Thingiverse

R20a1 by proof10010

by Thingiverse

Last crawled date: 3 years ago

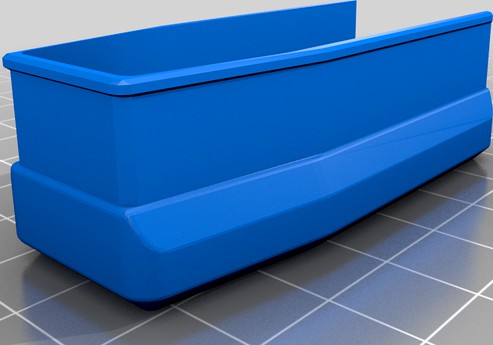

Proof AR-15 Magazine R20a1

-Proof10010

remix: https://www.thingiverse.com/thing:3367355

Advisory

Fabricate this magazine at your own risk. The publisher of this package

is not responsible for any damages to equipment during or after the fabrication

or use of this magazine. Publisher is not responsible for any legal violation

committed by the fabrication or use of this magazine.

SUMMARY

This package contains the STL files for a 20 round box magazine.

The Magazine is design to function under a wide array of filament material

including standard PLA. The following material will serve as a guide to successfully

creating a functional magazine. This magazine is an enhanced variant of the 20

round magazine created by BarCamel of Thingiverse. Mag body comes in two variants: with a divider and with out a divider. Enhancement variant was

completed

by proof10010.

Files

In the package, one will find three STL files. These files will include

Floor Plate, Follower, and Magazine Body.

Slicer

Ultimaker Cura 4.6 was used during development and is advised for use

in the fabrication.

Printer

The Creality Ender 3 pro was used in the development process and is the

recommended.

Filament

Duramic PLA+ was used during development and evaluation. Evaluation included

reliability in weapon cycling and long term survivabilty when loaded. Magazine is found

to be extremaly reliably after light sanding and using steel cased ammunition.

Magazine was left loaded for 1 week with approximately 0.1mm of feed lip exspansion.

Slicer Settings

Printed with the following settings:

Layer Height: 0.16mm

Wall Thickness: 1.2mm

Wall line Count: 4

Top/Bottom layers: 6

Infill Density: 40%

Infill Pattern: Cubic

Printing Temperature: 225 C

Build plate Temperature: 55 C

Print Speed: 50 mm/s

Support: Yes

Support Placement: Everywhere

Support Overhand Angle: 80

Build plate Adhesion: None

(Note: These setting are only recommendation and their values may vary from printer

to printer.)

Post Processing

Post processing mostly consist of sanding and smoothing the follower, especially it's rails . Smooth all side walls that can make contact with the inner wall of the magazine body, but be careful not to remove large amount of material. Test follower by sliding it inside the magazine body. If the follower catches, additional sanding is required. In some instances, it may be necessary to round corners.

Assembly

Equip the follower onto a spring and feed the combination into the magazine

body. Compress the spring into the magazine body until it is flush with the bottom.

Slide the floor plate into the magazine body track and capture the compressed spring. Slide the floor plate until it no longer can. Apply tape around the plate and mag body to secure it in place.

Trouble Shooting

If rounds are getting stuck mid way inside the magazine body, the tips of the

bullets are colliding with the front inner face of the magazine body and sanding is

required on that face.

If rounds are "nose diving" into the top of the magazine body during feeding,

Print new follow that is scaled up by 1% in all axis'. If issue is not resolved, sand

top of magazine body where the tip of the bullets make contact and ensure clearance

(Be extremely conservative with sanding if going the later option).

If mag catch is not well defined (loose filament on the top face) take a hot end and gentle press the loose filament into the material underneath.

If follower is catch on the mag body, sand all contact surfaces including the front face of the follower where it makes contact with the mag body divider.

-Proof10010

remix: https://www.thingiverse.com/thing:3367355

Advisory

Fabricate this magazine at your own risk. The publisher of this package

is not responsible for any damages to equipment during or after the fabrication

or use of this magazine. Publisher is not responsible for any legal violation

committed by the fabrication or use of this magazine.

