Thingiverse

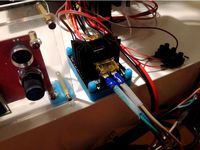

RAMPS & MOSFET Case by 8SquareFeet

by Thingiverse

Last crawled date: 3 years, 1 month ago

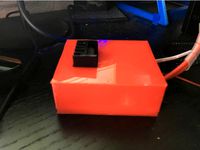

While building my new CoreXY printer, I wanted to consolidate all of the electronics into one case. So, this is my take on that.

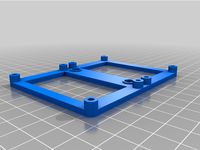

I designed the case so that all of the power and communication lines enter the rear of the case, and the ribbon cables running to the display exit the front.

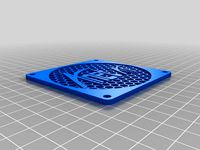

Air flow is from rear to front, passing over the MOSFET first, then baffled down over the "open" end RAMPS boards, finally exiting the case at the front under the ribbon cables.

The fan is mounted externally. I'm using a single 40mm, high CFM fan I salvaged from a server, so my cooling has been fine. However, if cooling does seem to be an issue, you could easily mount additional fans on the case and drill holes for airflow.

In testing, using a lower CFM fan, I found that while printing (no heatbed), I would see a one or two degree rise above ambient room temperatures (21C in the room, 23C at the exit of the case). If using the MOSFET, I saw a much higher delta. With the heatbed running at 95C, I was seeing 21C in the room, and 40C to 42C in the exit airflow (about 107F). All of the electronics are rated up to about 85C max (so sayeth the Chinese Mfgr's), but that's still quite warm. Hence, the higher CFM fan.

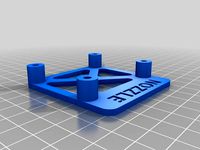

The base and side are one piece each, and they are pretty big (196mm long), so you'll either need a decent size printer, or you will have to edit the STL and make them two-piece parts. I'm busy at the moment, but I'll try and break them apart as soon as I can.

The ends and the tops are small enough that most printers should be able to handle them.

I built in access to the USB and power ports, and some basic cable management by raising the MOSFET board. Power and USB run under the MOSFET, everything else runs around the stand-offs. This keeps wiring out of the airflow for the most part.

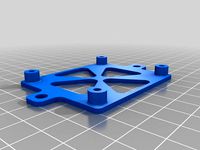

I've included the mounts I'm using to attach the case to my printer. These are designed for 15mm X 15mm MakerBeam XL extrusion. The case could be used without them for any printer. If you use the mounts, leave the mount-side corner screws out on the tops.

The mounts have slots in them to allow velcro to pass thru them, securing the case to the mounts. You could use wire or zip ties. Depending on how they are printed, they will probably need some supports.

I'm using locally sourced hardware for assembly (6mm x 3.4mm countersunk screws). The holes were drilled out using a 3mm drill. It could be assembled using 3mm hardware as well.

Everything was printed in PLA, flat side down, no supports, 3 perimeters and 2 top and bottom layers. Infill was 20% I think.

The Mega was mounted using 2mm hardware. The MOSFET uses 3mm X 6mm hardware.

I found attaching all the cabling to the RAMPS prior to installing the MOSFET worked best.

This is the MOSFET I'm using, but the mounting is about the same for all of the units like this one:https://www.amazon.com/gp/product/B01MY50JL3/ref=oh_aui_detailpage_o07_s01?ie=UTF8&psc=1

WARNING!!

I've had two of these type of MOSFET's (different Mfgr's) fail on me now. Both of them failed in the ON mode. The cheapest is often just that..... BE CAREFUL with these things!

I designed the case so that all of the power and communication lines enter the rear of the case, and the ribbon cables running to the display exit the front.

Air flow is from rear to front, passing over the MOSFET first, then baffled down over the "open" end RAMPS boards, finally exiting the case at the front under the ribbon cables.

The fan is mounted externally. I'm using a single 40mm, high CFM fan I salvaged from a server, so my cooling has been fine. However, if cooling does seem to be an issue, you could easily mount additional fans on the case and drill holes for airflow.

In testing, using a lower CFM fan, I found that while printing (no heatbed), I would see a one or two degree rise above ambient room temperatures (21C in the room, 23C at the exit of the case). If using the MOSFET, I saw a much higher delta. With the heatbed running at 95C, I was seeing 21C in the room, and 40C to 42C in the exit airflow (about 107F). All of the electronics are rated up to about 85C max (so sayeth the Chinese Mfgr's), but that's still quite warm. Hence, the higher CFM fan.

The base and side are one piece each, and they are pretty big (196mm long), so you'll either need a decent size printer, or you will have to edit the STL and make them two-piece parts. I'm busy at the moment, but I'll try and break them apart as soon as I can.

