Thingiverse

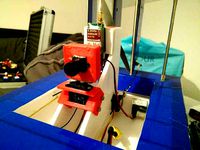

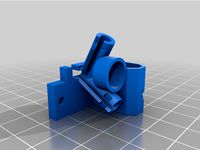

Robust Flight Camera Pan Assembly for FPV Flying Wings by Gigahurtz

by Thingiverse

Last crawled date: 2 years, 12 months ago

Update on 1/16/2021: Uploaded a newer version (2.1). This version works with more modern FPV cameras, including the Foxeer Falkor 2 as well as the DJI HD FPV Camera! Also uploaded a new "boot" which is useful for a strain relief with the DJI HD camera. Print in TPU and goop in. At the time of writing, I have not tested this setup with the DJI system, but plan to fly it soon and will report back. When using the DJI camera, the metal mount that comes with the Foxeer Falkor series works (others may be compatible as well).

Here's a video of the latest version on the bench: https://youtu.be/ugUoh5DFFRU .

This is a fairly robust yet reasonably lightweight pan assembly for a FPV flight camera. It was designed and intended for a Chimera Flying Wing for FPV, but can certainly be used for other craft as well. Here's a flight video of it in action (Older v1.8, analog FPV): https://www.youtube.com/watch?v=bapxTDwmhos

Required Parts List, in addition to the (4) printed parts:

(1) Turnigy TGY-R5180MG 180 Degree MG Analog Servo. http://www.hobbyking.com/hobbyking/store/uh_viewItem.asp?idProduct=65966

(4) M3 nylon lock nuts

(4) M3 bolts

(4) Small screws to attach the servo horn to the top pan assembly. I used some lock nuts with these. I think they are M2 screws.

(1) Mount for the FPV camera. The hole pattern in the above mount was designed to work with the one that comes with the Foxeer Falkor 2.

(1) Longer screw compatible with the servo to secure the top pan assembly.

I cannot guarantee that this pan will work with other servos. I highly recommend the above Turnigy servo as it's inexpensive, provides a smooth pan between steps, and has about +/-130 degrees of rotation if the transmitter endpoints are set to +/- 125% (800 to 2200us pulse width). I tried the RMRC 260 deg servo, and while it had better torque, it was slower and the steps were not nearly as smooth.

Many cameras may work. This was designed for the Foxeer Falkor 2. It happens to work with DJI's camera for the HD FPV system as well when using the mount from the Falkor 2.

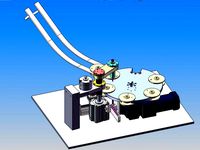

Here are the STL files for the pan assembly. There are 4 main parts:

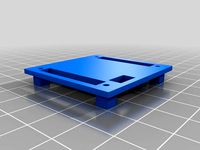

The plane "base" mount. It's designed to be printed with the captive nut holes facing upwards. Use M3 nylon lock nuts in this. I put in a drop of CA glue to hold them in place. This part gets physically bonded to the plane after cutting out foam in the nose. Hot glue works well as you can remove it with isopropyl alcohol if needed. E6000 around the perimeter helps seal even more.

A servo shim plate. It sits between the plane base mount and the base of the actual pan assembly.

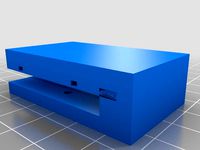

The lower part of the pan assembly.

The upper pan assembly. This is intended to be printed with the cylinder groove upwards.

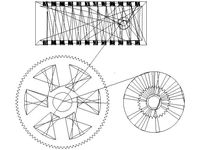

I printed everything in 0.2mm layer height in Colorfabb ngen filament. Others such as PETG probably work fine as long as it can be sanded. I wouldn't recommend PLA due to the thermal limitations. The parts fit very snugly and you'll probably need to file and/or sand them down to get a good fit between the upper and lower pan assemblies. You'll probably want to sand the top of each race flat as well. Once it rotates somewhat freely, clean away the excess grains of plastic with isopropyl alcohol. Then, use synthetic grease in the groove (Tri-flo works well). It should rotate 360 degrees smoothly and without binding.

If I recall correctly, the total weight of the pan assembly (minus the servo and the camera) is 35g. If you want to save weight, you can forego the lower plane mount piece and shim, and screw in the servo to the lower pan assembly using screws through the servo ears. That will reduce the pan assembly weight to around 25g. I prefer the option of being able to remove the pan assembly in case it breaks, though, so it can be replaced without re-gluing it to the plane.

