Thingiverse

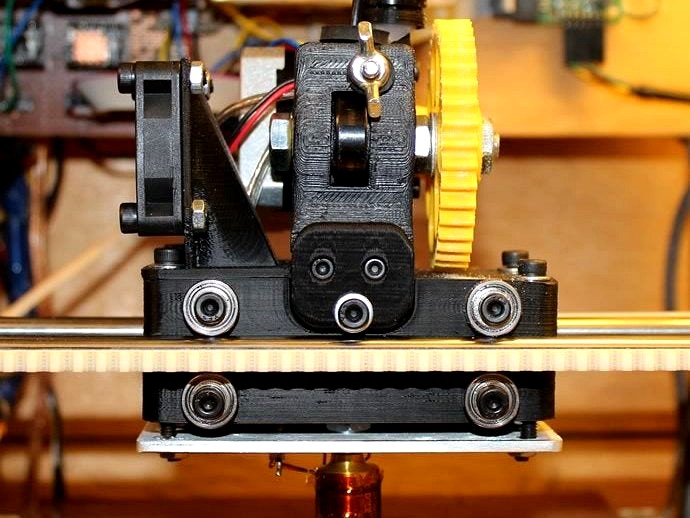

Sells Mendel improved X Carriage for EckerTech Hot End by eckertech

by Thingiverse

Last crawled date: 3 years ago

All of the plastic parts required to convert a standard Sells Mendel to an EckerTech all metal Hot End.

The EckerTech all metal hot end is available at http://www.eckertech.com/mendel-hot-end/

As well as adapting the extruder block to fit our hot end we made some improvements to the carriage:

We re-positioned the lower carriage rear bearing mounts after finding out that they were misaligned in the original files?!?

We replaced the original lower carriage tower with a flat printed independent unit which is much stronger.

We added belt alignment notches to the tower and blocks to the clamps to hold the belt in proper vertical position while clamping it tight. Eliminates the fiddly part of maintaining vertical alignment of the belt while you tighten it into place.

We adapted the upper carriage to fit our clip in eckstruder.

We covered the top gear side of upper carriage to better direct the airflow over the heatsink.

We updated the eckstruder to the new version wire capture model with spiral wrap tubing.

We front mounted the M3X25mm hot end extension locking bolts for easy access.

We notched the eckstruder base to provide a clip in attachment for the fan housing.

We counter bored the upper carriage to extend the heatsink mounting bolts for attachment to the heatsink.

We added nut captures to the outer clamping bolts on the lower carriage for easier tension adjustments of the bearings, as well as counter bored the bearing bolt holes to provide better clearance for the heatsink.

We also added spiral wrap tubing adaptors to clean up the wiring.

The EckerTech all metal hot end is available at http://www.eckertech.com/mendel-hot-end/

As well as adapting the extruder block to fit our hot end we made some improvements to the carriage:

We re-positioned the lower carriage rear bearing mounts after finding out that they were misaligned in the original files?!?

We replaced the original lower carriage tower with a flat printed independent unit which is much stronger.

We added belt alignment notches to the tower and blocks to the clamps to hold the belt in proper vertical position while clamping it tight. Eliminates the fiddly part of maintaining vertical alignment of the belt while you tighten it into place.

We adapted the upper carriage to fit our clip in eckstruder.

We covered the top gear side of upper carriage to better direct the airflow over the heatsink.

We updated the eckstruder to the new version wire capture model with spiral wrap tubing.

We front mounted the M3X25mm hot end extension locking bolts for easy access.

We notched the eckstruder base to provide a clip in attachment for the fan housing.

We counter bored the upper carriage to extend the heatsink mounting bolts for attachment to the heatsink.

We added nut captures to the outer clamping bolts on the lower carriage for easier tension adjustments of the bearings, as well as counter bored the bearing bolt holes to provide better clearance for the heatsink.

We also added spiral wrap tubing adaptors to clean up the wiring.

