Thingiverse

Repurpose Press Fit Pulley Motors for 8MM Shaft or 20T Pulley by SurgeFF

by Thingiverse

Last crawled date: 3 years ago

Update 2-18-21: Motor Shims didnt have holes in them so files have changed to 2mm shim and 4mm shim.

Update 2-17-21: GT2 belt version was just a bit too loose. New version uploaded.

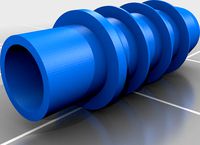

Update 2-17-21 : Uploaded a version for a installed GT2 belt for the outer ring. When I mean installed, I mean glued. But its better than iffy print quality for gears and the material should dampen the sound a bit.

Update 2-16-21: Found out some of the files are kinda wonky so Im pulling all the old files and reuploading new ones that will print as intended. Some files are the same part, but for ease of choosing I named them appropriately. If you find the file comes out weird or whatnot, then I probably already took it down and replaced it with a functional version.

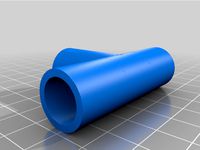

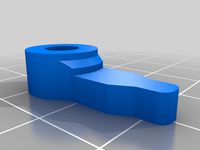

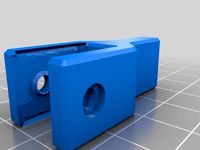

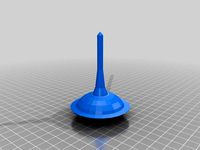

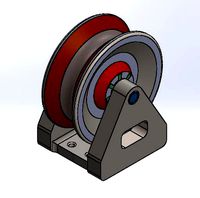

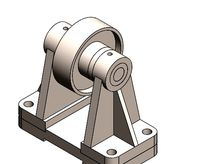

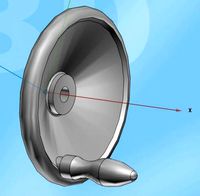

A very prototype repurpose/recycle old Nema17 motors with press fit pulleys on them. This will add some length on the motor body; but the carrier is designed to allow a custom 20T pulley to be added at a desired length, or you can manually drill or CAD cut a 8MM hole to secure a screw. The shaft is 12mm thick so no problems on durability for most materials. Once I get done testing Ill upload more instructions and whatnot.

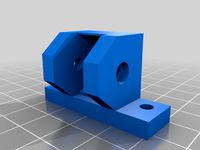

Assembly: Still getting the flaws out to make this as easy as possible. So after tweaking, start at the motor and install each part moving upwards.

1) Shim if needed

2) Gearbox housing lower

3) Fit gears(use medium to heavy weight grease or lube)

4) Lower/fit gearbox housing top

5) Fit Carrier

6) Screw in carrier retainer and whole assembly with M3 screws.

E-steps you need to multiply your current steps by 4. Turn down acceleration to NO MORE than 17% of what it was. This applies to standard Nema17 motors and a 8-bit controller. If you have better hardware, then you can experiment further. You have been warned. Currently mostly tuned in except for compensating for resonance frequencies are:

[Ender 3 Pro]

400 Axis steps per mm

3000-3400 Max Feedrate mm/min(If you havent changed much in Marlin and have a stock board)

100 mm per second Max Acceleration

0.4 mm per second Jerk

{I might be missing one but here are files used for reference.}https://grabcad.com/library/pulleys-gt2-20t-set-1

A video of it in action under its own steam. Testing going well.https://youtu.be/8Sn-LYkH3vo

Update 2-17-21: GT2 belt version was just a bit too loose. New version uploaded.

Update 2-17-21 : Uploaded a version for a installed GT2 belt for the outer ring. When I mean installed, I mean glued. But its better than iffy print quality for gears and the material should dampen the sound a bit.

Update 2-16-21: Found out some of the files are kinda wonky so Im pulling all the old files and reuploading new ones that will print as intended. Some files are the same part, but for ease of choosing I named them appropriately. If you find the file comes out weird or whatnot, then I probably already took it down and replaced it with a functional version.

A very prototype repurpose/recycle old Nema17 motors with press fit pulleys on them. This will add some length on the motor body; but the carrier is designed to allow a custom 20T pulley to be added at a desired length, or you can manually drill or CAD cut a 8MM hole to secure a screw. The shaft is 12mm thick so no problems on durability for most materials. Once I get done testing Ill upload more instructions and whatnot.

Assembly: Still getting the flaws out to make this as easy as possible. So after tweaking, start at the motor and install each part moving upwards.

