Thingiverse

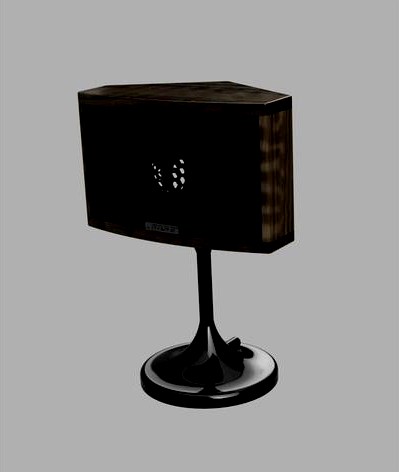

Retro Mini Computer Speakers (Nine Oh Ones) by CompuGlobalHyperMegaNet

by Thingiverse

Last crawled date: 5 years, 2 months ago

Here's one for the retro fanboy's.

I created these because I love the original Bose 901's, but I don't have room in my house to put a set, so I made a mini set for office instead.

These are designed to run these drivers from parts express: https://www.parts-express.com/dayton-audio-ce-series-ce32a-4-1-1-4-mini-speaker-4-ohm--285-103

You will need....9 per speaker, who would have guessed that!

I will upload wire schematics soon, just haven't had time to draw that up yet.

I will be designing 2 mini mono power amps and a mini Bose DSP soon, those will be uploaded into another project, internal components listed below:

2 x https://www.ebay.com.au/itm/DC-12V-26V-100W-Mono-Channel-TPA3116D2-Digital-Power-Audio-Amplifier-Board-gib/193172478035?hash=item2cf9fa1853:g:1AoAAOSwC2ldr8Pa

1 x https://www.parts-express.com/dayton-audio-dspb-icp1-in-circuit-programmer-usb--325-132

1 x https://www.parts-express.com/dayton-audio-dspb-k-dsp-kernel-board-and-dspb-ke-kernel-dsp-expansion-2-in-3-out--325-1300

1 x https://www.parts-express.com/wondom-brb6-bluetooth-v40-aptx--edr-audio-receiver-board-with-35mm-aux-in-and-control-butt--320-3530

I designed this entire project to be printed on a SLA photon based printer, all parts will fit in the constraints of the Anycubic Photon.

I recommend trying the new water washable resin from eSun, this stuff cures really fast, and is really accurate, I recommend only curing under lamp long enough for the surface to stop being sticky, then paint it to protect from over cure.

Setting for the eSun water washable:

0.025 per layer

8 second layer exposure

25 to 30 seconds for base layers

4 base layers

I also recommend once running the speaker cable through the pedestal stand, to seal it up as the stand is part of the sealed speaker chamber, I did this to increase the internal chamber size to help increase base depth.

Please note, this is work in progress, I will upload changes or fixes as the project develops

I created these because I love the original Bose 901's, but I don't have room in my house to put a set, so I made a mini set for office instead.

These are designed to run these drivers from parts express: https://www.parts-express.com/dayton-audio-ce-series-ce32a-4-1-1-4-mini-speaker-4-ohm--285-103

You will need....9 per speaker, who would have guessed that!

I will upload wire schematics soon, just haven't had time to draw that up yet.

I will be designing 2 mini mono power amps and a mini Bose DSP soon, those will be uploaded into another project, internal components listed below:

2 x https://www.ebay.com.au/itm/DC-12V-26V-100W-Mono-Channel-TPA3116D2-Digital-Power-Audio-Amplifier-Board-gib/193172478035?hash=item2cf9fa1853:g:1AoAAOSwC2ldr8Pa

1 x https://www.parts-express.com/dayton-audio-dspb-icp1-in-circuit-programmer-usb--325-132

1 x https://www.parts-express.com/dayton-audio-dspb-k-dsp-kernel-board-and-dspb-ke-kernel-dsp-expansion-2-in-3-out--325-1300

1 x https://www.parts-express.com/wondom-brb6-bluetooth-v40-aptx--edr-audio-receiver-board-with-35mm-aux-in-and-control-butt--320-3530

I designed this entire project to be printed on a SLA photon based printer, all parts will fit in the constraints of the Anycubic Photon.

I recommend trying the new water washable resin from eSun, this stuff cures really fast, and is really accurate, I recommend only curing under lamp long enough for the surface to stop being sticky, then paint it to protect from over cure.

Setting for the eSun water washable:

0.025 per layer

8 second layer exposure

25 to 30 seconds for base layers

4 base layers

I also recommend once running the speaker cable through the pedestal stand, to seal it up as the stand is part of the sealed speaker chamber, I did this to increase the internal chamber size to help increase base depth.

Please note, this is work in progress, I will upload changes or fixes as the project develops