Thingiverse

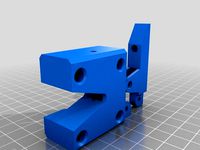

Rubberband Direct Extruder MK7 Hobbed Bolt by reversehaven

by Thingiverse

Last crawled date: 3 years, 1 month ago

Requires:

1 NEMA 17 Stepper Motor

1 Hobbed Bolt (Preferably a Makerbot Stepstruder Mk7 or Mk8)

2 M3X20 screws

2 M3X25 screws

1 608 bearing

Rubberbands

The idea for this extruder drive is for a simplistic design, but one that works and doesn't use too many parts you have to find from elsewhere. Most direct extruder drives require extra screws, washers, springs and nuts but this one only requires the use of rubberbands. Do not add too many rubberbands, as this will cause your motor to start skipping. This effect also occurs if you are using a spring-based direct extruder drive and your spring tension is too high.

I use Blue coloured round Theraband. I basically cut a few 2-3mm thick strips. you may use other colours like black instead, and use fewer rubberbands. I use up to 3 blue theraband strips like this and this works just fine, printing at speeds up to 100mm/min. haven't tried faster though.

The file 'bottom' is made specifically as a replacement for Reprap Mendel Prusa. there is sufficient space between the mounting plate and the 'bottom' mount for most nozzles. if you'd like you can design and print your own nozzle mount as appropriate.

Update:

I have shifted the Portabee files to another page to make things less confusing.

they may be found herehttp://www.thingiverse.com/thing:244084

1 NEMA 17 Stepper Motor

1 Hobbed Bolt (Preferably a Makerbot Stepstruder Mk7 or Mk8)

2 M3X20 screws

2 M3X25 screws

1 608 bearing

Rubberbands

The idea for this extruder drive is for a simplistic design, but one that works and doesn't use too many parts you have to find from elsewhere. Most direct extruder drives require extra screws, washers, springs and nuts but this one only requires the use of rubberbands. Do not add too many rubberbands, as this will cause your motor to start skipping. This effect also occurs if you are using a spring-based direct extruder drive and your spring tension is too high.

I use Blue coloured round Theraband. I basically cut a few 2-3mm thick strips. you may use other colours like black instead, and use fewer rubberbands. I use up to 3 blue theraband strips like this and this works just fine, printing at speeds up to 100mm/min. haven't tried faster though.

The file 'bottom' is made specifically as a replacement for Reprap Mendel Prusa. there is sufficient space between the mounting plate and the 'bottom' mount for most nozzles. if you'd like you can design and print your own nozzle mount as appropriate.

Update:

I have shifted the Portabee files to another page to make things less confusing.

they may be found herehttp://www.thingiverse.com/thing:244084

Similar models

thingiverse

free

Prusa I3 Direct Drive Extruder 3mm by alphapilot

...aliexpress.com/item/mk7-bore-8mm-extruder-drive-gear-for-3mm-hobbed-gear-for-makerbot-reprap-mendel-high-quality/32462285369.html

thingiverse

free

A direct drive bowden extruder for 3mm and a MK7 style hobbed pulley (BEARING 608ZZ) by depri51giu

...x8mm.

1 screw 3max30mm.

2 plate aluminum 30x7x3mm

2 thread bars 3max60mm

2 springs 4x15mm

2 nuts 2 blind 3ma

2 flat washers 3.5mm

thingiverse

free

Direct Drive (Gearless) Extruder by brnrd

...the hobbed bolt should work for 1.75 mm filament if a mk7 gear drive is used instead.

i've also included a 40 mm fan bracket.

thingiverse

free

Triple Bowden Rubberband Extruder Drive for Tri-colour by reversehaven

...:206211

please note that the original design features a mk7 hobbed bolt, this system has been adapted to use the mk8 hobbed bolt.

thingiverse

free

Direct drive extruder by InnerBushman

...-k103-08w stepper motor with modified shaft as hobbed bolt. the center of the hobbing should be 15mm from the face of the motor.

