Cults

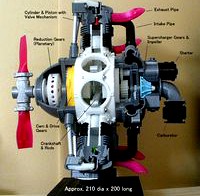

Radial Engine, 7-Cylinders, Cutaway

by Cults

Last crawled date: 6 years, 1 month ago

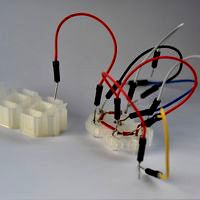

This is a model of the Radial Engine with 7-cylinder for old aircraft.

But, this type of engine includes many fundamental mechanisms.

This would be the optimal teaching material for the beginners' class engineers and students.

A. Features of this model are;

1. Cutaway model of entire engine;

①. Reduction Gears (Planetary)

②. Cam and Drive gears

③. Crankshaft and Rod assembly

④. Cylinder and Piston with Valve mechanism

⑤. Supercharger gears and Impeller

2. Air Intake and Exhaust Pipes

3. Simplified Accessories (Propeller Hub with half blades, Carburetor, Magneto and Starter etc.)

4. It can be rotational but not smoothly because of the valve mechanism resistance and friction.

Refer to: https://youtu.be/uaWTmbg4mlE

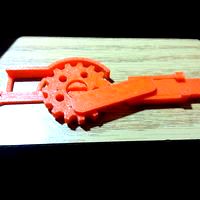

B. Print and parts information

There are approximately 80 stl parts and many hardware including the bearings.

Hardware can be purchased from DIY shop or WEB shop easily and can be changed to equivalent similar parts.

All parts data are included in the manual. Refer Numerical Index.

It takes very long hours to print parts, treatment after printing and assembling.

STL file name: "ws" of last 2 digits means "With Support" which special designed.

But some parts need additional slicer's support to these. Refer “Remarks” column.

Estimated net print hour will be more than 90 hours.

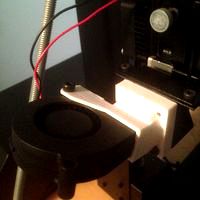

C. Assembly manual (.pdf format in Zip)

The detail assembly manual including "Parts-List", "After printing treatment" and "Assembly procedure" are prepared.

But there are many complicated parts which required finishing and machining (Filing, Drilling and Tapping).

Also there are many fits required adjustment of clearance and tightening using with many hardware.

Some sample manual pages are shown in photos.

This manual can be very helpful for disassembly and re-assembly just like overhaul.

D. General Notes

1. For M1.4 Screw: No need "Tapping". Drill with φ1.0 drill then direct screw-in.

2. Screw to AL pipe: Put in a screw into the pipe end, squeeze pipe by the plier. Check the fixed condition.

3. Small diameter shaft parts:

To keep the strength, Use "100% infill" at printing and apply the adhesive for acrylic resin.

4. Recommended Drills and Taps

Drill: 1.0, 1.5, 2.0, 2.5, 3.0, 3.2, 5.0, 5.2, 7.2

Tap: M2, M3

3D printing settings

Raft, Support, Layer Height, Infill: Depending on your experience.

But the parts having gear, small shaft and thin portion: 100% infill is recommended.

My models were printed by "idbox" using with 0.4 nozzle, 1.75 PLA.

Before "Down-Loading", please watch photos carefully and consider deeply.

I do hope your success!!

[Updated 2017.10.10]

YouTube Video changed to longer version.

[Updated 2017.10.16]

A typo was corrected on photo.

[Updated 2018.2.10]

"Assembly Manual" typo and hardware qty, etc. corrected.

"Revision Record" page is added as Page 28.

But, this type of engine includes many fundamental mechanisms.

This would be the optimal teaching material for the beginners' class engineers and students.

A. Features of this model are;

1. Cutaway model of entire engine;

①. Reduction Gears (Planetary)

②. Cam and Drive gears

③. Crankshaft and Rod assembly

④. Cylinder and Piston with Valve mechanism

⑤. Supercharger gears and Impeller

2. Air Intake and Exhaust Pipes

3. Simplified Accessories (Propeller Hub with half blades, Carburetor, Magneto and Starter etc.)

4. It can be rotational but not smoothly because of the valve mechanism resistance and friction.

Refer to: https://youtu.be/uaWTmbg4mlE

B. Print and parts information

There are approximately 80 stl parts and many hardware including the bearings.

Hardware can be purchased from DIY shop or WEB shop easily and can be changed to equivalent similar parts.

All parts data are included in the manual. Refer Numerical Index.

