Thingiverse

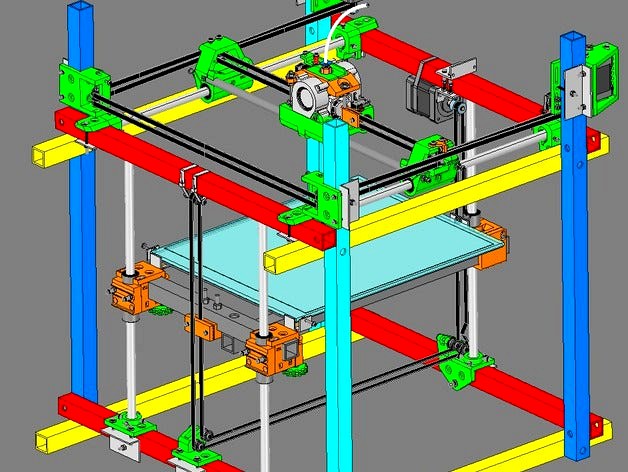

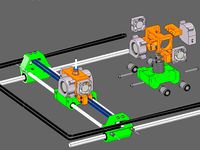

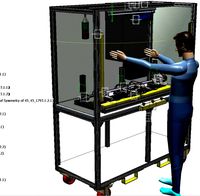

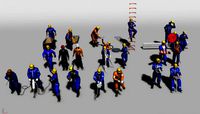

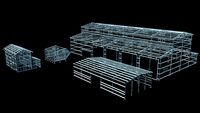

SCOUTcorexy 3D Printer (square aluminum tube frame, scout-tower-like corner nodes, dual-support Z, lots of adjustability to compensate for construction errors) by florinf-ro

by Thingiverse

Last crawled date: 3 years ago

Check latest version @ https://skfb.ly/Uuv7

!!WARNING: this is a WIP project and will take a lot of time on my side to finish due to ... life. I will often update it and correct it so come back often :).

Update 20170614: Added the .rsdoc source file for you to play with.

Navigate the 3D Model @ SketchFab:https://skfb.ly/Uuv7

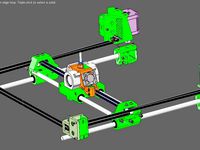

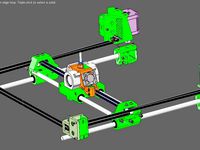

This is a CoreXY 3D printer design that has some features that should be appealing to many:

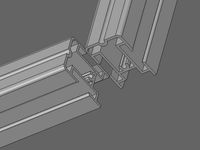

1) it uses tubular extrusion (square 20x20mm) Aluminum or Steel so it should be cheaper than T/V-slot but all parts are designed to be able to be fitted on 2020 extrusion also;;

2) all the cutting & drilling can be done by hand as the design is very forgiving, prefect straight cuts being unnecessary and perfectly matching holes are not a prerequisite;

3) all frame holes can be drilled by hand with a method I will describe when I will have built it and I release the docs (or can be drilled on a drill press according to the holes pattern I will release when ready). Holes can be slightly larger than the intended size bolts - I use M6 bolts which means holes can be M7;

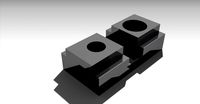

4) all the features of the printer are mobile, they slide on the tube via the square clamp that I have designed and which is a part of every part in the design;

5) Y rods are adjustable in 3D space due to the 4-points-adjusting-collars that I have designed specifically to take any misalignment of the frame and/or other errors in construction. Like I said, it's quite forgiving;

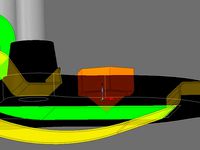

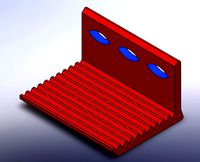

6) Z axis is dual supported, using 3 smooth rods (10mm) and has a very simple T(ee) support frame from the same square alu tubing. The important aspect of the Z is that the BearingBlocks/Bed_Clamps/Leveling&ShockAbsorbers are all embedded in a 3-part piece that can also take a lot of misalignment of the Z rods (drilling exact holes with the hand drill is impossible so I had to fix this in the design intent so you don't have to outsource any fabrication step).

Another important aspect of the Z axis is that the upper ends of the rods are inserted straight in holes in metal while the lower ends are floating in larger then their diameter holes so that perfect vertical alignment can be done -again using the 4 bolts in the collar of the lower receiving part). Once the verticality is ensured, resin can be poured in these holes to freeze the position.

Update 13/10/2016: I have uploaded the latest "RepStrap-ed" version of the original, with updated parts where better details were developed. This repstrap is due to the expensive price 3DHubs charge for the 3D printed parts and because I don't have my own printer to make them myself. The repstrap pieces are simple ALU angle pieces drilled so they are very easy to make and they use leftover aluminum angle that is used for the bed support (see 3D model). This is for now the basis for the SCOUTcorexy MotelT.

