Thingiverse

Simple sliced Wade's Geared Extruder by droftarts

by Thingiverse

Last crawled date: 3 years ago

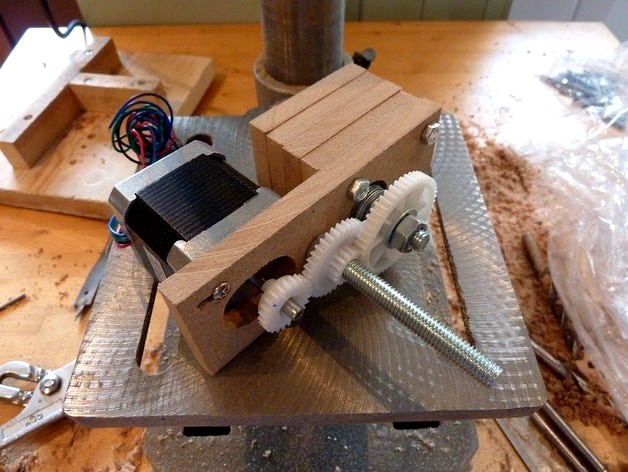

Yet another extruder design, but this one is designed to be built with simple tools for tightfisted repstrappers like me, who want to build it themselves, not just buy it. It's about the journey...

You know how it is; you're building your RepStrap and there's very few ways of building the extruder; you have to buy parts that you can't re-use when you print a Mendel, or use a compromised design in the knowledge a new extruder is about the first thing you're going to have to print before your lash-up breaks - if it works at all! And because the repstrap you're building has limited axes, the chunky thing you've made out of tree trunks limits your build size to 10mm x 10mm x 10mm cubes. Probably. So inspired a bit by seeing BodgeItQuick's version http://www.thingiverse.com/derivative:4878, I designed a simpler version of KurtCircuit's Sliced Wade's Geared Nema 17 Extruder http://www.thingiverse.com/thing:5548, which is itself based on the now legendary Wade's Geared Nema 17 Extruder by Wade http://www.thingiverse.com/thing:1794. KurtCircuit's version was designed to be laser cut, with minimal drilling. Mine is designed so it's ALL pretty much drilling.

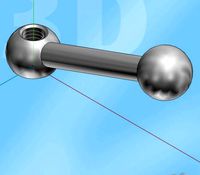

This version is built from 5 layers of 9mm MDF, ply or pretty much anything that you can machine. Depending on the depth of your bearings, you could use thinner wood eg 6mm. I've chosen MDF, and I'm planning on building this thing this week, but thought I'd share it with you lot in case I've overlooked something. It still needs the gears, but I am going to canabalise an old inkjet printer, and hope I can get something resembling the right size cogs out of it. Otherwise it's off to the bay of fleas to, er, "help support the community of independent reprap manufacturers". Or something. I have a set of taps and dies to make the hobbed bolt too.

I also expect to run this with a Bowden cable http://reprap.org/wiki/Erik%27s_Bowden_Extruder. I know they have their problems, but I'm hoping it's close enough to a Wade's that it will work okay, and built well enough and strong enough that it will survive for a while. It's a bit too chunky and print area limiting to mount on the Z-axis of my developing repstrap, a mrkim's 1X2 http://www.thingiverse.com/thing:5773. Also, it doesn't use springs to apply pressure to the idler, just captive nut/bolt. I'm not sure how well this will work, but didn't want it to be overcomplimicated.

Update 3rd May 2011

I have built this up now, and have hobbed the bolt etc. Seems to have good torque and grip on 3mm threaded rod. I'll have to wait for my electronics board and some 3mm filament to test it working. On to the hot end...

