CG Trader

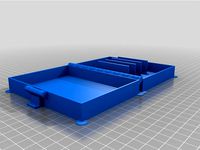

Sarmale roller self boxed cockooned technology version

by CG Trader

Last crawled date: 1 year, 10 months ago

Don't ask me what Sarmale is, you have google for that, recipes online from Romania, Turkey and a dozen other countries, all good, awesome dish. One problem thou: Rolling them takes for ever, and the pain in the fingers lasts days if you prepare for a dozen guest, say... 5 Sarmale each guest. Hence my wife bought this Sarmale roller, and made instead of like 50 Sarmale in one hour, some 500 of them in one hour. Why 500? Because the damn machine is small, flimsy and feeble, hence it only takes very fine cabbage sheets or it snaps, just a little infill and the end result are Sarmale the size of my little finger, tasty but you have to eat 4 instead of one, hence 5 Sarmale for a meal becomes... 20. The Sarmale everybody normally makes are far bigger, not fist size, but some half fist diameter size. For many reasons, first, fine cabbage is but a few, so you throw away 80% of your pickled cabbage for nothing, but if you go bigger you waste next to nil. And the taste is great anyway. Second, they are faster to roll and to place in the boiling pot (preferably ceramic) hence to manage in cooking. So I designed this monster, nearly twice as long, 30% wider, double height, and... instead of 1 mm walls, I went for 5 mm walls all over, so you can really push no fears. Speaking of pushing, you exercise a fair amount of force horizontally and vertically on this machine, hence PRINT IT HORIZONTAL please to triple it's strength. Technical irrelevancies: 1; Print with PETG or PETG plus Carbon Fiber (food grade stuff, stiff and sturdy) no ABS no PLA or similar. If you are rich and have a good hot machine you can go Ultem or PEEK, but this would be a Ferrari Sarmale roller. 2; You might notice I did not post a file to print the fabric... buy that one, no printer today can print such thing. Silk or similar strong ribbon width of the machine. 3; The processing start end has 3 slots, the nearest to the slider makes the rolls thicker, the further one from the slider makes them thinner. 4; What else can you roll with this? Hmmm... Cigars? 5; You will notice the central slide has 3 versions, that is because of your printer size, if you have a platter long on Y 350mm you can print the 280mm in one go wit supports, but if you don't... there is a 250mm long version for platforms that can accomodate maximum 300 mm (supports can take some space around) and a 140mm version, that is for small platters like 200mm maximum, you print 2 of them, there are holes in the central flange to bolt them together and make a 280mm one on the classic way. 6; Self boxed version, this is my invention, cockooning the STL file prior to printing with a second filament support helps preventing warping, at the condition that the support filament is not prone to warping (PLA for instance, or PETG if on a glas bed to which it sticks horibly well, so well that it snaps glass shards out of the bed when you try to separate it) because large prints warp horibly in ABS, PETG Polycarbonate and other materials. More about it in my engineering group in GrabCad.

grabcad(.)com/groups/3d-printers-makers-diy-hacks-solutions-and-post-printing-tools/discussions/printing-with-an-enclosure-cocoon-instead-of-a-whole-printer-enclosure family housework table food house kitchen cooking orientalfood foodstuff easteuropeanfood sarmale interior house interior kitchen table house interior kitchen table

grabcad(.)com/groups/3d-printers-makers-diy-hacks-solutions-and-post-printing-tools/discussions/printing-with-an-enclosure-cocoon-instead-of-a-whole-printer-enclosure family housework table food house kitchen cooking orientalfood foodstuff easteuropeanfood sarmale interior house interior kitchen table house interior kitchen table

Similar models

cg_trader

$10

Sarmale cabbage rolls machine might do cigars too | 3D

...ars too | 3d

cg trader

sarmale cabbage rolls machine might do 3d print model 1 , formats obj, stl, ready for 3d animation and ot

cults

$1

roller cabinet

...r size 750 gr

4 roller spreader media 750 gr

12 roller spreader dimension 1 kg

4 roller spreader media 1 kg

#dagocults

thingiverse

free

Filament roller for dispensing filament to your printer. by NorthernLayers

...ice as well.

happy printing! please post if you print!

released through my company northern layers: http://northernlayers.com

thingiverse

free

Bosch dishwasher roller

...gineered a new model.

used the original roll as template.

