Thingiverse

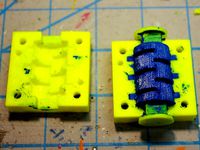

Rocking Compression Mould for the Apple Lightening Cable by sugru

by Thingiverse

Last crawled date: 3 years ago

This project brings industrial-quality production to your kitchen table! In the industry, they call it desktop manufacturing.

At Sugru, we developed this unique rocking compression mould for the single most popular cable in the universe: the Apple Lightning to USB Cable. Now you too can experiment with this exciting technology.

Whether it’s just for kicks or to start a bustling cable repair business, professional moulding is easier than you think.

All you need to create industrial-quality strain relief for your cable is a 3D printed mould, a pack of Sugru, a paintbrush and some dish soap (washing up liquid).

There are several options for getting your mits on your own 3D printed mould. You never need to own a 3D printer.

1: Order the parts printed directly from Shapeways.com. These guys print in an incredible range of materials and print resolutions, ideal if the surface finish is important to you. This does come at a cost though.

2: Order the parts from a local independent 3D printer through the very awesome 3DHubs.com. This is the fast budget option, we use this service all the time and love it.

3: Download this free open source file from the amazing ThingiVerse and get a friend to print it or bring it round to your local Hack Space.

STEP 1:

Paint your mould with a light coat of soapy water (that’s just a drop of dish soap in water) and shake off the excess.

STEP 2:

Use half a pack of Sugru - roll it into a long sausage roughly the length of the mould.

Press the Sugru flat.

Wrap the Sugru around the cable and press it into a rough shape making sure that there is more near the connector end of the cable.

STEP 3:

Place the cable into the mould and then put the top of the mould on.

Press the two parts of the mould together and rock from side to side. The crete the mould form and pushes the excess Sugru out - in professional compression moulding this is called flash.

STEP 4:

List off the top of the mould and trim the flash (excess Sugru) off.

Apply more soapy water to the mould and repeat the moulding and trimming process.

Leave to set.

At Sugru, we developed this unique rocking compression mould for the single most popular cable in the universe: the Apple Lightning to USB Cable. Now you too can experiment with this exciting technology.

Whether it’s just for kicks or to start a bustling cable repair business, professional moulding is easier than you think.

All you need to create industrial-quality strain relief for your cable is a 3D printed mould, a pack of Sugru, a paintbrush and some dish soap (washing up liquid).

There are several options for getting your mits on your own 3D printed mould. You never need to own a 3D printer.

1: Order the parts printed directly from Shapeways.com. These guys print in an incredible range of materials and print resolutions, ideal if the surface finish is important to you. This does come at a cost though.

2: Order the parts from a local independent 3D printer through the very awesome 3DHubs.com. This is the fast budget option, we use this service all the time and love it.

3: Download this free open source file from the amazing ThingiVerse and get a friend to print it or bring it round to your local Hack Space.

STEP 1:

Paint your mould with a light coat of soapy water (that’s just a drop of dish soap in water) and shake off the excess.

STEP 2:

Use half a pack of Sugru - roll it into a long sausage roughly the length of the mould.

Press the Sugru flat.

Wrap the Sugru around the cable and press it into a rough shape making sure that there is more near the connector end of the cable.

STEP 3:

Place the cable into the mould and then put the top of the mould on.

Press the two parts of the mould together and rock from side to side. The crete the mould form and pushes the excess Sugru out - in professional compression moulding this is called flash.

STEP 4:

List off the top of the mould and trim the flash (excess Sugru) off.

Apply more soapy water to the mould and repeat the moulding and trimming process.

Leave to set.