1) Shim if needed

2) Gearbox housing lower

3) Fit gears(use medium to heavy weight grease or lube)

4) Lower/fit gearbox housing top

5) Fit Carrier

6) Screw in carrier retainer and whole assembly with M3 screws.

E-steps you need to multiply your current steps by 4. Turn down acceleration to NO MORE than 17% of what it was. This applies to standard Nema17 motors and a 8-bit controller. If you have better hardware, then you can experiment further. You have been warned. Currently mostly tuned in except for compensating for resonance frequencies are:

[Ender 3 Pro]

400 Axis steps per mm

3000-3400 Max Feedrate mm/min(If you havent changed much in Marlin and have a stock board)

100 mm per second Max Acceleration

0.4 mm per second Jerk

{I might be missing one but here are files used for reference.}https://grabcad.com/library/pulleys-gt2-20t-set-1

A video of it in action under its own steam. Testing going well.https://youtu.be/8Sn-LYkH3vo

Similar models

cg_trader

$3

Repurpose Press Fit Pulley Motors for 8MM Shaft or 20T Pulley | 3D

... is 12mm thick so no problems on durability for most materials. once i get done testing ill upload more instructions and whatnot.

grabcad

free

gt2 20t pulley for DC550 motor

...gt2 20t pulley for dc550 motor

grabcad

gt2 20t pulley for dc550 motor

3dwarehouse

free

Nema17, (42,3x48 mm) with pulley, gt2-20T-6W, standing on damper and plate

...nema17, (42,3x48 mm) with pulley, gt2-20t-6w, standing on damper and plate

3dwarehouse

detailed

3dwarehouse

free

Nema17, (42,3x48 mm) with pulley, gt2-20T-6W, hanging on damper and plate

...nema17, (42,3x48 mm) with pulley, gt2-20t-6w, hanging on damper and plate

3dwarehouse

detailled

grabcad

free

Pulley GT2 - 20T B5

... 2 m4x4 grub screws.

created by dzino

gt2 - 20t napínacia ozubená kladka s ložiskom pre ozubené remene 2gt - 6mm. pre 5mm osku.

thingiverse

free

ToyREP NEMA 17 Adapter by Zakattacks

... in it at the time. also, the last two pictures shown are of the adapter uploaded here, the orange adapter is a previous version.

grabcad

free

GT2 Timing Pulley AXIS 5mm MOTOR

...gt2 timing pulley axis 5mm motor

grabcad

pulley to axis step motor nema 17. gt-2 16t bore 5mm.

grabcad

free

NMA 17 STEP MOTOR , GT2 PULLEY , GT2 PULLEY DOUBLE HEAD

...nma 17 step motor , gt2 pulley , gt2 pulley double head

grabcad

gt-2 tek kafa ve çi̇ft kafa kasnak

m6 deli̇kli̇

grabcad

free

GT2 20T Wheel Pulley

...gt2 20t wheel pulley

grabcad

gt2 20t wheel pulley

3dwarehouse

free

Pulley GT2 20T Without T 3B

...pulley gt2 20t without t 3b

3dwarehouse

pulley gt2 20t without t polia gt2 20t sem dente

Surgeff

thingiverse

free

LiNk FrAgMeNtEd by SurgeFF

...link fragmented by surgeff

thingiverse

just a sneak peak of a design im working on.

thingiverse

free

ReCool by SurgeFF

...re later, just need to get all the recently made design up at least. ask questions if you have them. tip if you want more faster.

thingiverse

free

Customized Harry Potter Chess Set by SurgeFF

...customized harry potter chess set by surgeff

thingiverse

a gift for a friend.

thingiverse

free

SmolV6 by SurgeFF

...up at least. ask questions if you have them. new file added, just a more realististic fan setup and room for a led strip up front

thingiverse

free

18mm probe 30mm fan mount by SurgeFF

...18mm probe 30mm fan mount by surgeff

thingiverse

18mm probe 30mm fan mounted.

thingiverse

free

Fluid Sprinkler for 10mmOD8MMID tubing by SurgeFF

... sprinkler for 10mmod8mmid tubing by surgeff

thingiverse

a scale down for 10mm tubing. screw to attach blades is now m3, not m8.

thingiverse

free

30mm fan ABL(18mm) mount by SurgeFF

...30mm fan abl(18mm) mount by surgeff

thingiverse

remixed to hold a 18mm sensor instead of a 12mm.

thingiverse

free

6mm Push Fit Fitting Clip by SurgeFF

...6mm push fit fitting clip by surgeff

thingiverse

a real simple retaining clip for 6mm tubing.

thingiverse

free

13mm ID 18 OD adaptor by SurgeFF

...13mm id 18 od adaptor by surgeff

thingiverse

a simple 13mm id 18od t split hose or tube adaptor.

thingiverse

free

Flow Indicator (Repaired) by SurgeFF

...s where scaled extremely small so i rescaled them. nothing else new. you can now print as is and will be meant for 6mm od tubing.

