Thingiverse

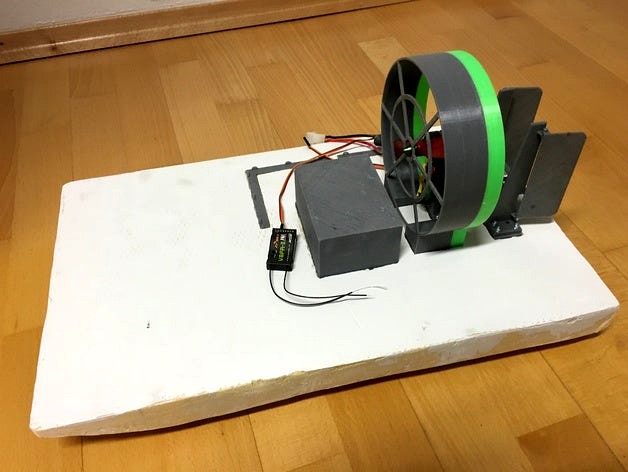

R/C - Swampboat by CRoesler

by Thingiverse

Last crawled date: 3 years ago

Update the mounts for the rudder, they were not stiff enough, as well as the mount for the motor, also optimized the cooling for the motor.

You need to print every part once, except for the skids (Sumpfboot_Kufe_xxx) those you need 2 of each and click them together with the dove tails (could not make them as one piece, because my printbed is only 200x200 mm).

Other parts you need:

14 x locking nuts M3 (insert them into the bottom side of the mounting plate)

14 x washers for M3 bolts

12 x M3x12 bolts (rudermount + motor)

4 x M3x10 bolts (motor mount)

2 x M3x8 bolts (servo mount)

6 x locking nuts M2.5

7 x washers for M2.5 bolts (the 7th one is for mounting the servo onto the guide)

6 x M2.5x8 bolts

1 x Motor Multistar Elite 2204-2300KV (that is the one, for which the holes on the motor mount fit) https://www.hobbyking.com/hobbyking/store/uh_viewItem.asp?idProduct=70353

1 x fitting ESC for the motor: I used this one https://www.hobbyking.com/hobbyking/store/uh_viewItem.asp?idProduct=47810

1 x propeller 6x4 or 6x4.5 https://www.hobbyking.com/hobbyking/store/uh_viewItem.asp?idProduct=91765

1 x Servo Towerpro MG90S Metal Gear RC Micro Servo http://www.banggood.com/4-X-Towerpro-MG90S-Metal-Gear-RC-Micro-Servo-p-961967.html

1 x battery 3s, mine is a 3s5p, made out of 18650 cells from Panasonic with a custom holder (Dimensions 100x65x72 mm), if you use any other battery, you need to make a custom cover and mill a different hole into the hull

1 x remot control + receiver

1 x hull: I made mine out of a PUR (polyurethane) foam insulating wall panel, after cutting and sanding it was 500x300x50 mm with a suitable form, bow, etc. (should look like a swampboat), before cutting the bow, attached the skids temporary to get the proper angle for the bow. You also need to cut and/or mill the holes for battery, ruder_base, cableguides and the propguard into the hull (you need to check for balance a couple of times, basically put the hull in the bathtub or something similar and put the parts ontop, you should look for a trim with little more weight to the stern) print the parts first and put them on the hull to get the correct dimensions. At last you should cover the hull with glass fibre and epoxy to get it waterproof.

I haven't finished mine, yet, but I will provide more pictures of the finished boat.

You need to print every part once, except for the skids (Sumpfboot_Kufe_xxx) those you need 2 of each and click them together with the dove tails (could not make them as one piece, because my printbed is only 200x200 mm).

Other parts you need:

14 x locking nuts M3 (insert them into the bottom side of the mounting plate)

14 x washers for M3 bolts

12 x M3x12 bolts (rudermount + motor)

4 x M3x10 bolts (motor mount)

2 x M3x8 bolts (servo mount)

6 x locking nuts M2.5

7 x washers for M2.5 bolts (the 7th one is for mounting the servo onto the guide)

6 x M2.5x8 bolts

1 x Motor Multistar Elite 2204-2300KV (that is the one, for which the holes on the motor mount fit) https://www.hobbyking.com/hobbyking/store/uh_viewItem.asp?idProduct=70353