Similar models

thingiverse

free

Rubber Foot Mould for Speakers by sugru

...hours.

that's it! share the mould with your friends or think about other objects that you could put these rubber feet onto...

grabcad

free

Soap Dish

... the complete assembly and all native files (.prt) and (.asm),

together in a (.7z)-folder, for users of »ptc creo parametric 2.0«

thingiverse

free

Soap dish tray by DaVinci2000

...ngle soap bar 80x60 mm with convenient spacing around.

check out my other designs:https://www.thingiverse.com/davinci2000/designs

thingiverse

free

Draining Soap Dish by GarageMonkeySan

...ottom of the dish is sloping with a hole on the bottom edge. this allows excess water to flow out of the dish. soap scum no more!

thingiverse

free

Sudsy the Whale - Bathroom soap dish & toothbrush holder by alsoHarrison

...height and sealed with a waterbased clearcoat for extra water resistance.

supports are required for both, body.stl & tail.stl

grabcad

free

Soap Dish for 3D Printing

...r 3d printing

grabcad

a simple soap dish, designed to be 3d printed. the removable bottom part collects the water from the soap.

thingiverse

free

oval soap dish by javaone

...prevent soap from falling off.

design to have water run off into the sink.

simple openscad file allows you to adjust the design.

thingiverse

free

Soap Bar Holder with a Controlled Drain

...e edge along with a perfect soap bar holder. this is designed to direct the soapy water from the soap off the ledge into the tub.

thingiverse

free

Real World Soap Dish by wl18

...ke sure to orient the interior piece with the 3 support pieces on top. bridging should not be an issue since the gaps are small.

cg_trader

$3

Soap Holder Dish Triangles - 2 Models | 3D

...

tugaprints3d clean holder soap dish 3d print house bathroom plant monstera water drain model bath hand stl obj 3mf fbx triangles

Sugru

thingiverse

free

Sugru Box by jason_atwood

...sugru box by jason_atwood

thingiverse

this is a simple box to keep sugru packets in.

thingiverse

free

Sugru and 3D printed feet for the Ultimaker by Droopas

...pas

thingiverse

print feet and mold sugru on the bottom, use mold to shape the sugru.

see procedure on:https://imgur.com/a/h7djk

thingiverse

free

Alternative Claw - Sugru Grip by MobileMaker

...into the holes so it stays in place. i think i will use a plasitic card to make a cross hatch pattern in the sugru for some grip.

thingiverse

free

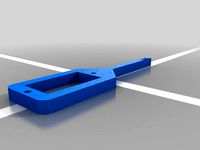

Sugru Passport Stamp Handle by jonadair

...dair

thingiverse

a handle for a passport-sized stamp. intended for use with sugru modelable rubber as seen in this instructable.

thingiverse

free

Sugru Experiment by RobotGrrl

...ning the motivation behind the experiment and how it didn't work (for us). let me know if you have any questions/suggestions!

thingiverse

free

Sugru Stamp kit by mattbeechan

...act the threads. helped out a bunch!

printer: metal printrbot simple

resolution: 0.25mm layer height

filament: 1.75mm white pla

thingiverse

free

Sugru Fixbot by mikevanis

...d this quirky happy robot!

fixbot video:http://youtu.be/azhi2yfsjvu

instructables:http://www.instructables.com/id/ebjzvmch5y9wd94

thingiverse

free

Rubber Foot Mould for Speakers by sugru

...hours.

that's it! share the mould with your friends or think about other objects that you could put these rubber feet onto...

thingiverse

free

3D printing + sugru = precision rubber parts - iPhone 4/4S or 5 molds by sugru

...39;re giving free sugru to the very best ideas.

what would you like to try?

get in touch touch via email to james@sugru.com

thingiverse

free

Mini Quadruped - optimized for 9G servos - Sugru Feet by MobileMaker

... a quick mod of my own to use with sugru as the feet.

i got the idea from the sugru fixbot where the notches are on the finger.