Update 01/06/2016: Another major overhaul: changed size to allow standard dimensions for belts (now a 5m roll is enough for both XY - <1.5m each - and Z - <2m -). To allow this change there have been some parts alterations (ex YRods clamps, ZRods Bearings housing and bumper pieces, etc)

Update 04/07/2016: I have uploaded the different sections' STLs in separate files, with parts arranged on bed with the right orientation for best printing. Now they are ready to be printed.

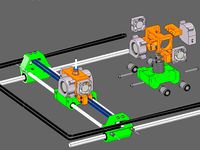

Update 26/04/2016: Pretty major change in XY Motors Support ALU tubes position (moved them to the exterior, making the frame symmetrical) and XY Motors Mounts (pictures attached). Also Updated all printed parts file.

Update 19/04/2016: Lots of fixes and streamlining of parts. New Floating Parts STL attached. Also check it @Sketchfab for a better experience: https://skfb.ly/MZR8

Update 15/04/2016: Major overhaul of the Z stage

I have updated the bearing blocks to better follow the square clamp design that all other parts feature. For some reason I didn't do this from the beginning and now it bit my backside. STL and Sketchfab models have been updated accordingly.

!!WARNING: this is a WIP project and will take a lot of time on my side to finish due to ... life. I will often update it and correct it so come back often :).

Update 20170614: Added the .rsdoc source file for you to play with.

Navigate the 3D Model @ SketchFab:https://skfb.ly/Uuv7

This is a CoreXY 3D printer design that has some features that should be appealing to many:

1) it uses tubular extrusion (square 20x20mm) Aluminum or Steel so it should be cheaper than T/V-slot but all parts are designed to be able to be fitted on 2020 extrusion also;;

2) all the cutting & drilling can be done by hand as the design is very forgiving, prefect straight cuts being unnecessary and perfectly matching holes are not a prerequisite;

3) all frame holes can be drilled by hand with a method I will describe when I will have built it and I release the docs (or can be drilled on a drill press according to the holes pattern I will release when ready). Holes can be slightly larger than the intended size bolts - I use M6 bolts which means holes can be M7;

4) all the features of the printer are mobile, they slide on the tube via the square clamp that I have designed and which is a part of every part in the design;

5) Y rods are adjustable in 3D space due to the 4-points-adjusting-collars that I have designed specifically to take any misalignment of the frame and/or other errors in construction. Like I said, it's quite forgiving;

6) Z axis is dual supported, using 3 smooth rods (10mm) and has a very simple T(ee) support frame from the same square alu tubing. The important aspect of the Z is that the BearingBlocks/Bed_Clamps/Leveling&ShockAbsorbers are all embedded in a 3-part piece that can also take a lot of misalignment of the Z rods (drilling exact holes with the hand drill is impossible so I had to fix this in the design intent so you don't have to outsource any fabrication step).

Another important aspect of the Z axis is that the upper ends of the rods are inserted straight in holes in metal while the lower ends are floating in larger then their diameter holes so that perfect vertical alignment can be done -again using the 4 bolts in the collar of the lower receiving part). Once the verticality is ensured, resin can be poured in these holes to freeze the position.

Update 13/10/2016: I have uploaded the latest "RepStrap-ed" version of the original, with updated parts where better details were developed. This repstrap is due to the expensive price 3DHubs charge for the 3D printed parts and because I don't have my own printer to make them myself. The repstrap pieces are simple ALU angle pieces drilled so they are very easy to make and they use leftover aluminum angle that is used for the bed support (see 3D model). This is for now the basis for the SCOUTcorexy MotelT.

Update 01/06/2016: Another major overhaul: changed size to allow standard dimensions for belts (now a 5m roll is enough for both XY - <1.5m each - and Z - <2m -). To allow this change there have been some parts alterations (ex YRods clamps, ZRods Bearings housing and bumper pieces, etc)

Update 04/07/2016: I have uploaded the different sections' STLs in separate files, with parts arranged on bed with the right orientation for best printing. Now they are ready to be printed.

Update 26/04/2016: Pretty major change in XY Motors Support ALU tubes position (moved them to the exterior, making the frame symmetrical) and XY Motors Mounts (pictures attached). Also Updated all printed parts file.

Update 19/04/2016: Lots of fixes and streamlining of parts. New Floating Parts STL attached. Also check it @Sketchfab for a better experience: https://skfb.ly/MZR8

Update 15/04/2016: Major overhaul of the Z stage

I have updated the bearing blocks to better follow the square clamp design that all other parts feature. For some reason I didn't do this from the beginning and now it bit my backside. STL and Sketchfab models have been updated accordingly.

Similar models

thingiverse

free

19mm Alu Square Tubing Threaded Rod Z Axis Motor Mount for the Smartrap Core by jjazzyj

...also use an m4x50 bolt not 60 as it is too long. other than that it works great! i will upload some additional build photos soon.

thingiverse

free

Endstop Mounting by dr_delta

...has wrong xy orientation. sry i will correct an update it.

