Thingiverse

Replicator or Creator multi-spool holder by notarat

by Thingiverse

Last crawled date: 3 years ago

20140508 UPDATE:

New version 3 available in my list of items. Much improved design which prints faster and handles multiple spools much better.

I usually bounce between several colors or materials when printing out stuff and the process of swapping out spools on my Rep2 and my Creator X is a PITA because some of the spools I get are those new, skinnier, but taller, spools that Makerware sells, or those spools that come from Flash Forge which have tiny-sized holes.

They don't fit well on either unit. In short, whomever designed them or approved their use should be made to walk barefoot through a room full of Legos. Twice.

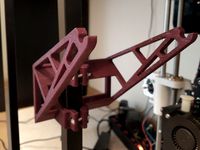

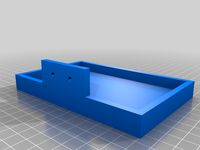

I decided I'd create a new spool holder that connects to the Flash Forge Creator X case (and a later design to fit the Replicator 2) which holds not only multiple spools, but spools of several different sizes at the same time.

To start, I needed vertical arms on which the crossbar holding the spools rests. For this, I went to Home Depot and purchased a 4 foot piece of .75"x.75" square aluminum tubing for about $15

http://www.homedepot.com/p/Everbilt-48-in-x-3-4-in-x-1-16-in-Aluminum-Square-Tube-40630/202183563

I also picked up a round bar of 3/8" Aluminum bar stock (it measures almost 10mm thick) for $5 to serve as a crossbar, which will hold the spools

http://www.homedepot.com/p/Crown-Bolt-3-8-in-x-36-in-Aluminum-Round-Rod-49380/202183519?keyword=aluminum+round+bar+stock

From there, I grabbed a hack saw and measured the square tubing and cut it into two, 18" pieces

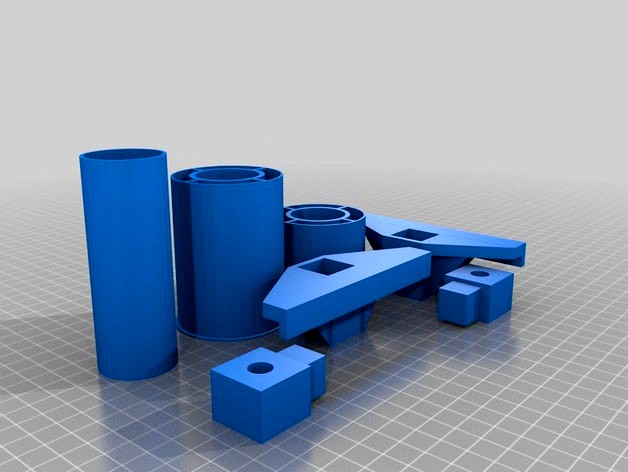

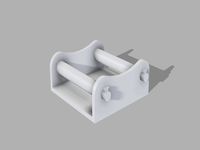

Then, I went into TinkerCad and created the "seats" (the parts that attach to the Creator X case and hold the vertical bars)

Then, I created bar end caps, which plug into the ends of the square tubing, to hold the 10mm cross bar on which the spools rest.

From here, I started thinking about how to mount different-sized spools while maintaining low resistance so the spool spins easily.

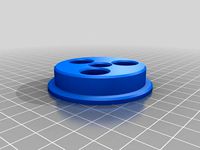

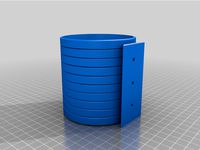

I came upon the idea of using a 3D printed hub for each different sized spool which has an inner diameter of 30.05mm

to keep rolling resistance low, I went to Amazon and bought 2 packs of (10mm I.D. x 30mm O.D. x 9mm W) bearings (5 pieces in each pack) for $12 (including overnight shipping!)\

Http://www.amazon.com/gp/product/B00JD4T4TC/

These bearings will be slipped onto the crossbar at equal intervals, then each will be glued into place with 1 drop of Krazy Glue (crazy, right?)

From here, any combination of different sized spool hubs can be slipped onto the 30mm O.D. bearing casings, and the bearings allow the hub to spin freely, reducing strain on the feeder mechanism for the printer.

Plus, it can hold 4 or 5 different spools (different-sized ones too) so I have easy loading/unloading when swapping spools, and somewhere handy to keep my open spools.

Swapping out filament colors/types will be far easier. And, the new location directly above the extruder, means the filament has a more direct route into the extruder(s) so I don't have to use the tubes if I do not need them.

Oh...it doesn't interfere with the 2 existing spool mount locations so now I can choose one of 6 different spools of filament to use and, it's removable if you need to move the printer around.

New version 3 available in my list of items. Much improved design which prints faster and handles multiple spools much better.

