Thingiverse

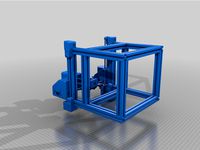

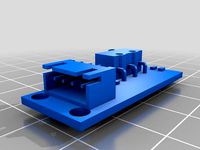

Seckit SK-GO² starter upgrade set - endstop bumper, cable mount, BL-touch, xy optical endstop, filament holder, clips - may als work for other SecKit printers by caesar_1111

by Thingiverse

Last crawled date: 3 years, 3 months ago

DISCLAIMER:

This is the v0.1 of this thing, so it may contain errors. Please let me know immediately if you stumble across some errors or inconsistencies, so I can improve the thing for all the others!

I do not guarantee that the things and Marlin configuration are working with your printer! If you are using any of those things or Marlin configuration you are doing it on our own risk!

First of all:

I want to thank Ernest Lin for providing such great printers and all the support you need to get up and running.

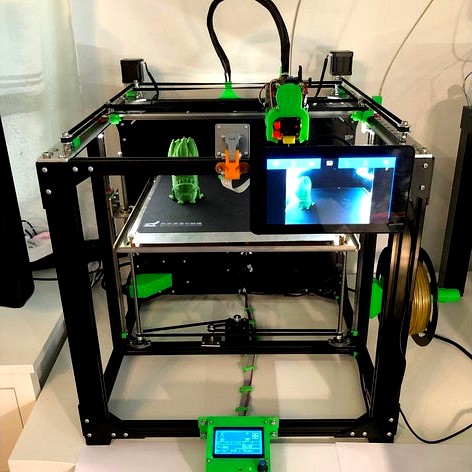

For those who are thinking of ordering a printer and will go along with the credo “SecKit, Your Second 3D Printer Kit the overkill CoreXY platform to get you out of endless repair-tweak-upgrade loop and get things done” it’s definitely worth the wait when ordering at https://seckit3dp.design/ since you will get a complete set which contains all the necessary parts to build (it took me around 20hrs) a working industry grade printer. During the build I already started to work on some upgrades I found on thingiverse and also designed myself. So I created this thing to:

Share the list/links of self printed parts I added to the printer including the stl files of some additionally designed parts I added to the printer. Some of the files will replace the files Ernest is providing on his github page, so you may always doublecheck which design you prefer. This also includes the optional Frame mounted filament holder DELUXE

Share the details about applying the optional optical endstops to my printer running 2209 stepper drivers (files and Marlin 2.x changes)

Share the details about adding an optional BL-Touch to my printer (files and Marlin 2.x changes)

Upgrades for direct drive setup with E3D V6 hotend

Some of the parts of the Shopping list might already be included in the SecKit kit.

Basic setup

Parts to be printed:

SK-Go2_Z-Rail_Lower_Endstop.stl (this protects the linear rail block from the z rail from sliding of the rail while assembly)

Shopping list:

-- 2 pcs M4x8 bolt

-- 2 pcs M4 t-nut

SK_Go2_X_min_sensorless_homing_bumper_and_assembly_bumper.stl (applied on both sides of the x axis this protects the linear rail block from the x rail from sliding of the rail while assembly; it is replacing the original SK-Go X-min sensorless homing bumper from SecKit github)

SK-Go2_Position_A_Y-Endstop_Railmounted.stl (This endstop ensures that the part cooling fan is not touching the upper frontal 20x20 aluminum extrusion if raised to the top, see picture of how I set up the frame)

Shopping list:

-- 2 pcs M3x20 bolt

-- 2 pcs M3 washers

SK-Go2_5mm_Shorter_Nylontube_Replacement_for_Bedlevellingscrew.stl (this replaces the 10mm nylon spacer for the left and right bed leveling screw at the z rails)

SK-Go2_Fanduct_Nut_Holder_LH.stl & SK-Go2_Fanduct_Nut_Holder_RH.stl (this clips are holding the M3 nuts for the fanduct assembly in place while clipping on the lower carriage spacers, see also picture; this will come in handy if you are tuning the hotend and have to reassemble the duct multiple times)

SK-Go2_Z-Axis_assembly_gauge_Lead_Screw_Only.stl & SK-Go2_Z-Axis_assembly_gauge_Lead_Screw_Nut.stl (this helps to allign the z-axis with the lead screw. First use the gauges to center the linear rail on the 2020 extrusion (this replaces the original gauge) then place the lead screw nut in the lower part, the lead screw in the upper part to assemble the lower lead screw bearing. Before tightening the bearing to the lower 2020 extrusion, just revolve the lead screw multiple times to make sure the bearing with the leadscrew in it is alligned to the linear rail)

SK-Go2_Z-Rail_Lower_Endstop.stl (this protects the linear rail block from the z rail from sliding of the rail while assembly)

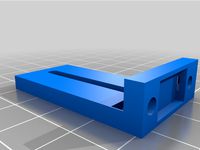

SK-Go2_Extruder_Frame_Cable_Bracket.stl (This bracket can be attached to the extruder and the frame at the back. It is featuring a 4mm hole to apply a standard PTFE tube for better cable guidance)

Shopping list:

-- 4 pcs M3x10 bolt (use M3x15 bolts if you also plan to go with the X and Y optical endstop)

-- 4 pcs M3 washers

-- 4 pcs M3 nut

-- 2 pcs M4x8 bolt

-- 2 pcs M4 t-nut

-- approx 50cm PTFE tube 4mm outer diameter

SK-Go2_Reverse_Bowden_Extruder_Bracket.stl (This bracket will take away the bending from the BMG extruder fitting where the reverse bowden tube is attached)

Shopping list:

-- 2 pcs M3x10 bolt (M3x15 will also fit)

-- 2 pcs M3 nut

SK-Go2_PTFE_Tube_antibend_50mm.stl and SK-Go2_PTFE_Tube_antibend_100mm.stl (optional) (If you are planning to replace the original reverse bowden tube with a softer one and experience some bending, just clip those on the outside of the tube where it should not bend)

SK-Go filament sensor holder by Michael Laws.stl (taken from printed parts STL folder from SecKit github)

Shopping list:

-- 2 pcs M4x10 bolt

-- 2 pcs M4 t-nut

-- 2 pcs M2 washers

-- 2 pcs M3x15 bolt

-- 2 pcs M3 washers

SK-Go fan duct.v2.direct.stl (taken from printed parts STL folder from SecKit github)

Shopping list:

-- 2 pcs M3x10 bolt

-- 2 pcs M3 nut

12864 display cover with slope.stl (taken from printed parts STL folder from SecKit github)

Shopping list:

-- 2 pcs M3x20 bolt

-- 2 pcs M3 nut

-- 2 pcs M4x10 bolt

-- 2 pcs M4 t-nut

-- 2 pcs M4 washers

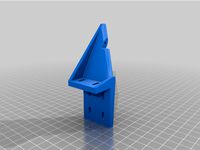

SG-Go2_20x20_angled_Bracket_for_Display_Cover.stl (fits only to the two additinal holes of the 12864 display cover with slope.stl)

Shopping list:

-- 2 pcs M4x8 bolt

-- 2 pcs M4x10 bolt

-- 2 pcs M4 t-nut

-- 2 pcs M4 nut

-- 2 pcs M4 washers

Seckit Go 2 - ZMount Shims (from Thingiverse Some z-leadscrew bearing tend to grind into the horizontal 2020 extrusion. alpokemon designed mulitple diameters. just put them under the bearing, tighten the nuts and make sure, the inner bearing is turing without any contact to the extrusion)

Meanwell LRS-350-24 cover for SecKit SK-GO (from Thingiverse)

Shopping list:

-- 2 pcs M4x8 bolt

-- 2 pcs M4 washers

SecKit open angled cover with logo (from Thingiverse)

Shopping list:

-- 2 pcs M3x15 bolt

-- 2 pcs M3 nut

Belt Tensioner for sk go 3d printer (from Thingiverse)

Shopping list:

-- 4 pcs M3x20 bolt

-- 4 pcs M3 nut

SKR v1.3 Ducted Stepper Driver Cooler (from Thingiverse replaces SK-Go driver cooling fan mount.stl)

