Thingiverse

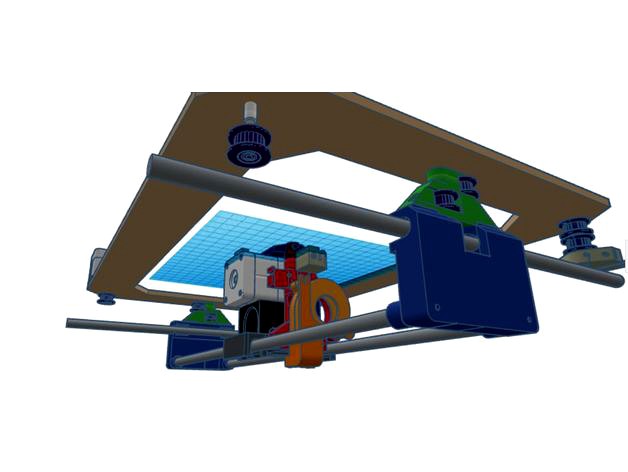

Replicator CoreXY Conversion (The Frankenbot) by pyr0ball

by Thingiverse

Last crawled date: 4 years, 5 months ago

WIP! Just finished the designs, about to start building the parts and drill guides this week and will be able to work out kinks from there.

Still to do:

Endstop mounts

Drill guide for the front pillow blocks

adjust height/spacing for fan blower duct

I had a lot of fun converting my Replicator to a RAMPS 1.4 open source kit, but I was plagued by persistent issues, problems with the extruders jamming, play in the Y-axis causing some difference in the print walls depending on which direction the perimeter was printed. Eventually one of the 5mm rods on the Y-axis bent, causing variances in tension that would in turn cause prints to fail. I guess that's what happens when you pull an old printer out of E-Waste ¯\_(ツ)_/¯

I've always been facinated by the concept of a CoreXY setup and figured this was a perfectly good opportunity to simultaneously fix some of the remaining issues with my printer, as well as explore a new style of kinematics.

Hardware Required:

8x GT20 5mm Pully Idler (toothed or smooth, doesnt matter)

2x MR105ZZ bearing (5x10x4mm)

4x M5 30mm countersunk bolt

2x M3 30mm bolts

4x M3 25mm bolts

8x M3 4x5mm embedded nuts

Various shorter M3 nuts and bolts

For those who would like to customize or make changes for themselves, here's the Tinkercad

Still to do:

Endstop mounts

Drill guide for the front pillow blocks

adjust height/spacing for fan blower duct

I had a lot of fun converting my Replicator to a RAMPS 1.4 open source kit, but I was plagued by persistent issues, problems with the extruders jamming, play in the Y-axis causing some difference in the print walls depending on which direction the perimeter was printed. Eventually one of the 5mm rods on the Y-axis bent, causing variances in tension that would in turn cause prints to fail. I guess that's what happens when you pull an old printer out of E-Waste ¯\_(ツ)_/¯

I've always been facinated by the concept of a CoreXY setup and figured this was a perfectly good opportunity to simultaneously fix some of the remaining issues with my printer, as well as explore a new style of kinematics.

Hardware Required:

8x GT20 5mm Pully Idler (toothed or smooth, doesnt matter)

2x MR105ZZ bearing (5x10x4mm)

4x M5 30mm countersunk bolt

2x M3 30mm bolts

4x M3 25mm bolts

8x M3 4x5mm embedded nuts

Various shorter M3 nuts and bolts

For those who would like to customize or make changes for themselves, here's the Tinkercad