GrabCAD

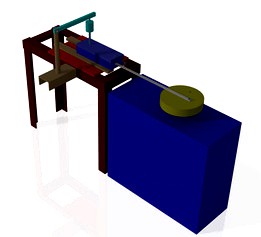

Reciprocating Mechanism for Rotary Wear Testing Machine

by GrabCAD

Last crawled date: 1 year, 11 months ago

The Objective of the project is to investigate the pin on disc wear testing machine and to develop a suitable mechanism to convert the continuous rotary motion to reciprocating motion without hindering the original functionality.

Steps:

1. The Project involved studying the existing machine, developing a concept such that it doesn't hinder the original functionality.

2. It involved developing a suitable concept, Designing the components through Hand calculations, Developing CAD Model in CATIA, Drafting with the Bill of Materials.

3. Manufacturing the components with the laboratory equipment and testing with a standard materials.

The Calculations involved:

1. Calculating the torque on the motor side to prove that it can overcome the resisting torque.

2. Calculating the length and cross-section of connecting rod based on stroke length.

3. Calculating the height and loads on the structure.

4. Calculating the dimensions of the block and plate.

5. Selection of appropriate materials for the components.

6. Fabrication with operations like shearing, drilling, and Milling

Manufacturing Processes Involved:

1. Drilling - For drilling the various holes and tapping them.

2. Shearing - For cutting MS Angle to the appropriate length for the structure.

3. Welding - Structure and base plate on the structure.

4. Milling - For making the slot in Slider Block

5. Lathe - Turning

List of Components:

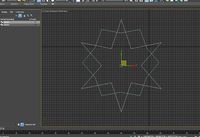

1. Circular Disc

2. Connecting Rod (12x6x480 mm)

3. Flat Plate (250×100×10mm)

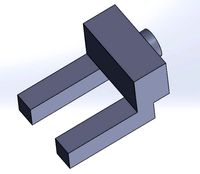

4. Slider Block

5. Slider

6. Flat Plate (350x250x1mm)

7. Structure made up of MS Angle (50x50x2mm)

8. C-Channel

9. Screw M4x16 and Screw M6x55

Steps:

1. The Project involved studying the existing machine, developing a concept such that it doesn't hinder the original functionality.

2. It involved developing a suitable concept, Designing the components through Hand calculations, Developing CAD Model in CATIA, Drafting with the Bill of Materials.

3. Manufacturing the components with the laboratory equipment and testing with a standard materials.

The Calculations involved:

1. Calculating the torque on the motor side to prove that it can overcome the resisting torque.

2. Calculating the length and cross-section of connecting rod based on stroke length.

3. Calculating the height and loads on the structure.

4. Calculating the dimensions of the block and plate.

5. Selection of appropriate materials for the components.

6. Fabrication with operations like shearing, drilling, and Milling

Manufacturing Processes Involved:

1. Drilling - For drilling the various holes and tapping them.

2. Shearing - For cutting MS Angle to the appropriate length for the structure.

3. Welding - Structure and base plate on the structure.

4. Milling - For making the slot in Slider Block

5. Lathe - Turning

List of Components:

1. Circular Disc

2. Connecting Rod (12x6x480 mm)

3. Flat Plate (250×100×10mm)

4. Slider Block

5. Slider

6. Flat Plate (350x250x1mm)

7. Structure made up of MS Angle (50x50x2mm)

8. C-Channel

9. Screw M4x16 and Screw M6x55

Similar models

cg_trader

$2

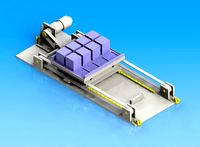

Slider Mechanism

...ion, as in a reciprocating piston engine, or to convert rotary motion to straight-line motion, as in a reciprocating piston pump.

grabcad

free

Slider Crank Mechanism (SCM)

...edly opening and closing drawers, tens of thousands of times. testing door handles by repeatedly lowering and lifting the handle.

grabcad

free

Slider Crank Mechanism

...ary motion, as in a reciprocating engine, or to convert rotary motion to straight line motion, as in a reciprocating piston pump.