Shopping list:

-- 4 pcs M3x15 bolt

-- 4 pcs M3 nut

SKR 1.3 Board Drivercooler Clips for Things 3576392 and 4163812 - SKR_1.3_Board_Drivercooler_Clip.stl and SKR_1.3_Board_Drivercooler_Fan_Side_Clip_thing_4163812.stl ([from Thingiverse]( https://www.thingiverse.com/thing:4570496) clips the SKR v1.3 Ducted Stepper Driver Cooler to the board)

YACC (Yet Another Cable Clip) for 20x20 Aluminum Extrusion 8mm (from Thingiverse)

Frame mounted filament holder DELUXE (optional)

Parts to be printed

SK-Go2_Filament_Holder_DELUXE_Bracket.stl (to mount the Ender 3 - Filament holder DELUXE to the frame. Replacing Mounting_bracket.stl and Mounting_bracket_nut.stl)

SG-Go2_20x20_angled_Bracket.stl (optional if you assemble the SK-Go2_Filament_Holder_DELUXE_Bracket.stl to the 20x20 rail)

Ender 3 - Filament holder DELUXE - Filament_holder.stl, Filament_nut.stl and Optional_thread_guide.stl (from Thingiverse)

Shopping list:

-- 16 cm long M8 threadbar

-- 2 pcs 608Z bearings

-- 2 pcs M8 nylon lock nuts

-- 2 pcs M8 washers

-- 4 pcs M4x10 bolt

-- 2 pcs M4x8 bolt

-- 4 pcs M4 t-nut

-- 2 pcs M4 nut

-- 6 pcs M4 washers

SK-Go2_Filament_Guide.stl (Mounts just above the SK-Go2_Filament_Holder_DELUXE_Bracket.stl on the vertical 2020 extrusion. It will stop the filament from getting tangled around the Filament_Holder_DELUXE bracket when having a new spool.)

Shopping list:

-- 2 pcs M3x10 bolt

-- 2 pcs M3 washers

-- 2 pcs M3 t-nut

X and Y optical endstop (optional)

Parts to be printed

SK_Go2_X_min_sensorless_homing_bumper_and_assembly_bumper_with_optical_endstop_trigger.stl (this is replacing the left SK_Go2_X_min_sensorless_homing_bumper_and_assembly_bumper.stl)

SK-Go2_X_Optical_Endstop_Mount_Addon_Bracket.stl (to be attached at the back of the SK-Go2_Extruder_Frame_Cable_Bracket.stl)

Shopping list:

-- 1 pcs LERDGE Optical Endstop (one is included in the kit)

-- 2 pcs M3x8 bolt

-- 2 pcs M3 nut

Y optical endstop mount.stl (taken from printed parts STL folder from SecKit github)

Shopping list:

-- 2 pcs M3x8 bolt

-- 2 pcs M3 nut

-- 2 pcs M4x8 bolt

-- 2 pcs M4 t-nut

Y optical endstop trigger.stl (taken from printed parts STL folder from SecKit github)

Connecting to mainboard

Unplug the xst and yst jumper on the SKR 1.3 board for the optical sensors to work with the board (board connect an pin layout picture included). Connect the Sensor to the x- and y- endstop pin. Make sure that the pins are matching up (see also assembly manual). you might have to change the order of the wires to have the V, G and S pin at the sensor matching the V, G and S pin at the board. If the sensor is wired up correctly, you will a a green LED shining as soon as you put an object into the sensor gap.

Fun fact : Consider the material you are using to print the SK_Go2_X_min_sensorless_homing_bumper_and_assembly_bumper_with_optical_endstop_trigger.stl and Y optical endstop trigger.stl endstop triggers. I was using SUNLU PETG green and it was somehow not triggering the sensor. I had to wrap it in black tape to make it work.

BL-Touch (optional)

Parts to be printed

SKGO Fan Duct with BLTouch (from Thingiverse replaces SK-Go fan duct.v2.direct.stl)

Shopping list:

-- ANTCLABS BL Touch V3.1 https://www.antclabs.com/bltouch-v3 (e.g. from Aliexpress )

-- Alternatively a cheaper clone like the 3D touch (e.g. from Aliexpress this one comes already with a 1m cable extension )

-- 5x 1m cable with cable to female dupont pins. (needed to extend the BL Touch wires. Some bundles are already including this cable)

Connecting to mainboard

Thanks to Chris Riley’s YouTube tutorial I was able to get this done easily.

Unplug the zst jumper on the SKR 1.3 board for the BLToouch to work with the board (board connect an pin layout picture included). Connect the your black/white cable to the z- endstop pins. Connect the brown/red/orange cable to the SERVOS pins on the SKR 1.3 board. Make sure that the pins are matching up (BLTouch wiring picture included). You have to exchange the red and the brown wire if you are using an 3 pin extension plug for the SERVOS cable.

Configuration of Marlin for X and Y optical endstop and BL-Touch

I included my current versions of:

Configuration.h

Configuration_adv.h

Make sure not to copy those files but use a text editor to compare those files with your original ones to identify the changes and modify your original files.

Every change is commented with “// upgrade_set:” so you also can search for all the changes if comparing is no good for you.

Octoprint on raspberry (octopi) with the 7″ touchscreen monitor for Raspberry Pi using the TouchUI with the Boot-To-Browser option. (optional)

If you were puzzled about the screen assembled to the top of my frame…..

Since I have done a lot of customizing on my octoprint to control my SK-Go² (e.g. temperature presents, movement and bed levelling support) by using the Terminal Commands Extended plugin, I now wanted to be able to use this without having a computer up and running.

And again thanks to Chris Rileys YouTube tutorial https://www.youtube.com/watch?v=rqy3dVZ4JH4 it was easy to utilize my 7″ touchscreen monitor for Raspberry Pi I had laying around to get it done.

Shopping list:

-- Raspberry pi incl. power supply (I used a 3B+)

-- approx.. 1.5m USB A cable (e.g. from AliExpress)

-- 7″ touchscreen monitor for Raspberry Pi (I used the original bought from Amazon which came with a housing I could directly mount to the 20x20 extrusion using 2x M4x8 bolt and 2x M4 t-nuts) you can also use other screens and sizes and for some you should find housings on thingiverse. I just had some trouble trying it with a 3.5″ touchscreen form KUMAN since the driver was somehow stopped my PiCamera from working.

-- Raspberry pi camera (I used a fisheye one from Amazon) you will need to also by a longer camera cable approx. 30-100cm, depending on where you want to mount your camera and you raspberry pi. Depending on your camera type you will already find some printable mounts fitting on a 20x20 extrusion (e.g. https://www.thingiverse.com/thing:434600 , https://www.thingiverse.com/thing:2804612 or https://www.thingiverse.com/thing:3565707

-- USB LED strip (e.g. 2m non remote from AliExpress) I just put the strip in the slot of the extrusions.

Octoprint configuration

I uploaded my octoprint configuration, so you just have to use the octoprint setting Backup & Restore to get all my add-ons and commands for the SK-Go². Since I am also running a Anet A8, Geeetech A10M and a Creality CR10sPRO you will also find some commands for those printers. Just delete the commands in the octoprint settings by configuring the Terminal Commands Extended plugin.

Dual Z-Axis Setup incl. Marlin 2.0.x for SKR 1.4 Turbo and S42B closed loop steppers

I decided to further upgrade my printer. You can find the details at my new thing :https://www.thingiverse.com/thing:4631780

Updates:

1.

I did some tuning the

Configuration.h

Configuration_adv.h

files, adjusting the bed position and size to my assembly. I also adjusted the filament preheat settings and some minor stuff. Again all the changes are flagged with “// upgrade_set:”.

2.

I added some commands to octoprint Terminal Commands Extended in order to follow the UBL procedure described by Chris Riley’s YouTube tutorial for UBL.

3.

I added some tiny clips which will hold the M3 nuts of the fanduct in place. (while tuning the hotend I had to reassemble the extruder some times and every time the two M3 nuts were a pain to hold in place for assembly) The clips will go on the lower spacers of the carriage.

4.

I create some gauges to help assembly the z-axis. You will also find the FreeCAD model if you have to adjust the tolerances for yourself.

