Thingiverse

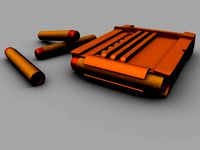

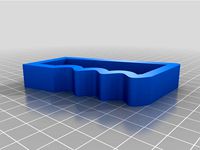

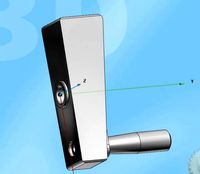

RapidMag Heavy - Nerf MEGA 20x95mm Magazine 10 and 17 round capacity by torukmakto4

by Thingiverse

Last crawled date: 3 years, 1 month ago

RapidMag Heavy

A printable 20mm MEGA magazine for hobby grade nerf blasters, especially designed for full auto or high ROF use. Intended to fit standard ~250mm (X) i3 beds.

Features:

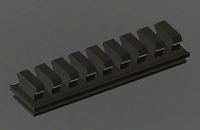

Rail-guided tall follower for tilt resistance.

Side reliefs and front sharp guide rail to prevent rubber tip scrubbing and wedging.

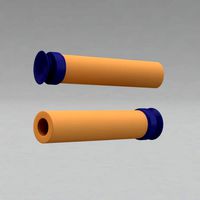

Toolpath control texture on inside surfaces that contact darts, as necessary to present only extrusions parallel to feed direction.

Printing:

Don't field PLA!

Recommended (for 0.45-ish mm extrusion width): 3 perimeters, 20% hex infill, 6 tops/bottoms.

Orientations: All body pieces outside surface on the bed. Follower standing on the bottom surface.

HARDWARE:

6-32 x 0.5" SHCS for body assembly x 11 (10 round monolithic) or x 15 (extended 17 round)

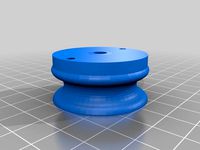

One 6-32 x 1.5" SHCS for the spring pulley shaft in the follower.

One constant force nerf drum mag spring, available from various hobby suppliers.

** It may be possible to substitute M3 SHCS for 6-32 - do not drill or tap, force into printed hole.

SUPPLIES, TOOLS:

Superglue or Devcon, only needed to build extended spliced version.

White lithium or other non-silicone grease to lube follower rails.

Drill and tap for 6-32 and clearance drill for 6-32 if using 6-32 hardware.

File or sanding stick.

Build Procedure:

Clean up parts meticulously (strings, burrs, etc.)

Clean out all clearance holes with drill

Clean out all holes to be tapped with tap drill

Tap all holes. (Hint: Use oil when threading PETG)

For extended version, splice body halves with connector bands, and adhesive of choice. (Best to bolt them together while gluing for alignment help)

Use file to clean up follower rails. Remove all layer lines completely

Grease follower rails and/or body slots, run follower up and down in each body half to distribute grease. Less grease is more

Clean up any grease that got on dart contact surfaces with alcohol.

Wind CFS onto spring pulley. Use 1.5" SHCS to mount pulley inside follower. Don't overtorque.

Flatten CFS hook end a little and clip it into the slot. Insert the end into the blind pocket to secure (Use a small blade to lift up the edge of the pocket opening if necessary)

Set follower into place.

Bolt body halves together.

Tested both versions to be reliable at 12rps full auto with a 20x95mm T19.and whirlwind darts.

Hasbro compatibility is unproven as I don't have any Hasbro blasters to test.

A printable 20mm MEGA magazine for hobby grade nerf blasters, especially designed for full auto or high ROF use. Intended to fit standard ~250mm (X) i3 beds.

Features:

Rail-guided tall follower for tilt resistance.

Side reliefs and front sharp guide rail to prevent rubber tip scrubbing and wedging.

Toolpath control texture on inside surfaces that contact darts, as necessary to present only extrusions parallel to feed direction.

Printing:

Don't field PLA!

Recommended (for 0.45-ish mm extrusion width): 3 perimeters, 20% hex infill, 6 tops/bottoms.

Orientations: All body pieces outside surface on the bed. Follower standing on the bottom surface.

HARDWARE:

6-32 x 0.5" SHCS for body assembly x 11 (10 round monolithic) or x 15 (extended 17 round)

One 6-32 x 1.5" SHCS for the spring pulley shaft in the follower.

One constant force nerf drum mag spring, available from various hobby suppliers.

** It may be possible to substitute M3 SHCS for 6-32 - do not drill or tap, force into printed hole.

SUPPLIES, TOOLS:

Superglue or Devcon, only needed to build extended spliced version.

White lithium or other non-silicone grease to lube follower rails.

Drill and tap for 6-32 and clearance drill for 6-32 if using 6-32 hardware.