Similar models

thingiverse

free

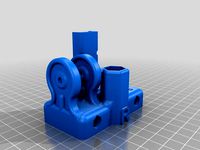

Eckstruder for Prusa by eckertech

...date: updated the eckstruder block to make it easier to mount different types of hot ends. basically just flattened the bottom.

thingiverse

free

eckertech Hot end conversion kit for Nema 17 Prusa style machines by eckertech

...orks files are available on our github account here: https://github.com/eckertech/ecksbot/tree/master/mods/prusa%20carriage%20mod

thingiverse

free

Vertical carriage for MGN12 rail on X-axis by TommyA

...nd mounts, and m3 for clamps. improved belt clamping with two top and bottom clamps. added holes for mounting endstopp actuators.

thingiverse

free

Simon's improved one-piece y-carriage by Wired1

...elt clamp exactly level with the idlers at each end and just clears the junk on the rails at either end to maximise print height.

thingiverse

free

i3 x carriage IGUS bearings (16mm OD) by Phil_Maddox

...llen head

added some fillets to aid in fitting belts

reduced bearing bores to 15.9 mm to better grip the igus rjzm-01-08 bearings

thingiverse

free

Modified x-carriage and Nozzle-mounting by yzorg

...r to the parts later... or maybe i design airchannels to reuse the air from the active-cold-end directing it to the print surface

thingiverse

free

Prusa Mendel i2 Hot End Clamp by tylerkrupicka

...to mount to the x carriage and hold it in place, and so far its worked great! hope this helps anyone else missing this component.

thingiverse

free

Bowden Volcano Hotend Carriage by JKHBuilder

...est to print the parts in the orientations shown.

photos of it assembled on a printer.https://photos.app.goo.gl/2yirkxyppwmcwqkca

thingiverse

free

Reinforced Mendel X Carriage with Sturdy LM8UU Holder by Cyberwizzard

...

added support bar for carriage clamps to divide tension between both attachments

based on the previous version: thing 173142

thingiverse

free

Rostock Carriage: Ball Ends, Screw LM8UU Mount and Belt Retainer by 0xPIT

...uu bearings

linear t2.5 belt retainer

source: https://github.com/0xpit/rostock

video: http://www.youtube.com/watch?v=gzwspo_lo3q

Eckertech

thingiverse

free

Eckertech 80mm led ring by outcastrc

...eckertech 80mm led ring by outcastrc

thingiverse

simple mount to attach an 80mm led ring to an eckertech extruder.

thingiverse

free

eckertech Hot end conversion kit for Nema 17 Prusa style machines by eckertech

...orks files are available on our github account here: https://github.com/eckertech/ecksbot/tree/master/mods/prusa%20carriage%20mod

thingiverse

free

Eckstruder for Prusa by eckertech

...date: updated the eckstruder block to make it easier to mount different types of hot ends. basically just flattened the bottom.

thingiverse

free

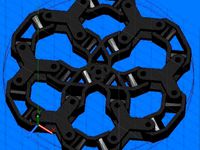

ecksbot Bearing Housing by eckertech

... for adhesion and fits together better than the old version.

for more information on the ecksbot please visit www.eckertech.com

thingiverse

free

40mm fan grill by eckertech

...t the number of times that i've felt that irritating ping on my finger tip while fiddling around near a running extruder fan.

thingiverse

free

ecksbot by eckertech

... z height adjustments. the new bearing housing requires only acetone for adhesion and fits together better than the old version.

thingiverse

free

ecksbot packing support by eckertech

...3d printers.

this support will help prevent your x-carriage from bouncing up and down when travelling/shipping to a new location.

thingiverse

free

ecksbot X End Idler with Z Adjuster by eckertech

... for easy z height adjustments. requires a 3mm x 25mm bolt.

for more information on the ecksbot please visit www.eckertech.com

thingiverse

free

Stronger Extruder Idler for Eckertech Extruder by Bracken

... in as nicely as the original.

any issues, let me know and i'll see about improving the part.

http://youtu.be/hmj9fmmfu7o

Mendel

thingiverse

free

Mendel Foot with pad for Alloy Mendel by maza250

...d for alloy mendel by maza250

thingiverse

40 mm high corner foot with base pad for use with 30x30mm extrusion - in alloy mendel.