5.

I tuned the reverse bowden setup. The SK-Go2_Filament_Guide.stl will prevent the filament from getting tangled around the filament holder deluxe. The SK-Go2_Reverse_Bowden_Extruder_Bracket.stl will allow you to take away the bending from the PTFE tube fitting at the BMG extruder. Since I had to replace the original, stiff reverse bowden tube with a standard PTFE tube to feed TPU (it would just not go through) I experienced a lot of bending due to the softness of my tube, so I did the SK-Go2_PTFE_Tube_antibend_50mm.stl and SK-Go2_PTFE_Tube_antibend_100mm.stl clips. Just put them around the tube where there should be no bending.

6.

Due to feedback I remoddled the z-axis assembly gauges (increased the hole size to improve the tolerances). I also included the step files for the gauges so you can tune it if you still have issues with the size of the holes.

This is the v0.1 of this thing, so it may contain errors. Please let me know immediately if you stumble across some errors or inconsistencies, so I can improve the thing for all the others!

I do not guarantee that the things and Marlin configuration are working with your printer! If you are using any of those things or Marlin configuration you are doing it on our own risk!

First of all:

I want to thank Ernest Lin for providing such great printers and all the support you need to get up and running.

For those who are thinking of ordering a printer and will go along with the credo “SecKit, Your Second 3D Printer Kit the overkill CoreXY platform to get you out of endless repair-tweak-upgrade loop and get things done” it’s definitely worth the wait when ordering at https://seckit3dp.design/ since you will get a complete set which contains all the necessary parts to build (it took me around 20hrs) a working industry grade printer. During the build I already started to work on some upgrades I found on thingiverse and also designed myself. So I created this thing to:

Share the list/links of self printed parts I added to the printer including the stl files of some additionally designed parts I added to the printer. Some of the files will replace the files Ernest is providing on his github page, so you may always doublecheck which design you prefer. This also includes the optional Frame mounted filament holder DELUXE

Share the details about applying the optional optical endstops to my printer running 2209 stepper drivers (files and Marlin 2.x changes)

Share the details about adding an optional BL-Touch to my printer (files and Marlin 2.x changes)

Upgrades for direct drive setup with E3D V6 hotend

Some of the parts of the Shopping list might already be included in the SecKit kit.

Basic setup

Parts to be printed:

SK-Go2_Z-Rail_Lower_Endstop.stl (this protects the linear rail block from the z rail from sliding of the rail while assembly)

Shopping list:

-- 2 pcs M4x8 bolt

-- 2 pcs M4 t-nut

SK_Go2_X_min_sensorless_homing_bumper_and_assembly_bumper.stl (applied on both sides of the x axis this protects the linear rail block from the x rail from sliding of the rail while assembly; it is replacing the original SK-Go X-min sensorless homing bumper from SecKit github)

SK-Go2_Position_A_Y-Endstop_Railmounted.stl (This endstop ensures that the part cooling fan is not touching the upper frontal 20x20 aluminum extrusion if raised to the top, see picture of how I set up the frame)

Shopping list:

-- 2 pcs M3x20 bolt

-- 2 pcs M3 washers

SK-Go2_5mm_Shorter_Nylontube_Replacement_for_Bedlevellingscrew.stl (this replaces the 10mm nylon spacer for the left and right bed leveling screw at the z rails)

SK-Go2_Fanduct_Nut_Holder_LH.stl & SK-Go2_Fanduct_Nut_Holder_RH.stl (this clips are holding the M3 nuts for the fanduct assembly in place while clipping on the lower carriage spacers, see also picture; this will come in handy if you are tuning the hotend and have to reassemble the duct multiple times)

SK-Go2_Z-Axis_assembly_gauge_Lead_Screw_Only.stl & SK-Go2_Z-Axis_assembly_gauge_Lead_Screw_Nut.stl (this helps to allign the z-axis with the lead screw. First use the gauges to center the linear rail on the 2020 extrusion (this replaces the original gauge) then place the lead screw nut in the lower part, the lead screw in the upper part to assemble the lower lead screw bearing. Before tightening the bearing to the lower 2020 extrusion, just revolve the lead screw multiple times to make sure the bearing with the leadscrew in it is alligned to the linear rail)

SK-Go2_Z-Rail_Lower_Endstop.stl (this protects the linear rail block from the z rail from sliding of the rail while assembly)

SK-Go2_Extruder_Frame_Cable_Bracket.stl (This bracket can be attached to the extruder and the frame at the back. It is featuring a 4mm hole to apply a standard PTFE tube for better cable guidance)

Shopping list:

-- 4 pcs M3x10 bolt (use M3x15 bolts if you also plan to go with the X and Y optical endstop)

-- 4 pcs M3 washers

-- 4 pcs M3 nut

-- 2 pcs M4x8 bolt

-- 2 pcs M4 t-nut

-- approx 50cm PTFE tube 4mm outer diameter

SK-Go2_Reverse_Bowden_Extruder_Bracket.stl (This bracket will take away the bending from the BMG extruder fitting where the reverse bowden tube is attached)

Shopping list:

-- 2 pcs M3x10 bolt (M3x15 will also fit)

-- 2 pcs M3 nut

SK-Go2_PTFE_Tube_antibend_50mm.stl and SK-Go2_PTFE_Tube_antibend_100mm.stl (optional) (If you are planning to replace the original reverse bowden tube with a softer one and experience some bending, just clip those on the outside of the tube where it should not bend)

SK-Go filament sensor holder by Michael Laws.stl (taken from printed parts STL folder from SecKit github)

Shopping list:

-- 2 pcs M4x10 bolt

-- 2 pcs M4 t-nut

-- 2 pcs M2 washers

-- 2 pcs M3x15 bolt

-- 2 pcs M3 washers

SK-Go fan duct.v2.direct.stl (taken from printed parts STL folder from SecKit github)

Shopping list:

-- 2 pcs M3x10 bolt

-- 2 pcs M3 nut

12864 display cover with slope.stl (taken from printed parts STL folder from SecKit github)

Shopping list:

-- 2 pcs M3x20 bolt

-- 2 pcs M3 nut

-- 2 pcs M4x10 bolt

-- 2 pcs M4 t-nut

-- 2 pcs M4 washers

SG-Go2_20x20_angled_Bracket_for_Display_Cover.stl (fits only to the two additinal holes of the 12864 display cover with slope.stl)

Shopping list:

-- 2 pcs M4x8 bolt

-- 2 pcs M4x10 bolt

-- 2 pcs M4 t-nut

-- 2 pcs M4 nut

-- 2 pcs M4 washers

Seckit Go 2 - ZMount Shims (from Thingiverse Some z-leadscrew bearing tend to grind into the horizontal 2020 extrusion. alpokemon designed mulitple diameters. just put them under the bearing, tighten the nuts and make sure, the inner bearing is turing without any contact to the extrusion)

Meanwell LRS-350-24 cover for SecKit SK-GO (from Thingiverse)

Shopping list:

-- 2 pcs M4x8 bolt

-- 2 pcs M4 washers

SecKit open angled cover with logo (from Thingiverse)

Shopping list:

-- 2 pcs M3x15 bolt

-- 2 pcs M3 nut

Belt Tensioner for sk go 3d printer (from Thingiverse)

Shopping list:

-- 4 pcs M3x20 bolt

-- 4 pcs M3 nut

SKR v1.3 Ducted Stepper Driver Cooler (from Thingiverse replaces SK-Go driver cooling fan mount.stl)

Shopping list:

-- 4 pcs M3x15 bolt

-- 4 pcs M3 nut

SKR 1.3 Board Drivercooler Clips for Things 3576392 and 4163812 - SKR_1.3_Board_Drivercooler_Clip.stl and SKR_1.3_Board_Drivercooler_Fan_Side_Clip_thing_4163812.stl ([from Thingiverse]( https://www.thingiverse.com/thing:4570496) clips the SKR v1.3 Ducted Stepper Driver Cooler to the board)

YACC (Yet Another Cable Clip) for 20x20 Aluminum Extrusion 8mm (from Thingiverse)

Frame mounted filament holder DELUXE (optional)

Parts to be printed

SK-Go2_Filament_Holder_DELUXE_Bracket.stl (to mount the Ender 3 - Filament holder DELUXE to the frame. Replacing Mounting_bracket.stl and Mounting_bracket_nut.stl)

SG-Go2_20x20_angled_Bracket.stl (optional if you assemble the SK-Go2_Filament_Holder_DELUXE_Bracket.stl to the 20x20 rail)

Ender 3 - Filament holder DELUXE - Filament_holder.stl, Filament_nut.stl and Optional_thread_guide.stl (from Thingiverse)

Shopping list:

-- 16 cm long M8 threadbar

-- 2 pcs 608Z bearings

-- 2 pcs M8 nylon lock nuts

-- 2 pcs M8 washers

-- 4 pcs M4x10 bolt

-- 2 pcs M4x8 bolt

-- 4 pcs M4 t-nut

-- 2 pcs M4 nut

-- 6 pcs M4 washers

SK-Go2_Filament_Guide.stl (Mounts just above the SK-Go2_Filament_Holder_DELUXE_Bracket.stl on the vertical 2020 extrusion. It will stop the filament from getting tangled around the Filament_Holder_DELUXE bracket when having a new spool.)