A bit of background:

I designed this because I wasn't satisfied with any of the inexpensive pan systems I found on the market, which typically bear the entire weight of the camera on a servo horn. Such a design, while lightweight, not only results in camera vibration, but the mechanism is prone to breaking where the horn is attached to the servo during a rough landing or a crash. This design is intended to minimize the stress on the servo axis and horn through the use of the larger diameter cylinder which tracks in a groove. It has held up many times in bad crashes. An improvement would be the addition of bearings, but honestly, I'm not sure it needs it as it moves very smoothly after sanding down the surfaces and applying synthetic grease.

Here's a video of the latest version on the bench: https://youtu.be/ugUoh5DFFRU .

This is a fairly robust yet reasonably lightweight pan assembly for a FPV flight camera. It was designed and intended for a Chimera Flying Wing for FPV, but can certainly be used for other craft as well. Here's a flight video of it in action (Older v1.8, analog FPV): https://www.youtube.com/watch?v=bapxTDwmhos

Required Parts List, in addition to the (4) printed parts:

(1) Turnigy TGY-R5180MG 180 Degree MG Analog Servo. http://www.hobbyking.com/hobbyking/store/uh_viewItem.asp?idProduct=65966

(4) M3 nylon lock nuts

(4) M3 bolts

(4) Small screws to attach the servo horn to the top pan assembly. I used some lock nuts with these. I think they are M2 screws.

(1) Mount for the FPV camera. The hole pattern in the above mount was designed to work with the one that comes with the Foxeer Falkor 2.

(1) Longer screw compatible with the servo to secure the top pan assembly.

I cannot guarantee that this pan will work with other servos. I highly recommend the above Turnigy servo as it's inexpensive, provides a smooth pan between steps, and has about +/-130 degrees of rotation if the transmitter endpoints are set to +/- 125% (800 to 2200us pulse width). I tried the RMRC 260 deg servo, and while it had better torque, it was slower and the steps were not nearly as smooth.

Many cameras may work. This was designed for the Foxeer Falkor 2. It happens to work with DJI's camera for the HD FPV system as well when using the mount from the Falkor 2.

Here are the STL files for the pan assembly. There are 4 main parts:

The plane "base" mount. It's designed to be printed with the captive nut holes facing upwards. Use M3 nylon lock nuts in this. I put in a drop of CA glue to hold them in place. This part gets physically bonded to the plane after cutting out foam in the nose. Hot glue works well as you can remove it with isopropyl alcohol if needed. E6000 around the perimeter helps seal even more.

A servo shim plate. It sits between the plane base mount and the base of the actual pan assembly.

The lower part of the pan assembly.

The upper pan assembly. This is intended to be printed with the cylinder groove upwards.

I printed everything in 0.2mm layer height in Colorfabb ngen filament. Others such as PETG probably work fine as long as it can be sanded. I wouldn't recommend PLA due to the thermal limitations. The parts fit very snugly and you'll probably need to file and/or sand them down to get a good fit between the upper and lower pan assemblies. You'll probably want to sand the top of each race flat as well. Once it rotates somewhat freely, clean away the excess grains of plastic with isopropyl alcohol. Then, use synthetic grease in the groove (Tri-flo works well). It should rotate 360 degrees smoothly and without binding.

If I recall correctly, the total weight of the pan assembly (minus the servo and the camera) is 35g. If you want to save weight, you can forego the lower plane mount piece and shim, and screw in the servo to the lower pan assembly using screws through the servo ears. That will reduce the pan assembly weight to around 25g. I prefer the option of being able to remove the pan assembly in case it breaks, though, so it can be replaced without re-gluing it to the plane.

A bit of background:

I designed this because I wasn't satisfied with any of the inexpensive pan systems I found on the market, which typically bear the entire weight of the camera on a servo horn. Such a design, while lightweight, not only results in camera vibration, but the mechanism is prone to breaking where the horn is attached to the servo during a rough landing or a crash. This design is intended to minimize the stress on the servo axis and horn through the use of the larger diameter cylinder which tracks in a groove. It has held up many times in bad crashes. An improvement would be the addition of bearings, but honestly, I'm not sure it needs it as it moves very smoothly after sanding down the surfaces and applying synthetic grease.

