Thingiverse

Sermoon D1 filament guide options see instructions by L3D_Help_Guide

by Thingiverse

Last crawled date: 3 years, 1 month ago

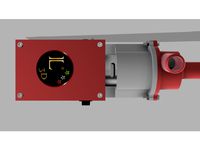

There are parts for several ways to guide the filament from the filament run out sensor to the hot end.

option 1 Sermoon D1 guide .stl , this gives a reduction in friction as the filament gets on top of the frame.

option 2 sermoon d1 guide .stl and the sermoon d1 extruder .stl, this involves drilling an 5/32" of 3.9mm hole 6mm down into the extruder arm.

option 3 just use the support arm, drill the 6mm hole and run ptfe from extruder arm to anchor at the corner guide with end above the filament run out sensor

option 4 Run a length of ptfe from extruder at max travel position to the run out sensor, then secure with end 60mm above sensor so filament can feed thru to the hot end. Possibly using zip ties to secure to the provided filament guide wheel frame. You do not have to drill the extruder arm for this, but it must be secure at the sensor end.

The Sermoon D1 Gcode is an pre sliced program with the support arm , the extruder, and the pin and wheels to make the 3d printed parts for option 1 and option 3, with 2 wheel types, one that is usable immediately, and wheels that accept a 608 skateboard bearing to even more reduce the rolling resistance of the guides.

608 wheel bearing fitment, if you are having trouble with the bearing fitting into the wheel, usually causing the wheel to split. Grab the individual .stl, and either use the XY scaling to make it slightly larger in the slicer. Note no Z scaling or it wont fit into the arm mount. Also you can lower the extrusion multiplier to try to effect the hole being larger.

option 1 Sermoon D1 guide .stl , this gives a reduction in friction as the filament gets on top of the frame.

option 2 sermoon d1 guide .stl and the sermoon d1 extruder .stl, this involves drilling an 5/32" of 3.9mm hole 6mm down into the extruder arm.

option 3 just use the support arm, drill the 6mm hole and run ptfe from extruder arm to anchor at the corner guide with end above the filament run out sensor

option 4 Run a length of ptfe from extruder at max travel position to the run out sensor, then secure with end 60mm above sensor so filament can feed thru to the hot end. Possibly using zip ties to secure to the provided filament guide wheel frame. You do not have to drill the extruder arm for this, but it must be secure at the sensor end.

The Sermoon D1 Gcode is an pre sliced program with the support arm , the extruder, and the pin and wheels to make the 3d printed parts for option 1 and option 3, with 2 wheel types, one that is usable immediately, and wheels that accept a 608 skateboard bearing to even more reduce the rolling resistance of the guides.

608 wheel bearing fitment, if you are having trouble with the bearing fitting into the wheel, usually causing the wheel to split. Grab the individual .stl, and either use the XY scaling to make it slightly larger in the slicer. Note no Z scaling or it wont fit into the arm mount. Also you can lower the extrusion multiplier to try to effect the hole being larger.

Similar models

thingiverse

free

TronXY X5SA Direct Drive Mount for Stock Extruder by Dropwire

...ounting and attachments, and print settings for slicing the parts.

this is my first design on thingiverse, hope it helps you out.

thingiverse

free

Wanhao D9 Filament Guide Tube Holder by jamesarm97

...p fits over the d9 extruder top above the filament hole. the extruder cap will fit either the tube or a ptfe press fit connector.

thingiverse

free

CR6 Filament Sensor Mount for use with Bondtech BMG (mirrored) by cyberFluke

...le persuasion, sits on the studs inside the arms of the guide. (note: screw the bracket to the machine before fitting the wheel.)

thingiverse

free

Sunlu S8 Filament Sensor Mount W Guide For Top Mount Holder by WonderWheezel

...0mm) and provides a guide for a top mounted spool holder. the pins and clips are provided so no additional hardware is required.

thingiverse

free

Biqu B1 Filament Runout Sensor Exit Guide by Lumoti

... that slots over the exit of the biqu b1 filament run-out sensor, bridging the gap and guiding the filament to the extruder hole.

thingiverse

free

Creativity Elf - Filament Guide by Junior_Barnes

...r and insert a piece of ptfe tubing. this makes for a smoother path to the extruder. print it on its side and no supports needed.

thingiverse

free

688ZZ Bearings Filament Guide, PTFE option

...the bearing, and the bearing in the base. other similar things: https://www.thingiverse.com/thing:2897228...

thingiverse

free

Filament runout sensor by kranix

...on both the in and out side, i run a bowden from the extruder back to this sensor, where it fits snugly and is held without glue.

thingiverse

free

CR-10s Pro Filament Guide Dual Bearing by SamTech3D

...de with 2 wheel to guide your filament from above or below,tested on cr10s pro also work on cr10max

only required 2x 608 bearing

thingiverse

free

Wanhao Duplicator extruder plate Flex File without PTFE extension by notedop

...e at own risk.

abs printing required! this part is touching hot parts of your 3d printer. use filament which can take some heat!

