Thingiverse

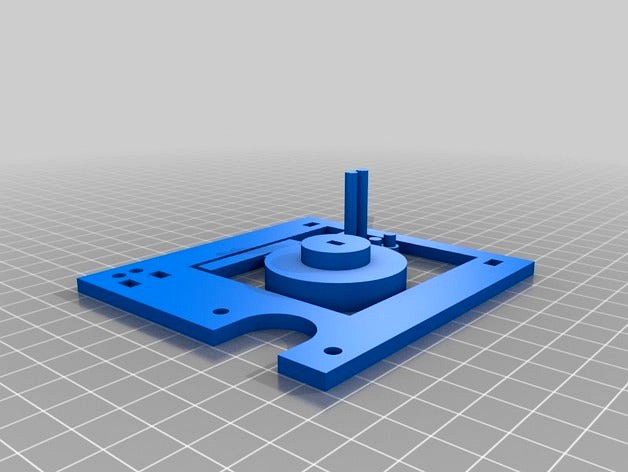

SemiAuto Filament Winder. by nomadshooter

by Thingiverse

Last crawled date: 4 years, 7 months ago

---UPDATE---MARCH-31-2017---

Changed the description to describe use of two 28BYJ-48 steppers geared for ~2048 steps per revolution. Turned out the extra torque is often needed when winding, had to help it by hand to often with two of the 513 step per revolution versions, and even worse with only one of the 513 step per revolution version.

--END-UPDATE--

---UPDATE---March-15-2017---

I updated the C source for the Raspberry Pi controller program, now easier to use.

--END-UPDATE--

This is a simple winder powered by a Raspberry Pi, requires also 2 - 28BYJ-48 5 volt stepper motors and a ULN2803 darlington array.

This uses keyboard input to adjust the speed of the stepper motor attached to a Raspberry Pi computer. Once you get the speed as close as possible to the rate of extrusion on your filament making extruder you will not have to adjust it as often.

This is a lot better than hand winding, and a lot more reliable than getting laser diodes and sensors to line up perfect every time (like the auto-winders do). Also this takes very little electricity.

As filament extrusion speed is not a constant, and will very in unpredictable ways you will still need to make an adjustment to the speed every now and again.

Even though just finished on the day of this posting, I have already put this to use.

Changed the description to describe use of two 28BYJ-48 steppers geared for ~2048 steps per revolution. Turned out the extra torque is often needed when winding, had to help it by hand to often with two of the 513 step per revolution versions, and even worse with only one of the 513 step per revolution version.

--END-UPDATE--

---UPDATE---March-15-2017---

I updated the C source for the Raspberry Pi controller program, now easier to use.

--END-UPDATE--

This is a simple winder powered by a Raspberry Pi, requires also 2 - 28BYJ-48 5 volt stepper motors and a ULN2803 darlington array.

This uses keyboard input to adjust the speed of the stepper motor attached to a Raspberry Pi computer. Once you get the speed as close as possible to the rate of extrusion on your filament making extruder you will not have to adjust it as often.

This is a lot better than hand winding, and a lot more reliable than getting laser diodes and sensors to line up perfect every time (like the auto-winders do). Also this takes very little electricity.

As filament extrusion speed is not a constant, and will very in unpredictable ways you will still need to make an adjustment to the speed every now and again.

Even though just finished on the day of this posting, I have already put this to use.