(update 17.09.2017)

i have corrected the orientation, now it works. :)

grabcad

free

Square drill hole Bit design in solidworks

...ll hole required frequently . i have shown all the process how to make the part and deeply explained i hope you guys will like it

thingiverse

free

Z Plate support by THE_SHRUB

...see instructions for bom required for this upgrade.

this upgrade is also great for squaring up and adjusting your y and z axes!

thingiverse

free

Drill press for a Dremel by mitchnajmitch

... plate has 8mm holes for rods to go through and be fixed by nuts. holes in the bottom plate should be threaded with m8 screw-tap.

thingiverse

free

E-Z Canopy foot by crnook

...eady had a hole in the metal leg so i used the the same size drill bit to drill the foot all the way through.

no supports needed.

thingiverse

free

SmartrapCore Alu Axis Support For Spool holder by darhf

... not been printed yet, so consider it a work in progress.

update 2016.02.22 : trimmed inside part; added m4 hole on the top part.

thingiverse

free

P3 Steel Z-Axis Support by Paolohin

...gs are 15 mm for the difficulty of removing all of the support material.

i also added a top cap to hide threaded rod and nut bar.

thingiverse

free

Tevo Tarantula Z axis support by tanasibob

...esive. should fit a 20mm extrusion using 4mm bolts and tnut.

now i can easily square the base with the z axis using this support.

thingiverse

free

Smartrapcore standard - HK13 (8mm rods - 13mm walls) by 3DFreezeMe

...s (not tested yet, currently printing)

added profile corner braces for top and bottom

added photo's of assembly xy gantry

Scoutcorexy

thingiverse

free

SCOUTcorexy SF remix for HCE by FrancescoF

...lease, i've yet to test it printing something (i must before dismantling existing xy stuff of my hce).

last update: august 09

thingiverse

free

![3D Printer 4xLM8UU Minimal X Carriage (with symmetric/balanced tensioning mechanism) for F694zz bearings & more [#SCOUTcorexy design] by florinf-ro](/t/8833985.jpg)

3D Printer 4xLM8UU Minimal X Carriage (with symmetric/balanced tensioning mechanism) for F694zz bearings & more [#SCOUTcorexy design] by florinf-ro

...ab: http://is.gd/1l27lz)

update 08/07/2016: added the ycarriage that goes with this xcarriage design. distance between rods 40mm.

thingiverse

free

SCOUTcorexy XY_Stage XCarriage 8mm YCarriage 10mm HorizontalRods SingleHotend by florinf-ro

...d pretty quickly;

tbd:

1) some way to remove wiggle/play from the linear bearings

2) design it for dual hotend

[...]

cheers,

flo.

thingiverse

free

![3D Printer 3xLM8UU Minimal X Carriage (with symmetric/balanced tensioning mechanism) [#SCOUTcorexy design] by florinf-ro](/t/8840995.jpg)

3D Printer 3xLM8UU Minimal X Carriage (with symmetric/balanced tensioning mechanism) [#SCOUTcorexy design] by florinf-ro

...designing this x carriage for: http://www.thingiverse.com/thing:1487375 (view it in 3d @sketchfab: http://is.gd/1l27lz)

regards.

thingiverse

free

![3D Printer Minimal X Carriage [#SCOUTcorexy design] by florinf-ro](/t/8857006.jpg)

3D Printer Minimal X Carriage [#SCOUTcorexy design] by florinf-ro

...me know if you want the inductive probe clamp too, or the directcontact probe maybe.

i have also attached the rsdoc of the mount.

thingiverse

free

SCOUTcorexy XY_Stage XCarriage !!10mm!! YCarriage 10mm HorizontalRods SingleHotend by florinf-ro

... undecided here];

tbd:

1) some way to remove wiggle/play from the linear bearings

2) design it for dual hotend

[...]

cheers,

flo.

thingiverse

free

SCOUTcorexy SF-1_1012 Bushings XY_Stage XCarriage !!10mm!! YCarriage 10mm HorizontalRods SingleHotend by florinf-ro

...e];

tbd:

1) even more simplification (looks rather complicated, albeit printable)

2) design it for dual hotend

[...]

cheers,

flo.

thingiverse

free

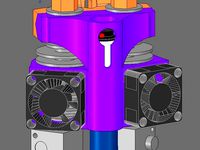

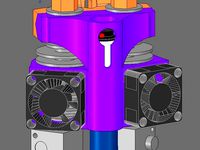

SCOUT Dual-Bowden Mount for E3D V6 CLONE Hotend (differs slightly from original dimensions) by florinf-ro

...this is the dual-bowden mount i am designing for scoutcorexy 3d printer concept (http://www.thingiverse.com/thing:1487375). it has most features common...