Similar models

thingiverse

free

Stratosurfer GoPro Hero7 and dual FPV camera mount by kdamon

...amon

thingiverse

mount i made to hold a gopro hero7, a foxeer micro camera, and dji camera on a servo os they're all on pan.

thingiverse

free

Minimalist FPV Pan/tilt

...you have. i had to fit my camera upside down, but this is not a problem for me because i use an fpv monitor that i can turn over.

thingiverse

free

Pan Tilt for ArWing Pro by baze

...y)

screw "arm" to second servo and into dji cameras upper mounting hole (not too tight so that camera can pivot freely)

thingiverse

free

GWS Servo Mount & FPV Cam Holder

...oop on the back which you can feed your camera wire through, this will help keep it in position when rotating all the way around.

thingiverse

free

Zohd drift mount for Foxeer Falkor 2 Micro FPV Camera by J40YKE

...he existing foam mount, glue in this new mount. the camera should be an interference fit, but apply hot glue if needed to secure.

thingiverse

free

45 degree Servo Mount / FPV camera pan mount by add1ct3dd

...going to cable tie it to the servo horn, but instead i used generous amounts of hot glue, it seems to bond to pla really well :).

thingiverse

free

Pan/tilt for FPV Mini size camera by Herman_

...n dm-s0090d, the pt_base_270 part is for that specific servo. in the pictures the pan/tilt unit is sitting on my x-uav snowgoose.

thingiverse

free

Pan/tilt for FPV Mini size camera by Herman_

...n dm-s0090d, the pt_base_270 part is for that specific servo. in the pictures the pan/tilt unit is sitting on my x-uav snowgoose.

thingiverse

free

Pan-Tilt Camera Mount by HICS

...user enough space to secure the gimbal however necessary. similary, a camera can be attached to the tilt mount...

thingiverse

free

Dart 250 camera mount with tilt by DmDe

...hd dart 250 wing

i use the foxeer razer micro camera and digital servo es9251

work in progress...

i need designed aerodynamic cap

Gigahurtz

thingiverse

free

Axn Clouds Skid Plate by Gigahurtz

...s well when taking off or landing on asphalt, where fiberglass tape wears down quickly. i've printed one and it works great!

thingiverse

free

Sony Effio-V Camera Case by Gigahurtz

...was inspired by this pz0420 camera case: http://www.thingiverse.com/thing:159726

suggestions for improvement are welcomed. enjoy!

thingiverse

free

Pixim Seawolf Camera Case by Gigahurtz

...enjoy!

update 7/6/2014: flipped back plate stl and re-uploaded so users don't need to flip it in their printer host software.

thingiverse

free

SKY2 800TVL RunCam - 38mm x 38mm FPV Camera Mount by chriskonieczny

...i ended up doing was using a design by "gigahurtzquot; found here http://www.thingiverse.com/thing:548679 i pretty much just sized it...

Robust

turbosquid

$45

Robust Skull

...oyalty free 3d model robust skull for download as fbx and obj on turbosquid: 3d models for games, architecture, videos. (1589230)

3ddd

$1

Кресло Materia - Robust

...кресло materia - robust

3ddd

materia , robust

материалы вирей. текстуры в комплекте.

3d_export

free

sofaboxplayswedese

...sofaboxplayswedese 3dexport boxplay is robust and elegant at the same time. the irregular shape...

3d_ocean

$49

Buggy Concept

...buggy bughy car concept heavy high poly massive outdoor robust vehicle just a model of are own buggy concept...

3d_ocean

$59

Buggy Concept 2

...buggy car concept extreme high poly military outdoor realistic robust vehicle our own concept of another buggy vehicle. just...

3d_export

$6

Ficus Elastica Burgundy Rubber Tree

...elastica burgundy rubber tree 3dexport the rubber tree is robust and dramatic, with large, glossy leaves. this striking houseplants...

3ddd

free

Angel Chair

...steel rods. the result is a very comfortable and robust stool that is both decorative and practical in...

3d_export

$99

Mercedes Benz Vito PanelVan Long 2011 3D Model

...panelvan long 2011 2010 commercial taxi transportation passenger crewbus robustess van mercedes benz vito panelvan long 2011 3d model...

3d_ocean

$89

Mercedes-Benz Vito PanelVan Long 2011

...2011 3docean commercial crewbus long mercedes mercedes-benz panelvan passenger robustess taxi transportation van vito tough, indestructible and dependable –...

3d_export

$5

Autopsy saw

...the saw blade raised the occupational health and safety. robust simple to clean with flexible connection. 3ds max 2012...