It takes very long hours to print parts, treatment after printing and assembling.

STL file name: "ws" of last 2 digits means "With Support" which special designed.

But some parts need additional slicer's support to these. Refer “Remarks” column.

Estimated net print hour will be more than 90 hours.

C. Assembly manual (.pdf format in Zip)

The detail assembly manual including "Parts-List", "After printing treatment" and "Assembly procedure" are prepared.

But there are many complicated parts which required finishing and machining (Filing, Drilling and Tapping).

Also there are many fits required adjustment of clearance and tightening using with many hardware.

Some sample manual pages are shown in photos.

This manual can be very helpful for disassembly and re-assembly just like overhaul.

D. General Notes

1. For M1.4 Screw: No need "Tapping". Drill with φ1.0 drill then direct screw-in.

2. Screw to AL pipe: Put in a screw into the pipe end, squeeze pipe by the plier. Check the fixed condition.

3. Small diameter shaft parts:

To keep the strength, Use "100% infill" at printing and apply the adhesive for acrylic resin.

4. Recommended Drills and Taps

Drill: 1.0, 1.5, 2.0, 2.5, 3.0, 3.2, 5.0, 5.2, 7.2

Tap: M2, M3

3D printing settings

Raft, Support, Layer Height, Infill: Depending on your experience.

But the parts having gear, small shaft and thin portion: 100% infill is recommended.

My models were printed by "idbox" using with 0.4 nozzle, 1.75 PLA.

Before "Down-Loading", please watch photos carefully and consider deeply.

I do hope your success!!

[Updated 2017.10.10]

YouTube Video changed to longer version.

[Updated 2017.10.16]

A typo was corrected on photo.

[Updated 2018.2.10]

"Assembly Manual" typo and hardware qty, etc. corrected.

"Revision Record" page is added as Page 28.

Similar models

cults

$16

Turboprop Engine, for Business Aircraft, Free Turbine Type, Cutaway

...m in the creations which i made before.

i do hope your success!!

[update] - 2018.3.14

photo of typical special support is added.

cults

$21

Propfan Engine, Pusher Type

...yer height, 40% infill and no raft and support)

note: when at actual print, each parameter may be adjusted by your experience.

cults

$10

Turboprop Engine, for Business Aircraft, Cutaway

... hope your success!!

[update 2017.12.15]

for "dummy propeller assy", related stl files (4), photo and image are added.

cults

free

Main Gear Box, Helicopter driven by 2-Engines

...15,2017)

new file (body-mid901.stl) and related photos are added to return "tail take-off output" at the same position.

cults

$1

Manual winch

...the set can be used to mount toys on the scale 0.5

gear ratio 0.5

the spring / lever assembly preparation see photo attached.

cults

$5

Jet Engine, Single-Spool with AfterBurner

...

price discount

[update 2017.12.14]

for "non-shrouded turbine blades rotor", stl file (3), photo and image are added.

cults

$5

Turbofan Engine, for Business Aircraft, Cutaway

...out 10 hours to print.

note: when at actual print, each parameter may be adjusted by your experience.

i do hope your success!!

cults

free

Turboprop Engine Modified Parts (No.3)

...ecommended.

still this is not the model to print and assemble easily, i hope your perseverance too.

thank you for your interest.

cults

free

Rotational Stand for Turboprop Engine Cutaway

...to.

- wood screws: appropriate screws can be used.

assembly points

- stl parts position will be adjusted by the model you made.

cults

free

Jet Engine, 2-Spool, Current

... layer height, 40% infill and no raft and support)

note: when at actual print, each parameter may be adjusted by your experience.

Cutaway

cults

free

Rotational Stand for Turboprop Engine Cutaway

...to.

- wood screws: appropriate screws can be used.

assembly points

- stl parts position will be adjusted by the model you made.

cults

$5

Turbofan Engine, for Business Aircraft, Cutaway

...out 10 hours to print.

note: when at actual print, each parameter may be adjusted by your experience.

i do hope your success!!

cults

$10

Turboprop Engine, for Business Aircraft, Cutaway

... hope your success!!

[update 2017.12.15]

for "dummy propeller assy", related stl files (4), photo and image are added.

cults

$16

Turboprop Engine, for Business Aircraft, Free Turbine Type, Cutaway

...m in the creations which i made before.

i do hope your success!!

