Thingiverse

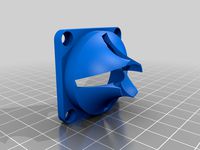

Slim Rostock Max V3/HE280 Fan Shroud, Light Weight, Rounded by TimStough

by Thingiverse

Last crawled date: 3 years ago

BIG UPDATE 11/7/2017:

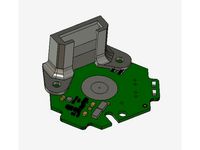

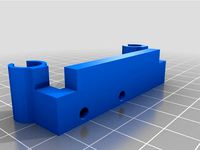

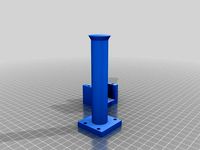

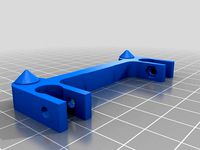

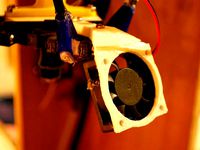

After many redesigns and tests, I am posting the 5th (and I hope final) version. This shroud fits within the slim enclosure and allows printing to the edge without hitting the bed clips. The autocalibration wizard and OctoPrint plugins run flawlessly. I should really do some bridging tests to see how much this improves bridging, but it does put a bunch of air on the plastic without cooling the nozzle. Also, note the green bowden coupler above the fans; this allows easier filament changes when the tube is tightened into the HE280 hot end. I have included STLs for the coupler and a Tall PTC tool so that you can tighten down the bowden tube without removing the fans. The coupler uses the following fittings: https://www.amazon.com/gp/product/B01IB81IHG

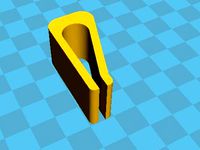

I have reprinted all of the parts in the Yellow PETG that you see in image for strength and heat resistance. I think that the fan shroud might be too close to the heater block to use PLA.

Note 3/23/2017:

I recognize that these shrouds cause issues printing at the very edge of the bed due to the bed clips and the enclosure wall. These shrouds currently prevent the 10 point auto-calibration via the SeeMeCNC wizard or the OctoPrint Delta Plugin. I am currently working on a redesign, but am not ready to post. If you wish to run the 10 point auto-calibration, please remove the fan shrouds to prevent crashes.

Update 1/24/2017:

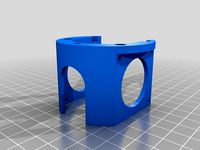

V2 is based on feedback that the shroud exit was too low and was hitting prints. This is designed to give more clearance (1mm from bottom to nozzle exit with the stock nozzle) and to direct the flow below the heater block. I've also slimmed the main duct to reduce chance of arm collision.

Original 1/23/2017:

From Noircogi: "This mod moves the three part fans on the HE280 in and up above the hot end. The point of this mod is to allow a narrow enclosure. The stock part fan layout moves the fans considerably outside the base frame when the head is near the bed limits. This allows full travel with a narrow enclosure.

Airflow is a bit less, but better directed. You still will not need to run the fans at 100% in my experience.

You will need to trim the small plastic tabs on the effector plate before installing the shrouds."

I would also like to credit http://www.thingiverse.com/thing:1900098 for inspiring the shape of the end of duct and the wall thickness and for pointers to the hotend models.

My contribution here is to make the part lighter, more rounded, and to improve the direction of the airflow towards the space directly beneath the nozzle. On my hotend, the shroud easily clears the bed/part when using the stock nozzle. This means that with the longer ED3 nozzles, there should be no clearance issues at all.

After many redesigns and tests, I am posting the 5th (and I hope final) version. This shroud fits within the slim enclosure and allows printing to the edge without hitting the bed clips. The autocalibration wizard and OctoPrint plugins run flawlessly. I should really do some bridging tests to see how much this improves bridging, but it does put a bunch of air on the plastic without cooling the nozzle. Also, note the green bowden coupler above the fans; this allows easier filament changes when the tube is tightened into the HE280 hot end. I have included STLs for the coupler and a Tall PTC tool so that you can tighten down the bowden tube without removing the fans. The coupler uses the following fittings: https://www.amazon.com/gp/product/B01IB81IHG

I have reprinted all of the parts in the Yellow PETG that you see in image for strength and heat resistance. I think that the fan shroud might be too close to the heater block to use PLA.