The ends and the tops are small enough that most printers should be able to handle them.

I built in access to the USB and power ports, and some basic cable management by raising the MOSFET board. Power and USB run under the MOSFET, everything else runs around the stand-offs. This keeps wiring out of the airflow for the most part.

I've included the mounts I'm using to attach the case to my printer. These are designed for 15mm X 15mm MakerBeam XL extrusion. The case could be used without them for any printer. If you use the mounts, leave the mount-side corner screws out on the tops.

The mounts have slots in them to allow velcro to pass thru them, securing the case to the mounts. You could use wire or zip ties. Depending on how they are printed, they will probably need some supports.

I'm using locally sourced hardware for assembly (6mm x 3.4mm countersunk screws). The holes were drilled out using a 3mm drill. It could be assembled using 3mm hardware as well.

Everything was printed in PLA, flat side down, no supports, 3 perimeters and 2 top and bottom layers. Infill was 20% I think.

The Mega was mounted using 2mm hardware. The MOSFET uses 3mm X 6mm hardware.

I found attaching all the cabling to the RAMPS prior to installing the MOSFET worked best.

This is the MOSFET I'm using, but the mounting is about the same for all of the units like this one:https://www.amazon.com/gp/product/B01MY50JL3/ref=oh_aui_detailpage_o07_s01?ie=UTF8&psc=1

WARNING!!

I've had two of these type of MOSFET's (different Mfgr's) fail on me now. Both of them failed in the ON mode. The cheapest is often just that..... BE CAREFUL with these things!

Similar models

thingiverse

free

Zonestar P802QR2 Case with 120mm Fan & Mosfet Mounts by AdamWP

...motherboard case for the zonestar p802qr2 that could accommodate the smaller mosfets and a fan so i remixed celtico12's case.

thingiverse

free

Anet A8 80mm PSU cooler fan grill by freddan_6

...s should go closes to "+" of the input for the mosfet. i wanted a logo and i like honeycomb pattern, so i remixed them.

thingiverse

free

Lerdge Heatbed/Mosfet Case by Insonic

...dge mosfet/heatbed controller board"

including the mounting options for a 40mm fan.

update : added a 2nd version of the case

thingiverse

free

Ramps Enclosure for AM8 (Vslot) by bufi

...am8

with a 80x80mm cooling fan,

with space for a heatbed mosfet and a 40x60mm custom pcb (in my case mosfets for rgb led stripes)

thingiverse

free

MKS Sbase Mount by iMakebyDesign

...rs as the new pcb are better insulated, however old habits die hard so i still use them under the screws when mounting pcb's.

thingiverse

free

Arduino Mega, Ramps 1,4 Plus Heatbed 210A Mosfet Enclosure by alanpwood

... added spots inside to be able to insert cable ties. i hope it is useful for someone.

i add a stl base for arduino mega 2560 r3.

thingiverse

free

Simple RAMPS 1.4 mount by pefozzy

... and ramps models- i did not create these and unfortunately i can't remember where i sourced them from- i think from grabcad.

thingiverse

free

Mosfet Case with 40mm Fan by 3DAntics

...ware store

lastly, the 4 holes for mounting the fan are sized for use with the self-tapping screws that come with the noctua fan.

grabcad

free

3D Printer Controller Case for RAMPS Board

...r any other 3d printer built with the 2020 aluminum extrusion frame.

in the video instruction below, you can check more details.

thingiverse

free

door glass handle by Axeman410

...

it fits trough a 3mm glass. i'm going to use it for a case for my printer.

the skp file is attached so you could modify it.

8Squarefeet

thingiverse

free

Cabinet Handle (Large) by 8SquareFeet

...mm self-tapping hardware.

it is a bigger handle, so it will hang out 35mm off the door on the outside.

print as many as you need!

thingiverse

free

Probe Cap for WSDCAM Cable Tester by 8SquareFeet

...y-security-firmware-upgraded-8600movtsadh-plus/dp/b00zx3b81y/ref=sr_1_2?ie=utf8&qid=1507406397&sr=8-2&keywords=wsdcam

thingiverse

free

Push out air vent by 8SquareFeet

...strength and heat resistance in the sun.

print with the largest flat side down. you will need some support for the retaining lip.

thingiverse

free

Machine Light Mount by 8SquareFeet

...ref=oh_aui_search_detailpage?ie=utf8&psc=1

i printed in pla with 45 or 50 percent infill, but it could probably do with less.

thingiverse

free

8.5" Boogie Board Mount by 8SquareFeet

...t now. i suspect it would work just as well in pla. i used 15% infill, 3 perimeters and 3 layers, but those are just my defaults.

thingiverse

free

Scraper Replacement Handle by 8SquareFeet

...d the tool rod up and pushed it into the hole.