Florinf

thingiverse

free

Thumbwheel for jam-nuts (M5) by florinf-ro

...i don't know if anybody else would need this but nevertheless i have uploaded it to thingiverse for reference or convenience.

thingiverse

free

Compact Twin-Stand Shoe Rack by florinf-ro

... re-export the stl with your modifications.

i welcome suggestions and comments should you feel you have something to say/add/etc.

thingiverse

free

Odd Extrusion Profile Panel from Office Partitioning System by florinf-ro

...39;s not perfect match.

this is the post i opened on reprap forums for this question:http://forums.reprap.org/read.php?177,616175

thingiverse

free

Hunchback Bowden Extruder by florinf-ro

...ainst which the "shaft support thingie" -whatever it might be named- can press when the the tension bolt is tightened.

thingiverse

free

SCOUT Dual-Bowden Mount for E3D V6 CLONE Hotend (differs slightly from original dimensions) by florinf-ro

...er you'd like to design in front of your hotends. i have uploaded a 12mm probe housing that was designed into the half clamp.

thingiverse

free

![3D Printer Minimal X Carriage [#SCOUTcorexy design] by florinf-ro](/t/8857006.jpg)

3D Printer Minimal X Carriage [#SCOUTcorexy design] by florinf-ro

...me know if you want the inductive probe clamp too, or the directcontact probe maybe.

i have also attached the rsdoc of the mount.

thingiverse

free

Electro-Mechanical Direct-Contact, Independent Auto-leveling Probe by florinf-ro

...min on the arduino.

i have attached both stl and rsdoc.

reprap forums discussion here: http://forums.reprap.org/read.php?1,620626

thingiverse

free

SCOUTcorexy XY_Stage XCarriage !!10mm!! YCarriage 10mm HorizontalRods SingleHotend by florinf-ro

... undecided here];

tbd:

1) some way to remove wiggle/play from the linear bearings

2) design it for dual hotend

[...]

cheers,

flo.

thingiverse

free

8min print: Bear Cub Coffee Stencil (75mm-1Layer) | Also a First Layer Calibration thing :) by florinf-ro

... well as the design spark mechanical .rsdoc file (solid geometry) that you can use.

feel free to comment and make suggestions.

thingiverse

free

SCOUTcorexy XY_Stage XCarriage 8mm YCarriage 10mm HorizontalRods SingleHotend by florinf-ro

...d pretty quickly;

tbd:

1) some way to remove wiggle/play from the linear bearings

2) design it for dual hotend

[...]

cheers,

flo.

Ro

3ddd

$1

RO-RO by Zilio Aldo

...ro-ro by zilio aldo

3ddd

zilio aldo

ro-ro by zilio aldo

turbosquid

$40

RO-RO military

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

design_connected

$18

Ro

...ro

designconnected

fritz hansen ro computer generated 3d model. designed by hayon, jaime.

3ddd

$1

RO by Fritz Hansen

... ro , fritz hansen

кресло ro от fritz hansen. текстуры в архиве.

turbosquid

$5

RO Table Lamp

...yalty free 3d model ro table lamp for download as max and fbx on turbosquid: 3d models for games, architecture, videos. (1658635)

3ddd

$1

RO-CHAIR-WOOD by Zilio Aldo

...ro-chair-wood by zilio aldo

3ddd

zilio aldo

ro-chair-wood by zilio aldo

turbosquid

$22

Ro Chair by Fritz Hansen

...el ro chair by fritz hansen for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1274002)

design_connected

$7

TIMO SARPANEVA & ANTONIO DA ROS Vases

...timo sarpaneva & antonio da ros vases

designconnected

timo sarpaneva & antonio da ros vases computer generated 3d model.

humster3d

$75

3D model of NSU Ro 80 1967

...uy a detailed 3d model of nsu ro 80 1967 in various file formats. all our 3d models were created maximally close to the original.

turbosquid

$15

KENT WATER PURIFIER SUPERB RO SMART

...urifier superb ro smart for download as ma, obj, fbx, and stl on turbosquid: 3d models for games, architecture, videos. (1322895)

Compensate

3d_export

$5

Compensator 3D Model

...compensator 3d model

3dexport

compensator 3d model kir1408 58429 3dexport

turbosquid

$10

Oil Power Compensator

...yalty free 3d model oil power compensator for download as max on turbosquid: 3d models for games, architecture, videos. (1534354)

3d_export

$15

flanged rubber compensator parametric

...anged rubber compensator parametric

3dexport

flanged rubber compensator-parametric<br>properties<br>2"-16"

3d_export

$5

Transformer 3D Model

...transformer 3d model

3dexport

transformer compensator electric

transformer 3d model poctob 72074 3dexport

3d_export

$5

ak-74m

...mous rifle in the world is presented in my model. it has a movable mag, handguard, butt, compensator,<br>and a pistol grip.

3d_export

$10

spacecraft stork

...; • experimental development in space of promising types of gallium arsenide solar cells, created on the basis of nanotechnology.

