3dExport

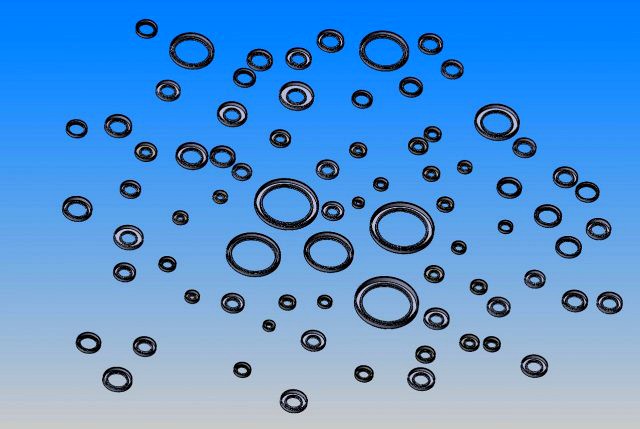

seal tc framework oil seal 126 specifications in total

by 3dExport

Last crawled date: 1 year, 9 months ago

[seal] tc framework oil seal model + technical parameters (126 specifications) can be produced according to the drawing or drawn as the selection standard 1:1. these models basically cover all the selection requirements of tc type. welcome to download! the role of the framework oil seal is to isolate the parts in the transmission parts that need to be lubricated from the output parts, so as to prevent the leakage of lubricating oil. it is usually used for the rotating shaft of the skeleton oil seal, which is a kind of rotary shaft lip seal. the skeleton is like the steel bar in the concrete component, which plays a reinforcing role and keeps the shape and tension of the oil seal. according to the framework type, it can be divided into inner framework oil seal, outer framework oil seal and inner and outer exposed framework oil seal. the framework oil seal is made of high quality nitrile rubber and steel plate, with stable quality and long service life. widely used in automobile, motorcycle crankshaft, camshaft, differential, shock absorber, engine, axle, front and rear wheels and other parts. 1. prevent sand, dust, water vapor from outside into the bearing; 2. limit the leakage of lubricating oil in the bearing. the requirements for oil seal are that the size (inner diameter, outer diameter and thickness) of oil seal should meet the requirements; it should have appropriate elasticity, be able to properly block the shaft and play a sealing role; it should be heat-resistant, wear-resistant, strong, medium resistant (oil or water, etc.) and have a long service life. reasonable use of oil seal, should pay attention to the following points: (1) due to the design and structure of the shaft, high speed oil seal should be used for high speed shaft, low speed oil seal should be used for low speed shaft, and low speed oil seal should not be used for high-speed shaft, otherwise, it is not suitable. (2) in the case of higher ambient temperature, polypropylene ester or silicon, fluorine and silicon fluorine rubber should be selected. try to reduce the oil temperature in the oil tank. when the temperature is too low, cold resistant rubber should be selected. (3) the oil seal with general pressure has poor bearing capacity, and the oil seal will deform when the pressure is too high. in case of excessive pressure, pressure bearing ring or reinforced pressure oil seal should be used. (4) if the eccentricity of oil seal and shaft is too large, the sealing performance will be poor, especially when the shaft speed is high. if the eccentricity is too large, the oil seal with "w" section can be used. (5) the surface finish of the shaft directly affects the service life of the oil seal, that is, if the shaft has a high finish, the service life of the oil seal will be long. (6) pay attention to the oil seal lip should have a certain amount of lubricating oil. (7) pay special attention to prevent dust from getting into oil seal.

Similar models

grabcad

free

Oil seal 50-62-7 / 65-85-10

...metal part and an inner flexible member that does the actual sealing and is bonded to the metal part by chemical adhesive agents.

thingiverse

free

Ninebot ESx Front wheel bearing seal by _Ilay_

...al protection of the bearing. prevents the ingress of moisture and dirt into the motor wheel, thereby extending its service life.

grabcad

free

Oil Ring

...oil ring

grabcad

its a seal which prevent oil leakage into combustion chamber

grabcad

free

Jacking Oil Plant

...e jop can be stopped after the lubricating oil film is

established between the shaft and bearings.

pressure produced is 120 bars

grabcad

free

Orenda 9/10 jet engine Centre bearing assembly

...als and are fed with air from the compressor to both cool the bearing and provide a pressure differential to prevent oil leakage.

grabcad

free

Orenda 9/10 jet engine rear bearing assembly

...urbine labyrinth seal. labyrinth seals are used to prevent excess air getting into the bearing and in turn preventing oil leakage

grabcad

free

Stuffing Box

...mbly or a shaft seal that is used as a sealing device to prevent leakages of air or water or steam from rotating or sliding shaft

grabcad

free

304 SS Roller Bearing 25.4mm Shaft Dia

...r cage

- outer race

no seal - feel free to modify and add your plastic seal

this is just an experiment in bearing design for me.

thingiverse

free

15mm 9mm slot roller bearing by Britsa007

...

use lubricating oil to ensure smooth working and minimal wear of the bearing. i packed mine with bearing grease during assembly.

grabcad

free

conveyor housing

...conveyor housing

grabcad

used to fix the shaft and sprockets of the conveyor with oil seals, bearings and sleeves

Tc

turbosquid

$750

TC

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$55

tc camel

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$15

hi tc

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$99

Scion tC 3D Model

...scion tc 3d model

3dexport

scion tc usa 2007 2008 2009 2010 2011 sport coupe

scion tc 3d model squir 11840 3dexport

3d_ocean

$89

Scion tC 2014

...y, in real units of measurement, qualitatively and maximally close to the original. model formats: - *.max (3ds max 2008 scanl...