Shopping list:

-- 2 pcs M3x10 bolt

-- 2 pcs M3 washers

-- 2 pcs M3 t-nut

X and Y optical endstop (optional)

Parts to be printed

SK_Go2_X_min_sensorless_homing_bumper_and_assembly_bumper_with_optical_endstop_trigger.stl (this is replacing the left SK_Go2_X_min_sensorless_homing_bumper_and_assembly_bumper.stl)

SK-Go2_X_Optical_Endstop_Mount_Addon_Bracket.stl (to be attached at the back of the SK-Go2_Extruder_Frame_Cable_Bracket.stl)

Shopping list:

-- 1 pcs LERDGE Optical Endstop (one is included in the kit)

-- 2 pcs M3x8 bolt

-- 2 pcs M3 nut

Y optical endstop mount.stl (taken from printed parts STL folder from SecKit github)

Shopping list:

-- 2 pcs M3x8 bolt

-- 2 pcs M3 nut

-- 2 pcs M4x8 bolt

-- 2 pcs M4 t-nut

Y optical endstop trigger.stl (taken from printed parts STL folder from SecKit github)

Connecting to mainboard

Unplug the xst and yst jumper on the SKR 1.3 board for the optical sensors to work with the board (board connect an pin layout picture included). Connect the Sensor to the x- and y- endstop pin. Make sure that the pins are matching up (see also assembly manual). you might have to change the order of the wires to have the V, G and S pin at the sensor matching the V, G and S pin at the board. If the sensor is wired up correctly, you will a a green LED shining as soon as you put an object into the sensor gap.

Fun fact : Consider the material you are using to print the SK_Go2_X_min_sensorless_homing_bumper_and_assembly_bumper_with_optical_endstop_trigger.stl and Y optical endstop trigger.stl endstop triggers. I was using SUNLU PETG green and it was somehow not triggering the sensor. I had to wrap it in black tape to make it work.

BL-Touch (optional)

Parts to be printed

SKGO Fan Duct with BLTouch (from Thingiverse replaces SK-Go fan duct.v2.direct.stl)

Shopping list:

-- ANTCLABS BL Touch V3.1 https://www.antclabs.com/bltouch-v3 (e.g. from Aliexpress )

-- Alternatively a cheaper clone like the 3D touch (e.g. from Aliexpress this one comes already with a 1m cable extension )

-- 5x 1m cable with cable to female dupont pins. (needed to extend the BL Touch wires. Some bundles are already including this cable)

Connecting to mainboard

Thanks to Chris Riley’s YouTube tutorial I was able to get this done easily.

Unplug the zst jumper on the SKR 1.3 board for the BLToouch to work with the board (board connect an pin layout picture included). Connect the your black/white cable to the z- endstop pins. Connect the brown/red/orange cable to the SERVOS pins on the SKR 1.3 board. Make sure that the pins are matching up (BLTouch wiring picture included). You have to exchange the red and the brown wire if you are using an 3 pin extension plug for the SERVOS cable.

Configuration of Marlin for X and Y optical endstop and BL-Touch

I included my current versions of:

Configuration.h

Configuration_adv.h

Make sure not to copy those files but use a text editor to compare those files with your original ones to identify the changes and modify your original files.

Every change is commented with “// upgrade_set:” so you also can search for all the changes if comparing is no good for you.

Octoprint on raspberry (octopi) with the 7″ touchscreen monitor for Raspberry Pi using the TouchUI with the Boot-To-Browser option. (optional)

If you were puzzled about the screen assembled to the top of my frame…..

Since I have done a lot of customizing on my octoprint to control my SK-Go² (e.g. temperature presents, movement and bed levelling support) by using the Terminal Commands Extended plugin, I now wanted to be able to use this without having a computer up and running.

And again thanks to Chris Rileys YouTube tutorial https://www.youtube.com/watch?v=rqy3dVZ4JH4 it was easy to utilize my 7″ touchscreen monitor for Raspberry Pi I had laying around to get it done.

Shopping list:

-- Raspberry pi incl. power supply (I used a 3B+)

-- approx.. 1.5m USB A cable (e.g. from AliExpress)

-- 7″ touchscreen monitor for Raspberry Pi (I used the original bought from Amazon which came with a housing I could directly mount to the 20x20 extrusion using 2x M4x8 bolt and 2x M4 t-nuts) you can also use other screens and sizes and for some you should find housings on thingiverse. I just had some trouble trying it with a 3.5″ touchscreen form KUMAN since the driver was somehow stopped my PiCamera from working.

-- Raspberry pi camera (I used a fisheye one from Amazon) you will need to also by a longer camera cable approx. 30-100cm, depending on where you want to mount your camera and you raspberry pi. Depending on your camera type you will already find some printable mounts fitting on a 20x20 extrusion (e.g. https://www.thingiverse.com/thing:434600 , https://www.thingiverse.com/thing:2804612 or https://www.thingiverse.com/thing:3565707

-- USB LED strip (e.g. 2m non remote from AliExpress) I just put the strip in the slot of the extrusions.

Octoprint configuration

I uploaded my octoprint configuration, so you just have to use the octoprint setting Backup & Restore to get all my add-ons and commands for the SK-Go². Since I am also running a Anet A8, Geeetech A10M and a Creality CR10sPRO you will also find some commands for those printers. Just delete the commands in the octoprint settings by configuring the Terminal Commands Extended plugin.

Dual Z-Axis Setup incl. Marlin 2.0.x for SKR 1.4 Turbo and S42B closed loop steppers

I decided to further upgrade my printer. You can find the details at my new thing :https://www.thingiverse.com/thing:4631780

Updates:

1.

I did some tuning the

Configuration.h

Configuration_adv.h

files, adjusting the bed position and size to my assembly. I also adjusted the filament preheat settings and some minor stuff. Again all the changes are flagged with “// upgrade_set:”.

2.

I added some commands to octoprint Terminal Commands Extended in order to follow the UBL procedure described by Chris Riley’s YouTube tutorial for UBL.

3.

I added some tiny clips which will hold the M3 nuts of the fanduct in place. (while tuning the hotend I had to reassemble the extruder some times and every time the two M3 nuts were a pain to hold in place for assembly) The clips will go on the lower spacers of the carriage.

4.

I create some gauges to help assembly the z-axis. You will also find the FreeCAD model if you have to adjust the tolerances for yourself.

5.

I tuned the reverse bowden setup. The SK-Go2_Filament_Guide.stl will prevent the filament from getting tangled around the filament holder deluxe. The SK-Go2_Reverse_Bowden_Extruder_Bracket.stl will allow you to take away the bending from the PTFE tube fitting at the BMG extruder. Since I had to replace the original, stiff reverse bowden tube with a standard PTFE tube to feed TPU (it would just not go through) I experienced a lot of bending due to the softness of my tube, so I did the SK-Go2_PTFE_Tube_antibend_50mm.stl and SK-Go2_PTFE_Tube_antibend_100mm.stl clips. Just put them around the tube where there should be no bending.

6.