3d_export

$25

Mushroomhouse subdivision and low poly

...added a color correction node to the textures to compensate for them. mushrooms and grass also have a translucency...

thingiverse

free

Airsoft 1911 Compensator (WE "Hitman" Compensator) by vxcheese

...ensator) by vxcheese

thingiverse

remixed flash hider to go off of the battlefield 4/hitman compensator. meant for we 1911's.

thingiverse

free

John Wick compensator by ttayw

...john wick compensator by ttayw

thingiverse

compensator for an airsoft or prop gun

thingiverse

free

Red Ryder Compensator by ideaform3d

...red ryder compensator by ideaform3d

thingiverse

a compensator for the daisy red ryder bb gun.

Scout

turbosquid

$80

Scout

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

Scout 3D Model

...scout 3d model

3dexport

scout space ship

scout 3d model halfquant 39713 3dexport

3d_export

$15

Scout 3D Model

...scout 3d model

3dexport

weapon scout counter strike

scout 3d model greenwan 12351 3dexport

turbosquid

$20

Scout ship

...turbosquid

royalty free 3d model scout ship for download as on turbosquid: 3d models for games, architecture, videos. (1364493)

turbosquid

$3

Scout ship

...turbosquid

royalty free 3d model scout ship for download as on turbosquid: 3d models for games, architecture, videos. (1337251)

turbosquid

$60

Viper Scout

...osquid

royalty free 3d model viper scout for download as fbx on turbosquid: 3d models for games, architecture, videos. (1209830)

turbosquid

$20

Robot Scout

...osquid

royalty free 3d model robot scout for download as max on turbosquid: 3d models for games, architecture, videos. (1404613)

turbosquid

$15

Scout Ship

...bosquid

royalty free 3d model scout ship for download as obj on turbosquid: 3d models for games, architecture, videos. (1401692)

turbosquid

$9

Scout Ship

...bosquid

royalty free 3d model scout ship for download as obj on turbosquid: 3d models for games, architecture, videos. (1440537)

turbosquid

$9

Scout Ship

...bosquid

royalty free 3d model scout ship for download as obj on turbosquid: 3d models for games, architecture, videos. (1434120)

Errors

3d_export

$9

of automobile component error proofing system

...cific product defects; the other is to check the products one by one through cheap means to determine whether they are qualified.

3d_export

$10

Vase 3D Model

...vase 3d model

3dexport

vase

vase 3d model escape since error 25561 3dexport

3d_export

$14

VaseCollection 3D Model

...vasecollection 3d model

3dexport

vase collection

vasecollection 3d model escape since error 25568 3dexport

3d_export

$16

Hungarian bow 3D Model

...hungarian bow 3d model

3dexport

arrow bow

hungarian bow 3d model escape since error 25583 3dexport

3d_export

$99

isadora table

...ered and banded in a matching polished bronze trim model hight poly no map error no texture error polys : 496,662 verts : 248,996

3ddd

$1

Tobias_Frighetto

...по референсам из каталога frighetto. stl check - no errors ...

3d_export

$5

wooldoor sockbat

...the image.<br>the only thing is that it has small errors in the mesh, that's why the...

3d_export

$15

Eraser 3D Model

... mistake error erase remove realistic detailed high definition def staedtler mars plastic

eraser 3d model terreo76 30845 3dexport

3d_export

$5

fantasy winged helmet and sword

...the sword and the helmet. if there are any errors pls comment and check out my...

3ddd

$1

Brianform AMELIE

...для 3d max 2014.obj файл,проверено модификатором stl check -no errors ...

Dual

turbosquid

free

Dual Pistols

...ls

turbosquid

free 3d model dual pistols for download as fbx on turbosquid: 3d models for games, architecture, videos. (1320360)

turbosquid

$2

Dual Axe

...urbosquid

royalty free 3d model dual axe for download as fbx on turbosquid: 3d models for games, architecture, videos. (1332372)

turbosquid

$10

Dual Lesaths

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

плитка Dual Bianco (Испания)

...й плитки venis dual (испания). технические качества: устойчивость к стирания, отличная геометрия, отсутствие проблем при укладке.

turbosquid

$35

Dual Mesh Fonts

...ree 3d model dual mesh fonts for download as ma, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1352989)

turbosquid

$29

Dual Flask with Bungs

...del dual flask with bungs for download as obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1210512)

turbosquid

$19

Dual Socket Plug

...3d model dual socket plug for download as obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1303912)

turbosquid

$13

Dual Adjustable Pulley

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

Amoi N809 Dual

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$5

Dual Turret Tank

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Nodes

3d_export

$8

steelcase node ws

...steelcase node ws

3dexport

3d_export

$8

steelcase node th

...steelcase node th

3dexport

3d_export

$8

steelcase node g

...steelcase node g

3dexport

3d_export

$5

Vase 3D with texture node

...vase 3d with texture node

3dexport

vase 3d with texture & node<br>blue ceramic

3d_export

$6

summary of detail drawing of civil construction node

... construction practices (complete set), including: node details, etc., with detailed contents for reference. welcome to download!

