Thingiverse

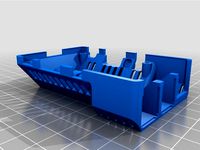

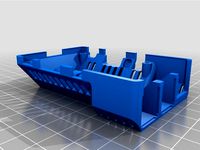

Raspberry Pi 7" Touchscreen Case by jzkmath

by Thingiverse

Last crawled date: 3 years ago

This is another Version of an enclosure for the Raspberry Pi official 7" touchscreen. By inverting the pi and rotating it 180 degrees, the USB/Ethernet ports barely stick out of the case for easy access!

This model was based off the Version made by deisterhold, although I built this design from scratch, using the dimensions of his bottom mount design.

****UPDATE 4/14/2016*****VERSION 2

-After learning how to use SolidWorks, I decided to redo my touchscreen case so that the parts all work together!

-The old version has been consolidated into a ZIP file called "OldRaspberryPi Case"

-I have a ZIP file of the New Solidworks files in "pack and go" format called "Pi Touchscreen 2016"

-The STL's with "NewTouchscreen Case" are the updated version.FIXES:

-the slot now fits the USB port perfectly

-Holes now match up

-there is now a border to protect the edge of the touchscreen

This is designed with an external USB Battery in mind, with a small slot for the microUSB cable to fit into.

I made 2 versions of the mounting plate, a plain one and a plate with the Raspberry Pi logo. (I also made one that has my name engraved on it, but y'all don't need that version!)

I will post pics and more details once I start putting it together!

UPDATE 10/14/2015

Thanks to SkyRider, I found that the screw holes did not line up with the case. It has since been fixed, so be sure to print the BottomNew.STL file instead!

UPDATE 10/16/2015

I did a test print of the BottomNew.STL and I need to do some work on it as far as thickness is concerned. I have made another file that should work instead. This is Bottom3.STL

UPDATE 10/17/2015

The parts came in the mail, so I was now able to put them together. First off, I found some long machine screws to find that the holes in the print were too small! I improvised by taking an 1/8" drill bit and redrilling the holes. I then cut the machine screws to length and screwed the enclosure together, completing the project!

This model was based off the Version made by deisterhold, although I built this design from scratch, using the dimensions of his bottom mount design.

****UPDATE 4/14/2016*****VERSION 2

-After learning how to use SolidWorks, I decided to redo my touchscreen case so that the parts all work together!

-The old version has been consolidated into a ZIP file called "OldRaspberryPi Case"

-I have a ZIP file of the New Solidworks files in "pack and go" format called "Pi Touchscreen 2016"

-The STL's with "NewTouchscreen Case" are the updated version.FIXES:

-the slot now fits the USB port perfectly

-Holes now match up

-there is now a border to protect the edge of the touchscreen

This is designed with an external USB Battery in mind, with a small slot for the microUSB cable to fit into.

I made 2 versions of the mounting plate, a plain one and a plate with the Raspberry Pi logo. (I also made one that has my name engraved on it, but y'all don't need that version!)

I will post pics and more details once I start putting it together!

UPDATE 10/14/2015

Thanks to SkyRider, I found that the screw holes did not line up with the case. It has since been fixed, so be sure to print the BottomNew.STL file instead!

UPDATE 10/16/2015

I did a test print of the BottomNew.STL and I need to do some work on it as far as thickness is concerned. I have made another file that should work instead. This is Bottom3.STL

UPDATE 10/17/2015

The parts came in the mail, so I was now able to put them together. First off, I found some long machine screws to find that the holes in the print were too small! I improvised by taking an 1/8" drill bit and redrilling the holes. I then cut the machine screws to length and screwed the enclosure together, completing the project!

Similar models

thingiverse

free

Raspberry PI 4 Case for Ender 3 printers by scottsavarese

...spberry pi, make the case pieces snap together. i don't have screws so the case is open a bit and doesn't look very nice.

thingiverse

free

3,5" Raspberry Pi Touchscreen Case for Ikea Lack

...y pi 3/3b without an riser cable, easy access to the usb ports and cable management hole in the backplate.

best printed as shown

thingiverse

free

Ender 3/Cr-10 Raspberry Pi Case by andr123k

...i. i think it work on every creality machine, but im not sure. the cap is still the same as on the other i only remixed the case.

thingiverse

free

Raspberry Pi 7 Inch Touchscreen Case w/ Power Button by bearclaw40

...t on the touchscreen and removed the one for the slot on the raspberry pi.

added indentation to screw holes on the middle section

thingiverse

free

Raspberry PI 7 Inch Screen CR-10 Rail Mount by zerofear

...instead. i would imagine that this could be mounted to any 3d printer rail.