Due to feedback I remoddled the z-axis assembly gauges (increased the hole size to improve the tolerances). I also included the step files for the gauges so you can tune it if you still have issues with the size of the holes.

Similar models

thingiverse

free

SecKit SK-Go linear rail end stop

...eed to print 4 of these which use the existing screw holes for position a rail setup.

designed to fit m3 screw 16mm+ and m3 nut.

thingiverse

free

Seckit Sk-go cable chain mount

...m3s.

find the cable chain here: https://www.amazon.com/gp/product/b07wdvjb8w/ref=ppx_yo_dt_b_asin_title_o00_s02?ie=utf8&psc=1

thingiverse

free

Universal Short Ender-3 Z-axis optical endstop by Mike_Toff

...olts м3х12 - 2 pcs for sensor mounting

m3 nuts - 2 pcs for sensor mounting

washers м3 - 2 pcs for sensor mounting

fits everything

thingiverse

free

SecKit Go Cable Manager

...seckit go cable manager

thingiverse

skr 1.3 cable management for the seckit go.

thingiverse

free

Seckit SK-Go Optical X and Y Endstops by oflithing

...39;s what can be seen in the pictures. in that latter configuration the endstop will only fit in position b for the linear rails.

thingiverse

free

Seckit SK-GO Filament Sensor Mount

... (two for the spacer on the m3x16)

2 m3x8 bolts

2 m3 t-nuts

the nuts on the back are a tight fit, i used pliers to press them in.

thingiverse

free

Hypercube EVO z-max sensor mount by rjcuomo1

...0 screws

(2) m5 t-nuts for 3030 extrusion

(2) m5 t-nuts for 2020 extrusion

(1) optical endstop (this style: http://a.co/4d1igfr )

thingiverse

free

Tevo Black Widow - Z Endstop Adjustable by bdwalker1

... as well)

m3 washer

m3 thumb screw nut

parts for attaching mount to printer:

m4x8 screw (x2)

m4 washer (x2)

m4 drop-in t-nut (x2)

thingiverse

free

Mechanical Endstop Side Mount and M3 Superman Pusher by ngoconwood

...ake it more fun, i decided to make a flying superman push it. for the reach3d printer, a m3x16 bolt and 2 m3 nuts will be needed.

thingiverse

free

Adjustable Endstop holder for Delta Kossel with 2020 AL by JanN_H

..." to interrupt the beam in the optical switch - find the best of thousands in thingiverse or construct one by yourself ;-).

Seckit

thingiverse

free

SecKit Go Cable Manager

...seckit go cable manager

thingiverse

skr 1.3 cable management for the seckit go.

thingiverse

free

Seckit SKGo2 Foot by stevenvo

...seckit skgo2 foot by stevenvo

thingiverse

printed foot that makes the base higher for customized z stepper placement.

thingiverse

free

SecKit Z Watch by Dude2475

...an color it with a pen.

the pointer: needs support

have fun with it :-)

youtube video:https://www.youtube.com/watch?v=jh0skkztefc

thingiverse

free

Seckit SkGo2 stepper support by L33dpl

...k and simple design.

step included, feel free to edit.

compatible with mount/tensioner:https://www.thingiverse.com/thing:4659141

thingiverse

free

SecKit Sk-Go2 Powercord connector box by tlex

...ctor box by tlex

thingiverse

power cord cover with the seckit logo.

printed with 0.6mm nozzle.

uses 2 t-nut to attach the frame.

thingiverse

free

Seckit Go Raspberry Pi Mount

...s for any raspberry pi case with mount screws at 68mm x 98mm. you can either press fit m3 nuts on the mount or screw in m3 bolts.

thingiverse

free

Seckit SkGo2 Z End stop by stevenvo

...seckit skgo2 z end stop by stevenvo

thingiverse

z end stop for alignment of bed

thingiverse

free

SecKit SK GO 350 Railcover by Dude2475

...es are for the left side - just mirror it in your slicer for the right side.

feel free to modify - the fusion360 file is included

thingiverse

free

Seckit Sk-Go2 Benoît Bed Bracket by sanblangar

...seckit sk-go2 benoît bed bracket by sanblangar

thingiverse

brackets for sk-go2 bed

thingiverse

free

Seckit SK-GO Camera holder by Marcelofs13

...-go camera holder by marcelofs13

thingiverse

for mounting the camera you need to print the screw mount that your camera supports

Caesar

turbosquid

$6

Caesars

...id

royalty free 3d model caesars for download as obj and c4d on turbosquid: 3d models for games, architecture, videos. (1423454)

turbosquid

$39

Caesar

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

Кровать CAESAR Ipe Cavalli Visionnaire CAESAR BED

...re

кровать caesar ipe cavalli visionnaire caesar bed

стиль: арт-деко / гламур

размеры:

(дхшхв): 222x235x118

(дхшхв): 242x235x118

3ddd

free

Smania Caesar Train

...d

caesar , smania , train

текстуры присутствуют

turbosquid

$9

Caesar Coin

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$35

caius julius caesar

...caius julius caesar

3dexport

caius julius caesar 3d model, multiple import formats.<br>thank you for reading

3ddd

$1

Caesar Palace armchair

...assical feeling, this single sofa is crafted from top-grade material, quite popular among customers.

dimensions: 1170*900*1050mm

3d_export

$12

Caesar 3D Model

...xport

dining set furniture chair table cupboard plate vase glass vray max hdri material

caesar 3d model dexter_hus 10592 3dexport

turbosquid

free

Bed Smania Caesar

...odel bed smania caesar for download as max, max, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1537972)

3ddd

$1

Кресло Caesar PLCAESAR01 Smania

...100x81 арт.plcaesar01

подробнее:http://italini.ru/mebel/smania/kreslo_caesar_plcaesar01

полигонов: 74149

вершин: 74803

1111

3d_export

$33

mountain 1111

...mountain 1111

3dexport

mountain 3d model

turbosquid

$30

1111.max

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$15

human-1111

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

vaz 1111

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$20

Ring 1111 3D Model

...3d model

3dexport

ring 1111

ring 1111 3d model download .c4d .max .obj .fbx .ma .lwo .3ds .3dm .stl gorgsalvatore 113325 3dexport

turbosquid

$119

Vaz -1111 Oka

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

free

Light Prestige Melbourne 1111-03

...ht prestige , восток

подвесной светильник light prestige серии melbourne артикул 1111-03

turbosquid

$10

Chelini Console Art. 1111

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

humster3d

$75

3D model of Lada Oka 1111 1989

... detailed 3d model of lada oka 1111 1989 in various file formats. all our 3d models were created maximally close to the original.

3d_export

$50

3D Home 1111 3D Model

...chair furniture texture table lamp apartment rug carpet restaurant hotel sitting

3d home 1111 3d model richard3015 45247 3dexport

Sk

3d_export

$5

rifle sks

...rifle sks

3dexport

rifle sks simonov

turbosquid

$13

sks

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$5

SK CAR

...

turbosquid

royalty free 3d model sk car for download as fbx on turbosquid: 3d models for games, architecture, videos. (1320169)

3ddd

free

Braun sk 2

...braun sk 2

3ddd

braun , радиоприемник.

легендарный braun sk 2.

turbosquid

$15

SK Kitchen

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

lowpoly sks

...lowpoly sks

3dexport

contact me if you need cheap lowpoly models

turbosquid

$26

SK-16 Kit

... free 3d model sk-16 kit(1) for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1281106)

humster3d

$75

3D model of SKS 45

...ter3d

buy a detailed 3d model of sks 45 in various file formats. all our 3d models were created maximally close to the original.