turbosquid

$2

wireless node (2005 model)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$6

Low Poly Bush with Node Group

... 3d model low poly bush with node group for download as blend on turbosquid: 3d models for games, architecture, videos. (1252252)

turbosquid

$400

Lung Lymph Vessels, Nodes, Trachea and Larynx

...essels, nodes, trachea and larynx for download as obj and lxo on turbosquid: 3d models for games, architecture, videos. (1236395)

evermotion

$595

Maxwell Render Suite v3 - Node Locked

...nloadlink and instructions will be delivered by the producer within 3 days after payment confirmation. evermotion 3d models shop.

turbosquid

$149

ISS module - Tranquility Node 3 + Cupola + PMA 3

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Aluminum

3d_export

$5

aluminum crutch

...aluminum crutch

3dexport

aluminum crutch

3d_export

free

aluminum cane

...aluminum cane

3dexport

aluminum cane

3d_export

$5

the aluminum canister

...

3dexport

the aluminum canister is designed for storing and transporting liquids( water), fuels and lubricants (gasoline, oils).

turbosquid

$2

Aluminum Wheel

...uid

royalty free 3d model aluminum wheel for download as fbx on turbosquid: 3d models for games, architecture, videos. (1371918)

turbosquid

$2

aluminum pulley

...

royalty free 3d model aluminum pulley for download as sldpr on turbosquid: 3d models for games, architecture, videos. (1671716)

turbosquid

$40

Aluminum Can

... free 3d model aluminum can for download as 3ds, max, and obj on turbosquid: 3d models for games, architecture, videos. (1301606)

turbosquid

$15

Curved aluminum

...ee 3d model curved aluminum for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1260293)

turbosquid

$12

Aluminum pot

... free 3d model aluminum pot for download as max, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1653492)

3d_export

$5

Aluminum Bottle

... for shampoo, conditioner or any liquids (500ml 17floz) separated all parts, able to customize any color, material and finishing.

turbosquid

$19

Aluminum windows

...model aluminum windows for download as max, max, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1646740)

Tube

archibase_planet

free

Tube

...tube

archibase planet

paint tube stationery

tube - 3d model (*.gsm+*.3ds) for interior 3d visualization.

turbosquid

free

tube

...tube

turbosquid

free 3d model tube for download as c4d on turbosquid: 3d models for games, architecture, videos. (1378271)

archibase_planet

free

Tube

...tube

archibase planet

mascara cosmetics make-up

tube 1 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

$5

Tube pants

...tube pants

3dexport

tube pants

3d_export

free

Tube

...tube

3dexport

turbosquid

free

TUBE

...

free 3d model tube for download as blend, dae, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1672199)

turbosquid

$29

tube

...lty free 3d model tube for download as 3ds, obj, c4d, and fbx on turbosquid: 3d models for games, architecture, videos. (1442047)

3ddd

$1

perfume tube

...perfume tube

3ddd

тюбик

perfume tube, тюбик

3ddd

$1

Olivieri Tube

...olivieri tube

3ddd

olivieri

кровать olivieri tube

turbosquid

$22

Tube

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Corner

archibase_planet

free

Corner

...corner

archibase planet

nook corner

corner n030708 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Corner

...corner

archibase planet

corner post rack

fp corner wh - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3ddd

$1

Country Corner

...country corner , комод , прованс

country corner

3ddd

$1

Corner 8140

... corner

corner 8140 - 16,5 x 17,4 (cm)

corner 8141 - 16,5 x 29,5 (cm)

corner 8142 - 16,5 x 41,5 (cm)

corner 8143 - 28 x 28 (cm)

archibase_planet

free

Corner

...corner

archibase planet

seat easy chair furniture

havanna corner - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3ddd

$1

Country corner

... country corner , romance

рамка country corner, romance,

артикул cc0141

3ddd

$1

Country corner

...country corner

3ddd

country corner , журнальный

country corner pbth размеры 169*69*49

3d_export

$5

Corner

...corner

3dexport

3ddd

$1

Table-Corner

...table-corner

3ddd

круглый

table,corner

3ddd

$1

Table,Corner

...table,corner

3ddd

журнальный

table,corner

Z

3d_export

$5

nissan z

...nissan z

3dexport

nissan z

3ddd

$1

Vase Z

...vase z

3ddd

vase z

3ddd

$1

полотенцесушить Z

...полотенцесушить z

3ddd

полотенцесушитель

полотенцесушить z

design_connected

free

Z-Chair

...z-chair

designconnected

free 3d model of z-chair designed by karman, aleksei.

design_connected

$11

Z Lamp

...z lamp

designconnected

phillips z lamp computer generated 3d model. designed by kalff, louis.

