Thingiverse

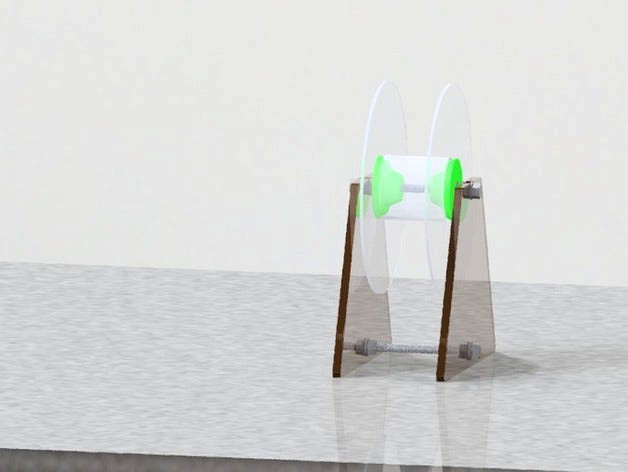

spool holder by fernydx

by Thingiverse

Last crawled date: 3 years ago

i received my 3d printer recently with a spool holder that i feel can be improved even if just a little

my printer came with a filament spool that had 55mm hub, later i bought 2 hatchbox rolls that had 30mm hubs, while printing they roll on an 8mm rod.

this is my attempt to making a spool holder for both.

i tried using a bearing at first but it failed, due to the bearing not having a cage built in.

after that i designed one with a cage, however the cage was too close to the inner and outer races so it bonded during print. so back to the drawing board.

------UPDATES-----

11/9 - edit 1:uploaded version 4 of bearing, have not tested but it should solve the original cage problem edit 2* i noticed a hiccup in repetier where the cage has a section that will still bond,therefore i do not recommend printing this yet, im currently redesigning the bearing itself.

edit 3 i have uploaded spool holder version 3 with edited internals to prevent contact with the inner bearing race

final edit uploaded bearing version 5 a lot less plastic but hopefully works :)

11/10 - Still haven't been home, but i just want to make it clear on the specs and how to use this, I recommend using an 8mm threaded rod, maybe 135-145mm length (I'm currently using 125mm), you may need the extra length for the 30mm hubs.

The bearing-less version has a 9mm pilot hole purposely meant to allow it to float on the shaft - i recommend using washers on each side and maybe a lock nut setup(2 nuts tightened into eachother) if possible, to hold it in place.

The bearing version on the other hand..... you may need to experiment with, currently up to date is the v5 bearing and the v3 spool holder, I have not had time to print this so all this is untested, except for bearing versions 1 2 and 3... which were for the most part failures...version 1 and 2 had problems where the actual ball bearings would group together causing friction, aaaaand version 3 the cage designed to prevent such issue bonded with the inner and outer race, making it 1 solid piece haha. version 4 had an issue were the bearing separator of the cage still bonded with the inner race, at least in Repetier-Host, which made me redesign the bearing to allow more space between the inner and outer races.

in theory all i was going to use the same lock nut setup mentioned up top, the i made the inner race pilot hole exactly 8mm to allow some friction with the shaft, this will ensure bearing operates properly.

Upload pics if you try id like to see them :)

any suggestions please let me know in the comments or pm me, im all ears!

my printer came with a filament spool that had 55mm hub, later i bought 2 hatchbox rolls that had 30mm hubs, while printing they roll on an 8mm rod.

this is my attempt to making a spool holder for both.

i tried using a bearing at first but it failed, due to the bearing not having a cage built in.

after that i designed one with a cage, however the cage was too close to the inner and outer races so it bonded during print. so back to the drawing board.

------UPDATES-----

11/9 - edit 1:uploaded version 4 of bearing, have not tested but it should solve the original cage problem edit 2* i noticed a hiccup in repetier where the cage has a section that will still bond,therefore i do not recommend printing this yet, im currently redesigning the bearing itself.

edit 3 i have uploaded spool holder version 3 with edited internals to prevent contact with the inner bearing race

final edit uploaded bearing version 5 a lot less plastic but hopefully works :)

11/10 - Still haven't been home, but i just want to make it clear on the specs and how to use this, I recommend using an 8mm threaded rod, maybe 135-145mm length (I'm currently using 125mm), you may need the extra length for the 30mm hubs.

The bearing-less version has a 9mm pilot hole purposely meant to allow it to float on the shaft - i recommend using washers on each side and maybe a lock nut setup(2 nuts tightened into eachother) if possible, to hold it in place.

The bearing version on the other hand..... you may need to experiment with, currently up to date is the v5 bearing and the v3 spool holder, I have not had time to print this so all this is untested, except for bearing versions 1 2 and 3... which were for the most part failures...version 1 and 2 had problems where the actual ball bearings would group together causing friction, aaaaand version 3 the cage designed to prevent such issue bonded with the inner and outer race, making it 1 solid piece haha. version 4 had an issue were the bearing separator of the cage still bonded with the inner race, at least in Repetier-Host, which made me redesign the bearing to allow more space between the inner and outer races.

in theory all i was going to use the same lock nut setup mentioned up top, the i made the inner race pilot hole exactly 8mm to allow some friction with the shaft, this will ensure bearing operates properly.