3ddd

$1

Дверь межкомнатная sk-001d

...ная sk-001d

3ddd

дверь

дверь межкомнатная sk-001d

дизайн от ооо "ск-студия"

сайт студии:http://1sk-studio.ru/

turbosquid

$2

Computer Desk SK-22

...el computer desk sk-22 for download as 3ds, max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1190666)

Xy

3ddd

$1

Вешалка напольная XY-027

...а штанги: 171 см

диаметр основания: 38 смhttp://mebelshopos.ru/aksessuary-ofisnye/veshalka-napolnaya-xy-027-detail.html

turbosquid

$9

XY Rectangular Dining Table

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

holly hunt xy bench

...eight: 17.75 in

width: 45 in, 26 in

depth: 18 in

больше превьюhttps://www.behance.net/gallery/24983999/bench-3d-model?

turbosquid

$8

Xy fine tuning handle adjusts the module

...odule for download as 3ds, max, ige, obj, fbx, stl, and sldas on turbosquid: 3d models for games, architecture, videos. (1331394)

3ddd

$1

pillows bed 2

...pillows bed 2 3ddd подушка , круглая dimensions: xy ...

3ddd

$1

Honeycomb Floor

...паркет parquet with metalic honeycomb floor demensions 500x500 cm xy multitexture +...

3d_export

$7

positioning screw mechanism

...and lead screw, constitute a double displacement adjustable mechanism, xy axis double position adjustable positioning.<br>**************************************<br>files format contains<br>-solidworks 2017<br>-step<br>-iges<br>- and...

3d_export

$9

positioning mechanism of heavy-duty platform

...activity -- ball mechanism activity ---- drive heavy load xy axis movement -- positioning completed<br>**************************************<br>files format contains<br>-solidworks 2017<br>-step<br>-iges<br>- and...

3d_export

$180

optical fiber laser marking machines assembly

...fiber laser marking machine<br>automatic loading and unloading laser marking machine<br>xy platform adjustable laser marking machine<br>laser marking machine used with...

thingiverse

free

XY ROBOT by ymtlab

...xy robot by ymtlab

thingiverse

xy robot

Bl

3ddd

$1

Blest bl

...blest bl

3ddd

blest

blest bl 2880х1500 мм

design_connected

$11

Hase BL

...hase bl

designconnected

kalmar hase bl computer generated 3d model. designed by j.t kalmar design team.

turbosquid

$49

Peterbilt BLS

...quid

royalty free 3d model peterbilt bls for download as max on turbosquid: 3d models for games, architecture, videos. (1349236)

turbosquid

$69

Sandra BL

...

royalty free 3d model sandra bl 3d model for download as fbx on turbosquid: 3d models for games, architecture, videos. (1575281)

turbosquid

$10

BL Skylark

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

BL Breezy

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

Blest BL 101

...blest bl 101

3ddd

blest

три конфигурации модульного дивана bl 101, от фабрики blest

3ddd

free

ITALUX EMPORIO V2305-BL

...italux emporio v2305-bl

3ddd

italux , emporio

italux emporio v2305-bl

3ddd

free

BILLY BL FLOOR LAMP

...billy bl floor lamp

3ddd

monoqi

billy bl floor lamp

kalmar werkstaetten

turbosquid

$10

pivotal 51799-bl

...d

royalty free 3d model pivotal 51799-bl for download as max on turbosquid: 3d models for games, architecture, videos. (1400644)

Starter

turbosquid

$12

Starter old

...royalty free 3d model starter old for download as obj and fbx on turbosquid: 3d models for games, architecture, videos. (1293428)

turbosquid

free

Cream Starter

...free 3d model cream starter for download as fbx, dae, and stl on turbosquid: 3d models for games, architecture, videos. (1408178)

turbosquid

$2

Fire Starter

...ree 3d model fire starter for download as obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1371386)

turbosquid

$11

starter castle.dxf

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

Fluorescent Starter

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$6

Philips starter

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Starter Spider

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$5

starter wheel for the brushcutter

...d model starter wheel for the brushcutter for download as stl on turbosquid: 3d models for games, architecture, videos. (1586931)

turbosquid

$1

man Head starter

...yalty free 3d model man head 3d starter for download as blend on turbosquid: 3d models for games, architecture, videos. (1575541)

turbosquid

$11

starter castle.3ds

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Endstop

thingiverse

free

Endstop-holder for endstop v1.2 by albiuz

...endstop-holder for endstop v1.2 by albiuz

thingiverse

endstop-holder designed for mech endstop v1.2

thingiverse

free

Endstop by 3dboxpro

...endstop by 3dboxpro

thingiverse

endstop

thingiverse

free

Endstop by 1sPiRe

...endstop by 1spire

thingiverse

endstop model for conceptions

thingiverse

free

Endstop holder for Opto or Mechanical endstops by LulzBot

... endstops by lulzbot

thingiverse

these are the standard 1.0 prusa endstops with an added mounting hole for mechanical endstops.

thingiverse

free

Endstop Holder by onurhamdiuzun

...endstop holder by onurhamdiuzun

thingiverse

endstop holder for makerbot endstop and other endstops

thingiverse

free

Endstop Cover

...endstop cover

thingiverse

cover for endstop boards for makerbot design.

thingiverse

free

Endstop Mount for optical Endstops by Whitehawk2000

...whitehawk2000

thingiverse

use two 20mm m3 screws and nuts to screw the endstop onto the mount and just clip it onto the 8mm rod.

thingiverse

free

C-beam endstop mount for Makerbot type endstops

...c-beam endstop mount for makerbot type endstops

thingiverse

c-beam endstop mount for makerbot type endstop boards.

thingiverse

free

Endstop Mount for MakerBot Mecanical Endstop. by nka

...v-slots carriage.

endstop is screw with m3 (8mm) tapped hole and the endstop hold on the extrusion using a m5 (8mm) and t-nuts.

thingiverse

free

ENDSTOP 10mm by desert500

...endstop 10mm by desert500

thingiverse

endstop

Optical

design_connected

$9

Optic

...optic

designconnected

alessi optic computer generated 3d model. designed by colombo, joe.

3ddd

$1

обои OPTIC

...обои optic

3ddd

в архиве текстуры и фото обоев из коллекции optic.

archive3d

free

Optics 3D Model

...optics 3d model

archive3d

optics

optics - 3d model (*.gsm+*.3ds) for interior 3d visualization.

turbosquid

$49

optical eyewear

...id

royalty free 3d model optical eyewear for download as max on turbosquid: 3d models for games, architecture, videos. (1592243)

3d_ocean

$5

optical mouses

...al mouses

3docean

3d models computer electronics mouse

optical mouses 3d models. realistic mouse model. custom and unique design.

turbosquid

$10

Optic cross

...yalty free 3d model optic cross for download as sldas and ige on turbosquid: 3d models for games, architecture, videos. (1683403)

turbosquid

$7

OPTIC Mirror

... free 3d model optic mirror for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1223927)

turbosquid

free

Fiber optics

...d model fiber optics for download as 3ds, obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1211912)

turbosquid

$8

Mouse optical

...3d model mouse optical for download as 3ds, obj, c4d, and fbx on turbosquid: 3d models for games, architecture, videos. (1504476)

turbosquid

free

Optical puzzle

... optical puzzle for download as max, ige, fbx, stl, and sldas on turbosquid: 3d models for games, architecture, videos. (1405925)

Bumper

turbosquid

free

Bumper

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

Bumper Front

...squid

royalty free 3d model bumper front for download as obj on turbosquid: 3d models for games, architecture, videos. (1550133)

turbosquid

$15

bumper car.br3

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

bumper arb toyota fortuner

...bumper arb toyota fortuner

3dexport

bumper arb toyota fortuner

3d_export

$7

front bumper

... it to use in other car, here it is for you. also if you need some help, tell us, and we will be happy to give you want you need.

turbosquid

$28

bumper chair by HermanMiller

...ree 3d model bumper chair by hermanmiller for download as max on turbosquid: 3d models for games, architecture, videos. (1642341)

turbosquid

$15

Dodgem Bumper car

...

royalty free 3d model dodgem bumper car for download as obj on turbosquid: 3d models for games, architecture, videos. (1418034)

turbosquid

$95

Bumper Pool Table

... 3d model bumper pool table for download as 3ds, max, and obj on turbosquid: 3d models for games, architecture, videos. (1298512)

turbosquid

$20

Red Bumper Car

...model red bumper car for download as 3ds, obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1322171)

turbosquid

$70

Bumper WAC rocket

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Upgrade

turbosquid

$15

Upgraded Glock

...e 3d model upgraded glock for download as obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1185950)