Sermoon

thingiverse

free

Sermoon D1 by DeXTeD

...sermoon d1 by dexted

thingiverse

sermoon d1.

side protection.

thingiverse

free

Cable Clips for Creality Sermoon D1 by M3DPS

... z-axis end stop microswitch cable.

updated on june 9, 2021 to add cable clips to keep a usb cable down near the vertical rails.

thingiverse

free

sermoon d1 tool holder by RG-Maker

... una precisione maggiore

lo potete scaricare anche da:https://cults3d.com/en/users/rgmaker/creations

https://youtu.be/elyonh-tbe4

thingiverse

free

Sermoon D1 BL Touch Mount by foo00

... creality must have some thoughts on support bl touch for the machine.

2 x m3x6 screws are required

1 x bl touch kit are required

thingiverse

free

Sermoon D1 BL Touch Mount by foo00

...creality must have some thoughts on support bl touch for the machine.

2 x m3x6 screws are required

1 x bl touch kit are required

thingiverse

free

Rack (Spool Holder) Gasket for Creality Sermoon D1 by JNJLabbe

...sembly:

part a goes inside;

part b goes outside;

part c in sandwiched in between; and

the fasteners hold all the parts in place.

thingiverse

free

sermoon d1 tool holder by RG-Maker

...ering and spade. star may need minor sanding but should push fit into the space tightly and not need anything else to secure it.

thingiverse

free

Corner by FreeTrailThief

...desinged this to make a top enclosure for my sermoon d1. the plates have: 1x) 420 mm x 420...

thingiverse

free

Low Profile Glass Frame and Internal Spool Holder Upgrades for Flashforge Inventor by JNJLabbe

...larger build plate than the flashforge inventor (e.g. creality sermoon d1) and with high temperature filament such as the...

L3D

cg_studio

$39

Morane Saulnier L3d model

... .c4d .fbx .lwo .ma .max .obj .xsi - morane saulnier l 3d model, royalty free license available, instant download after purchase.

cg_studio

$99

FN SCAR-L3d model

...can army

.max .obj .mb .lwo .fbx .c4d .3ds - fn scar-l 3d model, royalty free license available, instant download after purchase.

cg_studio

$35

WW2 PzKpfw II . Ausf. L3d model

...n

.3ds .x .lwo .ma .max .obj - ww2 pzkpfw ii . ausf. l 3d model, royalty free license available, instant download after purchase.

3d_export

$15

Christmas Color Ball 3D Model

...christmas color ball 3d model 3dexport christmas color l3d render snow sculpture carrot hat broom new year christmas...

thingiverse

free

no oral sex by L3D-

...no oral sex by l3d-

thingiverse

double color

thingiverse

free

batteria di alimentazione by L3D-

...without media, nozzle 0.4 layer 0.2

l3d design

you will find all the info at the following site : https://www.l3d.altervista.org/

thingiverse

free

Vacuum Cleaner by L3D-

...aner made entirely in 3d printing.

site for info file stl: https://www.l3d.altervista.org/spirella.php

printer 3d : ender 3 pro

thingiverse

free

Spool spacer and filiment guide by l3d

...spool spacer and filiment guide by l3d

thingiverse

i made this for my m3d filament.

thingiverse

free

WATER PUMP by L3D-

....2

7.4 / 12 v battery

screws bolts 3m

wheat 3m

you will find all the info at the following site : https://www.l3d.altervista.org/

thingiverse

free

L3D - Bigtreetech SKR 1.4 (Turbo) + MKS Hotbed Mos+ v1.1 Casing with Magentic Lid by lukeone

...+ 8x din 934 m3 nuts and 4 screws (+nuts) (max. m4) for the fan. supports are optional if you master your partscooling. have fun!

D1

turbosquid

$15

chair d1

...urbosquid

royalty free 3d model chair d1 for download as max on turbosquid: 3d models for games, architecture, videos. (1282621)

turbosquid

$19

Decor D1

...alty free 3d model decor d1 for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1230844)

3ddd

free

ODESD2 D1

...нная дубом фанера, мдф, фурнитура blum tandem

размеры: ширина: 450мм, длина: 1050мм, высота: 1180ммhttp://odesd2.com.ua

turbosquid

$15

Alvis Scarab D1

...squid

royalty free 3d model alvis scarab d1 for download as on turbosquid: 3d models for games, architecture, videos. (1363758)

turbosquid

$25

Nissan Sileighty D1

...issan sileighty d1 for download as max, unitypackage, and fbx on turbosquid: 3d models for games, architecture, videos. (1540431)

turbosquid

$15

D1.C4.30 Poster

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$5

D1.C3.04 Laptop

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

BSA Bantam D1

...bsa bantam d1

3ddd

мотоцикл

a classic motorcycle. (1948).