edit

seems the petg can't handle the warm water, it will warp :-(

grabcad

free

WARPING MACHINE

...warping machine

grabcad

roll warp from one pipe to onther pipe

thingiverse

free

Paint Roller cap by paenian

...aps on the rolls themselves. this lets you cut any roll down to fit on a smaller roller, so you can have a small rag roller :-).

thingiverse

free

Roll Support for Spools single part remix by ILikon

...too blocky and wanted to try to design something similar its probably possible to print this without any supports,...

thingiverse

free

A Fistful of TOWs Markers by Giddi

...aw pact and unaligned ones are coming soon.

some detail can be hard to print on fdm machines, mostly the nato symbol on the back.

thingiverse

free

Longer LK1 Filament Roller - Ball Bearing by LoadMaster1

...ectly for me.

the final printed parts make for a very nice filament roll support that doesn't add resistance to the extruder.

thingiverse

free

Trumpet mouthpiece box by wawaChief

...le pads that helps prevent warping when printing abs, but you will have to cut them off. if printing pla, use the normal version.

Sarmale

grabcad

free

sarmal

...sarmal

grabcad

keyfi

cg_trader

$10

Sarmale cabbage rolls machine might do cigars too | 3D

...ars too | 3d

cg trader

sarmale cabbage rolls machine might do 3d print model 1 , formats obj, stl, ready for 3d animation and ot

grabcad

free

Varil Isıtma Havuzu / Barrel Heating Pool

...d this design to heat drying paint drums. it's a study we brainstormed. then we discovered helical systems with copper pipes.

3dwarehouse

free

Sarmal Borudan Kalpli Led Lamba - Spiral Pipe Heart Led Lamp

...sarmal borudan kalpli led lamba - spiral pipe heart led lamp

3dwarehouse

sketchup 2015 x64, v-ray 2

3dwarehouse

free

MELEK İPEK KIZ ÖĞRENCİ YURDU

...ve panoramik asansörler ile özgünleştirilmiştir. #ankara #hatırlı #kız #melek_ipek #mimarlık #nami #türkiye #yeşim #yurt #öğrenci

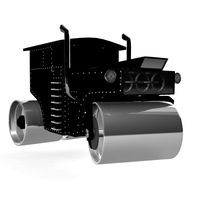

Roller

turbosquid

$26

Roller A

...urbosquid

royalty free 3d model roller a for download as fbx on turbosquid: 3d models for games, architecture, videos. (1350603)

turbosquid

$3

Roller

...oyalty free 3d model roller for download as 3ds, max, and obj on turbosquid: 3d models for games, architecture, videos. (1460818)

3ddd

$1

edilkamin roller

...edilkamin roller

3ddd

камин

edilkamin roller 360

3ddd

$1

Roller Blinds

...roller blinds

3ddd

рулонная

roller blinds black out finish

turbosquid

$50

Roller

... roller for download as max, max, c4d, max, max, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1700762)

3d_export

$10

rollers

...lers

3dexport

this is low-poly model of rollers.<br>model:<br>- low-poly<br>- textured<br>- uv unwrapped

3d_export

$28

Roller 3D Model

...roller 3d model

3dexport

roller construction boss evil

roller 3d model adagio15740837 50561 3dexport

3d_export

$6

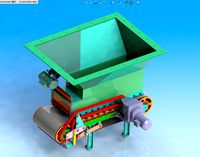

hopper roller conveyor

...hopper roller conveyor

3dexport

hopper roller conveyor

3d_export

$12

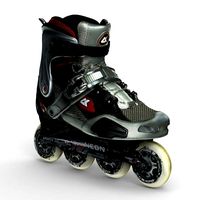

roller skates

...roller skates

3dexport

3d_ocean

$19

roller skate

...can scanned skates skating sport

3d scan of roller skate. the model has been retopologized and made fully compatible with zbrush.

Self

3ddd

$1

Self

... банкетка

каталог minotti 2010модель selfдизайнер rodolfo dordoniш\д\в 60\120\42

3ddd

$1

Minotti Self

...minotti self

3ddd

minotti

банкетка minotti self

3ddd

$1

Minotti Self

...minotti self

3ddd

minotti , self

текстуры и материалы прилагаются.