I usually bounce between several colors or materials when printing out stuff and the process of swapping out spools on my Rep2 and my Creator X is a PITA because some of the spools I get are those new, skinnier, but taller, spools that Makerware sells, or those spools that come from Flash Forge which have tiny-sized holes.

They don't fit well on either unit. In short, whomever designed them or approved their use should be made to walk barefoot through a room full of Legos. Twice.

I decided I'd create a new spool holder that connects to the Flash Forge Creator X case (and a later design to fit the Replicator 2) which holds not only multiple spools, but spools of several different sizes at the same time.

To start, I needed vertical arms on which the crossbar holding the spools rests. For this, I went to Home Depot and purchased a 4 foot piece of .75"x.75" square aluminum tubing for about $15

http://www.homedepot.com/p/Everbilt-48-in-x-3-4-in-x-1-16-in-Aluminum-Square-Tube-40630/202183563

I also picked up a round bar of 3/8" Aluminum bar stock (it measures almost 10mm thick) for $5 to serve as a crossbar, which will hold the spools

http://www.homedepot.com/p/Crown-Bolt-3-8-in-x-36-in-Aluminum-Round-Rod-49380/202183519?keyword=aluminum+round+bar+stock

From there, I grabbed a hack saw and measured the square tubing and cut it into two, 18" pieces

Then, I went into TinkerCad and created the "seats" (the parts that attach to the Creator X case and hold the vertical bars)

Then, I created bar end caps, which plug into the ends of the square tubing, to hold the 10mm cross bar on which the spools rest.

From here, I started thinking about how to mount different-sized spools while maintaining low resistance so the spool spins easily.

I came upon the idea of using a 3D printed hub for each different sized spool which has an inner diameter of 30.05mm

to keep rolling resistance low, I went to Amazon and bought 2 packs of (10mm I.D. x 30mm O.D. x 9mm W) bearings (5 pieces in each pack) for $12 (including overnight shipping!)\

Http://www.amazon.com/gp/product/B00JD4T4TC/

These bearings will be slipped onto the crossbar at equal intervals, then each will be glued into place with 1 drop of Krazy Glue (crazy, right?)

From here, any combination of different sized spool hubs can be slipped onto the 30mm O.D. bearing casings, and the bearings allow the hub to spin freely, reducing strain on the feeder mechanism for the printer.

Plus, it can hold 4 or 5 different spools (different-sized ones too) so I have easy loading/unloading when swapping spools, and somewhere handy to keep my open spools.

Swapping out filament colors/types will be far easier. And, the new location directly above the extruder, means the filament has a more direct route into the extruder(s) so I don't have to use the tubes if I do not need them.

Oh...it doesn't interfere with the 2 existing spool mount locations so now I can choose one of 6 different spools of filament to use and, it's removable if you need to move the printer around.

Similar models

thingiverse

free

Multi-Spool / Multi-Size Spool Holder (Ver. 3) by notarat

...here's a video of the completed assembly, showing the spools being spun in opposite directions

http://youtu.be/rrjgkwk-_0a

thingiverse

free

Filament Tube Holder by holycrapitsjosh

... creator pro printers. i relocated the spools on mine to the front and needed to hold the new tubes to the side of the printer.

thingiverse

free

Vertical Spool Holder by gromo

...9;s it :-)

should be strong enough to hold 2 pieces of 1kg filament spool...if not i'll redesign one for a 12mm alum tube....

thingiverse

free

Spool Holder by Ahnk

...spool holder by ahnk

thingiverse

end caps hold 1/2 " o.d. x 0.25 " i.d. x 0.2 " ball bearings .

thingiverse

free

Filament spool with aluminum bar by Clax

...ter 1.7 and 3mm to secure it (fig 7).

for this project, you need two bearing 608zz and aluminum bar pierced 10x10mm, about 600mm.

thingiverse

free

Spool holder (for 20mm square tube, space saving)

...n diameter and 90mm in width (depending on the spool's central hole size). this design needs an 8mm rod and 2 x 608 bearings.

thingiverse

free

Parametric Filament Spool Hub with 608ZZ bearing by AndrewBCN

...enscad source is available so it can be further remixed.

update 23/12/2014: reinforced the "petals" and code cleanup.

thingiverse

free

Inland Spool Hub w/ 608 bearing by kvanderloop

...th a 608 bearing. (4/30/17)

inland has a new factory making their filament. i added a new stl added for the new spool. (5/12/18)

thingiverse

free

Needle roller bearing filament spool hub by TimeFramed

..._details_o00_s00_i00?ie=utf8&psc=1

they're large enough i.d. to fit onto a piece standard 1/2" electrical conduit.

thingiverse

free

Filament Spool Roller for 2020 Aluminum Extrusion by Delphius

...m rough at first but are perfectly adequate after you break them in. designed using onshape. fits minimum spool diameter of 43mm.

