Thingiverse

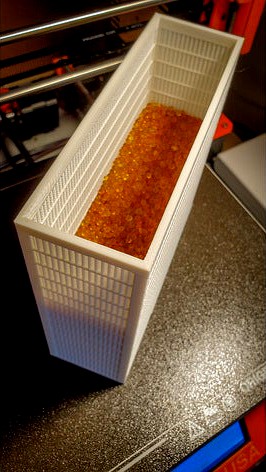

Silica Gel Tower by The_Redcoat

by Thingiverse

Last crawled date: 3 years, 3 months ago

An upgrade from using upcycled gelato tubs to hold silica beads in the upper deck of my lack printer enclosure where the open spools live. This container lets the air pass through, and can withstand the re-charge temperatures of my filament dehydrator which means less lost beads & mess.

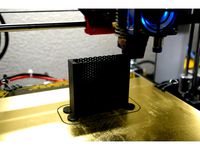

This is for advanced users only as it requires the use of (provided) slicer modifiers to make some of the model air-permeable. This technique makes the object very printable without thousands of retractions that the alternative slot-based design would require. It was also trivial to model, and the included OpenSCAD file allows you to create one in any dimensions you require.

For the container to withstand re-charge temperatures, it needs to be printed in ABS or other high glass-transition-temperature filament (PETG, ASA, PC etc.). If you recharge silica using an oven and a baking tray or something else not involving the container, then any filament works - clear transparent would be appropriate, so you can see the bead color change.

For the lid, get your first layer bed adhesion sorted out, the infill goes directly on the bed and will make a mess if you aren't calibrated when those lines don't stick. Print slooooow for that first layer, 10mm/s, and with ABS I found increasing the flow to 120% helped.

Recommended infill for the modifiers on the box is: 30% rectilinear at 0 degree rotation.

Recommended infill for the modifiers on the lid is: 30% gyroid at 0 degree rotation.

See screenshots of slicer for what 'works' looks like.

Things I thought about improving, but am too lazy to fix:

Instead of a cube, the box should have been based on the hull of four columns to give it nice rounded corners. ABS loves to try and lift those 90 degree corners off the bed.

For the lid, the modifiers could have been more advanced so the separator support bars exist only in the first 1mm, and last 1mm of layers, and the infill could run all the way along the lid for the layers between those which would have made printing slightly less complex.

This is for advanced users only as it requires the use of (provided) slicer modifiers to make some of the model air-permeable. This technique makes the object very printable without thousands of retractions that the alternative slot-based design would require. It was also trivial to model, and the included OpenSCAD file allows you to create one in any dimensions you require.

For the container to withstand re-charge temperatures, it needs to be printed in ABS or other high glass-transition-temperature filament (PETG, ASA, PC etc.). If you recharge silica using an oven and a baking tray or something else not involving the container, then any filament works - clear transparent would be appropriate, so you can see the bead color change.

For the lid, get your first layer bed adhesion sorted out, the infill goes directly on the bed and will make a mess if you aren't calibrated when those lines don't stick. Print slooooow for that first layer, 10mm/s, and with ABS I found increasing the flow to 120% helped.

Recommended infill for the modifiers on the box is: 30% rectilinear at 0 degree rotation.

Recommended infill for the modifiers on the lid is: 30% gyroid at 0 degree rotation.

See screenshots of slicer for what 'works' looks like.

Things I thought about improving, but am too lazy to fix:

Instead of a cube, the box should have been based on the hull of four columns to give it nice rounded corners. ABS loves to try and lift those 90 degree corners off the bed.

For the lid, the modifiers could have been more advanced so the separator support bars exist only in the first 1mm, and last 1mm of layers, and the infill could run all the way along the lid for the layers between those which would have made printing slightly less complex.

Similar models

thingiverse

free

Silica gel containers by Drenth_Engineering

...move the top and bottom layers to expose the 30% cubic infill and make sieve, 30% infill is enough for 3 to 4mm silica gel balls.

thingiverse

free

Modular sieve by wsreith

...rid size for your needs (e.g. 25% rectilinear)

alternatively edit the sieve plate model to punch holes at the size/shape you need

thingiverse

free

Silica Gel Container by ABH_

...screw lid. can be used for 750g filament spools with a 52 mm hole. to be filled with self-indicating silica gel 2-5 mm bead size.

thingiverse

free

Filament dryer by kometes

... filament dry. you can use aslo some silica gel.

you can use 0,6mm extrusion width to make it print faster. wall are 1,2mm thick.

thingiverse

free

Christian Cross

...ded for prusa slicer to show the ranges i mentioned.

angels tree topper can be found at https://www.thingiverse.com/thing:4052813

thingiverse

free

Round Silica Gel Container by dukk

... added a few lid files so you can print more than one lid at a time for those of you using a slicer that only supports one model.

thingiverse

free

45 Degree 3mm step bead roller / rolling die 3/4" drive axle by kirk_sim

...s

15 top solid layers

30% infill

no supports (print with larger surface on print bed)

basically trying to make a 3mm solid shell.

thingiverse

free

Silica gel container for your filaments by Soam16

...s so that you can customize them to your liking.

the total height of the container is 40mm, and it has an outer diameter of 70mm.

thingiverse

free

Repbox Silica gel container

...r 1 to 2 hours.

history:

2019-10-14 - increased lid size by 1mm so it doesn't snap when removing

2019-10-07 - initial version

thingiverse

free

Anti Moisture Silica Gel Box (container) by TORX1

...t; in cura, or the cover_thread_plus.

layer height. 0,20

wall line count. 7

top layers. 4

bottom layers. 4

infill density 35%

Redcoat

3d_export

$9

redcoat

...redcoat

3dexport

redcoat with musket 3d model.include max, fbs, obj. files.

unity_asset_store

$25

British Redcoat Soldier

...with the british redcoat soldier asset from wdallgraphics. find this & other characters options on the unity asset store.

thingiverse

free

RedCoat Cookie Cutter by LetuBotV4Rex

...erse

this is a cookie cutter for a project appleseed red coat d silhouette. i used the cookie caster web site to create the stl.

cg_trader

$75

British Redcoat Soldier

... soldier

cg trader

3d model british redcoat soldier soldier war redcoat, formats include max, bip, ready for 3d animation and ot

cg_trader

$10

British Redcoat Hat

...apoleonic redcoat red 18th century low poly lowpoly character army clothing pirate hat army soldier character clothing pirate hat

cg_trader

$18

The Patriot Fathers Revenge | 3D

...movie, the patriot! comes with bnejamin martin killing a redcoat after his son, thomas was killed, and his son...