Note 3/23/2017:

I recognize that these shrouds cause issues printing at the very edge of the bed due to the bed clips and the enclosure wall. These shrouds currently prevent the 10 point auto-calibration via the SeeMeCNC wizard or the OctoPrint Delta Plugin. I am currently working on a redesign, but am not ready to post. If you wish to run the 10 point auto-calibration, please remove the fan shrouds to prevent crashes.

Update 1/24/2017:

V2 is based on feedback that the shroud exit was too low and was hitting prints. This is designed to give more clearance (1mm from bottom to nozzle exit with the stock nozzle) and to direct the flow below the heater block. I've also slimmed the main duct to reduce chance of arm collision.

Original 1/23/2017:

From Noircogi: "This mod moves the three part fans on the HE280 in and up above the hot end. The point of this mod is to allow a narrow enclosure. The stock part fan layout moves the fans considerably outside the base frame when the head is near the bed limits. This allows full travel with a narrow enclosure.

Airflow is a bit less, but better directed. You still will not need to run the fans at 100% in my experience.

You will need to trim the small plastic tabs on the effector plate before installing the shrouds."

I would also like to credit http://www.thingiverse.com/thing:1900098 for inspiring the shape of the end of duct and the wall thickness and for pointers to the hotend models.

My contribution here is to make the part lighter, more rounded, and to improve the direction of the airflow towards the space directly beneath the nozzle. On my hotend, the shroud easily clears the bed/part when using the stock nozzle. This means that with the longer ED3 nozzles, there should be no clearance issues at all.

Similar models

thingiverse

free

Slim Rostock Max V3 part fan shroud by Noircogi

... 100% in my experience.

you will need to trim the small plastic tabs on the effector plate before installing the shrouds.

print 3

thingiverse

free

Printrbot Metal Plus Fan Shroud by dhayman11

...e existing harware and replaces the stock fan shroud on the printrbot metal plus. i printed the part out of petg at 100% infill.

thingiverse

free

Artist-D Circular Shroud for stock 4010 Blower Fan by ericlam_UCSF

...oud rather than leaking at fan/shroud interface.

may need to widen screw holes to prevent breaking if using screw to tap threads.

thingiverse

free

Robo R2 Improved Shroud by weston1968

...u will never get a heater failure no matter how high you set the fans. the air flow is so precise that i never go above 45% fan.

thingiverse

free

Modified Fan Shroud for Hexagon Hot End for my Makerfarm. by sTiNkFiZzLe

...e heater block was not touching shroud but still blocking airflow from heater block and lower. i will try to post pictures soon.

thingiverse

free

Dual MK8 parts fan shroud by bkgray115

...fan shroud by bkgray115

thingiverse

v3 is for running stock fans on the direct drive heatsinks - v2 is for running without fans

thingiverse

free

HE280 Fan Shroud by JMargush10

... could make an enclosure. there is no need to buy any more screws because this uses the screws from the injection molded shrouds.

thingiverse

free

Rostock Max Fan 25mm Shroud for HE280 by EhisforAdam

...l screws to attach it the the platform and wired everything based on the standard instructions with zip ties for wire management.

thingiverse

free

SeeMeCNC HE280 Fan Shrouds v2 by 80am33

...teration as i type. the only difference between this listing and the ones in the photos is the size of the air duct output holes.

thingiverse

free

Fan Shroud - Printrbot Metal Plus V0.2 by Phaenom

...irects airflow from blower fan around the nozzle to cool the part.

this design is still a work in progress so expect more changes

Timstough

thingiverse

free

ProStruder Locking Lever by TimStough

... freely. i rubbed a bit of bees wax on the sides near the hole. if you don't have bees wax, candle wax would work fine here.

thingiverse

free

Dual ProStruder Mount for Rostock Max v3 by TimStough

...a bit oversized to help with tolerances.

search on the prostruder tag to find the filament guides and the locking release button.

thingiverse

free

NEMA 17 Fan Duct for ProStruder in Rostock Max v3 by TimStough

... with the prostruder using small zip ties.

sorry for the lack of photos, they are already humming away bolted inside the printer.

thingiverse

free

TS100 Soldering Iron Weller Grip by TimStough

...ely damage the soldering iron if printed in pla and forced on.

please make comments and post makes to help me improve this thing!