You know how it is; you're building your RepStrap and there's very few ways of building the extruder; you have to buy parts that you can't re-use when you print a Mendel, or use a compromised design in the knowledge a new extruder is about the first thing you're going to have to print before your lash-up breaks - if it works at all! And because the repstrap you're building has limited axes, the chunky thing you've made out of tree trunks limits your build size to 10mm x 10mm x 10mm cubes. Probably. So inspired a bit by seeing BodgeItQuick's version http://www.thingiverse.com/derivative:4878, I designed a simpler version of KurtCircuit's Sliced Wade's Geared Nema 17 Extruder http://www.thingiverse.com/thing:5548, which is itself based on the now legendary Wade's Geared Nema 17 Extruder by Wade http://www.thingiverse.com/thing:1794. KurtCircuit's version was designed to be laser cut, with minimal drilling. Mine is designed so it's ALL pretty much drilling.

This version is built from 5 layers of 9mm MDF, ply or pretty much anything that you can machine. Depending on the depth of your bearings, you could use thinner wood eg 6mm. I've chosen MDF, and I'm planning on building this thing this week, but thought I'd share it with you lot in case I've overlooked something. It still needs the gears, but I am going to canabalise an old inkjet printer, and hope I can get something resembling the right size cogs out of it. Otherwise it's off to the bay of fleas to, er, "help support the community of independent reprap manufacturers". Or something. I have a set of taps and dies to make the hobbed bolt too.

I also expect to run this with a Bowden cable http://reprap.org/wiki/Erik%27s_Bowden_Extruder. I know they have their problems, but I'm hoping it's close enough to a Wade's that it will work okay, and built well enough and strong enough that it will survive for a while. It's a bit too chunky and print area limiting to mount on the Z-axis of my developing repstrap, a mrkim's 1X2 http://www.thingiverse.com/thing:5773. Also, it doesn't use springs to apply pressure to the idler, just captive nut/bolt. I'm not sure how well this will work, but didn't want it to be overcomplimicated.

Update 3rd May 2011

I have built this up now, and have hobbed the bolt etc. Seems to have good torque and grip on 3mm threaded rod. I'll have to wait for my electronics board and some 3mm filament to test it working. On to the hot end...

Similar models

thingiverse

free

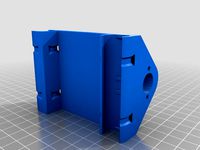

Thermal Barrier Clamp - Wades Gear Extruder by chris_hy88

...ing:1794

also this is a revised version of tb-clamping - wade's geared nema 17 extruder http://www.thingiverse.com/thing:5401

thingiverse

free

Bolt Hobbing Tool by timschmidt

...tool to help me hob a toothed channel in a drive bolt for a wade's extruder. i've printed one, and used it successfully.

thingiverse

free

Eventorbot Wade / Greg Extruder Parts by kkronyak

...may not be perfect but they work and i am open to suggestions to improve them. i hope some eventorbot owners find these helpful!

thingiverse

free

Extruder Idler Bracket by timschmidt

...acket for wade's geared extruder. part of the mendel openscad re-work being done here: http://www.thingiverse.com/thing:3118

thingiverse

free

Bowden geared extruder by Dabucci

...e gears used are the common greg's wade extruder ones. check out the size of the tube connector hole before print this thing.

thingiverse

free

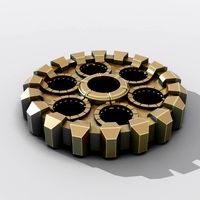

Wade's Extruder Gears using Parametric Involute Bevel and Spur Gears by nicholasclewis

...ore easily as they are modeled in openscad.

i am using vik's mendel_misc.inc found here http://www.thingiverse.com/thing:2192

thingiverse

free

Hobbed Bolt Manufactoring Tool for Piper3dGW extruder by Piper3D

...rings.

2 bearings are to hold the bolt in place and the third fits on top of the tap and serves as the guide to thread the bolt.

thingiverse

free

Wade Style Big Gear - Offset Hobbed Bolt Problem Solver by Yvan

...gon socket. with a few shims under the head of the bolt, you can line up the hobbed area with the feed path in the extruder body.

thingiverse

free

A Rostock max v2 mount for 2 geared extruders by Poorskeleton

...and the two plastic nut holders from alexstoff's dual ezstruder mount - found here - http://www.thingiverse.com/thing:364325.

thingiverse

free

Eric's Wade's Collaborative Dual Feed Extruder by PharaohABQ

...tive extruder because so many people have added so many great things to the wades, without all of you this would not be possible.