20T

turbosquid

$2

Lamp 20t

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$27

20T uncoiler full set of drawings

...20t uncoiler full set of drawings

3dexport

20t uncoiler full set of drawings

turbosquid

$50

Simple impact mine crusher 20t - h

...usher 20t / h for download as dxf, ige, stl, sldpr, and sldas on turbosquid: 3d models for games, architecture, videos. (1410905)

3ddd

$1

Barbara Barry и FF Flavia

...3ddd barbara barry стол barbara barry модель b8013-20b - b8013-20t и стулья ff...

thingiverse

free

20T Pinion by Trustable

...20t pinion by trustable

thingiverse

its just a 20t pinion

thingiverse

free

suport gt2 20t

...suport gt2 20t

thingiverse

suporte para pulia de gt2 20t

thingiverse

free

20T Belt Pulley by park1107k

...20t belt pulley by park1107k

thingiverse

20t belt pulley

thingiverse

free

Russian 20T Platform Wagon

...russian 20t platform wagon

thingiverse

a nscale russian 20t platform wagon

thingiverse

free

20T Servo Horn

...ervo horn

thingiverse

this suits any 20t, not 25t, servos.

20mm length, centre of servo output to end of arm, 25 mm total length

thingiverse

free

Tensioner For E3D Gates 20T Pulley

...se

the e3d gates precision 20t pulley is wider then the chinese no brand ones that are normally used. this is adjusted for this.

Repurpose

turbosquid

$16

Repurposing Old Crates

...odel repurposing old crates for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1280535)

3d_export

$25

gameready- rc spy helicopter

...gameready- rc spy helicopter 3dexport a repurpose rc helicopter with a camera attached beneath it, usefull...

unity_asset_store

$30

Repurposed Truck

...your workflow with the repurposed truck asset from ryan skinner. find this & other land options on the unity asset store.

thingiverse

free

Battle Top 1 by repurposer

...battle top 1 by repurposer

thingiverse

its a top. see top launcher

thingiverse

free

Repurposed Prusa MMU spool holder rails

...d prusa mmu spool holder rails

thingiverse

repurposed the mmu2 spool holders into drawers with some rails designed in tinkercad.

thingiverse

free

Battle Top 2 by repurposer

...purposer

thingiverse

this top has a receptacle for a 10d 3" finishing nail, for strength as an improvement on battle top 1.

thingiverse

free

Battle Top Launcher by repurposer

...und the stem of the top, put the top in the big hole and pull. more fun with more people.

no frills, just trying to get spinning.

thingiverse

free

Light Enclosure for a repurposed IR Board ex Security Camera

...light enclosure for a repurposed ir board ex security camera

thingiverse

cut a lense from an old cd cover...51mm dia...

thingiverse

free

repurposed cardboard thread rack by ameliechucky

...am using re purposed material that we got from equipment packages.

*ima: interactive media arts program

photos by kevin bin ni

thingiverse

free

Repurposed Wal-Mart Floor Lamp by doctriam

...all have this mount on the wall. just feed power cable through the side. you may want to sand it down there, but i haven't.

Pulley

3d_export

$1

pulley

...pulley

3dexport

3d_export

$30

Pulley export

...pulley export

3dexport

pulley export design render 3d modelling

3d_export

free

Pulley

...ort

this is a pulley<br>formats: ".3ds", ".fbx", ".obj", ".stl", "blend"

3d_export

$6

roller pulley

...r pulley

3dexport

this is the roller pulley 3d model its used for 3d printers and some other uses for toys and usefull things .

turbosquid

$2

aluminum pulley

...

royalty free 3d model aluminum pulley for download as sldpr on turbosquid: 3d models for games, architecture, videos. (1671716)

turbosquid

$29

pulley wheel

...d model pulley wheel for download as obj, wrl, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1319384)

turbosquid

free

Pulley.3ds

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$10

design and assembly of pulley

...design and assembly of pulley

3dexport

design and assembly of pulley 3d model which is used for drive and driven

3d_export

$10

Pulley 3D Model

...y sewing sewingmachine c4d fbx metal

pulley 3d model download .c4d .max .obj .fbx .ma .lwo .3ds .3dm .stl dixiony 107270 3dexport

3d_export

$10

Pulley 3D Model

...trial machine c4d fbx cinema4d metal

pulley 3d model download .c4d .max .obj .fbx .ma .lwo .3ds .3dm .stl dixiony 107271 3dexport