i've included the sketchup model in case you'd like to make modifications.

thingiverse

free

Raspberry Pi Mount for Mediasonic Enclosure by 8SquareFeet

...ort usb 3 cable, and still provides access to all of the pi's io ports.

i printed this in petg, but any filament should work.

thingiverse

free

Indicator Stand (uses 15 X 15 Extrusion) by 8SquareFeet

...ll hardware is 3mm.

the files should be oriented for proper printing.

i used petg, but that's just what i had loaded already.

thingiverse

free

RGB Matrix Stand by 8SquareFeet

...no can power this small matrix without issue, but if you build a bigger one, you may want to run power directly to the led's.

thingiverse

free

Remote Light Switch by 8SquareFeet

...ect, but it works great for me. now i don't have to walk all the way to the back of a dark room to turn the light on and off.

Mosfet

3d_export

$5

IC SMD Package TO263

...used for different types of semiconductors, such as transistor, mosfet voltage regulators and etcetra. a surface mount device for...

thingiverse

free

Support Mosfet

...support mosfet

thingiverse

support mosfet

remplissage 20%

thingiverse

free

i3 MOSFET Holder / i3 MOSFET Halter by JMDesigns

...i3 mosfet holder / i3 mosfet halter by jmdesigns

thingiverse

i3 mosfet holder / i3 mosfet halter

thingiverse

free

MOSFET Holder / MOSFET Halter 20x20 Extrusion by JMDesigns

...mosfet holder / mosfet halter 20x20 extrusion by jmdesigns

thingiverse

mosfet holder / mosfet halter 20x20 extrusion

thingiverse

free

TO-220 MOSFET Holder

...to-220 mosfet holder

thingiverse

this will hold 3x to-220 mosfets. the mosfets will snap into place.

free3d

free

MOSFET

...mosfet

free3d

metal oxide semiconductor field effect transistor

thingiverse

free

Double Mosfet Holder for Lerdge Mosfet Board by LorDXEO

... board by lordxeo

thingiverse

dual mosfet holder for lergde mosfet modules.

holes for m3 screws, you can also use brass inserts.

thingiverse

free

MOSFET Case by Nbbwarhammer

...mosfet case by nbbwarhammer

thingiverse

a case for mosfet.

thingiverse

free

MOSFET Support

...

2 3mm screws

design

i have uploaded the freecad design that i made, so you can remix it and mod it.

i hope it is useful for you!

thingiverse

free

mosfet holders by paulsonia

...mosfet holders by paulsonia

thingiverse

two mosfet holders

Ramps

turbosquid

$3

Kicker Ramp - Skate Ramp

...ramp - skate ramp for download as 3ds, obj, c4d, fbx, and dae on turbosquid: 3d models for games, architecture, videos. (1153575)

turbosquid

$2

Ramp

...squid

royalty free 3d model ramp for download as obj and fbx on turbosquid: 3d models for games, architecture, videos. (1494204)

turbosquid

$5

ramp

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

Ramp 3D Model

...ramp 3d model

3dexport

ramp jump carjump carramp car

ramp 3d model ryisnelly100 83186 3dexport

turbosquid

$10

Ramp and Barrels

...d

royalty free 3d model ramp and barrels for download as fbx on turbosquid: 3d models for games, architecture, videos. (1263040)

turbosquid

$19

Skate Ramp

...ty free 3d model skate ramp for download as dxf, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1187602)

turbosquid

$19

Skate Ramp

...ee 3d model skate ramp for download as dxf, obj, c4d, and fbx on turbosquid: 3d models for games, architecture, videos. (1187673)

turbosquid

$80

Hydralic Ramps

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$45

ramp door_center

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$40

Ramp.3DS

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Case

3d_export

$1

case

...case

3dexport

case

archibase_planet

free

Case

...case

archibase planet

showcase show-case glass case

glass-case + cakes - 3d model for interior 3d visualization.

archibase_planet

free

Case

...case

archibase planet

showcase show-case glass case

glass-case for chips - 3d model for interior 3d visualization.

archibase_planet

free

Case

...case

archibase planet

case shelving drawer

case - 3d model for interior 3d visualization.

archibase_planet

free

Case

...case

archibase planet

case rack locker

case - 3d model for interior 3d visualization.

archibase_planet

free

Case

...case

archibase planet

case drawer kitchen furniture

case - 3d model for interior 3d visualization.

archibase_planet

free

Case

...case

archibase planet

case cupboard shelving

glass case - 3d model for interior 3d visualization.

archibase_planet

free

Case

...case

archibase planet

case handbag suitcase

case - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Case

...case

archibase planet

case suitcase

case 5 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Case

...case

archibase planet

locker case dresser

case - 3d model (*.gsm+*.3ds) for interior 3d visualization.