Droftarts

thingiverse

free

Afghan Lathe by Vik Olliver by droftarts

... first saw this kind of technique being used by afghan gunsmiths to produce counterfeit firearms with remarkable precision."

thingiverse

free

28BYJ48 - timming puley by constantin

...of parametric pulley with multiple belt profiles made by droftarts ...

thingiverse

free

T5 Pulley 30 Teeth to 10 Teeth by Tanenthor

...teeth by tanenthor thingiverse this is a remix of droftarts parametric pulleys with to pulley merged together using...

thingiverse

free

Parametric Pulley Library - Customizer Optimized by TNS

...menues! all credit for the technical part goes to droftarts for a couple of precompiled pulleys and furhter information,...

thingiverse

free

Parametric bracing frame vertex by droftarts

...it, so careful arrangement of tall parts is needed.

questions, observations, comments and/or suggestions all gratefully received.

thingiverse

free

Parametric pulley - lots of tooth profiles by droftarts

...u model any, please pass them on to me and i will include them.

22 march 2012 - updated for issue spotted by mfinn - see comments

thingiverse

free

T5 & XL Parametric Pulley by droftarts

...ating the tooth profile.

any observations, comments and/or suggestion for additions or further improvement gratefully received.

thingiverse

free

PCB Mill mount for Vert-X axis by droftarts

...lling, and will be easily removed to convert back to printing.

any observations, comments and/or suggestions gratefully received!

thingiverse

free

Parametric Belt Biggear for Wades extruder by mblaster

...for wades extruder by mblaster thingiverse a version of droftarts fantastic parametric pulley with small modifications to turn it...

Wade

3ddd

$1

Wade Tivoli

...wade tivoli

3ddd

tivoli , wade

диван wade tivoli 3dsmax2009 vray

3ddd

$1

Сервант Wade

...сервант wade

3ddd

wade , сервант

сделано по фотографии в corona.

3ddd

$1

Диван Farnham Wade

...диван farnham wade

3ddd

farnham , wade

диван farnham, wade (англия)

turbosquid

$17

WADE BENCH

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$199

Wallace Wade Stadium

...ree 3d model wallace wade stadium for download as 3ds and skp on turbosquid: 3d models for games, architecture, videos. (1315361)

turbosquid

$8

Wade Floor Lamp

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

cg_studio

$139

M4A1 Sherman - Deep wading gear3d model

...

.3ds .c4d .lwo .obj - m4a1 sherman - deep wading gear 3d model, royalty free license available, instant download after purchase.

turbosquid

$6

Ronin LED Table Lamp by Wade Logan

...amp by wade logan for download as mat, 3ds, max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1513289)

cg_studio

$99

M4A1 Sherman with Deep wading gear3d model

...wo .c4d .3ds .obj - m4a1 sherman with deep wading gear 3d model, royalty free license available, instant download after purchase.

turbosquid

$6

Cael 31cm LED Table Lamp by Wade Logan

...amp by wade logan for download as mat, 3ds, max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1512497)

Sliced

design_connected

$13

Slice

...slice

designconnected

normann copenhagen slice computer generated 3d model. designed by hornemann, hans.

3d_export

$15

onion slice

...onion slice

3dexport

onion slice

3ddd

free

Pizza slice

...pizza slice

3ddd

пицца

pizza slice

3d_ocean

$15

Slice Board

...slice board

3docean

food kitchen knife onion pepper slice board

fully detailed slice board with knife – onion – pepper

design_connected

$4

Slice Of Teak

...slice of teak

designconnected

chista slice of teak computer generated 3d model.

3d_ocean

$20

Sliced ham

...y obj photorealistic scanned slice sliced vray

scanned 3d model of a ham with several slices. placed on rectangular wooden board.