File or sanding stick.

Build Procedure:

Clean up parts meticulously (strings, burrs, etc.)

Clean out all clearance holes with drill

Clean out all holes to be tapped with tap drill

Tap all holes. (Hint: Use oil when threading PETG)

For extended version, splice body halves with connector bands, and adhesive of choice. (Best to bolt them together while gluing for alignment help)

Use file to clean up follower rails. Remove all layer lines completely

Grease follower rails and/or body slots, run follower up and down in each body half to distribute grease. Less grease is more

Clean up any grease that got on dart contact surfaces with alcohol.

Wind CFS onto spring pulley. Use 1.5" SHCS to mount pulley inside follower. Don't overtorque.

Flatten CFS hook end a little and clip it into the slot. Insert the end into the blind pocket to secure (Use a small blade to lift up the edge of the pocket opening if necessary)

Set follower into place.

Bolt body halves together.

Tested both versions to be reliable at 12rps full auto with a 20x95mm T19.and whirlwind darts.

Hasbro compatibility is unproven as I don't have any Hasbro blasters to test.

Similar models

thingiverse

free

Nerf 6 mega dart rail holder by shizo20

...nerf 6 mega dart rail holder by shizo20

thingiverse

this is a dart rail holder for nerf mega blasters.

uom is inches.

thingiverse

free

21 Nerf Dart Rail by Doodleform

...21 nerf dart rail by doodleform

thingiverse

a top rail 21 dart holder for a variety of nerf blasters

thingiverse

free

Nerf 3 mega dart rail holder by shizo20

...rt rail holder for nerf mega blasters. i designed it for the tribreak gun, but it can be used for others as well.

uom is inches.

thingiverse

free

Nerf Reflex Compatibility Barrel (Compatible with N-Strike, Mega, Rival) by SirOhpacey

...it) the blaster works great with all dart types.

edit: i ended up painting it, as you can see. i think it turned out pretty well!

thingiverse

free

Nerf Mega Dart Holder by Doodleform

...nerf mega dart holder by doodleform

thingiverse

add an additional 15 dart storage to the top rail of your mega blaster.

thingiverse

free

Banana Talon Extender 26 Darts by racerethan

...ires sanding.

remix of https://www.thingiverse.com/thing:4597859, because thingiverse won't fix their remix search function.

thingiverse

free

Nerf Blaster Stand by nathanieldeal

...y or store your clip fed nerf blasters!

works best with 6-dart clips to keep a low profile.

also check out our nerf dart counter.

thingiverse

free

Nerf Ramrod holder/sight for n strike rail

...o a standard tactical rail and will hole most ramrods. my preferred ramrod is the dart peg twist removal tool designed by edskar.

thingiverse

free

NERF Vulcan extended ammo box by Tactical_nerf

...dart chain

non removable: the ammo box can not be removed by any means (other than disassembly of the blaster) after installation

thingiverse

free

Nerf Bow Blaster - N-Strike dart adapter barrel by hagemeyp

... darts. this is insanely useful since the bow blaster comes with 3 nerf arrows, and the n-strike darts are like 20 for $4.99.

Torukmakto4

thingiverse

free

Ear Saver Mask Strap, 2 Position Button Style by torukmakto4

... safe everyone.

use 5+ perimeters, and 100%. there really shouldn't be any infill in this other than tops and bottoms anyway.

thingiverse

free

Perky-Pet Bird Feeder Tube by torukmakto4

...he files on hand, the raccoons will find a way to knock it down again no matter what you try!

public domain.

designed in freecad.

thingiverse

free

Tiny-Con : A scaled down Hy-Con wheels and Ultra* cage based rapidstrike setup with groove fillers by mbregg

...wheels which can fit in the ultracage goes to torukmakto4 as well as the basic profile of these wheels,...

Nerf

turbosquid

$30

Nerf Soaker

...osquid

royalty free 3d model nerf soaker for download as obj on turbosquid: 3d models for games, architecture, videos. (1255038)

turbosquid

$9

Nerf Gun

...urbosquid

royalty free 3d model nerf gun for download as c4d on turbosquid: 3d models for games, architecture, videos. (1200860)

turbosquid

$1

Nerf Doubledown

... model nerf doubledown for download as jpg, 3ds, max, and fbx on turbosquid: 3d models for games, architecture, videos. (1477201)

turbosquid

$50

Nerf Clip

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Nerf Dart

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

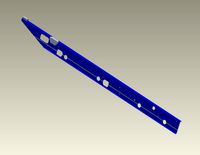

Nerf Picatinny Rail

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$2

Nerf Gun Low Poly

...royalty free 3d model nerf gun low poly for download as blend on turbosquid: 3d models for games, architecture, videos. (1632641)

3d_export

$19

nerf n-strike elite rough cut - 3d scan

...nerf n-strike elite rough cut - 3d scan

3dexport

free3d

$15

Nerf Darts

...nerf darts

free3d

nerf darts for any nerf gun!

thingiverse

free

Pistola a dardi NERF (Nerf Gun) by ruggeromarzocca

...pistola a dardi nerf (nerf gun) by ruggeromarzocca

thingiverse

nerf gun, pistola nerf...