grabcad

free

Slider Crank Mechanism

...ion, as in a reciprocating piston engine, or to convert rotary motion to straight-line motion, as in a reciprocating piston pump.

grabcad

free

slider crank mechanism

...ion, as in a reciprocating piston engine, or to convert rotary motion to straight-line motion, as in a reciprocating piston pump.

grabcad

free

Slider Crank

...slider crank

grabcad

slider crank is mainly used to convert rotary motion to a reciprocating motion or vice versa.

grabcad

free

slider crank mechanism

...aight-line motion, as in a reciprocating piston pump. ... on a reciprocating piston pump the crankshaft would be driven by a moto

grabcad

free

Slider Crank Mechanism

...ion, as in a reciprocating piston engine, or to convert rotary motion to straight-line motion, as in a reciprocating piston pump.

grabcad

free

Slider Crank Mechanism

...grabcad

slider crank mechanism involves conversion of reciprocating motion of piston into rotatry motion of shaft and viceversa.

grabcad

free

Slider Crank Mechanism

...tion, as in a reciprocating piston engine, or to convert rotary motion to straight-line motion, as in a reciprocating piston pump

Reciprocating

3d_export

$6

Reciprocating Motion

...#39;vinci's reciprocating motion contraption the model is used for picking up buckets of water from a well materials included

3d_export

$5

horizontal reciprocating mask packaging machine

... reciprocating mask packaging machine<br>3d drawing model of horizontal reciprocating mask packaging machine solidworks stp

3d_export

$14

reciprocating saw

...br textures. fbx obj pbr textures with 5 different colour variants packed grayscale textures, occlusion, roughness & metallic

3d_export

$15

horizontal reciprocating mask packaging machine

...r boxes, product cartons are placed on a row of crossbeam shelves by pallets, and can be accessed and accessed by any single tray

3d_export

$8

Cam and Follower

...follower rises and falls in a process known as reciprocating ...

3d_export

$95

Falcon 3D C182 Skylane F06 3D Model

...civilian civil commuter trainer personal family professional training monoplane reciprocating propeller opposed inline four place falcon 3d c182 skylane...

3d_export

$10

camshaft moped motorcycle motorbike

... the push rod, the valve is completely open. the valve is closed when the spring pulls it back and the cam is on its base circle.

3d_export

$5

traverse mechanism of heavy workpiece

...the conveyor.<br>in order to obtain the forward precision of reciprocating straight line.<br>key points of design<br>calculation process of main parts<br>verify...

thingiverse

free

Reciprocating Mechanism

...d in jig-saw typed power tools. could also be used to turn reciprocating energy back into rotational.https://youtu.be/vl-jwvzgpns

free3d

free

Reciprocating Saw v1

...reciprocating saw v1

free3d

reciprocating saw v1 printable, low poly model.

Rotary

3ddd

$1

Medical Rotary table

...medical rotary table

3ddd

медицинский стол

medical rotary table

turbosquid

$18

Codex Rotary

...squid

royalty free 3d model codex rotary for download as stl on turbosquid: 3d models for games, architecture, videos. (1439894)

turbosquid

$12

Rotary drill

...y free 3d model rotary drill for download as ma, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1394316)

3d_export

$6

The rotary module 3D Model

...the rotary module 3d model

3dexport

the rotary module

the rotary module 3d model armata2015 98145 3dexport

turbosquid

$40

Rotary Engine

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$15

Rotary Phone

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

ROTARY medal

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$9

Rotary conveyor

...veyor for download as 3ds, max, ige, obj, fbx, stl, and sldas on turbosquid: 3d models for games, architecture, videos. (1300472)

3d_export

$5

Rotary Cylinder 3D Model

...rotary cylinder 3d model

3dexport

rotary cylinder pneumatic pressure torque

rotary cylinder 3d model fau 71217 3dexport

3ddd

$1

Medical Rotary Table M2

...medical rotary table m2

3ddd

медицинский , стол

medical rotary table m2

Wear

turbosquid

free

soilder wear

...ar

turbosquid

free 3d model soilder wear for download as max on turbosquid: 3d models for games, architecture, videos. (1144149)