1 x fitting ESC for the motor: I used this one https://www.hobbyking.com/hobbyking/store/uh_viewItem.asp?idProduct=47810

1 x propeller 6x4 or 6x4.5 https://www.hobbyking.com/hobbyking/store/uh_viewItem.asp?idProduct=91765

1 x Servo Towerpro MG90S Metal Gear RC Micro Servo http://www.banggood.com/4-X-Towerpro-MG90S-Metal-Gear-RC-Micro-Servo-p-961967.html

1 x battery 3s, mine is a 3s5p, made out of 18650 cells from Panasonic with a custom holder (Dimensions 100x65x72 mm), if you use any other battery, you need to make a custom cover and mill a different hole into the hull

1 x remot control + receiver

1 x hull: I made mine out of a PUR (polyurethane) foam insulating wall panel, after cutting and sanding it was 500x300x50 mm with a suitable form, bow, etc. (should look like a swampboat), before cutting the bow, attached the skids temporary to get the proper angle for the bow. You also need to cut and/or mill the holes for battery, ruder_base, cableguides and the propguard into the hull (you need to check for balance a couple of times, basically put the hull in the bathtub or something similar and put the parts ontop, you should look for a trim with little more weight to the stern) print the parts first and put them on the hull to get the correct dimensions. At last you should cover the hull with glass fibre and epoxy to get it waterproof.

I haven't finished mine, yet, but I will provide more pictures of the finished boat.

Similar models

thingiverse

free

Tricopter Mounts by Daniel_Martell

...h_viewitem.asp?idproduct=11520

1x: shaft (5mm d shaft):http://www.hobbyking.com/hobbyking/store/uh_viewitem.asp?idproduct=24822

thingiverse

free

Mount LiPo by olo2000pm

...mount lipo by olo2000pm

thingiverse

mount for:http://www.hobbyking.com/hobbyking/store/uh_viewitem.asp?idproduct=36148

3dwarehouse

free

EZ-RUN Brushless Motor RC

...tor rc

3dwarehouse

ez-run brushless motor from hobbyking http://www.hobbyking.com/hobbyking/store/uh_viewitem.asp?idproduct=7194

thingiverse

free

70mm electric ducted fan housing by bblattbot

...ur own motor mounting holes too.

this edf unit is used in my electric football design. http://www.thingiverse.com/thing:191442

3dwarehouse

free

AX-2810Q KV-750 Brushless Motor

...

brushless motor purchased from hobbyking http://www.hobbyking.com/hobbyking/store/uh_viewitem.asp?idproduct=25556&aff=129354

thingiverse

free

Revision III Tricopter reinforced for 13mm aluminium by fabrimp

...w.hobbyking.com/hobbyking/store/uh_viewitem.asp?idproduct=22800

2 front arms with 250mm and back arm with 247 mm

videos soon...

thingiverse

free

F450 Flamewheel Pixhawk, FPV & Electronics Top plate, Canopy by ljbotero

...73&aff=1407499

gps: 50 mm diameterhttp://www.hobbyking.com/hobbyking/store/uh_viewitem.asp?idproduct=55558&aff=1407499

3dwarehouse

free

X-Quad

... 4 x turnigy plush 18amp speed controller -- http://www.hobbyking.com/hobbyking/store/uh_viewitem.asp?idproduct=4312; #megapirate

thingiverse

free

MOON ONE (((Cheburashka))) by Larkin_Michael

... is normal insulin syringes. they filled in a little water to stiffness. diameter of 6.5 mm

head designed for the camera gopro3

grabcad

free

Hobbyking Turnigy Talon Hexacopter frame

...urnigy talon haxacopter frame available from hobbyking (http://www.hobbyking.com/hobbyking/store/uh_viewitem.asp?idproduct=23790)

Croesler

thingiverse

free

Bottleholder - stackable by CRoesler

...r - stackable by croesler

thingiverse

print 2 for each bottle, can be joined via dove-tails. for bottles up to 85 mm in diameter

thingiverse

free

LED Desklamp for Patio table by CRoesler

...is intentional, i did not need full brightness (less blinding, more atmosphere :) ) and i wanted to keep it as small as possible.

Swampboat

renderosity

$25

MS17 Swamp Boat for DAZ

...artist many options.<br /> <br /> product name: ms17 swampboat for vue<br /> copyright 2017: don (london224)<br /> <br...