Mega

3ddd

$1

BoConcept / Mega

...boconcept / mega

3ddd

boconcept

boconcept mega

3ddd

free

Angelo - Mega shoin

... mega shoin , shoin

angelo - mega shoin - 3dmax 2008

3ddd

$1

Комод MEGA

...вана по фото с учетом реальных размеров.

стек не сколапсен, есть возможность регулировки уровня сглаживания.

текстуры в архиве.

3ddd

$1

Hulsta / Mega-design

...hulsta / mega-design

3ddd

hulsta

hulsta mega-design

design_connected

$18

Tolomeo Mega

...

photo-realistic 3d models of the tolomeo mega floor lamps from artemide for 3d architectural and interior design presentations.

turbosquid

$119

Mega Soldier

... free 3d model mega soldier for download as obj, c4d, and fbx on turbosquid: 3d models for games, architecture, videos. (1148568)

turbosquid

$100

Mega Yacht

... free 3d model mega yacht for download as obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1368903)

3ddd

$1

Massproductions Mega

... massproductions , mega

ширина: 180 см

глубина: 90 см

высота: 79 см

3d_export

$4

mega metro station

...mega metro station

3dexport

mega metro station. ready to game. thanks all downloaders!!

3ddd

$1

BAS Mega

...bas mega

3ddd

bas , ванна

ванна

Magazine

archibase_planet

free

Magazines

...ibase planet

magazine journal periodical magazines

magazines dual n200111 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Magazines

...magazines

archibase planet

magazine periodical journal

magazines - 3d model for interior 3d visualization.

3d_ocean

$5

3d magazine

...3d magazine

3docean

3d magazine book journal magazine newspaper

3d magazine model.

turbosquid

$2

magazines

...rbosquid

royalty free 3d model magazines for download as c4d on turbosquid: 3d models for games, architecture, videos. (1264164)

3d_export

$5

Magazine stand

...magazine stand

3dexport

magazine stand

3d_export

$5

magazine stand

...magazine stand

3dexport

magazine stand

3ddd

$1

Stool Magazine

...stool magazine

3ddd

stool magazine дизайнерское кресло

turbosquid

$10

magazine

...3d model magazine for download as max, max, max, fbx, and max on turbosquid: 3d models for games, architecture, videos. (1691943)

turbosquid

$2

Magazine

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

archive3d

free

Magazines 3D Model

...magazine periodical journal

magazines n160212 - 3d model (*.3ds) for interior 3d visualization.

Capacity

turbosquid

$4

Industrial capacity barrel 1

...ndustrial capacity barrel 1 for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1312489)

turbosquid

$19

Vertical capacity metering system

...pacity metering system for download as max, fbx, obj, and 3ds on turbosquid: 3d models for games, architecture, videos. (1589287)

turbosquid

$15

Capacity for food (1st part)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

oil can capacity of 5 ltr

...his is a oil can of 5 ltr. capacity which is use to store vegetable oil and other beverages. and this is made from polypropylene.

turbosquid

$5

Capacity for food (2nd part) - cap

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$10

9L Super-Capacity Composite Humidifier

...~ 100,000 model parts: 1 texture format: .png .jpg resolution: 1024*1024 pbr in substance painter formats: .obj .gltf .fbx .blend

3d_export

$99

LandRover Defender 110 High Capacity PickUp 2011 3D Model

... 2012 2013 2014 pickup pick up 4x4 suv offroad

landrover defender 110 high capacity pickup 2011 3d model humster3d 37708 3dexport

humster3d

$75

3D model of Land Rover Defender 110 High Capacity Pickup 2011

...r defender 110 high capacity pickup 2011 in various file formats. all our 3d models were created maximally close to the original.

