download as blend on turbosquid: 3d models for games, architecture, videos. (1486076)

turbosquid

$3

Fully Rigged shark

...ee 3d model fully rigged 3d shark model for download as blend on turbosquid: 3d models for games, architecture, videos. (1517695)

turbosquid

$75

Fully Customizable Hospital

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Fully Rigged Link

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

design_connected

$16

Troy W Fully Covered

...troy w fully covered

designconnected

magis troy w fully covered computer generated 3d model. designed by wanders, marcel.

cg_studio

$99

Pepe fully rigged3d model

...ully rigged3d model

cgstudio

.max - pepe fully rigged 3d model, royalty free license available, instant download after purchase.

3d_export

$60

Ankylosaur 8K - fully animated

...ankylosaur 8k - fully animated

3dexport

Cooled

turbosquid

free

Cool Inc. Cool Box

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

cool penguin

...cool penguin

3dexport

cool penguin

turbosquid

$1

cooling

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$26

cooling tower

...ers.<br>model with full detail in real size. all nodes and bolted connections are built. it was designed for nuclear power.

3ddd

$1

Mantra Cool

...14 версиях и obj-файл, а также материал для включенного и для выключенного светильника. turbosmooth/meshsmooth при необходимости.

3d_export

$5

cool electric guitar

...cool electric guitar

3dexport

cool electric guitar

turbosquid

$5

Cooling glass

...quid

royalty free 3d model cooling glass for download as obj on turbosquid: 3d models for games, architecture, videos. (1193829)

turbosquid

$30

CPU Cooling

...royalty free 3d model cpu cooling for download as max and fbx on turbosquid: 3d models for games, architecture, videos. (1386263)

turbosquid

$5

Cool CLoud

...

royalty free 3d model cool cloud for download as ma and obj on turbosquid: 3d models for games, architecture, videos. (1572300)

3d_export

$5

table cooling fan

...table cooling fan

3dexport

table cooling fan made of black plastic. individual small size cooling fan for office desk.

Water

turbosquid

$2

water bin water tank

...e 3d model water bin water tank for download as blend and obj on turbosquid: 3d models for games, architecture, videos. (1594026)

archibase_planet

free

Water purifier

... purifier water purification water treatment

water purifier n050914 - 3d model (*.gsm+*.3ds+*.max) for interior 3d visualization.

3d_ocean

$6

glass water

...glass water

3docean

clear glass glass water

glass filled with water

3ddd

$1

Watering pot

...watering pot

3ddd

watering pot лейка поливалка , лейка

watering pot

3d_ocean

$12

Water Dispenser

...dispenser furnishings lowpoly water

this is a water dispenser hot water for tea is winter and summer is cold for souls. have fun!

3d_ocean

$2

Water

...water

3docean

this is a tile able, hand painted water texture tile. included is one versions at 512×512 pixels in .tga format.

3d_export

$6

water tanker

...water tanker

3dexport

water tanker

3d_export

$6

water bottle

...water bottle

3dexport

water bottle

3d_export

$5

water bottle

...water bottle

3dexport

water bottle

3d_export

$5

water thermos

...water thermos

3dexport

water thermos

Full

3ddd

$1

Full Mobili

...ull mobili , шкаф

группа шкафов, серия мебели "классика" фабрики «full mobili»

turbosquid

$80

full man body+full facials

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

Full Mobili

...сика , стол

стол круглый офисный серия мебели "классика" фабрики «full mobili»

3ddd

$1

FULL MOBILI

... стол

cтол офисный серии мебели "классика" итальянской компании full mobili

design_connected

$16

Full Circle

...full circle

designconnected

atmosphere full circle computer generated 3d model.

3d_export

$5

full office

...full office

3dexport

this is full office cgi model created with maya -detailed -textured -uv mapped

design_connected

$16

Full Moon

...full moon

designconnected

roche bobois full moon computer generated 3d model. designed by ragot, cedric.

turbosquid

$100

FULL KITCHEN

...squid

royalty free 3d model full kitchen for download as skp on turbosquid: 3d models for games, architecture, videos. (1345817)

turbosquid

$15

Full Bedroomset

...id

royalty free 3d model full bedroomset for download as max on turbosquid: 3d models for games, architecture, videos. (1540649)

3d_export

$10

full human body

...full human body

3dexport

it is a full human sculpt

Diamond

3d_ocean

$5

Diamond

...monds. render details. model is rendered in mental ray and renders setup is ready. diamonds are ready to render and photo real...

3d_export

free

diamond

...diamond

3dexport

diamond

3d_ocean

$5

Diamond

...of cinema 4d. included: diamond, material and the studio! there are 2 files included : diamond.c4d : diamond.obj thank you for...

3d_ocean

$5

Diamond

...diamond

3docean

4d c4d cinema diamond glass shine

diamond 3d model in cinema 4d, ready scene to render.

3d_export

$5

diamond

...diamond

3dexport

diamond cnc laser -3d printer -cnc router

3ddd

$1

Diamonds

... diamonds

высота: 156 см

диаметр: 48 смhttp://www.moltoluce.com/index.cfm?seite=diamonds&sprache;=en

3d_ocean

$3

Diamond

...this is a highly detailed, realistic diamond model made in maya. included: diamond, material. files included are .mb, .lox, .obj.

3ddd

$1

DIAMOND

.... nightstand

master bedroom collection

measures:

width: 770 mm (30.31 in.)

depth: 370 mm (14.56 in.)

height: 480 mm (18.89 in.)

3d_export

$7

diamond

...diamond

3dexport

realistic diamond includes: - fbx obj stl & 3ds - keyshot files

3ddd

$1

Diamond

... капитоне , угловой

диван фабрики marinelli. текстуры в архиве

Color

design_connected

$11

Colors

...colors

designconnected

zanotta colors lounge chairs computer generated 3d model. designed by ilkka suppanen.

3ddd

$1

pillows colors

...pillows colors

3ddd

pillows colors , подушка

pillows colors

3ddd

free

color dress

...3ddd

color dress , манекен , одежда

color dress

3ddd

$1

светильники Colors

... massive , бельгия

светильники massive серия colors, очень веселые

3d_export

$30

color chameleon

...color chameleon

3dexport

color chameleon

3ddd

$1

color vase

...color vase

3ddd

color vase

3d_ocean

$2

color pen

...3d model of color pen. model is based on edge loop topology. all materials are included. model is render ready and ready for use.

3ddd

$1

Color Parquet

...color parquet

3ddd

паркет

color parquet

3ddd

free

color console

...color console

3ddd

консоль

color console

3d_export

$5

Technum Color

...technum color

3dexport

technum color led от imperiumloft https://imperiumloft.ru/dizajn-loft/technum-color-led.html