thingiverse

free

Compact Bowden Extruder, direct drive 1.75mm MK7 Gear, bigger mounting holes by axelsp

...direct drive 1.75mm mk7 gear, bigger mounting holes by axelsp

thingiverse

mk7 12mm dia, 13mm length, 10mm hob, 3.2mm hob offset.

thingiverse

free

Rubberband Direct Extruder for Portabee with E3d nozzle mount and X carriage by reversehaven

... rubberband extruder, which is fully printable except for the screws required to mount it, and rubberbands to clamp the filament.

thingiverse

free

Extruder Motor Spacer for 3DFused Direct Drive mount by Critterninja

...ere, just a 3mm thick spacer, set to the same shape of the standard 42x42mm motor and a hole in the middle to fit over the shaft.

thingiverse

free

Alpha Direct Drive Extruder by engineglue

...upply list; this is a minimal design. you can use m4 bolts and nuts to mount it. it mounts to a standard aluminum mounting plate.

thingiverse

free

direct extruder - mk7 gear - E3D v6 - 1.75 filament by raziber

...mm filament.

very compact and easy to install.

for filament compression adjust the screws in the oval holes.

bearing used: 10x5x4

Reversehaven

thingiverse

free

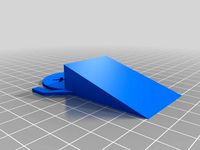

Doorstopper by reversehaven

...ttp://www.thingiverse.com/thing:65168

i have basically modified it so that it prints a lot faster and uses a lot less material.

thingiverse

free

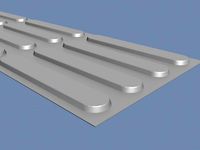

Belt Tensioner by reversehaven

...belt tensioner by reversehaven

thingiverse

i made a very simple belt tensioning device. usage is quite idiot-proof.

thingiverse

free

Nerf Snapfire Holster by reversehaven

... the snapfire itself, and 4 for the holster itself. or you can always superglue or screw this to your snapfire if you'd like.

thingiverse

free

Finger Splint by reversehaven

... print at high speed, otherwise the overhangs will sag. or, print with support. otherwise, print on its side to reduce overhangs.

thingiverse

free

Minimalistic Spool holder (Old) by reversehaven

...e spool crossbar thicker and longer to accommodate more spools. this also helps the spool holder to last longer without breaking.

thingiverse

free

Guitar Pick by reversehaven

...mount of filament, just about 3 minutes to print one, and if you print them in translucent material they look quite pretty too :)

thingiverse

free

Kitty litter shovel. by reversehaven

... got holes just about big enough to let the clay bits pass through, and yet is small enough to catch the poop and pee'd bits.

thingiverse

free

Centurion Mag Well Updated by reversehaven

...iece of plastic on the original mag well. what i did was to shorten the mag well adapter just a bit. you guys try and lemme know!

thingiverse

free

NERF Jolt Holster by reversehaven

...l be fitted in but you'll have to remove the annoying muzzle tip. i may come up with a newer version of this if i'm free.

thingiverse

free

Archery Sight Pin by reversehaven

... will be creating sight attachments that will function similarly to the beiter sight pin systems in the future. watch this space!

Rubberband

thingiverse

free

Rubberband Car

...his is a rubberband powered car. it tooke me 12 hours to print.

you have to print every part one time but the wheeles four times.

thingiverse

free

ShapeOko rubberband Penholder by nischi

...shapeoko rubberband penholder by nischi

thingiverse

shapeoko rubberband penholder

thingiverse

free

loomboard set for rubberband by john3d

...loomboard set for rubberband by john3d

thingiverse

loom board set for rubberband

thingiverse

free

A Rubberband Motor by shadowplayz34

...4

thingiverse

i made this to try and make a working rubberband motor for a plane with a length of 4 inches not including the tip

thingiverse

free

Rubberband mask holder by MaxPotter

...rubberband mask holder by maxpotter

thingiverse

simply knot both sides with 22cm rubberband.