3d_export

$10

Marimo Washing Large Capacity Humidifier 33L

...~ 100,000 model parts: 1 texture format: .png .jpg resolution: 1024*1024 pbr in substance painter formats: .obj .gltf .fbx .blend

3d_export

$99

LandRover Defender 130 High Capacity Double Cab P 3D Model

...12 2013 2014 pikup 4x4 suv offroad long 4door

landrover defender 130 high capacity double cab p 3d model humster3d 38044 3dexport

Heavy

design_connected

$16

Heavy

...heavy

designconnected

decode heavy computer generated 3d model. designed by hubert, benjamin.

turbosquid

$12

Spar TRAIN-Heavy HEAVY-DUTY

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

The Heavy Rabbit

...the heavy rabbit

3ddd

табурет

project: heavy rabbit

designed by bongo design

3d_ocean

$40

Heavy vehicles

...el this model is created with 3ds max 2009 and content .max (3ds max), size: 7,65 mb this model can be used in any scene. enjoy !

3d_export

$8

heavy plastic crusher

...heavy plastic crusher

3dexport

heavy plastic crusher

3d_export

$5

heavy rotation handle

...heavy rotation handle

3dexport

heavy rotation handle

turbosquid

free

heavy sword

...ord

turbosquid

free 3d model heavy sword for download as fbx on turbosquid: 3d models for games, architecture, videos. (1223423)

turbosquid

free

Heavy Shield

...squid

royalty free 3d model heavy shield for download as fbx on turbosquid: 3d models for games, architecture, videos. (1382280)

turbosquid

$42

Heavy Tank

...

royalty free 3d model heavy tank for download as max and fbx on turbosquid: 3d models for games, architecture, videos. (1311230)

turbosquid

$3

Heavy Ball

...

royalty free 3d model heavy ball for download as ma and obj on turbosquid: 3d models for games, architecture, videos. (1515557)

17

3d_export

$6

rocks 17

...rocks 17

3dexport

rocks 3d model 17

3ddd

$1

PLANTS 17

...plants 17

3ddd

цветок , горшок

plants 17,, pots in diameter 100,80,60,40cm,,, enjoy

3d_export

$6

tap-17

...tap-17

3dexport

3d_export

$6

set-17

...set-17

3dexport

3d_export

$27

C-17 Globemaster

...c-17 globemaster

3dexport

c-17 globemaster

3ddd

free

Renault FT-17

...renault ft-17

3ddd

ft-17 , renault , танк

turbosquid

$40

cottage 17

...bosquid

royalty free 3d model cottage 17 for download as max on turbosquid: 3d models for games, architecture, videos. (1377003)

turbosquid

$30

Apartment 17

...squid

royalty free 3d model apartment 17 for download as max on turbosquid: 3d models for games, architecture, videos. (1432680)

turbosquid

$10

Surfboard 17

...squid

royalty free 3d model surfboard 17 for download as max on turbosquid: 3d models for games, architecture, videos. (1375686)

turbosquid

$7

Rock 17

...turbosquid

royalty free 3d model rock 17 for download as obj on turbosquid: 3d models for games, architecture, videos. (1486522)

Round

turbosquid

$18

round chairs with round table

...und chairs with round table for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1454090)

3d_export

$5

round knob

...round knob

3dexport

round knob

3d_export

$5

Italian round table Millennium Round

...italian round table millennium round

3dexport

3ddd

$1

Round Ottoman

...round ottoman

3ddd

пуф

round ottoman

3ddd

$1

Round pillow

...round pillow

3ddd

подушка

round pillow

3ddd

free

Round bed

...round bed

3ddd

круглая

round bed

3ddd

$1

round table

...round table

3ddd

круглый

round table, стол

3ddd

free

ROUND TABLE

...round table

3ddd

журнальный , круглый

round table

3ddd

$1

Round Table

...round table

3ddd

круглый , кофейный

rounded coffee table

3ddd

$1

Round Rug

...round rug

3ddd

ковер , круглый

useful rounded rug

10

turbosquid

$25

10

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

a-10

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

EX 10

...ex 10

3ddd

samsung , фотоаппарат

ex 10

3ddd

$1

Bed 10

...bed 10

3ddd

постельное белье

bed 10

evermotion

$25

Scene 10 Archinteriors vol. 10

...dering design interior

take a look at textured and shadered visualization scene ready to be rendered.. evermotion 3d models shop.

3ddd

$1

Curtains 10

...curtains 10

3ddd

curtains 10

3ds max 2011,fbx + textures

polys: 100355

3ddd

free

PLANTS 10

...plants 10

3ddd

цветок , горшок

plants 10,, with 3 different color planter boxes

turbosquid

$24

Chandelier MD 89310-10+10 Osgona

... chandelier md 89310-10+10 osgona for download as max and fbx on turbosquid: 3d models for games, architecture, videos. (1218762)

design_connected

$29

Nuvola 10

...nuvola 10

designconnected

gervasoni nuvola 10 computer generated 3d model. designed by navone, paola.

design_connected

$22

Kilt 10

...kilt 10

designconnected

zanotta kilt 10 computer generated 3d model. designed by progetti, emaf.