thingiverse

free

Rigid Prusa mendel/mendel Bar clamp by wakalics

...iverse

original prusa mendel bar clamp is so weak.

i remade the bar clamp by idea from sells mendel.

www.wakalics.blogspot.kr

thingiverse

free

Mendel Squashfeet by superdoek

...mendel squashfeet by superdoek

thingiverse

shoes for your mendel (original vertex)

thingiverse

free

RepRap Mendel Stabilizer by g0nz00

...tabilizer by g0nz00

thingiverse

a stabilizer for reprap mendel, i use it for a bigger version of the reprappro tricolour mendel.

thingiverse

free

Fan Prusa Mendel by Rafertech

...fan prusa mendel by rafertech

thingiverse

fan prusa mendel.

thingiverse

free

Mendel Inspired Snowflake by flintols

...mendel inspired snowflake by flintols

thingiverse

holiday fun with mendel corners!

thingiverse

free

Tweezer Holder for Mendel (or Prusa Mendel) by MakerCubed

...opping mine, so if there's a spot for it, it won't get lost.

it's parametric in openscad to set it for left or right.

thingiverse

free

Fan holder - Mendel by rafaellsi

...fan holder - mendel by rafaellsi

thingiverse

experimental for 40x40mm fan - mendel reprappro

thingiverse

free

Mendel Feet by tonokip

...mendel feet by tonokip

thingiverse

thingiverse

free

Mendel Z tensioner by timschmidt

...rse

openscad remake of mendel's z tensioner. part of the mendel openscad re-work being done here: thingiverse.com/thing:3118

Carriage

archibase_planet

free

Carriage

...arriage

archibase planet

perambulator baby carriage pram

carriage n250908 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

free

carriage

...carriage

3dexport

old fashion carriage model, more files here:

turbosquid

$140

Carriage

...urbosquid

royalty free 3d model carriage for download as max on turbosquid: 3d models for games, architecture, videos. (1482052)

turbosquid

$25

Carriage

...urbosquid

royalty free 3d model carriage for download as max on turbosquid: 3d models for games, architecture, videos. (1285944)

3d_export

free

carriage

...carriage

3dexport

game cart

3d_ocean

$15

Barrel Carriage

...ieval oak old transport wheels wine wood

this model contains a barrel and a carriage. it is a medieval type of wood oak carriage.

turbosquid

$40

Carriage

...ty free 3d model carriage for download as obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1290094)

turbosquid

free

Carriage

...yalty free 3d model carriage for download as ma, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1239157)

3d_export

$5

Medieval carriage

...medieval carriage

3dexport

medieval carriage in fairy style

turbosquid

$58

Carriage

...d model carriage with scene for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1276262)

Sells

turbosquid

$1

pointer sell

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$10

BLOOD SELLS 3D Model

...blood sells 3d model

3dexport

blood sells organic

blood sells 3d model bsmeher 26533 3dexport

turbosquid

$50

stand selling porcelain

...alty free 3d model stand selling porcelain for download as ma on turbosquid: 3d models for games, architecture, videos. (1529051)

turbosquid

$20

sofa sell.3DS

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

sofa sell.3DS

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$4

Christmas Sell Cap

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

03 SELL PATTERN WALL

...l 03 sell pattern wall for download as 3ds, max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1505079)

turbosquid

$10

02 SELL PATTERN WALL

...l 02 sell pattern wall for download as 3ds, max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1505075)

turbosquid

$10

01 SELL PATTERN WALL

...l 01 sell pattern wall for download as 3ds, max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1505069)

turbosquid

$25

sell knife 01.max

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Hot

turbosquid

$1

HOT

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$12

Hot Tub

...hot tub

3dexport

hot tub - 4k png/tif textures

3d_export

$9

Hot Tub

...hot tub

3dexport

hot tub - 4k png/tif textures

3d_export

free

hot chili

...hot chili

3dexport

hot chili<br>for fruits and getegables collection

3d_export

$5

hot air balloon

...hot air balloon

3dexport

hot air balloon

3d_export

free

Hot dog shop

...hot dog shop

3dexport

hot dog shop

turbosquid

$90

hot venue

...rbosquid

royalty free 3d model hot venue for download as fbx on turbosquid: 3d models for games, architecture, videos. (1336949)

turbosquid

$20

Hot Rod

...