thingiverse

free

Rubberband Gun Wheel Redux by mceisel

...rubberband gun wheel redux by mceisel

thingiverse

redux to avoid rubberband binding

thingiverse

free

Rubberband Run! by cmault123

...nd racer! they will design and build a racer, experiment with wheel and drum diameters to balence tork and rotations under power.

thingiverse

free

Rubberband push by squiqui

...sh. i tried to make a rubber gun with a trigger in one part. shooting worked fine with my first version.

still work in progress.

thingiverse

free

18650 3S Rubberband Holder by ramall

...8650 3s (12v), its a fast replacement just strap it under the rubberband. you need to glue the holder to the item as the picture.

thingiverse

free

Rubberband Gun by LloydNebulon

...tinuously pull the trigger to release the rubberbands. its a semi-automatic. it holds six rubberbands.

any questions please ask!

Mk7

3d_export

$75

Ford Fiesta mk7 Zetec S 3D Model

...ford fiesta mk7 zetec s 3d model

3dexport

ford fiesta mk7 red zetec

ford fiesta mk7 zetec s 3d model richems1 50820 3dexport

3d_export

$49

Ford Transit MK7 2006 3D Model

...2010 2011 panel van high roof transport utitily germany low poly textured

ford transit mk7 2006 3d model 3dlabsnet 65840 3dexport

turbosquid

$20

Desert Eagle 44 Magnum MK7

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$99

Volkswagen Golf Mk7 5door 2013 3D Model

...2013 2014 2015 2016 5-door hatchback compact family city germany

volkswagen golf mk7 5door 2013 3d model humster3d 59813 3dexport

3d_export

$99

Volkswagen Golf Mk7 3door 2013 3D Model

...2013 2014 2015 2016 3-door hatchback compact family city germany

volkswagen golf mk7 3door 2013 3d model humster3d 71827 3dexport

3d_export

$99

Volkswagen Golf Mk7 variant 2014 3D Model

...2014 2015 2016 5-door wagon estate variant family city germany

volkswagen golf mk7 variant 2014 3d model humster3d 75028 3dexport

3d_export

$119

Volkswagen Golf MK7 2013 3D Model

...pact germany

volkswagen golf mk7 2013 3d model download .c4d .max .obj .fbx .ma .lwo .3ds .3dm .stl swan3dstudios 112664 3dexport

cg_studio

$99

Volkswagen Golf Mk7 variant 20143d model

... .lwo .max .mb .obj - volkswagen golf mk7 variant 2014 3d model, royalty free license available, instant download after purchase.

humster3d

$75

3D model of Volkswagen Golf Mk7 variant 2014

...odel of volkswagen golf mk7 variant 2014 in various file formats. all our 3d models were created maximally close to the original.

cg_studio

$99

Volkswagen Golf Mk7 5-door 20133d model

...x .lwo .ma .max .obj - volkswagen golf mk7 5-door 2013 3d model, royalty free license available, instant download after purchase.

Hobbed

turbosquid

$2

Hob

...hob

turbosquid

royalty free 3d model hob for download as c4d on turbosquid: 3d models for games, architecture, videos. (1195289)

turbosquid

$49

Hob

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

Hob

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

плита hob teka

...ddd

hob , teka , варочная панель

плита hob teka

turbosquid

$2

gas hob

...rbosquid

royalty free 3d model gas hob for download as blend on turbosquid: 3d models for games, architecture, videos. (1498414)

turbosquid

$2

Induction hob

...quid

royalty free 3d model induction hob for download as skp on turbosquid: 3d models for games, architecture, videos. (1564919)

turbosquid

free

hob goblin

...bosquid

royalty free 3d model hob goblin for download as fbx on turbosquid: 3d models for games, architecture, videos. (1480519)

3ddd

$1

Regency hob grate

...regency hob grate

3ddd

классический камин, regency hob grate

turbosquid

$10

Induction Hob

... 3d model whirlpool induction hob for download as max and obj on turbosquid: 3d models for games, architecture, videos. (1390871)