3d_ocean

$89

Scion tC 2012

...y, in real units of measurement, qualitatively and maximally close to the original. model formats: - *.max (3ds max 2008 scanl...

3d_export

$99

Scion tC 2014 3D Model

...scion tc 2014 3d model

3dexport

2013 2014 usa 2015 2016 sport coupe 2017 scion tc

scion tc 2014 3d model squir 68322 3dexport

3d_export

$20

scion tc

...s.<br>car textures:png - 2k resolution other available formats: obj, 3ds, fbx, stl, max. polycount: 34241 poly / 34139 tris

cg_studio

$99

Scion tc 20103d model

... 20103d model

cgstudio

.3ds .max .obj - scion tc 2010 3d model, royalty free license available, instant download after purchase.

cg_studio

$99

Scion tC 20143d model

...scion tc

.3ds .c4d .fbx .lwo .max .obj - scion tc 2014 3d model, royalty free license available, instant download after purchase.

Framework

3d_export

$10

Framework 3D Model

...framework 3d model

3dexport

framework photo frames

framework 3d model vano777 101431 3dexport

turbosquid

$49

Framework cabinet

...

royalty free 3d model framework cabinet for download as max on turbosquid: 3d models for games, architecture, videos. (1291302)

turbosquid

$9

industrial framework

...oyalty free 3d model industrial framework for download as skp on turbosquid: 3d models for games, architecture, videos. (1274479)

turbosquid

$32

house framework

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

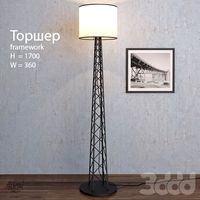

Торшер Framework

...нструкцию можно недорого изготовить. нужны лишь металл, патрон с проводом от любой промышленной переноски и умелые руки сварщика.

turbosquid

$29

Interior Framework Lamps Collection

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Framework for Ardulogic (for car acceleration measurement))

...logic (for car acceleration measurement)) for download as stl on turbosquid: 3d models for games, architecture, videos. (1448303)

3ddd

$1

Axo light Framework modelli

...axo light framework modelli

3ddd

axo light

axo light pl fw p 090, pl fw m 180, pl fw g 270

3d_export

$10

framework type rubber sealing ring for vacuum jb t1091-1991 12 specifications in total

...991 12 specifications in total

3dexport

framework type rubber sealing ring for vacuum jb t1091-1991 (12 specifications in total)

3d_export

$6

framework type rubber sealing ring for vacuum jb t1091-1991 12 specifications in total

...991 12 specifications in total

3dexport

framework type rubber sealing ring for vacuum jb t1091-1991 (12 specifications in total)

126

design_connected

$16

Otto 126

...otto 126

designconnected

gervasoni otto 126 chairs computer generated 3d model. designed by paola navone.

turbosquid

$9

Office 126

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Fiat 126

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

evermotion

$7

railing 126 am79

...key sculptures 126 am79 railing

highly detailed architecture railing with all textures and materials.. evermotion 3d models shop.

evermotion

$120

Archmodels vol. 126

...ghly detailed 3d models of grass and small plants. all models are ready to use in your visualizations. evermotion 3d models shop.

evermotion

$7

chair 126 AM147

...model of chair with textures, shaders and materials. it is ready to use, just put it into your scene.. evermotion 3d models shop.

3ddd

$1

minka group 955-126

... 955-126

minka group

minka-lavery

belcaro

№ 955-126

width: 22 in

height: 22.5 in

weight: 15.87 in

evermotion

$8

Furniture 126 AM29

...f armchair with all textures, shaders and materials. it is ready to use, just put it into your scene.. evermotion 3d models shop.

3d_export

$6

Plug for jack Mercedes 126

...ack mercedes 126

3dexport

plug for jack mercedes 126<br>заглушка для домкрата в пороги mercedes 126 l+r оригинальный скан

turbosquid

$15

126 shoe low

...oyalty free 3d model 126 shoe low for download as obj and fbx on turbosquid: 3d models for games, architecture, videos. (1259362)

Seal

3d_export

$25

seal

...seal

3dexport

seal

archibase_planet

free

Seal

...seal

archibase planet

seal pinniped

seal - 3d model (*.gsm+*.3ds) for exterior 3d visualization.

3d_export

$8

seal

...seal

3dexport

seal swims at sunset, not a high-poly model.