3ddd

$1

Slice board

... лук , разделочная доска

fully detailed slice board and knife

design_connected

$7

Slice Table

...slice table

designconnected

chista slice table coffee tables computer generated 3d model. designed by n/a.

3d_ocean

$18

Pizza slice

...l ray obj photorealistic pizza salami scanned slice vray

scanned 3d model of slice of salami pizza. placed on white square plate.

turbosquid

$29

Watermelon Slice

...d

royalty free 3d model watermelon slice for download as fbx on turbosquid: 3d models for games, architecture, videos. (1238391)

Extruder

3ddd

$1

Extruded Chair

...extruded chair

3ddd

extruded , tom dixon

inspired by tom dixon extruded chair

turbosquid

$15

Extruded Table

... extruded table for download as blend, dae, fbx, obj, and stl on turbosquid: 3d models for games, architecture, videos. (1634137)

turbosquid

$2

3D Printer Extruder

...d

royalty free 3d model 3d printer extruder for download as on turbosquid: 3d models for games, architecture, videos. (1537359)

turbosquid

$1

Zombie extruded text

...oyalty free 3d model zombie extruded text for download as obj on turbosquid: 3d models for games, architecture, videos. (1322198)

turbosquid

$4

Extruder conical screw

...el extruder conical screw for download as sldpr, ige, and stl on turbosquid: 3d models for games, architecture, videos. (1524433)

turbosquid

$50

3d PRINTER - Extruder

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$15

Extruded Table 2

...xtruded table 2 for download as blend, dae, fbx, obj, and stl on turbosquid: 3d models for games, architecture, videos. (1621846)

turbosquid

$10

Maya Extrude Tool

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

world earth extrude map

...world earth extrude map

3dexport

3ddd

$1

Simply Elegant Extruded Tree Coffee Table Design

...ble by link studios. the silhouette of a tree is visible at one angle, extruded from the surface to create the support structure.

Geared

3d_ocean

$4

Gears

...gears

3docean

gear gears iron

4 different size of gears

3d_export

$5

gear

...gear

3dexport

gear

3d_export

free

Gears

...gears

3dexport

gears

3d_export

$5

gear

...gear

3dexport

a simple model of gear

3d_export

$5

gear

...gear

3dexport

gear for transmission , case machine

3d_ocean

$3

Gears

...nical parts process steampunk vehicle wheel work

10 different gear models volume 01-10 files: .3ds .c4d .obj note: you need vray

3d_ocean

$1

Spur Gear

...spur gear

3docean

decoration gear

a typical spur gear

3d_ocean

$4

Gear wheels

...gear wheels

3docean

engine engineering gear gears industry machinery mechanical toothwheel wheel

pair of gear wheels : animated.

turbosquid

$9

Gear

...gear

turbosquid

royalty free 3d model gear for download as on turbosquid: 3d models for games, architecture, videos. (1712328)

turbosquid

$2

Gears

...rs

turbosquid

royalty free 3d model gears for download as ma on turbosquid: 3d models for games, architecture, videos. (1166710)

Simple

turbosquid

$1

Simple goblet (Taca simples)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

simple bench

...simple bench

3dexport

the simple bench which can be used in simple projects or video-games.

3d_export

$5

simple knob

...simple knob

3dexport

simple knob

3d_export

$5

simple handle

...simple handle

3dexport

simple handle

3d_export

$5

simple button

...simple button

3dexport

simple button

3d_export

$5

simple spindle

...simple spindle

3dexport

simple spindle

3d_export

$5

simple wheel

...simple wheel

3dexport

simple wheel

3d_export

$5

simple chair

...simple chair

3dexport

simple blue chair

3d_export

free

Simple room

...simple room

3dexport

here is a simple but beautiful room

3ddd

free

SIMPLE | Кресло

...io cianfarra , simple

производитель area declic дизайн giulio cianfarra коллекция simple