3d_export

$6

Hob 3D Model

...hob 3d model

3dexport

stove

hob 3d model ashvathnarayana 61904 3dexport

Direct

design_connected

free

Compas Direction

...compas direction

designconnected

free 3d model of compas direction by vitra designed by prouvé, jean.

design_connected

$18

Direction Pivotant

...direction pivotant

designconnected

vitra direction pivotant computer generated 3d model. designed by prouvé, jean.

turbosquid

$6

not direct the front

...oyalty free 3d model not direct the front for download as max on turbosquid: 3d models for games, architecture, videos. (1213034)

turbosquid

$10

Rails Direct

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

Picto toilet directions

...lude 3d files next to rhino6: x3dv, step, igus, obj and stl. double-sided, flipping changes the gender directions to the toilets.

3ddd

$1

fauteuli direction

...d

chair , vitra , fauteuli

fauteuli vitra chair

design_connected

$18

Fauteuil Direction, 1951

...fauteuil direction, 1951

designconnected

vitra fauteuil direction, 1951 computer generated 3d model. designed by prouvé, jean.

3d_export

$5

Directional tactile 3D Model

...tactile 3d model

3dexport

directional tactile braille tile flooring interior

directional tactile 3d model renob000 71068 3dexport

turbosquid

$26

Radio direction finder A

...ty free 3d model radio direction finder a for download as fbx on turbosquid: 3d models for games, architecture, videos. (1212490)

turbosquid

$7

Wooden direction signage

...ty free 3d model wooden direction signage for download as max on turbosquid: 3d models for games, architecture, videos. (1453747)

Extruder

3ddd

$1

Extruded Chair

...extruded chair

3ddd

extruded , tom dixon

inspired by tom dixon extruded chair

turbosquid

$15

Extruded Table

... extruded table for download as blend, dae, fbx, obj, and stl on turbosquid: 3d models for games, architecture, videos. (1634137)

turbosquid

$2

3D Printer Extruder

...d

royalty free 3d model 3d printer extruder for download as on turbosquid: 3d models for games, architecture, videos. (1537359)

turbosquid

$1

Zombie extruded text

...oyalty free 3d model zombie extruded text for download as obj on turbosquid: 3d models for games, architecture, videos. (1322198)

turbosquid

$4

Extruder conical screw

...el extruder conical screw for download as sldpr, ige, and stl on turbosquid: 3d models for games, architecture, videos. (1524433)

turbosquid

$50

3d PRINTER - Extruder

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$15

Extruded Table 2

...xtruded table 2 for download as blend, dae, fbx, obj, and stl on turbosquid: 3d models for games, architecture, videos. (1621846)

turbosquid

$10

Maya Extrude Tool

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

world earth extrude map

...world earth extrude map

3dexport

3ddd

$1

Simply Elegant Extruded Tree Coffee Table Design

...ble by link studios. the silhouette of a tree is visible at one angle, extruded from the surface to create the support structure.

Bolt

3d_export

$2

bolt

...

bolt - a fastener in the form of a rod with an external thread, usually with a hex head wrench, forming a connection with a nut.

3d_export

$5

bolted ring

...bolted ring

3dexport

bolted ring

3d_export

$5

royal bolt

...royal bolt

3dexport

royal bolt

turbosquid

$10

Bolt

...lty free 3d model bolt for download as max, c4d, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1681373)

turbosquid

$10

Bolt

...lty free 3d model bolt for download as max, c4d, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1680879)

turbosquid

$10

Bolt

...lty free 3d model bolt for download as max, c4d, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1680869)

turbosquid

$10

Bolt

...lty free 3d model bolt for download as max, c4d, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1680866)

turbosquid

$10

Bolt

...lty free 3d model bolt for download as max, c4d, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1680860)

turbosquid

$10

Bolt

...lty free 3d model bolt for download as max, c4d, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1680480)

turbosquid

$13

bolt

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.