3ddd

$1

Мозаика Better B-MOS D1

...os d1

3ddd

better , мозаика

мозаика better b-mos d1.

розтайленая мною.

+ бамп

+ рефлеккт

turbosquid

$16

Current Front Door D1

...model current front door d1 for download as max, c4d, and fbx on turbosquid: 3d models for games, architecture, videos. (1291682)

Instructions

3d_ocean

$5

Instruction pole

...ole signboard

here is the 3d model of instruction pole. model is low poly and good for games texture size – 2048*2048. poly – 381

3d_export

$30

Instructional Smart whiteboard 3D Model

...rt blackboard school education learning academic chalkboard classroom

instructional smart whiteboard 3d model braz 10766 3dexport

turbosquid

$5

instruction table140 cm x 70 cm x 76 cm

...m x 70 cm x 76 cm for download as c4d, 3ds, dxf, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1593138)

3d_ocean

$10

Realistic Cassette with Rendering Instructions

...ity recording devices acquired the most prestigious in its time, with its unique original design made ??by renowned manufactur...

3d_export

$20

Chest of drawers for laser cutting

...drawers for laser cutting 3dexport the file has assembly instructionsvectors for laser cutting and other product information,personal...

3d_ocean

$49

Lego Tie-vector

...ean

lego maya star wars starwars tie vector

3d lego tie-vector created by instruction step-by-step. included materials, .obj .mb

3d_ocean

$2

Stop Sign Game Asset

...other projects. this asset is uv mapped and comes with textures. package includes: stopsign_new.obj stopsign_old.obj stopsign_...

3d_ocean

$9

House

...4d with an element 3d compatible texture map and instructions ...

3d_ocean

$49

Lego X-wing

...stic shadow star wars toy toys x-wing

3d lego x-wing created by instruction step-by-step. included materials, textures, .obj .mb

3d_ocean

$3

Road Signs and Traffic

...ed speed signals stop sign traffic warnings

20 models of road signs and traffic mental ray render textures of each of the objects

Guide

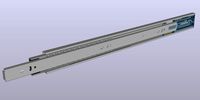

turbosquid

$15

Guide drawer

...squid

royalty free 3d model guide drawer for download as dwg on turbosquid: 3d models for games, architecture, videos. (1261387)

turbosquid

$1

Road Guide

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

archive3d

free

Guide-board 3D Model

...ion sign guide sign

guide-board n170112 - 3d model (*.gsm+*.3ds) for exterior 3d visualization.

turbosquid

$2

soap cutter guide

...

royalty free 3d model soap cutter guide for download as stl on turbosquid: 3d models for games, architecture, videos. (1694030)

turbosquid

$15

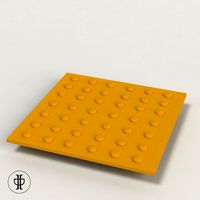

Blind Guiding tiles

...free 3d model blind guiding tiles for download as 3dm and dae on turbosquid: 3d models for games, architecture, videos. (1156598)

turbosquid

$69

Japanese Tour Guide

...d model japanese tour guide for download as max, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1614288)

turbosquid

$10

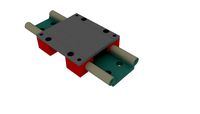

CNC Linear Guide

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$1

Tank Model Guide

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$1

Road Guide 2

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_ocean

$9

Guide Books 3

...sformed separately and each have unique texture map on front and back cover. to make your work easier this model comes in thre...

Filament

3ddd

$1

Filament Cage

...filament cage

3ddd

лофт , filament cage

модель бра, делалась по фото!

turbosquid

$3

FILAMENT COUNTER

...d

royalty free 3d model filament counter for download as stl on turbosquid: 3d models for games, architecture, videos. (1563049)

3d_export

$5

Filament lamp 3D Model

...filament lamp 3d model

3dexport

filament lamp 3d model kevin 54161 3dexport

3d_export

$5

Filament bulb candle 3D Model

...filament bulb candle 3d model

3dexport

filament bulb-candle

filament bulb candle 3d model kevin 54163 3dexport

3d_export

$5

Filament led light bulb

...filament led light bulb

3dexport

realistic 3d model of filament light bulb with v-ray materials.

3d_export

$5

Filament led light bulb

...filament led light bulb

3dexport

realistic 3d model of filament light bulb with v-ray materials.