thingiverse

free

Horga'hn Idol from Star Trek. Composite for Tall Printers by TimStough

... i have not printed the reduced version, but it looks nearly identical when rendered.

happy printing and may you find jamaharon!

thingiverse

free

Rostock Max v3 Low Profile Bed Clip for BuildTak FlexPlate by TimStough

...tightened.

be sure to print out of petg or, better yet, abs. it will be subjected to temperatures that pla will not put up with.

thingiverse

free

Rostock Max v3 Case Enhancements for Enclosure Heating by TimStough

... a raspberry pi on top of my printer and plug it in here.

i will be posting photos later, but i wanted to get the stls up sooner.

thingiverse

free

HE280 Hotend Whip Retention Clip for Rostock Max V3 by TimStough

...ady printed it, no fear, you can modify it with a razor blade or file. i'm actually running v1 on my printer with no issues.

thingiverse

free

Star Trek Cruise - Horgon Pendant by Terefenko

...remix of the horgon done by mrcleanr6, geoffro and timstough i turned it into a pendant and gave them...

He280

thingiverse

free

He280 Plug Holder with Window by SgrA8

...

thingiverse

this is a remix of rinaldi94's he280 plug holder. i added a window so the leds can be seen through the holder.

thingiverse

free

HE280 fan shroud, The best EVER!! by Protea_Design

...the best fan shroud youll find for your he280. its super lightweight, clips securely to the three fan holders and actually works!

thingiverse

free

Plug Holder for HE280 Hot End by Rinaldi94

...nd. this clip is used to keep the plug secured. i had problems with the plug coming loose so i designed this to fix that problem.

thingiverse

free

HE280 cable locking clip by mattster98

...llides with a few small components on the board, but it doesn't appear to be an issue yet. might resolve in a later version.

thingiverse

free

Rostock Max Fan 25mm Shroud for HE280 by EhisforAdam

...l screws to attach it the the platform and wired everything based on the standard instructions with zip ties for wire management.

thingiverse

free

HE280 LED Ring Mount by wagnermark52

...duct/b01c85pvee/ref=oh_aui_detailpage_o06_s00?ie=utf8&th=1

i hope you all like this simple mod for the he280 as much as i do!

thingiverse

free

HE280 Fan Shroud by JMargush10

... could make an enclosure. there is no need to buy any more screws because this uses the screws from the injection molded shrouds.

thingiverse

free

HE280 Silicone Mold by Turpinator

...s centered in the mold, without making going to a multiple piece mold and stuff. but then again... ive already got 2+core as is.

thingiverse

free

Fan Shroud for HE280 Hot End by IdeaBeansNZ

...upgrades. i've designed them for my own rmv2 so i can get more localised cooling on the smaller prints with tricky overhangs.

thingiverse

free

Rostock Max Dual HE280 by Turpinator

...ogress. any and all comments appreciated, this probably wont go any further, but it was a fun couple hours spent playing around.

Rostock

thingiverse

free

Endstop for Rostock by Raz0neR

...endstop for rostock by raz0ner

thingiverse

endstop for rostock.

thingiverse

free

Rostock Cooling by nobicore

...rostock cooling by nobicore

thingiverse

rostock cooling

thingiverse

free

ROSTOCK PARTS by OC3D

...rostock parts by oc3d

thingiverse

parts for our modified rostock extruder assembly

thingiverse

free

Rostock squirrel fan by MarioPanic

...rostock squirrel fan by mariopanic

thingiverse

rostock squirrel fan

thingiverse

free

FC Hansa Rostock by ron86

...fc hansa rostock by ron86

thingiverse

fc hans rostock logo

thingiverse

free

rostock mini carriage by cjol

...rostock mini carriage by cjol

thingiverse

carriage for my rostock mini project

thingiverse

free

Rostock and Rostock Mini Dual Extruder Mount by westonshakespear

...ht.

sorry about the pictures, my filament jammed for part of the print and i am waiting for a new part to print a better version.

thingiverse

free

Rostock mini clip by Scott_Chen

...rostock mini clip by scott_chen

thingiverse

rostock mini clip for printer base glass

thingiverse

free

Rostock Board holder by drewan

...rostock board holder by drewan

thingiverse

this is a clip for using a rostock board as a print surface.

thingiverse

free

Rostock Fan Bracket by ImprisonedByTime

...rostock fan bracket by imprisonedbytime

thingiverse

this bracket is for a 40mm fan to attach to the rostock 3d printer

Shroud

3d_export

$500

Centrifugal pump volute casing with impeller

...casing with impeller 3dexport volute casing with impeller and shroud ...