Notarat

thingiverse

free

Accessory Box by notarat

...or knives, sandpaper, and the tools that you use most often for maintenance.

hangs off the right side panel of the replicator 2

thingiverse

free

Storage Box Jr. by notarat

...e printer is 6.25mm wide.

fits replicator 2, flash forge creator x, and other 3d printers and holds a lot of stuff for its size

thingiverse

free

Thermaltake Core W200 Power Supply Shroud by notarat

...ling and psu in my thermaltake core w200 case(right side) so i made this. it's got the amd and ryzen logos in it for my build

thingiverse

free

Front Acrylic Panel Guides by notarat

...ure materials.

as i spent all my money on fixes to my creator x i haven't got the money for acrylic so i used cardboard. :(

thingiverse

free

Build Plate Screw Lock by notarat

... place wing nuts on my leveling screws so they cannot loosen up. this means the build plate does not have to be leveled as often.

thingiverse

free

5mm Z Axis Shim for Creator X by notarat

...mashing into the glass panes on my build plate. please see the original design for instructions on installation. it is located at

thingiverse

free

ODD Mounting Brackets for ThermalTake Core W200 Case by notarat

... to allow you to install accessories like the max 3504 or max 3503 or max 2506 or thermaltake commander fc6 fan/rgb control unit.

thingiverse

free

Clip Mount to attach Digital Dial Gauge to Flash Forge Creator X Extruders by notarat

...der's great design and decided i wanted to use it on my creator x...unfortunately, it no fit...

so i decided to make my own

thingiverse

free

Universal Spool Guides by notarat

...ol and i've put nearly 300 hours of use on the printer after installing the guide (so it's been tested pretty thoroughly)

thingiverse

free

2-piece Universal Spool Holders for FFC Pro by notarat

...o a single piece which can easily handle 2.2kg spools from any mfgr

i've been using these for a week now and they work great.

Creator

thingiverse

free

Armband creator by nick3085

...armband creator by nick3085

thingiverse

bracelet/keychain creator

thingiverse

free

Creator Coin by coteamz

...reator coin by coteamz

thingiverse

my creator coin for my twitch fans (https://www.twitch.tv/teamz_co) hope you all enjoy it :)

thingiverse

free

Lantern by FP-Creator

...lantern by fp-creator

thingiverse

lantern

thingiverse

free

Horse by FP-Creator

...horse by fp-creator

thingiverse

horse

thingiverse

free

helicopter by FP-Creator

...helicopter by fp-creator

thingiverse

helicopter

thingiverse

free

Yacht by FP-Creator

...yacht by fp-creator

thingiverse

yacht

thingiverse

free

Aircraft by FP-Creator

...aircraft by fp-creator

thingiverse

aircraft

thingiverse

free

Clamp by FP-Creator

...clamp by fp-creator

thingiverse

clamp

thingiverse

free

Goku by FP-Creator

...goku by fp-creator

thingiverse

dragonballz

thingiverse

free

Gorilla by FP-Creator

...gorilla by fp-creator

thingiverse

gorilla

Replicator

thingiverse

free

Replic by nagato

...replic by nagato

thingiverse

replic

thingiverse

free

Spool holder for Prototype Supply filament. (Replicator, Replicator 2, and Replicator 2X) by toybuilder

...e spool holder for replicator 2 -- http://www.thingiverse.com/thing:44906 to make the tongue fit into the slot on the replicator.

thingiverse

free

Replicator Hood by ToddF

...replicator hood by toddf

thingiverse

this is a removable hood for the makerbot replicator.

thingiverse

free

Gate Latch Replication by

...gate latch replication by

thingiverse

a gate latch part i replicated for a client.

thingiverse

free

Torus Replicator Tree

...torus replicator tree

thingiverse

a mathematical tree created by replicating torus structures.

thingiverse

free

Replicator Feet by BrianStamile

...replicator feet by brianstamile

thingiverse

printable replacement replicator feet are finally here!

thingiverse

free

Replicator windows by teachermakesthings

...replicator windows by teachermakesthings

thingiverse

add some windows to your replicator to help with cooling and drafts.