3d_export

$5

Filament led light bulb

...filament led light bulb

3dexport

realistic 3d model of filament light bulb with v-ray materials.

3d_export

$5

Filament led light bulb

...filament led light bulb

3dexport

realistic 3d model of filament light bulb with v-ray materials.

3d_export

$5

Filament led light bulb

...filament led light bulb

3dexport

realistic 3d model of filament light bulb with v-ray materials.

3ddd

$1

Factory filament metal shade

...factory filament metal shade

3ddd

restoration hardware

restoration hardware. 20th c. factory filament metal shade.

Help

3d_export

$5

Woman offering help

...woman offering help

3dexport

woman offering help

3ddd

$1

COUPLE STATUE man help

...couple statue man help

3ddd

статуэтка

couple statue man help

turbosquid

free

help wanted biplane banner.blend

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$7

German soldier ww2 help wounded G5

... 3d model german soldier ww2 help wounded g5 for download as on turbosquid: 3d models for games, architecture, videos. (1687738)

turbosquid

$3

Uttermost Helping Hand Nickel Plated Bookends

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$45

3d Printable May I Help YOu sign STL OBJ 3D Model

...ntable sign may help you mall airport public sidnaique

3d printable may i help you sign stl obj 3d model sidnaique 48477 3dexport

3d_export

free

Diamond Ring

...in 3d, please contact, i will be glad to help ...

3d_export

$15

police badge photorealistic pbr low-poly

...support, or questions? contact me, i'll be happy to help ...

3ddd

$1

Door

...door 3ddd двери hope it help ...

3d_export

$15

Prototype version of the robot assistant

...a person in a variety of tasks, both in helpng in the garden and in armed...

See

turbosquid

$25

See Lion

...on for download as 3ds, max, dxf, obj, wrl, fbx, dwg, and stl on turbosquid: 3d models for games, architecture, videos. (1485798)

turbosquid

$11

All Seeing Eye

...d

royalty free 3d model all seeing eye for download as blend on turbosquid: 3d models for games, architecture, videos. (1419354)

turbosquid

$10

Elica See You

...3d model elica see you for download as max, max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1648557)

turbosquid

$19

Sight Seeing Tours

...ight seeing tours for download as max, max, fbx, obj, and stl on turbosquid: 3d models for games, architecture, videos. (1645329)

3d_export

$7

Sight Seeing Tours

...al sizes. unit's centimeters. includes all scene, lighting, cameras, materials and textures. many file formats are available.

turbosquid

free

Ring all-seeing eye

... all-seeing eye for download as png, 3ds, obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1474213)

cg_studio

$22

All Seeing Eye of God3d model

...

.wrl .obj .fbx .dae .c4d .3ds - all seeing eye of god 3d model, royalty free license available, instant download after purchase.

3ddd

$1

Aris Concept See - me

...aris concept see - me

3ddd

aris concept

leather wing armchair

max2014/fbx, v-ray

turbosquid

$30

BLIND EYE SEES RESEARCH SHIP

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Religious Icon of the All Seeing Eye

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Options

3ddd

$1

Фритюр SG14S with Options

...фритюр sg14s with options

3ddd

фритюр

проф. фритюр sg14s with options

3d_ocean

$15

trophy options

...e material property props trophy winner

-trophy options -low polys -obj, fbx,blender, 3ds. -zip : 5.7 mb - include gold material.

turbosquid

$2

keyboard 3 options

...oyalty free 3d model keyboard 3 options for download as blend on turbosquid: 3d models for games, architecture, videos. (1711408)

design_connected

$18

Swivel Chairs with Footrest Option

...swivel chairs with footrest option

designconnected

swivel chairs with footrest option computer generated 3d model.

design_connected

$16

Swivel Armchairs with Footrest Option

...swivel armchairs with footrest option

designconnected

swivel armchairs with footrest option computer generated 3d model.

3d_export

$19

1955 sideboard 3 options

...1955 sideboard 3 options

3dexport

turbosquid

$29

Office Chair with Multi Options

... 3d model office chair with multi options for download as max on turbosquid: 3d models for games, architecture, videos. (1380794)

turbosquid

$25

claddagh ring two options

...y free 3d model claddagh ring two options for download as 3dm on turbosquid: 3d models for games, architecture, videos. (1673087)

turbosquid

$20

PADDY PLANE OPTION 12

...yalty free 3d model paddy plane option 12 for download as max on turbosquid: 3d models for games, architecture, videos. (1696286)

turbosquid

$18

pendant sun three options

...free 3d model pendant sun three options for download as 3dm on turbosquid: 3d models for games, architecture, videos. (1555386)