3d_export

$5

seal

... printed on a 3d printer and get a high-quality figure. the seal model consists of simple objects, but it looks very interesting.

turbosquid

$10

Seal

...al

turbosquid

royalty free 3d model seal for download as obj on turbosquid: 3d models for games, architecture, videos. (1261349)

turbosquid

$3

Seal

...

turbosquid

royalty free 3d model seal for download as blend on turbosquid: 3d models for games, architecture, videos. (1388674)

3d_export

$25

walrus seal

...walrus seal

3dexport

walrus seal

turbosquid

$5

Seal

...lty free 3d model seal for download as c4d, fbx, obj, and stl on turbosquid: 3d models for games, architecture, videos. (1549324)

3ddd

$1

Sealing Plaster

...sealing plaster

3ddd

розетка

decorative sealing plaster

3ddd

$1

Magical Seal

...magical seal

3ddd

ночник , seal

h=220мм

Oil

3d_ocean

$5

Oil Drum

...oil drum

3docean

gas gasoline industry oil oil barrel oil drum petrol petroleum shell texaco

an oil drum

3d_ocean

$12

Oil lamp

...oil lamp

3docean

candle lamp oil traditional

high poly oil lamp model

3d_export

$5

oil derrick

...oil derrick

3dexport

oil derrick

3ddd

$1

oil lamp

...oil lamp

3ddd

лампа

oil lamp

3d_export

$7

oil map

...l gas production displays the full cycle of production and transportation of oil and gas. created in archicad 22. file in archive

turbosquid

$1

oil

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_ocean

$5

Barrel and Oil Drum

...barrel and oil drum

3docean

barrel oil drum

oil, barrel, drum, game props

3d_export

$5

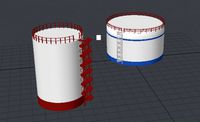

Oil storage

...oil storage

3dexport

big oil storage or barrel or storage tank 2 formats lwo & obj

3ddd

$1

Olive Oil

... масло , бутылка

fully detailed olive oil

polygon : 129,872

verts: 65,038

3d_ocean

$6

olive oil and vinegar

...olive oil and vinegar

3docean

decoration kitchen oil olive vinegar

olive oil and vinegar for kitchen renders

Total

3ddd

free

Total design

... тумба

тумба с рельефным фасадом из шпона. total design.

производитель www.ttl-design.com

3ddd

$1

Total Trainer

...total trainer

3ddd

тренажер

тренажер total trainer. моделил по фото.

3d_ocean

$8

Colgate total

...ckage tooth brush toothpaste toothpaste 3d toothpaste model toothpaste pack

colgate total is 3d model package colgate brand name.

3ddd

$1

Total Divan

...total divan

3ddd

dv home

http://www.dvhomecollection.it/en/lens_galleries/giorno/

turbosquid

$15

Total Oil barrel

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$13

Total Cereal 2

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$13

Total Cereal 1

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$7

inflatable caster 8 specifications in total

...inflatable caster 8 specifications in total

3dexport

inflatable caster (8 specifications in total)

turbosquid

$20

Total model bed classic

...lty free 3d model total model bed classic for download as max on turbosquid: 3d models for games, architecture, videos. (1143569)

3d_export

$15

Total oil Barrel 3D Model

...w stribed total oil metal barrel drum 55 gallon container textures materials

total oil barrel 3d model janiashvili 32534 3dexport

Specifications

3d_export

$10

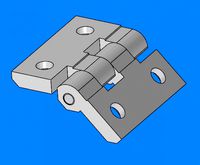

hinge and hinge 148 specifications

...hinge and hinge 148 specifications

3dexport

hinge and hinge (148 specifications)

turbosquid

free

Car No Specific Brand

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$10

of switching power supply15 specifications

...of switching power supply15 specifications

3dexport

3d model of switching power supply(15 specifications)

3d_export

$7

inflatable caster 8 specifications in total

...inflatable caster 8 specifications in total

3dexport

inflatable caster (8 specifications in total)

3d_export

$7

american light castors 13 specifications

...american light castors 13 specifications

3dexport

american light castors (13 specifications)

3d_export

$6

integrated signal lamp 20 specifications

...integrated signal lamp 20 specifications

3dexport

integrated signal lamp (20 specifications)

3d_export

$29

caterpillar 793d specifications

...caterpillar 793d specifications

3dexport

available 3d formats: .3ds .fbx .obj+mtl .jt .bin .dwf .dwg .stl .dae .skp .gltf

3d_export

$20

aluminum profile 56 specifications

...used by designers by stretching according to the length. they are widely used in mechanical, electronic and instrument equipment.

3d_export

$17

wp series reducer 34 specifications in total

...wp series reducer 34 specifications in total

3dexport

wp series reducer (34 specifications in total)

3d_export

$15

ple040 planetary reducer 18 specifications in total

...ple040 planetary reducer 18 specifications in total

3dexport

ple040 planetary reducer (18 specifications in total)