Thingiverse

Soldering Helping Hands Remixed³ by wavexx

by Thingiverse

Last crawled date: 3 years, 1 month ago

Soldering Helping hands, re-re-remixed

A further evolution of the re-remix, based on this, inspired by this which originated from this. Phew..

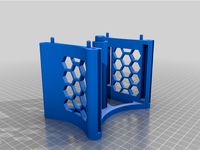

Third-hand designed to solder wires and/or component leads, featuring:

Adjustable distance between the clamps

Weighted support for stability (using 2x 40x80x2mm steel bars)

Ample space around the soldering job

Different clamp teeth for varying grip/hold

Press-down to open for improved ergonomics

Printing

Optimized for a 0.4mm nozzle, 0.2mm layers, 3 perimeters, 15-20% infill. No supports required.

Several printing options are available:

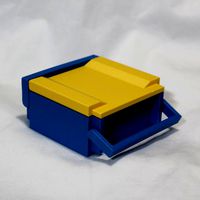

hands_full_plate.stl contains all printable parts. You'll need two 40x80x2mm steel bars to be used as weight and two short elastic bands.

hands_clamps_only.stl contains only the clamps. If you already printed the previous remix the base is compatible and can be reused (the new base differs just by slightly improved feet).

hands_solid_base.stl contains the full base as a solid single piece. If you don't care about the weight, you can print this along with hands_clamps_only.stl. Printing vertical is recommended: some friction provided by layer lines is beneficial.

hands_solid_core.stl can be used as a template for the weight size or printed in order to join the two hollow bases until you have the required hardware.

Assembly

Assembly is trivial. Fit two 40x80x2mm steel bars stacked on top of each other on one end of the base:

If the fit is not tight, a dab of hot glue is recommended in order to keep the base steady. The base has four thin feet to avoid wobble, however adding adhesive rubber pads is still recommended to avoid sliding.

Fitting the elastic on the clamps is more annoying. Use some packing wire and wrap a short elastic around it, making as many turns as required (more turns = stiffer clamp):

Bend the wire into an U shape, then insert the wire into one hole of the clamp:

Insert the pin between the elastic loops (hold it from both sides using your fingertips), then pull the wire to drag it fully into the slot:

Join the articulated lever, then repeat:

Pull on the wire to make space for the second pin into the elastic, then release.

Open and close the clamp a few times to test it. If it's too hard, remove one loop from the elastic. If it's too soft, add a loop instead. Remove the packing wire when satisfied.

A further evolution of the re-remix, based on this, inspired by this which originated from this. Phew..

Third-hand designed to solder wires and/or component leads, featuring:

Adjustable distance between the clamps

Weighted support for stability (using 2x 40x80x2mm steel bars)

Ample space around the soldering job

Different clamp teeth for varying grip/hold

Press-down to open for improved ergonomics

Printing

Optimized for a 0.4mm nozzle, 0.2mm layers, 3 perimeters, 15-20% infill. No supports required.

Several printing options are available:

hands_full_plate.stl contains all printable parts. You'll need two 40x80x2mm steel bars to be used as weight and two short elastic bands.

hands_clamps_only.stl contains only the clamps. If you already printed the previous remix the base is compatible and can be reused (the new base differs just by slightly improved feet).

hands_solid_base.stl contains the full base as a solid single piece. If you don't care about the weight, you can print this along with hands_clamps_only.stl. Printing vertical is recommended: some friction provided by layer lines is beneficial.

hands_solid_core.stl can be used as a template for the weight size or printed in order to join the two hollow bases until you have the required hardware.

Assembly

Assembly is trivial. Fit two 40x80x2mm steel bars stacked on top of each other on one end of the base:

If the fit is not tight, a dab of hot glue is recommended in order to keep the base steady. The base has four thin feet to avoid wobble, however adding adhesive rubber pads is still recommended to avoid sliding.

Fitting the elastic on the clamps is more annoying. Use some packing wire and wrap a short elastic around it, making as many turns as required (more turns = stiffer clamp):

Bend the wire into an U shape, then insert the wire into one hole of the clamp:

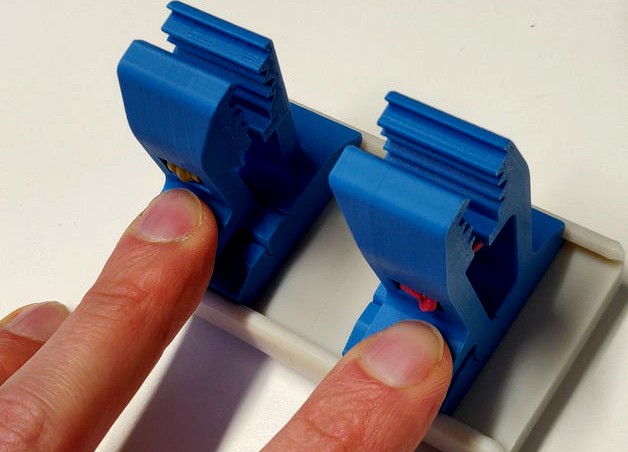

Insert the pin between the elastic loops (hold it from both sides using your fingertips), then pull the wire to drag it fully into the slot:

Join the articulated lever, then repeat:

Pull on the wire to make space for the second pin into the elastic, then release.

