GrabCAD

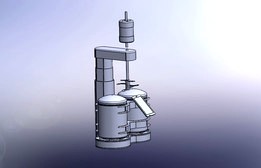

small cheese machine - part1

by GrabCAD

Last crawled date: 1 year, 2 months ago

...does it make sense to construct a small cheese machine - for the household, for small businesses - with which you can process small quantities of milk from a few animals - goats, sheep - yourself into cream, butter, cheese?

shall we say - a small machine for 2 x 5 liters with a gas cooker, stirrer, cheese curd press - and the possibility of producing whole milk, or UHT milk or milk from water, milk powder and cream or butter yourself?

a kind of double boiler with two hotplates, which makes it possible to boil milk in a water bath, to sterilize it, to thicken and press the milk - then to pump whey into the second vessel in order to produce whey cheese, soft cheese there!

let's say you have two or three goats and you have to do something with the goats' milk every day. a goat gives about 3-4 liters a day - about 250 days a year! with three goats, that would be 9-12 liters of milk a day.

and boiling the milk by hand would be too cumbersome, as would shaping and storing the cheese!

let's say - someone has an inn - and because the site is a bit larger - you need goats to keep the property in a manageable condition! goats eat everything, so to speak.

8-9 goats quickly come together and deliver 24-

27-36 liters of milk: it would make sense to process it on site...

you can make at least two cheeses from 5 liters of milk: the hard cheese and a soft cheese or white cheese, whatever!

ideal for gastronomy that wants to offer cheese dishes and gratins.

so i think: it makes sense to construct a cheese machine!

we start here first with the pots and the inserts.....

We can also use the two cookers to fry, cook, roast and prepare other things - it doesn't always have to be cheese production: this makes the cheese machine here versatile!

ideal for large families and restaurants!

basic requirements:

- automatic, fully automatic system

- two times 5 liters capacity

- production in the first step- cream for the production of

pure fat butter and cream

- Production in the second step of hard cheese with a protective wax layer for maturing d=162 mm, h= 48 mm- weight approx. 980 grams of raw cheese mass

- Processing of whole milk and whey, also UHT milk and milk

dried milk flakes with water and cream

- production in the third step - cheese, soft cheese from the whey of the second production

- Gas heated with butane, propane, butane-propane mixture, methane gas

- cooking and cooling with double-walled water cooling in the containers

step, igs, stl, pdf

shall we say - a small machine for 2 x 5 liters with a gas cooker, stirrer, cheese curd press - and the possibility of producing whole milk, or UHT milk or milk from water, milk powder and cream or butter yourself?

a kind of double boiler with two hotplates, which makes it possible to boil milk in a water bath, to sterilize it, to thicken and press the milk - then to pump whey into the second vessel in order to produce whey cheese, soft cheese there!

let's say you have two or three goats and you have to do something with the goats' milk every day. a goat gives about 3-4 liters a day - about 250 days a year! with three goats, that would be 9-12 liters of milk a day.

and boiling the milk by hand would be too cumbersome, as would shaping and storing the cheese!

let's say - someone has an inn - and because the site is a bit larger - you need goats to keep the property in a manageable condition! goats eat everything, so to speak.

8-9 goats quickly come together and deliver 24-

27-36 liters of milk: it would make sense to process it on site...

you can make at least two cheeses from 5 liters of milk: the hard cheese and a soft cheese or white cheese, whatever!

ideal for gastronomy that wants to offer cheese dishes and gratins.

so i think: it makes sense to construct a cheese machine!

we start here first with the pots and the inserts.....

We can also use the two cookers to fry, cook, roast and prepare other things - it doesn't always have to be cheese production: this makes the cheese machine here versatile!

ideal for large families and restaurants!

basic requirements:

- automatic, fully automatic system

- two times 5 liters capacity

- production in the first step- cream for the production of

pure fat butter and cream

- Production in the second step of hard cheese with a protective wax layer for maturing d=162 mm, h= 48 mm- weight approx. 980 grams of raw cheese mass

- Processing of whole milk and whey, also UHT milk and milk

dried milk flakes with water and cream

- production in the third step - cheese, soft cheese from the whey of the second production

- Gas heated with butane, propane, butane-propane mixture, methane gas

- cooking and cooling with double-walled water cooling in the containers

step, igs, stl, pdf

Similar models

grabcad

free

Milk dairy plant

... plant design. completed dairy process machine raw milk to cream ,cheese ,butter ,sweets and ghee production units in this plant.

grabcad

free

Dairy Cheese Production Plant (Turnkey)

...soft water units

hot water - cold water units

if you have questions, please contact : iayastro@gmail.com and iay@yagmurmedya.com

grabcad

free

mold for small cheese

... production of small cheese from sheep's milk, goat's milk ...

also suitable for automation ......

step, igs, solidworks

grabcad

free

Machine Cheese making

...rabcad

design cheese making machine for milk product cheese items. design for cheese product.solid works software used in this.

grabcad

free

Mozzarella cheese making machine

...rabcad

design cheese making machine for milk product cheese items. design for cheese product.solid works software used in this.

grabcad

free

cheese processing-1

...itable - double-walled - for cooling the fresh milk and should also be used for both purposes, for the sake of simplicity.

step

grabcad

free

hand-cheese 125

...grabcad

here the molds for goat's cheese, hand-held cheese for daily production in small portions ...