i did have to have longer screws to put it together.

thingiverse

free

Raspberry Pi Zero USB Stem case by curcuz

...ts for the 40 pin gpio hat, the usb and minihdmi ports.

i attached 2 lid versions, one with the resin.io logo and one without it.

thingiverse

free

7" Waveshare LCD Enclosure Standalone Remix by Paran0ic

...port.

i plan to design a support like normal computer lcd display. now i use very simple support.

openscad source files attached.

thingiverse

free

Raspberry Pi 2 Enclosure(Pietendo) by Ostantric

...ty space in the enclosure so i can put some switches and buttons later. but for now it only has holes for the raspberry pi 2 i/o.

thingiverse

free

Raspberry Pi Zero Snap Together Case by KH6EF

...dmi solder pads for a flush fit. the lid has four posts with holes to snap down onto the case as well as an opening for the gpio.

thingiverse

free

Raspberry Pi 3_Modell B - Sleeve with 3.5 TFT (Updated) by CSD_Salzburg

...ing of the cap)

enlarged the hole for the micro sd card

more width for the screen

additional clip for a better holding of the cap

Jzkmath

thingiverse

free

Beats Case by jzkmath

...beats case by jzkmath

thingiverse

for another student.

thingiverse

free

Moog Music Keychain by jzkmath

...moog music keychain by jzkmath

thingiverse

this is a 3" diameter keychain of the moog music logo.

thingiverse

free

Wood Badge Hatchet and Log by jzkmath

...wood badge hatchet and log by jzkmath

thingiverse

wood badge hatchet and log model designed for scouting.

thingiverse

free

Double Fidget Spinner by jzkmath

...dget spinner by jzkmath

thingiverse

based off 2robotguy's fidget spinner design, but with two outside bearings instead of 3.

thingiverse

free

VT Cookie Cutter by jzkmath

...his is a cookie cutter i made for my graduation party. i will be going there to major in electrical engineering this fall (2017).

thingiverse

free

Resistor Lead Bender by jzkmath

...

thingiverse

a resistor lead bender for getting resistors bent to the correct dimension. sizes range from 0.4" to 1.5"

thingiverse

free

Wood Badge Bear Neckerchief Ring by jzkmath

...wood badge bear neckerchief ring by jzkmath

thingiverse

designed a bear head neckerchief ring for my scoutmaster...

thingiverse

free

Crossfit Pisgah Maker Coin by jzkmath

...th

thingiverse

designed this for my mom, who is a member of crossfit pisgah, near asheville nc.

based off the maker coin design.

thingiverse

free

VT Hillel - Star of David Test Print by jzkmath

...vt hillel - star of david test print by jzkmath

thingiverse

test print designed for hillel at virginia tech.

thingiverse

free

Buddha Enzo- FRC 5854 GLITCH by jzkmath

...nzo- frc 5854 glitch by jzkmath

thingiverse

made a pop buddha with our first robotics team mascot, enzo.

why? because...why not?

Touchscreen

3d_ocean

$10

Touchscreen Phone

...r stand alone renderings. the button as well as speaker on the front are modelled for added realism and depth for those tight ...

turbosquid

$2

Touchscreen Kiosk

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$35

TF 700 Tablet PC 10 in touchscreen 3D Model

...export

universal tablet pc 10 in touchscreen android notebook

tf 700 tablet pc 10 in touchscreen 3d model plasticv 80776 3dexport

3d_ocean

$10

Sleek Touchscreen Smart Phone

... of multi-touch smart phone designs. the small details such as the buttons, camera lens, speaker and other components have bee...

3ddd

$1

Celular Samsung

...3ddd телефон , samsung samsung s5230 mid level full touchscreen ...

3d_export

$30

LG arena 3D Model

...arena 3d model 3dexport lg km900 arena phone mobile touchscreen lg arena 3d model s.e.3ddd 26566...

3d_export

$30

SONY Xperia Tablet 3D Model

...xperia tablet 3d model 3dexport sony xperia tablet android touchscreen sony xperia tablet 3d model barbarosa222 58716...

3d_export

$15

Iphone Black 3D Model

...black 3d model 3dexport phone electronics iphone cellphone smartphone touchscreen touch screen iphone black 3d model ryleyswan 81168...

3d_export

$40

Google Nexus One 3D Model

...3d model 3dexport google nexus one phone mobile cellular touchscreen google nexus one 3d model h1studio 21421...

3d_export

$45

HTC Flyer Tablet 3D Model

...htc flyer tablet 3d model 3dexport touchscreen tablet htc 3d model 3ds max phone htc flyer...