3ddd

$1

Calligaris / UPGRADE

...calligaris / upgrade

3ddd

calligaris

c материалом

3d_export

free

cz upgrade

...cz upgrade

3dexport

https://www.buymeacoffee.com/mestrezen3d https://linktr.ee/mestrezen3

turbosquid

$80

Custer Tank upgrade

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$39

Domestos 1 upgrade

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$10

Upgraded tea cup

...upgraded tea cup

3dexport

a cup with an unusual design and a unique shape for a more enjoyable tea experience

3d_export

$8

dixy outlander classic style upgraded poplar wood lounge chair

...utlander classic style upgraded poplar wood lounge chair

3dexport

dixy outlander classic style upgraded poplar wood lounge chair

turbosquid

free

AK-12 + Upgrades low-poly 3D model

...ow-poly 3d model for download as fbx, blend, and unitypackage on turbosquid: 3d models for games, architecture, videos. (1501145)

evermotion

$700

Upgrade from V-ray 1.5 to 3.5 for 3ds max

...here is no need to purchase a new dongle - your current dongles will be reprogrammed to carry v-ray 3. evermotion 3d models shop.

evermotion

$300

Upgrade from V-Ray 2.0 to V-ray 3.5 for 3ds Max

... interface (gui) for editing settings on one machine and one render node for rendering on one machine. evermotion 3d models shop.

Als

design_connected

$11

Ales

...ales

designconnected

willisau ales computer generated 3d model. designed by kössl , ulrich.

3ddd

$1

GINGER ALE CHAIR

...ginger ale chair

3ddd

ginger , ale

ginger ale chair

turbosquid

$100

abed al kader al jaziery house

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

Jaber Al-Ahmad Al-Sabah trophy

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$3

Ale Horn

...turbosquid

royalty free 3d model ale horn for download as ma on turbosquid: 3d models for games, architecture, videos. (1390503)

3ddd

$1

Стол Bene AL

...водителя bene al

длина 2000, ширина 1000, высота 755http://bene.com/ru/ofisnye-reshenija/ofisnye-interery/al-executive/

3ddd

$1

stool al

...stool al

3ddd

барный

www.tsinos.gr

turbosquid

$20

als AutoLoading.max

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$14

Bene Al

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$10

al-jazeera representative

...al-jazeera representative

3dexport

colgante alusivo a la isla- al jazeera. diseño sencillo pero audaz

Touch

3ddd

$1

Touch

...touch

3ddd

touch , альфа банк

электронный терминал для очереди

3ddd

$1

GSG / Touch

... ванна

http://www.ceramicagsg.com/sanitaryware-touch/bathtub-touch-free-standing.html

turbosquid

$10

Oculus Touch

...squid

royalty free 3d model oculus touch for download as skp on turbosquid: 3d models for games, architecture, videos. (1462433)

turbosquid

$64

iPod Touch

...ty free 3d model ipod touch for download as 3ds, max, and obj on turbosquid: 3d models for games, architecture, videos. (1299603)

3ddd

$1

iPod Touch 5

...ipod touch 5

3ddd

apple , плеер

модель ipod touch 5

3ddd

$1

Asnaghi "Touch"

...asnaghi "touch"

3ddd

asnaghi , touch

фабрика: asnaghi

модель: touch

3ddd

free

Japanese stone touch

...japanese stone touch

3ddd

фонарь

japanese stone garden touch

японский садовый фонарь

икеокоми-гата

3d_ocean

$15

IPOD TOUCH 5

...apple blender ipad iphone ipod mp3 nano player touch

3d model of ipod touch 5 in 3 colours. available in .3ds, .blend, .obj, .x3d

3d_ocean

$12

iPod touch 5G

...pod jobs nano steve touch

ipod touch 3d model. formats, fbx, obj, max(2010) textures and materials with multiple colors included.

3ddd

$1

HTC Touch HD

...http://www.gsmarena.com/htc_touch_hd-2525.php фото:http://i.smartphone.ua/img/phones/htc-touch-hd/foto_001.jpg

Clips

archibase_planet

free

Clip

...clip

archibase planet

paper-clip clip office equipment

clip band - 3d model for interior 3d visualization.

3d_export

$5

screw clip

...screw clip

3dexport

screw clip

3d_ocean

$4

Butterfly clip

... a butterfly clip, it comes with a ready to render set for out of the box rendering. obj version and max alones version included.

turbosquid

$2

clip

...

royalty free 3d model clip for download as ma, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1358622)

turbosquid

$5

Clip

...lty free 3d model clip for download as c4d, 3ds, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1521355)

turbosquid

$19

Clip

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$4

Clips

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$3

clip

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$2

clips

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Clip

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Cable

3d_export

free

Cables

...cables

3dexport

cables for your purposes

3d_export

free

cable belt for cable organization

...ze your cables in 3d printers. it will bend only to one direction. the area to put the cables per piece is aprox. 1,6cmx2,6cmx1cm

3d_ocean

$16

Ethernet Cable

...ethernet cable

3docean

cable computer electronics ethernet internet network connected

ethernet cable 3d model

3d_export

$65

cable

...cable

3dexport

simple rendering of the scene file

turbosquid

$14

Cable

...l cable for download as ma, max, fbx, 3ds, gltf, obj, and stl on turbosquid: 3d models for games, architecture, videos. (1631358)

3ddd

$1

Cable Cover

...cable cover

3ddd

кабель

vertebra passacavo - cable cover

max + vray 2.20.03

3d_export

$15

Cable reel

...without cable. textures 4k 4096x4096 targa, png, jpeg.<br>number of polygons without cable: 2896<br>with cable: 35328

3d_export

$7

short cable

...short cable

3dexport

rubber cord. very detailed. cable thickness: 2.55 mm total length: 55mm

3d_export

$5

USB CABLE

...usb cable

3dexport

turbosquid

$30

Cable Reels

...osquid

royalty free 3d model cable reels for download as fbx on turbosquid: 3d models for games, architecture, videos. (1439507)

Filament

3ddd

$1

Filament Cage

...filament cage

3ddd

лофт , filament cage

модель бра, делалась по фото!

turbosquid

$3

FILAMENT COUNTER

...d

royalty free 3d model filament counter for download as stl on turbosquid: 3d models for games, architecture, videos. (1563049)

3d_export

$5

Filament lamp 3D Model

...filament lamp 3d model

3dexport

filament lamp 3d model kevin 54161 3dexport

3d_export

$5

Filament bulb candle 3D Model

...filament bulb candle 3d model

3dexport

filament bulb-candle

filament bulb candle 3d model kevin 54163 3dexport

3d_export

$5

Filament led light bulb

...filament led light bulb

3dexport

realistic 3d model of filament light bulb with v-ray materials.

3d_export

$5

Filament led light bulb

...filament led light bulb

3dexport

realistic 3d model of filament light bulb with v-ray materials.

3d_export

$5

Filament led light bulb

...filament led light bulb

3dexport

realistic 3d model of filament light bulb with v-ray materials.

3d_export

$5

Filament led light bulb

...filament led light bulb

3dexport

realistic 3d model of filament light bulb with v-ray materials.

3d_export

$5

Filament led light bulb

...filament led light bulb

3dexport

realistic 3d model of filament light bulb with v-ray materials.

3ddd

$1

Factory filament metal shade

...factory filament metal shade

3ddd

restoration hardware

restoration hardware. 20th c. factory filament metal shade.

Go²

turbosquid

$3

Going Merry Go

...e 3d model going merry go for download as blend, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1669967)

3ddd

$1

GO chair

...go chair

3ddd

go , bernhardt design

stacking chair,

design_connected

$18

Go Chair

...go chair

designconnected

danerka go chair computer generated 3d model. designed by lovegrove, ross.