3d_export

$5

Dragon balls z

...dragon balls z

3dexport

dragon ball z

turbosquid

$20

Fighter Z

...

turbosquid

royalty free 3d model fighter z for download as on turbosquid: 3d models for games, architecture, videos. (1292563)

turbosquid

$9

Pen Z

...pen z

turbosquid

free 3d model pen z for download as obj on turbosquid: 3d models for games, architecture, videos. (1686775)

turbosquid

free

z chair

...z chair

turbosquid

free 3d model z chair for download as max on turbosquid: 3d models for games, architecture, videos. (1410230)

turbosquid

$5

Letter Z

...urbosquid

royalty free 3d model letter z for download as max on turbosquid: 3d models for games, architecture, videos. (1408540)

Construction

3d_export

$21

construction

...construction

3dexport

construction 8k texture

3d_export

$20

construction worker

...construction worker

3dexport

construction worker

3d_export

$65

Construction

...construction

3dexport

simple rendering of the scene file

3d_export

$65

Construction

...construction

3dexport

simple rendering of the scene file

3d_export

$65

Construction

...construction

3dexport

simple rendering of the scene file

3d_export

$65

Construction

...construction

3dexport

simple rendering of the scene fil

3d_export

$65

construction

...construction

3dexport

simple rendering of the scene file

3d_export

$5

construction barrier

...construction barrier

3dexport

construction barrier + 8k texture

3d_export

$5

construction barrier

...construction barrier

3dexport

construction barrier + 8k texture

3d_ocean

$19

Steel Construction

...steel construction

3docean

construction frame h-beam house steel

4 models of steel construction. maya, obj, fbx

Square

turbosquid

free

Square

...squid

free 3d model square for download as max, obj, and stl on turbosquid: 3d models for games, architecture, videos. (1510355)

3d_export

$5

square table

...square table

3dexport

square table

turbosquid

$12

Square

...oyalty free 3d model square for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1294110)

3ddd

$1

Square Ottoman

...square ottoman

3ddd

пуф

square ottoman

turbosquid

$25

The Square

...ee 3d model the square for download as mat, max, dxf, and obj on turbosquid: 3d models for games, architecture, videos. (1186399)

3d_export

$65

square

...square

3dexport

simple rendering of the scene file

3d_export

$65

square

...square

3dexport

simple rendering of the scene file

3d_export

$65

square

...square

3dexport

simple rendering of the scene file

3d_export

$65

square

...square

3dexport

simple rendering of the scene file

3d_export

$65

square

...square

3dexport

simple rendering of the scene file

Tower

archibase_planet

free

Tower

...kremlin tower spasskaya tower

tower kremlin spasskaya tower n120615 - 3d model (*.gsm+*.3ds+*.max) for exterior 3d visualization.

archibase_planet

free

Tower

...r kremlin tower petrovskaya tower

tower petrovskaya kremlin n120615 - 3d model (*.gsm+*.3ds+*.max) for exterior 3d visualization.

archibase_planet

free

Tower

...ino-eleninskaya tower

tower constantino eleninskaya kremlin n120615 - 3d model (*.gsm+*.3ds+*.max) for exterior 3d visualization.

archibase_planet

free

Tower

...tower

archibase planet

tower statuette eiffel tower

tower decor n180914 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Tower

...lanet

tower construction building

tower polices post street tower n110913 - 3d model (*.gsm+*.3ds) for exterior 3d visualization.

3d_export

$5

tower

...tower

3dexport

a fortified tower with a moat.

archibase_planet

free

Tower

...tower

archibase planet

building tower construction

tower n300712 - 3d model (*.gsm+*.3ds) for exterior 3d visualization.

archibase_planet

free

Tower

...uilding kremlin construction

tower 2 vtoraya bezymyannaya kremlin n100914 - 3d model (*.gsm+*.3ds) for exterior 3d visualization.

archibase_planet

free

Tower

...tower

archibase planet

forcetower tower

forcetower - 3d model for interior 3d visualization.

archibase_planet

free

Transmission tower

...lectricity pylon lattice tower framework tower

transmission tower n121015 - 3d model (*.gsm+*.3ds) for exterior 3d visualization.

Adjustability

3d_ocean

$7

Adjustable Wrench

...adjustable wrench

3docean

adjustable wrench highly detailed wrench

highly detailed adjustable wrench.

3ddd

$1

Adjustable Stool

...adjustable stool

3ddd

табурет

wooden adjustable stool.

3d_ocean

$20

Adjustable Gym Bench

...st adjustable bench black equipement gym gymnastic indoor silver sport workout

3d model of black and silver adjustable gym bench.

3d_ocean

$20

Adjustable Gym Bench

...st adjustable bench black equipement gym gymnastic indoor silver sport workout

3d model of black and silver adjustable gym bench.