Lightening

3d_export

$15

P-38 Lightening 3D Model

...dexport

p38 p-38 lockheed lightening ww2 plane fighterplane warplane p38lightening

p-38 lightening 3d model jaketw 98449 3dexport

turbosquid

$95

36 Complex Buildings _ Textured and Lightened

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_ocean

$18

Sconce Intrecci, Lamp - 3D Model

...3d model 3docean 3d furniture illumination intrecci lamp light lightening lighting modern sconce wall light this model is made...

3d_export

$20

Lamp COLOSSEO 701091W FLORIANA 3D Model

...lamp lighting furniture interior bulb illumination wall colosseo modern lightening lamp colosseo 701091w floriana 3d model jane5 75407...

3d_export

$20

Lamp boya ikea 3D Model

...furniture interior bulb illumination table lamp ikea boya modern lightening reading-lamp lamp boya ikea 3d model jane5 75721...

3d_export

$19

Ashley Logan Table Lamp 3D Model

...lamp light lighting ashley logan stone interior illumination ashley lightening sofa loveseat sofa ashley logan table lamp 3d model...

3d_export

$19

Ashley Colter Table Lamp 3D Model

...lamp light lighting ashley colter panel interior illumination ashley lightening sofa loveseat bedroom ashley colter table lamp 3d model...

3d_export

$20

Chandelier VISUAL COMFORT 3D Model

...3d model 3dexport chandelier visual comfort lighting illumination light lightening irradiation chandelier visual comfort 3d model download .c4d .max...

3d_export

$19

Ashley Erin Table Lamp 3D Model

...light lamp ashley erin table lighting ashley furniture illumination lightening rosalie bedroom set bulb ashley erin table lamp 3d...

3d_export

$19

Ashley Karissa Table Lamp 3D Model

...lamp karissa lamp light table lighting ashley furniture illumination lightening lena putty living room bulb ashley karissa table lamp...

Mould

3ddd

$1

moulding

...moulding

3ddd

moulding classic plaster ornament

moulding

turbosquid

$35

mould

...ty free 3d model mould for download as max, obj, fbx, and stl on turbosquid: 3d models for games, architecture, videos. (1438489)

turbosquid

$29

moulding

...free 3d model moulding for download as max, obj, fbx, and stl on turbosquid: 3d models for games, architecture, videos. (1467257)

turbosquid

$27

Moulding

...free 3d model moulding for download as max, obj, fbx, and stl on turbosquid: 3d models for games, architecture, videos. (1239199)

turbosquid

$21

Moulding

...free 3d model moulding for download as max, obj, fbx, and stl on turbosquid: 3d models for games, architecture, videos. (1367303)

turbosquid

$17

moulding

...free 3d model moulding for download as max, obj, fbx, and stl on turbosquid: 3d models for games, architecture, videos. (1438701)

turbosquid

$7

Moulding

...free 3d model moulding for download as max, obj, fbx, and stl on turbosquid: 3d models for games, architecture, videos. (1466555)

turbosquid

$40

Moulding

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$29

Moulding

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$29

Moulding

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Compression

turbosquid

$20

compresser

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$4

Compression Tap

...for download as blend, gltf, obj, stl, dae, fbx, wrl, and usd on turbosquid: 3d models for games, architecture, videos. (1650763)

turbosquid

$7

Compression reducing tee

...ty free 3d model compression reducing tee for download as max on turbosquid: 3d models for games, architecture, videos. (1540313)

3d_export

$5

Mustang Compressed blend

...mustang compressed blend

3dexport

turbosquid

$19

Compression hips trainer

... compression hips trainer for download as , fbx, stl, and obj on turbosquid: 3d models for games, architecture, videos. (1684685)

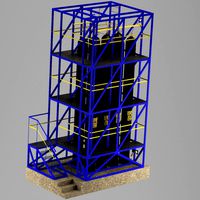

turbosquid

$10

Compressed air station

...compressed air station for download as max, 3ds, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1598414)

turbosquid

$35

Compressed-air Engine

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$19

Concrete Compression Tester

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$4

Compression TAP worn

...for download as blend, usd, dae, gltf, fbx, obj, stl, and wrl on turbosquid: 3d models for games, architecture, videos. (1652641)

turbosquid

$49

Compressed Gas Cylinder and Regulator

...odel compressed gas cylinder and regulator for download as ma on turbosquid: 3d models for games, architecture, videos. (1170670)