3d_export

$35

The Holy Face base relief 3D Model

...the holy face base relief 3d model 3dexport shroud turin veronica veronica's veil gospel ikon jesus holy face...

3d_export

$20

present car cloth presentation transport transportation shape concepts show celebration cover showro

...transportation shape concepts show celebration cover showroom covered revealin shroudd cover covering tarp draped fabric cloth showroom reveal revealing...

3d_export

$5

Lockheed F-117 Nighthawk lowpoly stealth bomber

...initial operating capability status in 1983. the aircraft was shroudd in secrecy until it was revealed to the public...

3d_export

$49

kriss vector gen 2 sub-d

...rear flip sight.<br>- vector ejection port.<br>- vector crb square shroud / 16"" sliencer.<br>- ds150 stock.<br>- .ma (maya 2020 ascii)<br>-...

3d_export

$10

vichy dining table

...in oak, sycamore and walnut marquetry.<br>even if the restaurant shroud the vichy in a long table cloth, two slender...

3d_export

$500

us navy pcu sterett ddg-104 arleigh burke class destroyer flight iia max

...the position has been shifted.<br>q. where are the exhaust shroud for the stacks?<br>a. since ddg-89, the exhaust system was...

thingiverse

free

shroud by samshay317

...shroud by samshay317

thingiverse

shroud

thingiverse

free

Fan Shroud

...fan shroud

thingiverse

this is a fan shroud for a 140mm fan

thingiverse

free

40mm fan shroud

...40mm fan shroud

thingiverse

40mm fan shroud

Slim

3ddd

$1

Кровать Jupiter slim

...кровать jupiter slim

3ddd

jupiter slim

кровать jupiter slim

design_connected

$10

Slim Chair

...slim chair

designconnected

ligne roset slim chair computer generated 3d model.

3ddd

$1

Minotti Andersen Slim

...minotti , andersen , slim

minotti andersen slim

3ddd

$1

Bottoni Slim

... кресло из коллекции moooi.

oдноместный,плотность пены несколько на фанерной раме, ноги из нержавеющей стали.

размеры: 62x76x86cm

3ddd

$1

Slim Sofa

... slim , arbel

om website: beltafrajumar.com

designer: arbel

formats: 3ds, c4d, fbx, obj

3ddd

free

Складной стол SLIM

...кладной , стол

складной стол для переговоров slim.

размеры соблюдены, текстуры в архиве

3ddd

$1

Slim - Dema

...slim - dema

3ddd

dema

3ddd

free

Luce Verde Slim

... verde , slim

luce verde slim

ø 1300 h 45 mm

lumen led 6500

kg 35

artikel 790.69.01.00

turbosquid

$29

FLOW SLIM

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$29

FLOW SLIM

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

V3

3d_export

$5

Poison-v3

...poison-v3

3dexport

poison-v3

3ddd

$1

Curtain v3

...curtain v3

3ddd

полупрозрачная штора v3

turbosquid

free

v3

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

potato v3

...potato v3

3dexport

turbosquid

$69

Skeletor v3

...royalty free 3d model skeletor v3 for download as ztl and obj on turbosquid: 3d models for games, architecture, videos. (1712713)

turbosquid

$49

Zombie v3

...

royalty free 3d model zombie v3 for download as obj and ztl on turbosquid: 3d models for games, architecture, videos. (1342458)

turbosquid

$2

Bitcoin v3

...

royalty free 3d model bitcoin v3 for download as c4d and prj on turbosquid: 3d models for games, architecture, videos. (1182845)

turbosquid

$29

Turret V3

...alty free 3d model turret v3 for download as ma, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1217498)

turbosquid

$20

Radiators v3

... free 3d model radiators v3 for download as max, max, and obj on turbosquid: 3d models for games, architecture, videos. (1607437)

turbosquid

$10

Wheel V3S

...e 3d model wheel v3s for download as 3ds, obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1344250)

Fan

3d_export

$5

fan

...fan

3dexport

fan 3d model, table fan, fan, electric fan, ventilator

archibase_planet

free

Fan

...fan

archibase planet

fan large fan

fan out n260707 - 3d model for interior 3d visualization.