[update] - 2018.3.14

photo of typical special support is added.

cults

free

Quadcopter 915F

...futuristic. stealthy. a lamborghini in a world of jeeps. cutaway chevrons, sleek propellers and elegant proportions lift this high-concept...

cults

free

Turboprop Engine Modified Parts (No.2)

...engine modified parts (no.2) cults engine jet engine turboprop cutaway mid class passenger airp ane i am a designer...

cults

$21

Propfan Engine, Pusher Type

...by a home type vacuum cleaner. 2. engine (gas-generator) cutaway model is inside of cowling, but it is not...

Radial

cults

free

Radial Door Bolt

...radial door bolt for exteriors or interiors.

feel free to customize it here: https://www.vectary.com/u/meshtush/radial-door-bolt

cults

free

Radial low-RPM Halbach array PM Generator with serpentine coils.

...radial low-rpm halbach array pm generator with serpentine coils.

radial low-rpm halbach array pm generator with serpentine coils.

cults

$10

DUMMY RADIAL ENGINE

...100 mm from hobby king, but can be printed to any model plane that have cowling diameter about 95 - 110 mm , also can be scalled.

cults

$22

Dummy radial engine. Pratt & Whitney R2800

... - 57 mm inside the joiner ring.

the model can be scaled up or down to fit your model.

for personal use only, not for resale.

cults

free

Radial drinks coasters with holder

...inting in multiple colours. for ours we printed them in our bubblegum pink, cool breeze blue and arctic white.

happy printing x

cults

$6

T28 Trojan dummy radial engine

...iameter about 95 - 110 mm , also can be scalled.

diameter - 96.oo mm

high - 16.oo mm

hole diameter for electric motor - 37.oo mm

cults

$13

Le Rhone spinning radial dummy engine for RC planes

...or low rpm motors spinning big, scale props. high rpm use can be dangerous. how you use the printed model is your responsibility.

cults

free

Wanhao Duplicator i3 Fan Duct

...to a 12v dc 50mm blow radial cooling fan. https://www.amazon.com/connector-cooling-blower-50mmx15mm-uxcell/dp/b00mju6jr2/ref=sr_1_fkmr0_1?s=pc&ie=utf8&qid=1476920027&sr=1-1-fkmr0&keywords=2v+dc+50mm+blow+radialcooling+fan the fan duct is to be mounted around the...

cults

free

Square Extrusion Clamp

...90 degree angle. it is meant for axial and radial loads, it will probably not do a good job...

Piston

cults

free

Toy Piston

...toy piston

cults

toy piston

toy piston

cults

$5

Piston Trophy

... car fun toy rock roll

piston style toy trophy

download contains both capped and cup style piston top, base and faux bolts.

cults

free

PISTON KEY RING

...piston key ring

cults

porteclef piston clef key keychain keyring ring

porte clef piston

cults

free

Detroit Pistons - Logo

...troit pistons - logo

cults

detroit pistons - logo

support your favorite sport team with this 3d printable 3d model!

cheers csd

cults

free

Hand spinner Two pistons

...hand spinner two pistons

cults

fdm_center spinner hand_spinner

hand spinner two pistons

cults

free

piston toy

...piston toy

cults

watch video! https://www.youtube.com/watch?v=oihurkj56mg

2016.10.23-fixed(more lite)

cults

free

New Hand spinner Two pistons

...new hand spinner two pistons

cults

fdm_center spinner hand_spinner

new hand spinner two pistons

cults

$3

Piston Cup - Duplo - Cars

...nted in the form of lego duplo, but may be suitable for other uses, leave the choice to your ideas ...

dimensions 41x35,5x37

cults

$1

Piston and connecting rod

...n adaptant le taille de ce piston et de cette bielle, cela peut devenir un objet de déco ou un nouveau porte clé pour la voiture.

cults

free

Stihl Piston Keychain

...tor of this is gary brinsden (brinny).

http://www.thingiverse.com/thing:7893

i made some changes and turned it into a keychain.

Cylinder

cults

free

Cylinder

...cylinder

cults

cylinder education school school.

educational material. cylinder.

x: 3 cm

y: 3 cm

z: 5 cm

cults

free

Cylinder Shape

...cylinder shape

cults

cylinder shape

cylinder shape

cults

free

3D Cylinder

...3d cylinder

cults

3d cylinder

3d cylinder

cults

free

Ring - Bevelled Cylinder

...ring - bevelled cylinder

cults

ring - bevelled cylinder

ring - bevelled cylinder

cults

free

Ambiguous Cylinder Illusion

...ambiguous cylinder illusion

cults

ambiguous cylinder illusion

ambiguous cylinder illusion

cults

free

Simple Cylinder Test

...simple cylinder test

cults

simple cylinder test

simple cylinder test

cults

free

European tool cylinder / European cylinder tool

...e needle screw

thickness of layer 0.3

shell thickness 0.6

fill rate 25

print temperature 220c °

support type everywhere

cults

free

Ring - Bevelled cylinder - holes

...ring - bevelled cylinder - holes

cults

ring - bevelled cylinder holes

ring - bevelled cylinder - holes

cults

$2

rotary cylinder furniture

...