Apple

3ddd

$1

apple

...apple

3ddd

табурет , apple

apple

3d_export

$7

apple

...apple

3dexport

this is a 3d model of an apple. just an apple.

turbosquid

$40

Cut apples - Apple core- Red apple - Green apple

...ed apple - green apple for download as max, 3ds, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1687346)

archibase_planet

free

Apples

...apples

archibase planet

apples fruit apple

apples - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Apples

...apples

archibase planet

apples food apple

apples n040110 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Apples

...apples

archibase planet

fruits apples. apple

apples n300508 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

free

Apple

...apple

3dexport

apple

3d_export

$5

Apple

...apple

3dexport

just apple

3ddd

$1

Apples

...apples

3ddd

яблоко

apples in the kitchen.

archibase_planet

free

Apple

...apple

archibase planet

apples fruits

apple - 3d model (*.gsm+*.3ds) for interior 3d visualization.

Rocking

3d_export

$5

Rock

...rock

3dexport

simple rock.

3d_export

$5

Rock

...rock

3dexport

20 rock

3d_ocean

$5

Rock

...rock

3docean

game ready low poly old stone rock

rock,low poly,

3d_export

$6

Rock

...rock

3dexport

rock 3d model

3d_ocean

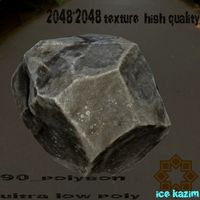

$5

Rock

...rock

3docean

game rock low polygon old rock rock stone

2048*2048 texture. 90 polygon low poly. obj,blend,fbx , format

3d_ocean

$2

Rock

...rock

3docean

cliff crag organic rock stone

this is a rock 3d model. it works in horizontal and vertical position, too.

3ddd

$1

rock on

...rock on

3ddd

кресло качалка

кресло valdichenti rock on

3d_export

$5

the rock

...the rock

3dexport

the rock 3d model good quality for animation

design_connected

$27

On The Rocks

...on the rocks

designconnected

edra on the rocks computer generated 3d model. designed by binfaré, francesco.

design_connected

$13

Rock

...rock

designconnected

foscarini rock computer generated 3d model. designed by diesel creative team.

Cable

3d_export

free

Cables

...cables

3dexport

cables for your purposes

3d_export

free

cable belt for cable organization

...ze your cables in 3d printers. it will bend only to one direction. the area to put the cables per piece is aprox. 1,6cmx2,6cmx1cm

3d_ocean

$16

Ethernet Cable

...ethernet cable

3docean

cable computer electronics ethernet internet network connected

ethernet cable 3d model

3d_export

$65

cable

...cable

3dexport

simple rendering of the scene file

turbosquid

$14

Cable

...l cable for download as ma, max, fbx, 3ds, gltf, obj, and stl on turbosquid: 3d models for games, architecture, videos. (1631358)

3ddd

$1

Cable Cover

...cable cover

3ddd

кабель

vertebra passacavo - cable cover

max + vray 2.20.03

3d_export

$15

Cable reel

...without cable. textures 4k 4096x4096 targa, png, jpeg.<br>number of polygons without cable: 2896<br>with cable: 35328

3d_export

$7

short cable

...short cable

3dexport

rubber cord. very detailed. cable thickness: 2.55 mm total length: 55mm

3d_export

$5

USB CABLE

...usb cable

3dexport

turbosquid

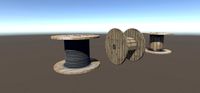

$30

Cable Reels

...osquid

royalty free 3d model cable reels for download as fbx on turbosquid: 3d models for games, architecture, videos. (1439507)