turbosquid

royalty free 3d model hot rod for download as ma on turbosquid: 3d models for games, architecture, videos. (1351690)

turbosquid

$14

Hot Pepper

...bosquid

royalty free 3d model hot pepper for download as obj on turbosquid: 3d models for games, architecture, videos. (1611643)

turbosquid

$1

Hot dog

...turbosquid

royalty free 3d model hot dog for download as max on turbosquid: 3d models for games, architecture, videos. (1450961)

Improved

cg_studio

$49

Robot Z300 (improved version)3d model

...o

.3ds .fbx .max .obj - robot z300 (improved version) 3d model, royalty free license available, instant download after purchase.

3d_export

$39

Robot Z300 improved version 3D Model

...fantasy sci-fi robots bot humanoid droid sci fi materials character

robot z300 improved version 3d model alekrazum 55067 3dexport

3d_export

$75

CV-90 Improved

...nnon. export versions are fitted with hägglunds e-series turrets, armed with either a 30 mm mk44 or a 35 mm bushmaster autocannon

turbosquid

$55

(Important textures coming back soon after improvements)Cuboid gazebo bench area

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$15

COMPLETE AUDI 80-100 SHIFT LEVER REPAIR KIT WITH IMPROVED BUSHING

...dexport

• sleeve - 1 pc. • elastic band - 1 pc. • hinge - 1 pc. audi 100c3 audi 100 c4 audi 80 b3 (checked) audi 80 b4 (checked)

3d_export

$7

REPAIR KIT FOR GEARSHIFT LEVER AUDI 80-100 IMPROVED

...ar of the gum is excluded. - rusk - 1 pc. - elastic band - 1 pc. audi 100c3 audi 100 c4 audi 80 b3 (checked) audi 80 b4 (checked)

3d_export

$30

cup mask machine front section stereo mask manufacturing machine improved version

...ing rack cad outsourcing list. the drawings are mature drawings that have been produced.<br>drawing version solidworks 2018

3d_export

free

oven - forno

...oven - forno

3dexport

gradually i'm trying to improve my 3d.

3d_export

$75

T-55

...nally, but these improvements made the tank more efficient and lethal. the t-55 was officially adopted by the soviet army in 1958

3d_export

$5

civil registration authorities

...civil registration authorities

3dexport

city wedding square. the model can be used for projects, to improve the project, etc.

End

archibase_planet

free

Cigarettes end

...d

archibase planet

cigarettes end cigarette stub cigar-butt

cigarette-end - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

$5

end table

...end table

3dexport

end table 3d model dimensions:(w)60cm×(d)60cm×(h)56cm

3d_export

$5

end table

...end table

3dexport

end table 3d model dimensions:(w)60cm×(d)60cm×(h)56cm

turbosquid

$10

End Table

...rbosquid

royalty free 3d model end table for download as max on turbosquid: 3d models for games, architecture, videos. (1570610)

turbosquid

$5

End Table

...urbosquid

royalty free 3d model end table for download as ma on turbosquid: 3d models for games, architecture, videos. (1622809)

turbosquid

$3

End Table

...rbosquid

royalty free 3d model end table for download as fbx on turbosquid: 3d models for games, architecture, videos. (1315115)

3d_export

$5

rope end ring

...rope end ring

3dexport

rope end ring

turbosquid

$2

End Tables

...

royalty free 3d model end tables for download as max and obj on turbosquid: 3d models for games, architecture, videos. (1706896)

turbosquid

$14

End Table

...lty free 3d model end table for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1403051)

turbosquid

$12

End Table

...lty free 3d model end table for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1574707)