8 drawer

1 structure

1 foot with axis of rotation

1 cover that sticks on the axis of rotation of the foot

#dagocults

cults

free

Telescopic Cylinder, Math, Geometry

...iece. the result, however, is aesthetically motivating.

have fun!

reference:

https://en.wikipedia.org/wiki/telescopic_cylinder

Cylinders

cults

free

Cylinder

...cylinder

cults

cylinder education school school.

educational material. cylinder.

x: 3 cm

y: 3 cm

z: 5 cm

cults

free

Cylinder Shape

...cylinder shape

cults

cylinder shape

cylinder shape

cults

free

3D Cylinder

...3d cylinder

cults

3d cylinder

3d cylinder

cults

free

Ring - Bevelled Cylinder

...ring - bevelled cylinder

cults

ring - bevelled cylinder

ring - bevelled cylinder

cults

free

Ambiguous Cylinder Illusion

...ambiguous cylinder illusion

cults

ambiguous cylinder illusion

ambiguous cylinder illusion

cults

free

Simple Cylinder Test

...simple cylinder test

cults

simple cylinder test

simple cylinder test

cults

free

European tool cylinder / European cylinder tool

...e needle screw

thickness of layer 0.3

shell thickness 0.6

fill rate 25

print temperature 220c °

support type everywhere

cults

free

Ring - Bevelled cylinder - holes

...ring - bevelled cylinder - holes

cults

ring - bevelled cylinder holes

ring - bevelled cylinder - holes

cults

$2

rotary cylinder furniture

...

8 drawer

1 structure

1 foot with axis of rotation

1 cover that sticks on the axis of rotation of the foot

#dagocults

cults

free

Telescopic Cylinder, Math, Geometry

...iece. the result, however, is aesthetically motivating.

have fun!

reference:

https://en.wikipedia.org/wiki/telescopic_cylinder

Engine

cults

free

Metronome Engine

...metronome engine

cults

metronome engine

metronome engine

cults

free

Engine block

...engine block

cults

engine car motor

monoblock

cults

free

V6 engine block

...v6 engine block

cults

engine v6

cylinder block engine v6

cults

free

Xaar: Zyntari Engineer

...xaar: zyntari engineer

cults

xaar: zyntari engineer

xaar: zyntari engineer

cults

free

Working Train Engine "Kevin's Engine"

...p;quot;

cults

working train engine "kevin's engine"

working train engine "kevin's engine"

cults

free

Train Engine

...train engine

cults

model railroad constructor part number 1 train engine

model railroad. constructor. part number 1

cults

free

Jet Engine

...n assembling. remember: glue and patience go a long way!

all pieces print without support.

this model was designed by makerbot.

cults

free

Perendev engine

...perendev engine

cults

stl, solidworks, rar, ...

cults

free

RC model engine

...rc model engine

cults

this is a mockup of an enya rc model engine.

cults

free

STAR SERVO-ENGINE

...star servo-engine

cults

accessory

star for servo-engine with interior of 10 mm with thread and grip

7

cults

free

Bowl 7

...bowl 7

cults

bowl 7

bowl 7

cults

free

Poly Vase 7

...poly vase 7

cults

poly vase 7

poly vase 7

cults

free

Wire Box 7

...wire box 7

cults

wire box 7

wire box 7

cults

free

Hemisphere Bowl 7

...hemisphere bowl 7

cults

hemisphere bowl 7

hemisphere bowl 7

cults

free

String Vase 7

...string vase 7

cults

string vase 7

string vase 7

cults

free

Arrayed Vase 7

...arrayed vase 7

cults

arrayed vase 7

arrayed vase 7

cults

free

iPhone 7 Plus

...iphone 7 plus

cults

iphone 7 plus

iphone 7 plus

cults

free

7 segment display

...7 segment display

cults

7 segment display

7 segment display

cults

free

Trophy Riser 7

...trophy riser 7

cults

trophy riser 7

trophy riser 7

cults

free

Nexus 7 Bumper

...nexus 7 bumper

cults

nexus 7 bumper

nexus 7 bumper