3d_ocean

$16

Adjustable Weight Bench

...arbell bench black equipement gym gymnastic indoor sport weight workout

3d model of black adjustable weight bench with a barbell.

turbosquid

$5

Adjustable wrench

...

royalty free 3d model adjustable wrench for download as fbx on turbosquid: 3d models for games, architecture, videos. (1313414)

3d_export

$5

adjustable tension lock

...adjustable tension lock

3dexport

adjustable tension lock

turbosquid

$1

Adjustable Wrench

...free 3d model adjustable wrench for download as obj and blend on turbosquid: 3d models for games, architecture, videos. (1446736)

turbosquid

$1

Adjustable Wrench

...y free 3d model adjustable wrench for download as c4d and fbx on turbosquid: 3d models for games, architecture, videos. (1379022)

3d_export

$5

Adjustable key

...adjustable key

3dexport

Lots

3d_export

$15

parking lot

...parking lot

3dexport

desing from parking lot / diseño de estacionamiento

turbosquid

$3

Parket Lot

...bosquid

royalty free 3d model parket lot for download as c4d on turbosquid: 3d models for games, architecture, videos. (1273832)

turbosquid

$29

Parking Lot

...e 3d model parking lot for download as 3ds, obj, c4d, and fbx on turbosquid: 3d models for games, architecture, videos. (1190823)

turbosquid

$10

Lampatron LOT

...3d model lampatron lot for download as max, max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1563025)

turbosquid

$15

Furniture Lot

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$65

Desert Lot

...del desert lot for download as 3ds, dxf, obj, x, c4d, and fbx on turbosquid: 3d models for games, architecture, videos. (1147471)

3d_export

$65

parking lot

...parking lot

3dexport

simple rendering of the scene file

3d_export

$65

Parking lot

...parking lot

3dexport

simple rendering of the scene file

3d_export

$65

parking lot

...parking lot

3dexport

simple rendering of the scene file

3d_export

$65

Parking lot

...parking lot

3dexport

simple rendering of the scene file

Frame

archibase_planet

free

Frame

...frame

archibase planet

frame photo frame

frame n190813 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Frame

...frame

archibase planet

frame photo frame

frame n071113 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3ddd

$1

Frame

...frame

3ddd

frame

3ddd

free

Frame

...frame

3ddd

frame

archibase_planet

free

Frame

...frame

archibase planet

frame mirror frame ornament

frame n260113 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Frame

...frame

archibase planet

frame photo frame

frame photo n190813 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Frame

...frame

archibase planet

frame window window frame

frame 1 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Frame

...frame

archibase planet

frame window frame window

frame 3 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Frame

...frame

archibase planet

frame wall frame decoration

frame 1 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Frame

...frame

archibase planet

frame window window frame

frame 2 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

Printer

archibase_planet

free

Printer

...inter

archibase planet

printer laser printer pc equipment

printer n120614 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Printer

...rchibase planet

laser printer office equipment computer equipment

printer - 3d model (*.gsm+*.3ds) for interior 3d visualization.

turbosquid

$100

Printer

...er

turbosquid

royalty free 3d model printer for download as on turbosquid: 3d models for games, architecture, videos. (1487819)

turbosquid

$3

Printer

...turbosquid

royalty free 3d model printer for download as max on turbosquid: 3d models for games, architecture, videos. (1670230)

turbosquid

$1

printer

...turbosquid

royalty free 3d model printer for download as max on turbosquid: 3d models for games, architecture, videos. (1595546)

turbosquid

$1

printer

...turbosquid

royalty free 3d model printer for download as max on turbosquid: 3d models for games, architecture, videos. (1595105)

turbosquid

$10

Printer

...id

royalty free 3d model printer for download as max and 3dm on turbosquid: 3d models for games, architecture, videos. (1607146)

turbosquid

$7

Printer

...royalty free 3d model printer for download as ma, ma, and obj on turbosquid: 3d models for games, architecture, videos. (1644580)

turbosquid

$30

Printer

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

Printer

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Support

turbosquid

$5

Support

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$8

Support 3D Model

...support 3d model

3dexport

support cantilever console

support 3d model tasal 73900 3dexport

3d_export

$5

phone support

...phone support

3dexport

phone

turbosquid

$12

Support bars

...squid

royalty free 3d model support bars for download as max on turbosquid: 3d models for games, architecture, videos. (1411542)

turbosquid

$8

support weights

...id

royalty free 3d model support weights for download as max on turbosquid: 3d models for games, architecture, videos. (1411538)

turbosquid

$2

headphone support

...royalty free 3d model headphone support for download as sldpr on turbosquid: 3d models for games, architecture, videos. (1357583)

turbosquid

$2

Support for flowers

...royalty free 3d model support for flowers for download as max on turbosquid: 3d models for games, architecture, videos. (1463543)

turbosquid

$14

Flower Support

...alty free 3d model flower support for download as max and obj on turbosquid: 3d models for games, architecture, videos. (1497066)

turbosquid

$5

serum support

...yalty free 3d model serum support for download as c4d and obj on turbosquid: 3d models for games, architecture, videos. (1551267)

3d_export

$10

spyro joystick support

...spyro joystick support

3dexport

joystick support of spyro dragon