Raspberry

3d_export

free

raspberry

...raspberry

3dexport

3d model of a raspberry. i tried to make it realistic.

turbosquid

$27

Raspberries

...y free 3d model raspberries for download as max, obj, and stl on turbosquid: 3d models for games, architecture, videos. (1354176)

turbosquid

$14

Raspberries

...y free 3d model raspberries for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1364663)

3d_export

$5

raspberry pi

...raspberry pi

3dexport

carcasa para la raspberry pi

turbosquid

$99

Raspberry

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

raspberries

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

archive3d

free

Raspberries 3D Model

...raspberries 3d model archive3d raspberries raspberry raspberries n300911 - 3d model (*.3ds) for interior 3d...

3d_export

$5

raspberry fruit

...raspberry fruit

3dexport

3d_export

$5

raspberry

...y different sizes. their color ranges from light burgundy to pink. there are formats: obj, 3ds, blend, dae, fbx, mtl.<br>:)

evermotion

$12

raspberries 23 am130

...evermotion raspberries 23 am130 evermotion key 23 food fruit raspberry fruits am130 raspberries highly detailed 3d model of raspberries...

Pi

design_connected

$11

Pi

...pi

designconnected

ligne roset pi chairs computer generated 3d model. designed by thibault desombre.

3d_export

$5

raspberry pi

...raspberry pi

3dexport

carcasa para la raspberry pi

turbosquid

$18

pied

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

Emme pi light

...emme pi light

3ddd

emme pi light

люста emme pi light

3ddd

$1

Emme pi light

...emme pi light

3ddd

emme pi light

бра классическое emme pi light

3ddd

$1

Emme Pi Light

...emme pi light

3ddd

emme pi light

3ddd

$1

Emme Pi Light

...emme pi light

3ddd

emme pi light

design_connected

$16

Pi-Air

...pi-air

designconnected

living divani pi-air lounge chairs computer generated 3d model. designed by harry & camila.

3d_ocean

$15

Manneken Pis

...picting a naked little boy urinating into a fountain’s basin. (wikipedia) the model was sculpted in blender 2.70a rendered wit...

3ddd

$1

Emme pi light

...emme pi light

3ddd

emme pi light

люстра классическая фирма: emme pi light

артикул: 3595/5/cot/12/wh

Case

3d_export

$1

case

...case

3dexport

case

archibase_planet

free

Case

...case

archibase planet

showcase show-case glass case

glass-case + cakes - 3d model for interior 3d visualization.

archibase_planet

free

Case

...case

archibase planet

showcase show-case glass case

glass-case for chips - 3d model for interior 3d visualization.

archibase_planet

free

Case

...case

archibase planet

case shelving drawer

case - 3d model for interior 3d visualization.

archibase_planet

free

Case

...case

archibase planet

case rack locker

case - 3d model for interior 3d visualization.

archibase_planet

free

Case

...case

archibase planet

case drawer kitchen furniture

case - 3d model for interior 3d visualization.

archibase_planet

free

Case

...case

archibase planet

case cupboard shelving

glass case - 3d model for interior 3d visualization.

archibase_planet

free

Case

...case

archibase planet

case handbag suitcase

case - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Case

...case

archibase planet

case suitcase

case 5 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Case

...case

archibase planet

locker case dresser

case - 3d model (*.gsm+*.3ds) for interior 3d visualization.

7

turbosquid

$6

Rock 7-7

...urbosquid

royalty free 3d model rock 7-7 for download as obj on turbosquid: 3d models for games, architecture, videos. (1647866)

turbosquid

$8

Rock 7-7

...id

royalty free 3d model rock 7-7 for download as ma and fbx on turbosquid: 3d models for games, architecture, videos. (1693416)

design_connected

$16

No 7

...no 7

designconnected

sibast no 7 computer generated 3d model. designed by sibast, helge.

3ddd

$1

Team 7

...team 7

3ddd

team 7

моделилось с кталога team 7

3d_export

$5

hinge 7

...hinge 7

3dexport

hinge 7

turbosquid

$9

IS-7

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$12

Calligraphic Digit 7 Number 7

...hic digit 7 number 7 for download as max, obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1389338)

3ddd

free

team 7

...team 7

3ddd

team 7

стол фабрики team 7.

типы размеров /900,1000/x/1750,2000,2250/x/750/

раздвигается +600 или +1200

3ddd

$1

PLANTS 7

...plants 7

3ddd

цветы , горшок

plants 7.. hope u all enjoying the series

3ddd

$1

Pillows #7

...pillows #7

3ddd

подушка , pillows

pillows #7

3ds max 2011,fbx + textures