3ddd

$1

Self cleaning ashtrays

...self cleaning ashtrays

3ddd

пепельница

self cleaning ashtrays

turbosquid

$15

Book self

...

royalty free 3d model book self for download as max and fbx on turbosquid: 3d models for games, architecture, videos. (1502520)

3d_export

free

self-tapping screw

...self-tapping screw

3dexport

self-tapping screw 55 мм

turbosquid

$12

Book Self

...lty free 3d model book self for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1473695)

turbosquid

$4

Self with Desk

...d model self with desk for download as 3ds, max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1511139)

turbosquid

$2

Book Self

...ree 3d model book self for download as max, fbx, 3ds, and obj on turbosquid: 3d models for games, architecture, videos. (1544366)

turbosquid

$2

Book self

...ree 3d model book self for download as 3ds, max, fbx, and dwg on turbosquid: 3d models for games, architecture, videos. (1300384)

Technology

turbosquid

$3

Technology

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

technological robot

...urbosquid

free 3d model technological robot for download as on turbosquid: 3d models for games, architecture, videos. (1327354)

turbosquid

$35

Technology Robot

...ty free 3d model technology robot for download as obj and fbx on turbosquid: 3d models for games, architecture, videos. (1160448)

3d_export

$25

Steampunk technology

...f science fiction that incorporates technology and aesthetic designs inspired by 19th-century industrial steam-powered machinery.

3ddd

$1

Concept Technology

...concept technology

3ddd

концепт уборочной техники.

3ds max design 2009

3d_ocean

$30

Technology Mascot

...tup technology

cinema 4d r14 file format global illimunation render setup metalic materials hdri light settings high detail model

3d_export

$12

Wheels of old Soviet technology

...wheels of old soviet technology

3dexport

wheels of old soviet technology for 3d printing

turbosquid

$49

Technologic Accessories Set

...model technologic accessories set for download as max and obj on turbosquid: 3d models for games, architecture, videos. (1452166)

3d_export

free

technology complex building

...technology complex building

3dexport

headquarters for a tech firm company modeled in revit 2018

turbosquid

$79

Ancient Technology Megalithic Structure

...l ancient technology megalithic structure for download as c4d on turbosquid: 3d models for games, architecture, videos. (1389200)

Boxed

archibase_planet

free

Box

...box

archibase planet

box carton cardboard box

box 2 - 3d model (*.3ds) for interior 3d visualization.

archibase_planet

free

Box

...box

archibase planet

carton cardboard box box

box 1 - 3d model (*.3ds) for interior 3d visualization.

3d_export

$6

box

...box

3dexport

box

3d_export

$5

Box

...box

3dexport

box

3d_export

$5

box

...box

3dexport

box

3d_export

$5

box

...box

3dexport

box

archibase_planet

free

Box

...box

archibase planet

box box for paper notebook pencil

box - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Box

...box

archibase planet

box carton cardboard box

box n170111 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Box

...box

archibase planet

box carton cardboard box

box n050411 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Boxes

...boxes

archibase planet

boxes box case bin

boxes n281213 - 3d model (*.gsm+*.3ds+*.max) for interior 3d visualization.

Version

3ddd

$1

Diamond version

...nd , version , ванна

visionnaire - diamond bath

turbosquid

$50

LibraryMini Version

...free 3d model librarymini version for download as max and jpg on turbosquid: 3d models for games, architecture, videos. (1617724)

design_connected

$34

Barocco Version 01

...barocco version 01

designconnected

zanotta barocco version 01 computer generated 3d model. designed by progetti, emaf.

design_connected

$27

Barocco Version 02

...barocco version 02

designconnected

zanotta barocco version 02 computer generated 3d model. designed by progetti, emaf.

turbosquid

free

![Door [2 versions]](/t/13243146.jpg)

Door [2 versions]

...rbosquid

free 3d model door [2 versions] for download as fbx on turbosquid: 3d models for games, architecture, videos. (1223985)

turbosquid

$2

seat version 0.1

...

royalty free 3d model seat version 0.1 for download as blend on turbosquid: 3d models for games, architecture, videos. (1432653)

turbosquid

$12

Chip Version 03

...lty free 3d model chip version 03 for download as c4d and fbx on turbosquid: 3d models for games, architecture, videos. (1241145)

3d_export

$10

magnolia grandiflora mature version

...magnolia grandiflora mature version

3dexport

magnolia grandiflora mature version

3d_export

$8

room assets and voxel version

...room assets and voxel version

3dexport

room assets and voxel version

turbosquid

$35

Zil Civilian version

... model zil civilian version for download as cgf, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1639420)