3d_export

$5

diving wear fbx

...diving wear fbx

3dexport

diving wear fbx made sofeware clo,marvelous designer

turbosquid

$60

Male In Casual Wear

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$60

Arnold_ formal wear

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$18

women wear 01 3D Model

...women wear 01 3d model

3dexport

women wear shoes sandles beach vray

women wear 01 3d model prediator 6294 3dexport

turbosquid

$40

Boy wearing Mask and Gloves

... free 3d model boy wearing mask and gloves for download as ma on turbosquid: 3d models for games, architecture, videos. (1562410)

turbosquid

$5

Modern PBR Stove with Wear

...odern pbr stove with wear for download as obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1186746)

turbosquid

$39

Young Guy in Casual Wear

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

Musket Pistol Gun With Wearing

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

Realistic Mannequin - Ladies Western Wear

...d model ladies western wear for download as obj, fbx, and pac on turbosquid: 3d models for games, architecture, videos. (1462327)

Mechanism

3d_export

$50

Mechanism

...mechanism

3dexport

mechanism -------- animation is present only in the blender file.

3d_export

$5

mechanics

...mechanics

3dexport

turbosquid

$50

mechanic

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

Mechanical Wasp

...mechanical wasp

3ddd

робот

mechanical wasp

3d_export

$20

Mechanical tail

...mechanical tail

3dexport

mechanical tail<br>four-part movement

3d_export

$5

mechanical ballista

...mechanical ballista

3dexport

a mechanical ballista useful for medieval or fantasy games does not contain animations

turbosquid

$59

Mechanical Part

...id

royalty free 3d model mechanical part for download as c4d on turbosquid: 3d models for games, architecture, videos. (1410833)

turbosquid

$50

Mechanical Spider

...royalty free 3d model mechanical spider for download as blend on turbosquid: 3d models for games, architecture, videos. (1599864)

turbosquid

$45

Mechanical Pencil

...royalty free 3d model mechanical pencil for download as blend on turbosquid: 3d models for games, architecture, videos. (1503379)

turbosquid

$35

Mechanical fish

...id

royalty free 3d model mechanical fish for download as max on turbosquid: 3d models for games, architecture, videos. (1152530)

Machine

archibase_planet

free

Machine

...machine

archibase planet

sewing-machine sewing machine equipment

singer machine- 3d model for interior 3d visualization.

archibase_planet

free

Machine

...hine

archibase planet

percolator equipment coffee-machine

machine n230708 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Machine

...chibase planet

percolator coffee-machine kitchen equipment

coffee machine - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Slot machine

...ase planet

slot machine slot-machine playing machine

slot machine n260311 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

turbosquid

$7

Machine

...ne

turbosquid

royalty free 3d model machine for download as on turbosquid: 3d models for games, architecture, videos. (1391792)

3d_ocean

$10

War machine

...war machine

3docean

camuflage machine robot war war machine

war machine created in 3dmax 2009 15.497-poly count

turbosquid

$7

machine

...turbosquid

royalty free 3d model machine for download as obj on turbosquid: 3d models for games, architecture, videos. (1452674)

3d_ocean

$12

Weighing-machine

...weighing-machine

3docean

market shop weighing-machine

3d model weighing-machine

archibase_planet

free

Sewing machine

...ine

archibase planet

sewing machine sewing-machine

sewing machine n080311 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Coffee machine

...se planet

coffee machine percolator coffee-machine

coffee machine n010715 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

Testing

turbosquid

$99

test

...st

turbosquid

royalty free 3d model test for download as max on turbosquid: 3d models for games, architecture, videos. (1251637)

turbosquid

$63

TEST

...st

turbosquid

royalty free 3d model test for download as max on turbosquid: 3d models for games, architecture, videos. (1446233)

turbosquid

$1

test

...st

turbosquid

royalty free 3d model test for download as fbx on turbosquid: 3d models for games, architecture, videos. (1360941)

3d_export

free

johnny test

...johnny test

3dexport

johnny test 3d

turbosquid

$15

Test

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$2

test

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Test

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

test

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Test

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

gripper test

...gripper test

3dexport

robot gripper test model