3dwarehouse

free

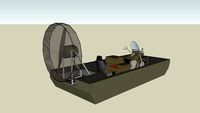

Military Air Boat

...#camo #camoflauge #cia #military #navy #navy_seals #socom #swamp #swamp_boat #swampboat #us...

3dwarehouse

free

Kaik / riverboat / swampboat

...riverboat from 17th , up to 20th century. also known as swampboat. #boat #bulgarian #river_transportation #riverboat #wooden_boat

R

3d_export

$99

Vauxhall Agila 2008 3D Model

...vauxhall agila 2008 3d model 3dexpor vauxhall agila 2008 2009 2010 europe suzuki wagon r+...

3d_export

$99

Volkswagen Golf VII R 5door 2015 3D Model

...or volkswagen vw detailed interior golf vii 2017 hothatch 5door 5d

volkswagen golf vii r 5door 2015 3d model squir 90150 3dexport

3d_export

$129

Scania R1000 2014 AeroTrailer 3D Model

...mi transport scania r1000 r-1000 hevy wheeler trailer tir aerotrailer

scania r1000 2014 aerotrailer 3d model squir 73046 3dexport

3d_export

$15

Wheel Detroit Cobra R rims and tire 3D Model

...ormance disk brake caliper brembo yokohama detroit cobra

wheel detroit cobra r rims and tire 3d model 3dlogicline 54693 3dexport

3ddd

$1

мойка накладная "Imperial" 6080-R

...мойка накладная "imperial" 6080-r

3ddd

мойка

мойка накладная "imperial", размер 800*600, арт. 6080-r

3ddd

$1

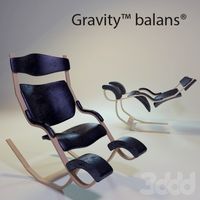

Gravity balans

...зводитель: varier

модель: gravity balans

дизайнер: peter opsvikhttp://www.varier.ru/collections/relax/gravity-balans-r/

3ddd

$1

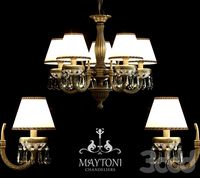

Maytoni СL1028-05-R

...dd

maytoni

люстра maytoni сl1028-05-r

(коллекция classic)

высота: 360

диаметр: 520

цвет: брасс

ламп: 5 x e14 (60w)

www.maytoni.ru

3d_ocean

$29

Scania Truck

...poly machine scania scania r scania r420 swedish car tractor truck trailer vehicle

high poly truck with vray lighting and camera.

3d_ocean

$49

English Family House

...the objects are modeled using real world dimensions. the r.. ...

3d_ocean

$85

Vauxhall Combo Tour H1L1 2015

...of measurment. all car parts are correctly named. model is created in autodesc maya 2012, visualization (rendering) – mental r...

C

3d_export

$99

MercedesBenz C coupe 2012 3D Model

...mercedes-benz c-class coupe sport fast car germany mb 2012 2013 2014 2015

mercedesbenz c coupe 2012 3d model squir 53725 3dexport

3ddd

$1

BAYERN IVORY

...code: white pvc base code: c/baye/iv shade code: 18rmd/lmoch cble: ivory twisted dimensions full height with shade: 700 mm...

3ddd

$1

C-280REM Caribbean Paradize Limited Edition+TV

...ил. модель содержит 256 124 tris. материалы вирей, все текстуры присутствуют. версии 2010, 2011, фбх.

3ddd

$1

BAROQUE RAVENNA ETCHED LEANER MIRROR

...ror

3ddd

19th c.baroque ravenna , напольное

19th c. baroque ravenna etched leaner mirror

3ddd

$1

Molteni & C

...molteni & c

3ddd

molteni&c

светильник

3ddd

$1

ETHOS C

...d integrated solutions. ethos collection is enriched with a sauna module associated to a shower space with steam generator inside

3ddd

$1

Sphere C

... sphere

http://flashdq.com/upload_ru/collections/1351105993_fdq_sphere_catalogue_card_eng.pdf

3d_ocean

$5

WOOD TEXTURES SET 002

...the interiors, or make great design solution with it! c.. ...

3d_ocean

$5

Concrete Textures 032

...textures that help to make your own project beautiful use it for texturize walls, ground or anything what you want! also you c...

3d_ocean

$5

WOOD TEXTURES SET 003

...the interiors, or make great design solution with it! c.. ...