Pan

design_connected

$16

Pan Pan

...pan pan

designconnected

ligne roset pan pan computer generated 3d model. designed by kuehne-thompson, barbara.

archibase_planet

free

Pan

...pan

archibase planet

lavatory pan w.c. pan sanitary ware

lavatory pan - 3d model for interior 3d visualization.

archibase_planet

free

Pan

...pan

archibase planet

lavatory pan w.c. pan sanitary ware

lavatory pan - 3d model for interior 3d visualization.

archibase_planet

free

Pan

...pan

archibase planet

lavatory pan pan sanitary ware

lavatory pan 666310_9926k1 - 3d model for interior 3d visualization.

archibase_planet

free

Pan

...pan

archibase planet

lavatory pan pan sanitary ware

lavatory pan 666110 - 3d model for interior 3d visualization.

archibase_planet

free

Pan

...pan

archibase planet

frying pan; pan kitchen ware

pan - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Pan

...pan

archibase planet

lavatory pan w.c. pan sanitary ware

lavatory pan k5018 - 3d model for interior 3d visualization.

archibase_planet

free

Pan

...pan

archibase planet

lavatory pan w.c. pan sanitary ware

lavatory pan r3701 - 3d model for interior 3d visualization.

archibase_planet

free

Pan

...pan

archibase planet

lavatory pan w.c. pan sanitary ware

lavatory pan v3122 - 3d model for interior 3d visualization.

archibase_planet

free

Pan

...pan

archibase planet

lavatory pan w.c. pan sanitary engineering

pan - 3d model (*.gsm+*.3ds) for interior 3d visualization.

Fpv

turbosquid

$1

FPV VTX Antenna

...e 3d model fpv vtx antenna for download as obj, fbx, and stl on turbosquid: 3d models for games, architecture, videos. (1230317)

3d_export

$9

Fpv logo 3D Model

...onogram vehicle part of auto transport 3d model logo emblem detailed high quality badge

fpv logo 3d model rmodeler 59628 3dexport

3d_export

$8

dji fpv battery slot holder

...er for 3 dji fpv batteries. holds perfectly without shaking. need 1 m3 countersunk head bolt. need to print 6 pin, 1 case, 1 cap.

3d_export

$10

fpv camera hd 700tvl

...aterials are logically named<br>the main format is in 3ds max 2009.<br>satisfcation garranteed..<br>thank you !

thingiverse

free

FpV Mount (SOPORTE FPV) by elborjas1987

...fpv mount (soporte fpv) by elborjas1987

thingiverse

this is a fpv mount with the same holes of naza base.

thingiverse

free

fpv by tbutera

...fpv by tbutera

thingiverse

fpv

thingiverse

free

fpv by tbutera

...fpv by tbutera

thingiverse

fpv

thingiverse

free

FPV DRONE ROOSTER DJI FPV PART

...fpv drone rooster dji fpv part

thingiverse

fpv drone rooster dji fpv install part

thingiverse

free

FPV monitor

...tml?rmmds=myorder&cur_warehouse=cn

link for download : https://cults3d.com/fr/mod%c3%a8le-3d/divers/fpv-monitor-ecran-fpv-faf

thingiverse

free

FPV receiver mount for FPV display by petrex

...eceiver mount for fpv display by petrex

thingiverse

aomway receiver mount for field view 777 fpv monitor. with small cable tray.

Flight

3d_export

$5

flight case

...flight case

3dexport

flight case

3ddd

$1

Zgallerie / Flight

...zgallerie / flight

3ddd

profi.кофейный , zgallerie

кофейный столик flight, zgallerie

archibase_planet

free

Flight suit

...archibase planet

flight suit clothing clothes

flight suit 2005-v3 n070712 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3ddd

$1

Flight

... zgallerie , приставной

приставной столик фирмы zgallerie

3ddd

$1

Flight Nicoletti Home

...flight nicoletti home

3ddd

nicoletti home , угловой

flight nicoletti home

turbosquid

$29

Flight of stairs

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$13

Flight case

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

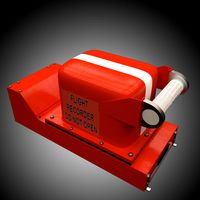

Flight Recorder

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

Flight nus 310

...flight nus 310

3ddd

сопрано-укулеле

flight nus 310 - четырехструнный сопрано- укулеле без звукоснимателя.

archive3d

free

Flight suit 3D Model

...ng clothes

flight suit 2005-v3 n070712 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

Flying

design_connected

$13

Fly-Fly

...fly-fly

designconnected

foscarini fly-fly computer generated 3d model. designed by palomba, ludovica.

3ddd

$1

Foscarini FLY-FLY

...foscarini fly-fly

3ddd

foscarini , fly-fly

foscarini fly-fly

полигонов: 73 022

3ddd

$1

Foscarini Fly-Fly

...foscarini fly-fly

3ddd

foscarini

люстра fly-fly

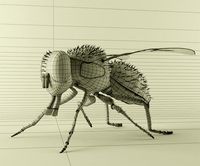

3d_export

free

fly

...fly

3dexport

fly

turbosquid

$15

fly fishing fly

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

design_connected

free

Fly

...fly

designconnected

free 3d model of fly by alias designed by acerbis, marco.

design_connected

$13

Fly

...fly

designconnected

kartell fly computer generated 3d model. designed by laviani, ferruccio.

design_connected

$13

Fly

...fly

designconnected

zanotta fly computer generated 3d model. designed by robson , mark .