8Mm

turbosquid

$50

8MM CAMERA.max

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$19

kodak 8mm

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$1

Brass Bush Bearing 8mm ID

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

wrench big collection from 8mm to 32mm

...llection from 8mm to 32mm for download as obj, fbx, and sldas on turbosquid: 3d models for games, architecture, videos. (1438111)

turbosquid

$1

Flexible Shaft Coupling 6mm x 8mm

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$1

Flexible shaft coupling 5mm x 8mm

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$15

German WWII Breda MG-8mm Ammo Box (Low Poly)

...g-8mm ammo box (low poly) for download as obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1395526)

3ddd

free

Treasures of the Sea

...treasures of the sea 3ddd бижутерия d=8mm ...

3d_export

$5

double thread screw

...thread length: 10 mm total length: 41 mm diameter: 8mm ...

3d_export

$5

large double thread screw

...thread length: 10 mm total length: 115 mm diameter: 8mm ...

Shaft

3d_export

$5

shaft handle

...shaft handle

3dexport

shaft handle

3d_export

$5

shaft bracket

...shaft bracket

3dexport

shaft bracket

turbosquid

$3

Shaft

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$2

shaft

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

free

crank shaft

...crank shaft

3dexport

crank shaft with piston with different materials

3d_export

$8

shaft bearing

...shaft bearing

3dexport

shaft bearing m10, m12,m16, m20 and m27

3d_export

$5

hexagonal shaft knob

...hexagonal shaft knob

3dexport

hexagonal shaft knob

3d_export

$5

shaft hand wheel

...shaft hand wheel

3dexport

shaft hand wheel

3d_export

$5

triangular shaft knob

...triangular shaft knob

3dexport

triangular shaft knob

3d_export

$5

octagonal shaft knob

...octagonal shaft knob

3dexport

octagonal shaft knob

Press

archibase_planet

free

Press

...ibase planet

press squeezer masher

press garment heat press n131213 - 3d model (*.gsm+*.3ds+*.max) for interior 3d visualization.

archibase_planet

free

Press

...press

archibase planet

newspaper daily paper magazine

press - 3d model for interior 3d visualization.

archibase_planet

free

Press

...press

archibase planet

gymnastic apparatus gym

gym leg press - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Press bench

...press bench

archibase planet

bench press press bench gym

press bench - 3d model (*.gsm+*.3ds) for exterior 3d visualization.

3d_export

$20

iron press

...iron press

3dexport

iron press

3d_export

$15

punch press

...punch press

3dexport

punch press

3d_export

$10

Grape press

...grape press

3dexport

grape press

3d_ocean

$9

Fruit Press

...fruit press

3docean

food and drinks fruit press furnishing

fruit press,food and drinks, furnishing

turbosquid

$20

Press

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

Press

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Motors

archibase_planet

free

Motor

...base planet

motor motor engine engine electric motor

motor wagner n250213 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Motor

...motor

archibase planet

motor motor engine engine

motor n151112 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Motor

...motor

archibase planet

motor motor engine engine

motor n150615 - 3d model (*.gsm+*.3ds+*.max) for interior 3d visualization.

turbosquid

$15

Motor

...otor

turbosquid

royalty free 3d model motor for download as on turbosquid: 3d models for games, architecture, videos. (1639404)

3d_ocean

$5

Electric motor

...electric motor

3docean

car electric engine industry motor phase train vehicle

an electric motor enjoy!

3d_ocean

$18

Electric Motor

...electric motor

3docean

electric motor engine machine mover parts

3d model electric motor for hoist crane

turbosquid

$29

Motor

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$5

Motor

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

electric motor

...electric motor

3dexport

electric motor use for industrial purposes

3d_export

$5

servo motor

...tor

3dexport

it's a simple part of servo motor 0.75kw for used in machines assembly to show specified motor in own project.

Fit

turbosquid

$21

Fitting

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

fitness

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$5

Fitness

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$1

fitness

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

fittings

...fittings

3dexport

low poly 3d model for games

3d_export

$5

fittings

...fittings

3dexport

low poly 3d model for game

3d_export

$30

pipe fit

...pipe fit

3dexport

this models basically used for pipe fitting

3d_ocean

$19

Fitting room

...m fitting fitting room furniture interior materials photorealistic restaurant table textured wardrobe

fitting room with textures.

turbosquid

free

Fitness equipment, technogym tools, fitness ball

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

ITRE FIT

...itre fit

3ddd

itre

itre fit, моделировалась по фото. высота 800 мм, диаметр одного - 130 мм.