archibase_planet

free

Fan

...fan

archibase planet

fan ceiling fan ventilator

fan stealth n300615 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

$15

fan

...fan

3dexport

is an ancient fan

3ddd

$1

Fan-C-Fan by marco gallegos

...n-c-fan by marco gallegos

3ddd

вентилятор , marco gallegos

fan-c-fan by marco gallegos

3d_export

$10

fan

...fan

3dexport

a detailed fan designed for home or space blowing is now available for only 19.99!

turbosquid

$1

Fan

...fan

turbosquid

free 3d model fan for download as on turbosquid: 3d models for games, architecture, videos. (1427865)

turbosquid

$14

Fan

...fan

turbosquid

royalty free 3d model fan for download as on turbosquid: 3d models for games, architecture, videos. (1415642)

3ddd

$1

Светильник Fan

...светильник fan

3ddd

fan , italamp

светильник fan, производитель italamp

turbosquid

$25

Fan

...fan

turbosquid

royalty free 3d model fan for download as c4d on turbosquid: 3d models for games, architecture, videos. (1483246)

Weight

archibase_planet

free

Weight

...weight

archibase planet

weight

weight n030907 - 3d model for interior 3d visualization.

3ddd

$1

Weighted

...weighted

3ddd

weighted

высота (см)165ширина (см)75

archibase_planet

free

Weight

...weight

archibase planet

weight dumb-bell dumbbell

weight 24 kg n290313 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

free

weight

...weight

3dexport

archibase_planet

free

Weight

...weight

archibase planet

gym sport equipments

sport`s weight n010907- 3d model for interior 3d visualization.

turbosquid

$14

Weight

...uid

royalty free 3d model weight for download as max and obj on turbosquid: 3d models for games, architecture, videos. (1197215)

turbosquid

$19

Weight

...alty free 3d model weight for download as , stl, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1684982)

turbosquid

$4

Weights

...yalty free 3d model weights for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1494762)

turbosquid

$6

weights

... free 3d model weights for download as 3ds, obj, c4d, and fbx on turbosquid: 3d models for games, architecture, videos. (1261435)

turbosquid

$3

weight

...free 3d model weight for download as blend, dae, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1558127)

Rounded

turbosquid

$18

round chairs with round table

...und chairs with round table for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1454090)

3d_export

$5

round knob

...round knob

3dexport

round knob

3d_export

$5

Italian round table Millennium Round

...italian round table millennium round

3dexport

3ddd

$1

Round Ottoman

...round ottoman

3ddd

пуф

round ottoman

3ddd

$1

Round pillow

...round pillow

3ddd

подушка

round pillow

3ddd

free

Round bed

...round bed

3ddd

круглая

round bed

3ddd

$1

round table

...round table

3ddd

круглый

round table, стол

3ddd

free

ROUND TABLE

...round table

3ddd

журнальный , круглый

round table

3ddd

$1

Round Table

...round table 3ddd круглый , кофейный rounded coffee...

3ddd

$1

Round Rug

...round rug 3ddd ковер , круглый useful rounded ...

Light

archibase_planet

free

Light

...light

archibase planet

lamp lighting light

light - s2 - 3d model for interior 3d visualization.

archibase_planet

free

Light

...light

archibase planet

light luminaire lighting

light l0465 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

$5

lighting

...lighting

3dexport

lighting

3d_export

$5

lighting

...lighting

3dexport

lighting in livingroom

turbosquid

$3

Lighting Tree with Lights

...d model lighting tree with lights for download as max and 3ds on turbosquid: 3d models for games, architecture, videos. (1585507)

archibase_planet

free

Light

...light

archibase planet

luster lighting solution

light - s - 3d model for interior 3d visualization.

archibase_planet

free

Light

...light

archibase planet

luster lamp lighting

light 1 - 3d model for interior 3d visualization.

archibase_planet

free

Lights

...lights

archibase planet

surgical lights surgical lamp

surgical lights (floor) - 3d model for interior 3d visualization.

archibase_planet

free

Light

...light

archibase planet

lighting luminaire candlelight

light l0463 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

$18

street light-lighting-light-xia bing

...

3dexport

street light-lighting-light-xia bing<br>max 2015 v-ray 3 max 2015<br>textures<br>all files in zip...