3d_ocean

$10

3D Fly

...3d fly

3docean

3d fly 3ds max fly

this is a 3d fly model.

3ddd

free

Fly mood

...fly mood

3ddd

fly mood , душ

душевая панель fly mood

Wings

3ddd

$1

The Wing

...the wing

3ddd

wing , appledesign

the wing seating by appledesignstudio

3d_export

$5

wings

...wings

3dexport

beautiful wings model.

archibase_planet

free

Wing

...wing

archibase planet

wing decoration ornament

wing angel n180215 - 3d model (*.gsm+*.3ds+*.max) for interior 3d visualization.

3ddd

$1

Wing Chair

...wing chair

3ddd

baker , wing

wing chair

3ddd

$1

Диван WING

...диван wing

3ddd

flexform , wing

модель дивана wing

производитель: flexform

3ddd

$1

Диван WING

...диван wing

3ddd

flexform , wing

модель дивана wing

производитель: flexform

3ddd

$1

Кушетка WING

...кушетка wing

3ddd

flexform , wing

модель дкушетки wing

производитель: flexform

turbosquid

free

A-Wing

...id

free 3d model a-wing for download as fbx and unitypackage on turbosquid: 3d models for games, architecture, videos. (1164828)

3ddd

$1

Кресло Wing

...кресло wing

3ddd

wing

кресло wing из каталога в двух сочетаниях конфигурации.

3d_export

$5

wing nut

...wing nut

3dexport

wing nut

Camera

archibase_planet

free

Camera

...base planet

camera surveillance camera video camera

camera surveillance n090211 - 3d model (*.3ds) for interior 3d visualization.

archibase_planet

free

Camera

...hibase planet

camera security camera video camera

camera security n210515 - 3d model (*.gsm+*.3ds) for exterior 3d visualization.

archibase_planet

free

Camera

...se planet

camera web camera webcam

camera butterfly usb pc camera n090713 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Camera

...mera

archibase planet

surveillance camera video camera camcorder

camera n011211 - 3d model (*.3ds) for exterior 3d visualization.

archibase_planet

free

Camera

...camera

archibase planet

camera digital camera

camera canon digital n041211 - 3d model (*.3ds) for interior 3d visualization.

archibase_planet

free

Camera

...camera

archibase planet

camera film camera phototechnique

camera n100214 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Camera

...amera

archibase planet

camera video camera camcorder

camera video n070315 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Camera

...rchibase planet

camera video camera camcorder

camera studio n101213 - 3d model (*.gsm+*.3ds+*.max) for interior 3d visualization.

archibase_planet

free

Camera

...ibase planet

digital camera camera phototechnique

camera canon ixus 400 n310311 - 3d model (*.3ds) for interior 3d visualization.

archibase_planet

free

Camera

...ase planet

photocamera video camera camera

camera sony t300 black n291010 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

Assembly

3d_export

$7

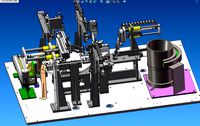

Electronic product assembly machine assembly machine

...electronic product assembly machine assembly machine

3dexport

electronic product assembly machine assembly machine

3d_export

$15

generator assembly line

...ced and assembled in the form of module block. it is a demonstration project of generator assembly. welcome to download and learn

3d_export

$10

elevator traction machine assembly line motor assembly process

... traction machine assembly line motor assembly process

3dexport

elevator traction machine assembly line (motor assembly process)

3d_export

$16

pin assembly machine

...pin assembly machine

3dexport

pin assembly machine

3d_export

$7

tower-crane-assembly

...tower-crane-assembly

3dexport

tower-crane-assembly

turbosquid

$100

Engine Assembly

...id

royalty free 3d model engine assembly for download as stl on turbosquid: 3d models for games, architecture, videos. (1658296)

turbosquid

$100

Engine Assembly

...id

royalty free 3d model engine assembly for download as stl on turbosquid: 3d models for games, architecture, videos. (1658293)

turbosquid

$100

Engine Assembly

...id

royalty free 3d model engine assembly for download as stl on turbosquid: 3d models for games, architecture, videos. (1658291)

turbosquid

$75

Platform Assembly

...royalty free 3d model platform assembly for download as blend on turbosquid: 3d models for games, architecture, videos. (1472939)

turbosquid

$15

generator assembly

...y free 3d model generator assembly for download as and sldas on turbosquid: 3d models for games, architecture, videos. (1469469)