Upload pics if you try id like to see them :)

any suggestions please let me know in the comments or pm me, im all ears!

Similar models

thingiverse

free

Spool holder with bearing 6201rs by Little_Buddy

...der, but i had only such bearings.

bearing height = 10mm.

bearing outer diameter = 32mm; inner diameter = 12mm.

with 8mm adapter.

thingiverse

free

Sunlu PLA+ spool hub (72mm) by poorbullfrog

...z bearing. and i use it with the original spool holder and threaded rod. i use two nuts just touching the outer part of the hubs.

thingiverse

free

Spool Holder

...spool holder

thingiverse

will need:-

m4 bolt (8mm) and a t nut to secure to frame :-)

x2 bearings (22mm - outer, 8mm inner)

thingiverse

free

Spool hub with bearings by MaschinenCode

... 28mm and an inner diameter with 12mm. this hub is ideal for lowering the friction of the spool when printing flexible filaments.

thingiverse

free

TUSH Spool Holder for 6001 Bearings by FatsGW

...tush's original spool holder is for 608 bearings.

608 bearing dimensions:

inner diameter: 8mm

outer diameter: 22mm

width: 7mm

thingiverse

free

reduced friction Spool Holder by Connorus

...oolholder1.stl

4 bearings 20mm diameter

8mm threaded rod

20x20mm aluminium profile

spool holder which fits into the hole of spool

thingiverse

free

Spool Holder with 608 bearings by Chris42H

...me nuts.

the spool holder is designed to fit anything from 36mm spool hole diameter up. the outer diameter of the holder is 60mm.

thingiverse

free

Spool holder with bearings by Pitomio

...on. it should fit to most spools.

dimensions:

length: 118mm

width: 45mm

type of bearing(2x):

zkl 608-2zr - 22mm(outer), 8mm inner

thingiverse

free

Spool hub and holder. 52.5, 56.5 mm by galaxius

...the base bracket i used is the robo3d base bracket i designed.

2 x nuts per spool.

2 x 608 bearings per spool.

2 x hub per spool.

thingiverse

free

One Piece spool holder by junang3

... spool holder by junang3

thingiverse

stable spool holder

you need 4 of this and 4 x 608z bearing (22mm outer 8mm inner diameter)

Spool

3ddd

$1

spool c53301

...spool c53301

3ddd

spool

spool c53301 650х350х145

turbosquid

$3

Cable Spool

...royalty free 3d model cable spool for download as max and fbx on turbosquid: 3d models for games, architecture, videos. (1457009)

turbosquid

free

Pallets and Spool

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

Spool of String

...ol of string pink for download as c4d, 3ds, fbx, obj, and stl on turbosquid: 3d models for games, architecture, videos. (1647892)

3ddd

$1

Подвесные светильники Spool

...ye/podvesnoy_svetilnik_spool_d320/ http://www.cosmorelax.ru/catalog/podvesnyye/podvesnoy_svetilnik_spool_d420/

3ddd

free

Spool 001 sofa

...spool 001 sofa

3ddd

roda

roda

collection spool

design rodolfo dordoni

dimensions:

lenght 90 cm

depth 94 cm

height 79 cm

turbosquid

$15

Roda Spool Sofa

...ee 3d model roda spool sofa for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1502650)

turbosquid

$95

wire spools 3ds

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

spool of TV wire

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$3

Simple and Fast Spool Holder

...ree 3d model simple and fast spool holder for download as stl on turbosquid: 3d models for games, architecture, videos. (1548546)

Holder

archibase_planet

free

Holder

...holder

archibase planet

holder toilet paper holder

holder paper n070712 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Holder

...e planet

holder rack toilet paper holder

holder toilet roll n240715 - 3d model (*.gsm+*.3ds+*.max) for interior 3d visualization.

archibase_planet

free

Holder

...holder

archibase planet

pen holder support prop

pen holder - 3d model for interior 3d visualization.

archibase_planet

free

Holder

...holder

archibase planet

pole post holder

сhurch cross pole holder - 3d model for interior 3d visualization.

archibase_planet

free

Holder

...holder

archibase planet

holder bathroom ware

shower holder - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Holder

...oilet paper holder

holder paper devon&devon; time black n241113 - 3d model (*.gsm+*.3ds+*.max) for interior 3d visualization.

archibase_planet

free

Holder

...holder

archibase planet

holder hanger hanger for towel

holder 7 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Holder

...holder

archibase planet

holder hanger hanger for towel

holder 3 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Holder

...holder

archibase planet

holder towel rack towel-horse

holder - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Holder

...lder

archibase planet

holder hanger hanger for towel

holder towel n250912 - 3d model (*.gsm+*.3ds) for interior 3d visualization.