3ddd

$1

GO IN barista

...ta

3ddd

barista , барный

стул барный go in barista

h112cm, d51cm, w42cm, seatheight 81cm

turbosquid

$40

Pixelbook GO

... free 3d model pixelbook go for download as obj, c4d, and fbx on turbosquid: 3d models for games, architecture, videos. (1473349)

turbosquid

$10

Go boy

...royalty free 3d model go boy for download as ma, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1292463)

turbosquid

$5

JBL GO

...alty free 3d model jbl go for download as obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1501036)

turbosquid

$1

Go-kart

... free 3d model go-kart for download as jpg, 3ds, obj, and md3 on turbosquid: 3d models for games, architecture, videos. (1501040)

turbosquid

$40

Go Cart.c4d

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$35

Go kart

...e 3d model go kart for download as ma, max, obj, c4d, and fbx on turbosquid: 3d models for games, architecture, videos. (1388925)

Printers

archibase_planet

free

Printer

...inter

archibase planet

printer laser printer pc equipment

printer n120614 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Printer

...rchibase planet

laser printer office equipment computer equipment

printer - 3d model (*.gsm+*.3ds) for interior 3d visualization.

turbosquid

$100

Printer

...er

turbosquid

royalty free 3d model printer for download as on turbosquid: 3d models for games, architecture, videos. (1487819)

turbosquid

$3

Printer

...turbosquid

royalty free 3d model printer for download as max on turbosquid: 3d models for games, architecture, videos. (1670230)

turbosquid

$1

printer

...turbosquid

royalty free 3d model printer for download as max on turbosquid: 3d models for games, architecture, videos. (1595546)

turbosquid

$1

printer

...turbosquid

royalty free 3d model printer for download as max on turbosquid: 3d models for games, architecture, videos. (1595105)

turbosquid

$10

Printer

...id

royalty free 3d model printer for download as max and 3dm on turbosquid: 3d models for games, architecture, videos. (1607146)

turbosquid

$7

Printer

...royalty free 3d model printer for download as ma, ma, and obj on turbosquid: 3d models for games, architecture, videos. (1644580)

turbosquid

$30

Printer

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

Printer

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

May

3ddd

$1

MAIS

...mais

3ddd

mais

описание отсутствует)

design_connected

$9

May

...may

designconnected

bonaldo may computer generated 3d model. designed by carollo, gino.

design_connected

$11

May Day

...may day

designconnected

may day computer generated 3d model. designed by grcic, konstantin.

3ddd

$1

May-lily lamp

... table lamp , may , lily

may-lily, table lamp

turbosquid

$150

jinja mai

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$10

Mai Shiranui 3D Model

...mai shiranui 3d model

3dexport

mai shiranui king of fighters

mai shiranui 3d model enryke01 25350 3dexport

3ddd

$1

полочки APRIL, MAY, JUNE

...а

полочки april, may, june

vray, max 2014, 2011, obj

http://www.archiproducts.com/ru/продукты/126395/april-may-june-bonaldo.html

turbosquid

$5

Souvenir of the May beetle

... souvenir of the may beetle for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1304506)

turbosquid

$45

Mai Dragon Nao

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$1

Bryant and May Matches

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Holder

archibase_planet

free

Holder

...holder

archibase planet

holder toilet paper holder

holder paper n070712 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Holder

...e planet

holder rack toilet paper holder

holder toilet roll n240715 - 3d model (*.gsm+*.3ds+*.max) for interior 3d visualization.

archibase_planet

free

Holder

...holder

archibase planet

pen holder support prop

pen holder - 3d model for interior 3d visualization.

archibase_planet

free

Holder

...holder

archibase planet

pole post holder

сhurch cross pole holder - 3d model for interior 3d visualization.

archibase_planet

free

Holder

...holder

archibase planet

holder bathroom ware

shower holder - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Holder

...oilet paper holder

holder paper devon&devon; time black n241113 - 3d model (*.gsm+*.3ds+*.max) for interior 3d visualization.

archibase_planet

free

Holder

...holder

archibase planet

holder hanger hanger for towel

holder 7 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Holder

...holder

archibase planet

holder hanger hanger for towel

holder 3 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Holder

...holder

archibase planet

holder towel rack towel-horse

holder - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Holder

...lder

archibase planet

holder hanger hanger for towel

holder towel n250912 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

Mount

3d_export

free

mounting bracket

...mounting plate is the portion of a hinge that attaches to the wood. mounting plates can be used indoors, cabinetry and furniture.

turbosquid

$2

MOUNTING

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Mounts

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Mount Fuji

...fuji

turbosquid

free 3d model mount fuji for download as obj on turbosquid: 3d models for games, architecture, videos. (1579977)

3d_export

$5

Headphone mount LR

...headphone mount lr

3dexport

headphone mount l+r

turbosquid

$39

Mount rainier

...quid

royalty free 3d model mount rainier for download as fbx on turbosquid: 3d models for games, architecture, videos. (1492586)

turbosquid

$5

pipe mounting

...quid

royalty free 3d model pipe mounting for download as obj on turbosquid: 3d models for games, architecture, videos. (1293744)

turbosquid

$3

Mounting Tires

...uid

royalty free 3d model mounting tires for download as fbx on turbosquid: 3d models for games, architecture, videos. (1708511)

3d_export

$5

Magnetic GoPro Mount

...pro mount

3dexport

cool magnetic mount for gopro. allows you to mount the camera on flat metal surfaces and get exclusive shots.

turbosquid

$5

Stone Mount

...ty free 3d model stone mount for download as ma, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1370306)

Work

3d_export

$5

WORKING PLATFORM

...working platform

3dexport

working platform 4000x3000x1500mm

design_connected

$16

Working set

...working set

designconnected

smallaccents working set computer generated 3d model.

3ddd

free

Pinao / Stelar Works

...pinao / stelar works

3ddd

stelar works , stellar works

стулья pinao от stelar works

design_connected

$13

Work Lamp

...work lamp

designconnected

design house stockholm work lamp computer generated 3d model. designed by form us with love.

turbosquid

$6

Road Works

...turbosquid

royalty free 3d model road works for download as on turbosquid: 3d models for games, architecture, videos. (1151328)

3ddd

free

Stellar Works Lumar

...llar works , lumar , барный

stellar works lumar

turbosquid

$20

Work boots

...bosquid

royalty free 3d model work boots for download as stl on turbosquid: 3d models for games, architecture, videos. (1313566)

turbosquid

$8

Desk Work

...osquid

royalty free 3d model desk work for download as blend on turbosquid: 3d models for games, architecture, videos. (1381338)

turbosquid

$5

Work Desk

...osquid

royalty free 3d model work desk for download as blend on turbosquid: 3d models for games, architecture, videos. (1435344)

turbosquid

$1

Plant for work

...uid

royalty free 3d model plant for work for download as obj on turbosquid: 3d models for games, architecture, videos. (1557514)

Set

archibase_planet

free

Setting

...setting

archibase planet

setting cover place setting

setting - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Setting

...setting

archibase planet

setting place setting cover

setting - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Setting

...setting

archibase planet

setting place setting cover

setting - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

$8

decorative set mens set

...decorative set mens set

3dexport

decorative set men's set

archibase_planet

free

Set

...anet

set kitchen ware kitchen set kitchen tools

set kitchen tools n281114 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Set

...set

archibase planet

beer set bar equipment

beer set - 3d model for interior 3d visualization.

archibase_planet

free

Set

...set

archibase planet

cover place setting

set - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Set

...set

archibase planet

kitchen set kitchen ware

set - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Set

...set

archibase planet

set cup glass kitchen ware

set - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Set

...set

archibase planet

flatware cover place setting

set n311210 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

Other

design_connected

$16

ST12 Other

...signconnected

photo-realistic 3d models of the st12 other stool from e15 for 3d architectural and interior design presentations.

turbosquid

$26

Oar and Other

...quid

royalty free 3d model oar and other for download as fbx on turbosquid: 3d models for games, architecture, videos. (1473409)

turbosquid

$5

chair with other

...id

royalty free 3d model chair with other for download as ma on turbosquid: 3d models for games, architecture, videos. (1171468)

3ddd

$1

parfume and other

...parfume and other

3ddd

тумбочка

create by sametyuzer

turbosquid

$79

The Others Collection

...others collection for download as 3ds, max, obj, fbx, and dae on turbosquid: 3d models for games, architecture, videos. (1480228)

turbosquid

$25

Other Man

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$15

other car.max

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$2

Other Mothers Hand

... 3d model other mothers hand for download as ma, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1663825)

turbosquid

$8

other sport wheel

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$2

pool and other elements

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.