3dwarehouse

free

redcoats

...redcoats

3dwarehouse

redcoats #british_soldier #napoleonic_soldier #redcoat #soldier

3dwarehouse

free

Redcoat

...h #brittan #england #flintlock #fort #fort_edward #king_george #musket #napoleonic #revolution #soldier #war #war_of_independence

3dwarehouse

free

nepolionic war

...nepolionic war 3dwarehouse redcoats vs french #redcoat ...

3dwarehouse

free

Napoleonic Stegoceras Dinosaur cavalry

...montcalm for the tricornes. #british #cavalry #dinosaur #lance #napoleon #redcoat #stegoceras...

Silica

3d_export

$10

vray glass cup

...primary constituent of sand. soda-lime glass, containing around 70% silica accounts for around 90% of manufactured glass. the term...

3d_export

$5

filament dry box

...within the box to keep the filament dry. without silica this box will not solely keep the filament...

thingiverse

free

SAO Silica stencil

...sao silica stencil

thingiverse

silica stencil

thingiverse

free

Silica Gel Container

...silica gel container

thingiverse

silica gel container

thingiverse

free

Caja para silica gel - silica gel box by pololoz

...caja para silica gel - silica gel box by pololoz

thingiverse

caja para silica gel.

thingiverse

free

silica gel box by TK_DESIGN

...silica gel box by tk_design

thingiverse

silica gel box

thingiverse

free

Silica Gel Containers by xsgroup

...silica gel containers by xsgroup

thingiverse

silica gel containers...

thingiverse

free

Silica Gel Container by singwanlew

...silica gel container by singwanlew

thingiverse

silica gel container for center of the spool hole.

thingiverse

free

Silica Gel Box by Korgano

...fill this box with silica gel to keep your filament dry.

it features a hole in the middle which increases the surface of the box.

thingiverse

free

Silica gel case (Dreyer) by kmltbtozgl

...silica gel case (dreyer) by kmltbtozgl

thingiverse

silica gel box

Gel

archibase_planet

free

Gel

...gel

archibase planet

shaving gel shaving things

shaving gel- 3d model for interior 3d visualization.

archive3d

free

Gel 3D Model

...model

archive3d

shaving gel shaving things

shaving gel- 3d model for interior 3d visualization.

turbosquid

$5

Gel Bottle

...bosquid

royalty free 3d model gel bottle for download as c4d on turbosquid: 3d models for games, architecture, videos. (1414994)

turbosquid

$1

Shower Gel

...bosquid

royalty free 3d model shower gel for download as fbx on turbosquid: 3d models for games, architecture, videos. (1474627)

turbosquid

$19

Gel Gillette

... free 3d model gel gillette for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1557011)

turbosquid

$8

SHOWER GEL

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$10

gel dispenser

... image, with non-slip caps.<br>you can add the graphic you like and the die you need with your company logo or information.

3d_export

$5

Gel Dispenser 3D Model

...gel dispenser 3d model

3dexport

gel cream dispenser beauty cosmetics virtualz

gel dispenser 3d model virtualz 72573 3dexport

3d_export

$9

Cleansing Gel Bottle

...cleansing gel bottle

3dexport

turbosquid

$5

Blue Gel Bottle

...id

royalty free 3d model blue gel bottle for download as c4d on turbosquid: 3d models for games, architecture, videos. (1415072)

Tower

archibase_planet

free

Tower

...kremlin tower spasskaya tower

tower kremlin spasskaya tower n120615 - 3d model (*.gsm+*.3ds+*.max) for exterior 3d visualization.

archibase_planet

free

Tower

...r kremlin tower petrovskaya tower

tower petrovskaya kremlin n120615 - 3d model (*.gsm+*.3ds+*.max) for exterior 3d visualization.

archibase_planet

free

Tower

...ino-eleninskaya tower

tower constantino eleninskaya kremlin n120615 - 3d model (*.gsm+*.3ds+*.max) for exterior 3d visualization.

archibase_planet

free

Tower

...tower

archibase planet

tower statuette eiffel tower

tower decor n180914 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Tower

...lanet

tower construction building

tower polices post street tower n110913 - 3d model (*.gsm+*.3ds) for exterior 3d visualization.

3d_export

$5

tower

...tower

3dexport

a fortified tower with a moat.

archibase_planet

free

Tower

...tower

archibase planet

building tower construction

tower n300712 - 3d model (*.gsm+*.3ds) for exterior 3d visualization.

archibase_planet

free

Tower

...uilding kremlin construction

tower 2 vtoraya bezymyannaya kremlin n100914 - 3d model (*.gsm+*.3ds) for exterior 3d visualization.

archibase_planet

free

Tower

...tower

archibase planet

forcetower tower

forcetower - 3d model for interior 3d visualization.

archibase_planet

free

Transmission tower

...lectricity pylon lattice tower framework tower

transmission tower n121015 - 3d model (*.gsm+*.3ds) for exterior 3d visualization.