Open and close the clamp a few times to test it. If it's too hard, remove one loop from the elastic. If it's too soft, add a loop instead. Remove the packing wire when satisfied.

Similar models

thingiverse

free

Soldering Helping Hands Re-Remix

... base has two thin legs to avoid wobble which will get you started. however i still added four thin rubber pads to avoid sliding.

grabcad

free

Solder Organizer

...50 grams.

as a result you get really compact and solid organizer which will help you avoid the mess on your workshop's desk.

thingiverse

free

Electrical Wire Spool

... pieces, the hole in the cylinders are lined up. if they're not, you can't attach the beginning of the wire to the spool.

thingiverse

free

Soldering Cable Holder by apexskier

...lder. it avoids damage that can be cause by alligator clips on a helping hand.

printing time lapse – https://youtu.be/nhj6ezel46e

thingiverse

free

Weighted Soldering hand Base by PrintAddiction

...as well will add later.

prints with base flat on build plate no supports

requires cooling lines

1 3/4 x bolts course thread bolt

thingiverse

free

Reversible Elastic Band PCB vice vise by Hagster

...b vice is ideal for holding your parts.

an optional cable clamp can be used to hold wires and cables in place while you solder.

thingiverse

free

Soldering iron tip cleaner, steel wire container by szalat

...dering-solder-iron-tip-cleaner-cleaning-steel-wire-with-stand-set-soldering-iron-stand/32580430800.html

you need only steel wire.

thingiverse

free

Wire Coupler

...r to avoid shorts.

these should be used as an alternative when soldering is impossible, or if you have to make quick connections.

thingiverse

free

Helping Hand Base - Soldering Assistant by HJW012

...t x 4 (required)

m3 nut x 4 (required)

rubber feet x 8 (not required)

weight x 1 (not required)

helping hand x 8 (required) (duh)

thingiverse

free

solder reel stand by Jaisl

...xt element, but the fitment is tight enough to just press fit the elements together. main body is printed in pla, and feet in tpu

Wavexx

thingiverse

free

Petri Dish Cap by wavexx

...cap by wavexx

thingiverse

a simple cap for a standard petri dish.

in this case it was printed in black to act as a light shield.

thingiverse

free

STM32 Nucleo F4 / F4* bumper by wavexx

...stm32 nucleo f4 / f4* bumper by wavexx

thingiverse

super-simple, minimal bumper for the st nucleo f4* boards.

thingiverse

free

Tarantula display hanging hooks by wavexx

...arantula display to a vertical surface, such as the side of a cabinet. the hooks must be glued (i used strong double-sided tape).

thingiverse

free

Cat Stand for IPhone 5 by wavexx

...r it wins on cuteness alone.

stretch on z as desired. might hold other mobiles, however getting the right fit can be challenging.

thingiverse

free

Piston Keychain (press-fit version) by wavexx

...required! i used a vice:

https://youtu.be/d8rxq-3lft8

tested with petg, 0.2 layers, 0.4 nozzle, 2 perimeters, no infill required.

thingiverse

free

GM328 Transistor-tester battery holder by wavexx

...around the pcb (<0.1mm gap). push firmly the pcb until it snaps into place. m3 screws can be directly fastened on the support.

thingiverse

free

Sausage Dipole Antenna mount by wavexx

...up. when satisfied, line the interior with silicone and close shut.

be sure to take an action shot during the first comm-check ;)

thingiverse

free

Zassenhaus coffee grinder Sliding Cap by wavexx

...ate freely, with just a little bit of friction.

petg with 0.4 nozzle, 0.2 layer height, 4 perimeters and 100% infill recommended.

thingiverse

free

Orange Scientific Comfopette screw-cap v2 by wavexx

...ue. please note the correct orientation of the teeth by looking at the images (same as provided in the model: teeth lining down).

thingiverse

free

IFlight XL5 BN-880 GPS holder by wavexx

... support holes (these are press-fit) until the bottom faces are flush. once screwed back in place the holder/gps is fully locked.