thingiverse

free

Replicator mug by NX01Enterprise

...replicator mug by nx01enterprise

thingiverse

the mug a replicator gives you with any hot drink from earth

thingiverse

free

fan duct for Makerbot Replicator by mjchen

...akerbot replicator dual and replicator 2x.http://lunglungdesign.blogspot.tw/2013/06/makerbot-replicator-dual-replicator-2-ii.html

thingiverse

free

Tool Box for Replicator 2

...tool box for replicator 2

thingiverse

tool box for replicator 2

Multi

thingiverse

free

Multi-articulated, multi-purpose 2

...multi-articulated, multi-purpose 2

thingiverse

multi-purpose articulated system, for all types of handling

thingiverse

free

Multi-Fun (Multi-functional - Multi-Funktional) by JMDesigns

...ingeld, schlüssel, seifen, schwammschale, (3d drucker) kleinteilebehälter und noch vieles mehr. lasst eurer fantasie freien lauf.

thingiverse

free

multi cigarette, multi weed by luisfer102009

...lti cigarette, multi weed by luisfer102009

thingiverse

perfect element to smoke three cigars at a time or three joints at a time

thingiverse

free

multi cube by mediamata69

...multi cube by mediamata69

thingiverse

multi cube

thingiverse

free

snowflake multi by norcalz7

...snowflake multi by norcalz7

thingiverse

multi yo

thingiverse

free

La multi ani !

...la multi ani !

thingiverse

la multi ani !

thingiverse

free

Multi Filament Holder

...multi filament holder

thingiverse

multi filament holder.

thingiverse

free

Pumuckl - multi color / multi part version by Stwebster

...i part version by stwebster

thingiverse

this is the pumuckl in a multiple part version for multi color printing.

its not tested!

thingiverse

free

multi colour tardis

...multi colour tardis

thingiverse

type 42 tardis

multi colour

thingiverse

free

Drone Multi Drop

...drone multi drop

thingiverse

this is a parametric version of the drone multi dropper by by alperssl.

;-)

Spool

thingiverse

free

Spool Support For Anycubic Spool Holder and AMZ3D Spools by Kobaratsu

... amz3d spools by kobaratsu

thingiverse

spool axis support to avoid jerks on spool, using anycubic spool holder and amz3d spools

thingiverse

free

Spool adapter for Warhorse spool

...spool adapter for warhorse spool

thingiverse

a simple spool adapter to use abs warhorse spool with a 72 mm hole diameter.

thingiverse

free

Spool holder for 1KG Spools by angkor

...spool holder for 1kg spools by angkor

thingiverse

spool holder for 1kg spools

thingiverse

free

Spool holder

...spool holder

thingiverse

i use this spool holder for up to 1kg spools and should fit all spools.

thingiverse

free

Spool assembler

... empty spool with this spool assembler

just cut an empty spool in half , put your filament and assemble with this spool assembler

thingiverse

free

Small Spool and Spool Stand by Beckman13

...ool holder are meant for 50 gram flexible filaments. the two sides of the spool holder are meant to slide together and interlock.

thingiverse

free

spool spindle cap for 25mm spools by Seadevil

...spool spindle cap for 25mm spools by seadevil

thingiverse

spool spindle cap for 25mm spools

thingiverse

free

spool ! by St0rmingBr4in

...spool ! by st0rmingbr4in

thingiverse

this is a spool !

thingiverse

free

Spool Holder for large spools by dmonkey

...y

thingiverse

a spool holder that you can attach to the back of a makerbot replicator that can hold large filament spools (1kg)

thingiverse

free

Spool roll

...spool roll

thingiverse

spool roll

Holder

thingiverse

free

Stubby holder holder

...der

thingiverse

bottom on the holder is sized for a can or bottle. top of the holder is sized for one in a cooler/stubby holder.

thingiverse

free

Soap holder holder

...soap holder holder

thingiverse

it's a holder to hold the famous soap holder.

thingiverse

free

bottle holder Jar holder can holder

...bottle holder jar holder can holder

thingiverse

hole diameter 38.6mm

thingiverse

free

Spool holder holder by vemotion

...spool holder holder by vemotion

thingiverse

pipe holder (16mm diameter)

thingiverse

free

smartphone holder with usb cable holder and key holder

...other of invention

this is my first creation basically smartphone holder with usb cable holder and key holder

i hope you like it

thingiverse

free

Holder of plate holders by budvar

...t; ;) holder for 5 pieces of modular plate holders from dave o https://www.prusaprinters.org/en/prints/15367-modular-plate-holder

thingiverse

free

Pen Holder/card holder by Pinky561

...pen holder/card holder by pinky561

thingiverse

a pen holder/card holder in one.

thingiverse

free

Toilet paper holder with phone holder

...toilet paper holder with phone holder

thingiverse

toilet paper holder with phone holder

thingiverse

free

Radio equipment holder and microphone holder

...radio equipment holder and microphone holder

thingiverse

radio equipment holder and microphone holder

thingiverse

free

Popsicle Holder Holder by billiamthesecond

...popsicle holder holder by billiamthesecond

thingiverse

keep popsicle holders upright so that they can be set down