step, igs, solidworks

cg_trader

$15

Butane Gas Bottle

...butane gas bottle

cg trader

a detailed 3d model of a butane/propane gas bottle and regulator.

grabcad

free

forms for soft cheese

...ing like that: just we press there the cheese - and fill it as parts - to "cream blanc" processed from.

step, igs, stl

grabcad

free

hand-cheese 160 mm

...the molds for goat cheese, sheep's cheese, hand-held cheese for daily production in small portions ...

step, igs, solidworks

Part1

turbosquid

$1

Part1

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$15

KREOO SINK part1

...model kreoo sink part1 for download as 3ds, max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1443519)

turbosquid

$59

City lowpoly PART1

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$7

castle pack part1

...e element for your projects.<br>low polygon, fast rendering, realistic coating and appearance, suitable for computer games.

3ddd

$1

Italian Sofa Collection Part1-002

...italian sofa collection part1-002

3ddd

модульный

italian sofa collection part1-002

3d_export

$25

Bmw x6 part1 3D Model

...bmw x6 part1 3d model

3dexport

bmw x6 part1 3d model evgeniy bishev 26497 3dexport

turbosquid

$15

VIVA LUSSO SPRING part1

... 3d model viva lusso spring part1 for download as max and fbx on turbosquid: 3d models for games, architecture, videos. (1444540)

turbosquid

$15

VIVA LUSSO bath part1

...ee 3d model viva lusso bath part1 for download as max and fbx on turbosquid: 3d models for games, architecture, videos. (1444537)

turbosquid

$15

KREOO LOTO SINK part1

... kreoo loto sink part1 for download as 3ds, max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1443608)

turbosquid

$15

CONTENITORI UNIVERSALI EVO part1

...i universali evo part1 for download as 3ds, max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1443605)

Cheese

3d_export

$20

cheese line

...cheese line

3dexport

cheese line

design_connected

$13

Cheese

...gnconnected

photo-realistic 3d models of the cheese stool from riva 1920 for 3d architectural and interior design presentations.

turbosquid

$1

Cheese

...

turbosquid

royalty free 3d model cheese for download as max on turbosquid: 3d models for games, architecture, videos. (1448392)

turbosquid

$4

Cheese

...uid

royalty free 3d model cheese for download as obj and fbx on turbosquid: 3d models for games, architecture, videos. (1686453)

turbosquid

$15

Cheese

...ty free 3d model cheese for download as ma, max, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1553160)

turbosquid

$29

Cheese

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$29

Cheese

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$15

Cheese

...ee 3d model cheese for download as ma, max, fbx, dae, and obj on turbosquid: 3d models for games, architecture, videos. (1616065)

turbosquid

$6

Cheese

...3d model cheese for download as 3ds, obj, fbx, blend, and dae on turbosquid: 3d models for games, architecture, videos. (1168919)

turbosquid

$4

Cheese

...e 3d model cheese for download as max, 3ds, fbx, obj, and stl on turbosquid: 3d models for games, architecture, videos. (1669465)

Machine

archibase_planet

free

Machine

...machine

archibase planet

sewing-machine sewing machine equipment

singer machine- 3d model for interior 3d visualization.

archibase_planet

free

Machine

...hine

archibase planet

percolator equipment coffee-machine

machine n230708 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Machine

...chibase planet

percolator coffee-machine kitchen equipment

coffee machine - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Slot machine

...ase planet

slot machine slot-machine playing machine

slot machine n260311 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

turbosquid

$7

Machine

...ne

turbosquid

royalty free 3d model machine for download as on turbosquid: 3d models for games, architecture, videos. (1391792)

3d_ocean

$10

War machine

...war machine

3docean

camuflage machine robot war war machine

war machine created in 3dmax 2009 15.497-poly count

turbosquid

$7

machine

...turbosquid

royalty free 3d model machine for download as obj on turbosquid: 3d models for games, architecture, videos. (1452674)

3d_ocean

$12

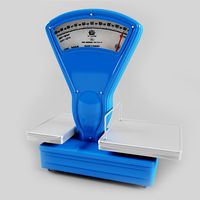

Weighing-machine

...weighing-machine

3docean

market shop weighing-machine

3d model weighing-machine

archibase_planet

free

Sewing machine

...ine

archibase planet

sewing machine sewing-machine

sewing machine n080311 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Coffee machine

...se planet

coffee machine percolator coffee-machine

coffee machine n010715 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

Small

3d_export

$10

small bed

...small bed

3dexport

small bed design for small house or small room with storage

3d_export

$10

small house

...small house

3dexport

a small house. the project of a small country house.

3d_ocean

$4

Small Cake

...small cake

3docean

cake food small

just a small cake ready for render

3d_export

$6

small armchair

...small armchair

3dexport

small armchair

3d_export

$5

a small world

...a small world

3dexport

a small world

3d_export

$5

small room

...small room

3dexport

small cozy room

3d_export

$5

small tank

...small tank

3dexport

small tank modeling in blender

design_connected

free

small lounge

...small lounge

designconnected

free 3d model of small lounge

design_connected

$11

Watermelons Small

...watermelons small

designconnected

watermelons small computer generated 3d model.

3d_export

$5

small house

...small house

3dexport

a small cozy house on the foundation, the interior is missing.