Soldering

3d_export

$6

Solder toy

...solder toy

3dexport

solder toy arnold render

3d_export

$6

Automatic soldering machine

...automatic soldering machine

3dexport

automatic soldering machine

turbosquid

$10

Solder Tools

...rbosquid

royalty free 3d model solder tools for download as on turbosquid: 3d models for games, architecture, videos. (1624226)

turbosquid

$1

Solderer simple

...squid

royalty free 3d model solderer simple for download as on turbosquid: 3d models for games, architecture, videos. (1171836)

turbosquid

$2

tin for soldering

...free 3d model tin for soldering for download as blend and fbx on turbosquid: 3d models for games, architecture, videos. (1689841)

turbosquid

$1

Soldering Iron

...ty free 3d model soldering iron for download as obj and blend on turbosquid: 3d models for games, architecture, videos. (1447146)

3d_export

$15

Solder 3D Model

...model 3dexport solder fusible metal alloy join melt melting soldering iron electronic gun alloys tin lead electrical wire coil...

turbosquid

$14

Soldering iron

...d model soldering iron for download as 3ds, max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1389924)

turbosquid

$13

Soldering station

...el soldering station for download as blend, fbx, obj, and stl on turbosquid: 3d models for games, architecture, videos. (1552016)

turbosquid

$5

Steel solder

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Remixed³

turbosquid

$5

MODA Collection Remix Chair

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$12

remix yamaha rm1x

...remix yamaha rm1x

3dexport

geometry triangles 15.2k vertices 7.6k pbr no textures 1 materials 1 uv layers yes

3d_ocean

$5

Vray fabric Kvadrat remix green - tileable

...th vray and 3dsmax. high-resolution texture images (2000×2000 px) file included: shader vray 2.40 texture image 3ds max 2011 file

turbosquid

$20

Gerrit Rietveld 1938 Zig Zag Chair Remix

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$10

multicolored remix parametric table furniture

... fbx, obj, mtl, archive with textures. the model has no glitches. render and materials - vray . without using plugins. good use!

3ddd

$1

Barovier&Toso / Manhattan Remix 7192

... 004293-142405

в коллекции есть люстры 7, 9, 12 рожковые. диаметр соответственный 1000, 1250, 1500 мм.

3ddd

$1

Muuto fiber chair

...ture/black, nature/oak, remix 133/grey, remix 183/black, remix 643/dusty red, black silk leather/black, cognac silk leather/black

3ddd

$1

Barovier&Toso 7190-7195

...лочнай люстра фабрики barovier&toso;, коллекция manhattan remix, артикул 7190-7195.

размеры в inches: 39" 1/2wх26"h

3d_export

$5

3D Locking Handle Weatherproof Storage Box Container

... silicone to make a watertight seal. original box: https://cults3d.com/en/3d-model/gadget/3d-locking-rugged-storage-box-container

cg_studio

$49

HTC One Mini 2 Amber Gold3d model

...bj .mb .lwo .fbx .c4d .3ds - htc one mini 2 amber gold 3d model, royalty free license available, instant download after purchase.

Hands

3d_export

$8

hand

...hand

3dexport

fantasy hand

3d_export

$5

hand

...hand

3dexport

male hand

3d_export

$5

hand

...hand

3dexport

realistic male hand

3d_export

$5

hand

...hand

3dexport

hand with nails and structure

archibase_planet

free

Hand

...hand

archibase planet

hand

hand n190111 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3ddd

$1

Hand

...hand

3ddd

hand

модель руки будды

3d_export

$5

hand

...hand

3dexport

it is my wrist of hand and this is on 3d sculpt

3d_export

$5

hand

...hand

3dexport

realistic male hand obj file

3d_export

$7

hand-006 rigged hand

...hand-006 rigged hand

3dexport

rigged right hand 3d model additional textures for pbr rendering included

3d_ocean

$6

Hand

...poly rigged texture two this 3d models of the hands made in 3ds max, has textures(.jpg), materials(.mat), rigged, the...

Helping

3d_export

$5

Woman offering help

...woman offering help

3dexport

woman offering help

3ddd

$1

COUPLE STATUE man help

...couple statue man help

3ddd

статуэтка

couple statue man help

turbosquid

free

help wanted biplane banner.blend

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$7

German soldier ww2 help wounded G5

... 3d model german soldier ww2 help wounded g5 for download as on turbosquid: 3d models for games, architecture, videos. (1687738)

turbosquid

$3

Uttermost Helping Hand Nickel Plated Bookends

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$45

3d Printable May I Help YOu sign STL OBJ 3D Model

...ntable sign may help you mall airport public sidnaique

3d printable may i help you sign stl obj 3d model sidnaique 48477 3dexport

3d_export

free

Diamond Ring

...diamond ring

3dexport

blue diamond ring. who needs help in 3d, please contact, i will be glad to help.

3d_export

$15

police badge photorealistic pbr low-poly

...police badge photorealistic pbr low-poly

3dexport

need help, support, or questions? contact me, i'll be happy to help.

3ddd

$1

Door

...door

3ddd

двери

hope it helps .

3d_export

$15

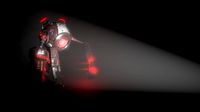

Prototype version of the robot assistant

...a person in a variety of tasks, both in helping in the garden and in armed...