SUMMARY

This package contains the STL files for a 20 round box magazine.

The Magazine is design to function under a wide array of filament material

including standard PLA. The following material will serve as a guide to successfully

creating a functional magazine. This magazine is an enhanced variant of the 20

round magazine created by BarCamel of Thingiverse. Mag body comes in two variants: with a divider and with out a divider. Enhancement variant was

completed

by proof10010.

Files

In the package, one will find three STL files. These files will include

Floor Plate, Follower, and Magazine Body.

Slicer

Ultimaker Cura 4.6 was used during development and is advised for use

in the fabrication.

Printer

The Creality Ender 3 pro was used in the development process and is the

recommended.

Filament

Duramic PLA+ was used during development and evaluation. Evaluation included

reliability in weapon cycling and long term survivabilty when loaded. Magazine is found

to be extremaly reliably after light sanding and using steel cased ammunition.

Magazine was left loaded for 1 week with approximately 0.1mm of feed lip exspansion.

Slicer Settings

Printed with the following settings:

Layer Height: 0.16mm

Wall Thickness: 1.2mm

Wall line Count: 4

Top/Bottom layers: 6

Infill Density: 40%

Infill Pattern: Cubic

Printing Temperature: 225 C

Build plate Temperature: 55 C

Print Speed: 50 mm/s

Support: Yes

Support Placement: Everywhere

Support Overhand Angle: 80

Build plate Adhesion: None

(Note: These setting are only recommendation and their values may vary from printer

to printer.)

Post Processing

Post processing mostly consist of sanding and smoothing the follower, especially it's rails . Smooth all side walls that can make contact with the inner wall of the magazine body, but be careful not to remove large amount of material. Test follower by sliding it inside the magazine body. If the follower catches, additional sanding is required. In some instances, it may be necessary to round corners.

Assembly

Equip the follower onto a spring and feed the combination into the magazine

body. Compress the spring into the magazine body until it is flush with the bottom.

Slide the floor plate into the magazine body track and capture the compressed spring. Slide the floor plate until it no longer can. Apply tape around the plate and mag body to secure it in place.

Trouble Shooting

If rounds are getting stuck mid way inside the magazine body, the tips of the

bullets are colliding with the front inner face of the magazine body and sanding is

required on that face.

If rounds are "nose diving" into the top of the magazine body during feeding,

Print new follow that is scaled up by 1% in all axis'. If issue is not resolved, sand

top of magazine body where the tip of the bullets make contact and ensure clearance

(Be extremely conservative with sanding if going the later option).

If mag catch is not well defined (loose filament on the top face) take a hot end and gentle press the loose filament into the material underneath.

If follower is catch on the mag body, sand all contact surfaces including the front face of the follower where it makes contact with the mag body divider.

Similar models

thingiverse

free

Star Trek Knob for Monoprice Select Mini V2 by GrubbyPaw

...nkid=ba6d823cc70a0752a3085dc73b0f1929&language=en_us&ref_=as_li_ss_tl"> select mini</a>'s control knob.

thingiverse

free

Prusa i3 MK3 Arducam OVA5647 Camera Mount by pvanhouten

...he plate using microscrews from a glasses repair kit (6mmx1.5mm). the other screws i used were leftovers from the mk3 build kit.

thingiverse

free

Proof AR-15 Magazine R20 by proof10010

... enhanced variant of the 20

round magazine created by barcamel of thingiverse. enhancement variant was completed

by proof10010.

thingiverse

free

Onefinity Monitor Arm Connector by cyberreefguru

...g=cyberreefgu0c-20&linkid=14415004f4b141eaae9525187bb68eb3&language=en_us&ref_=as_li_ss_tl (for 7" monitor only)

thingiverse

free

Spacecat - Launch pad v2 Case by jneubeck

...amp;psc=1&linkcode=sl1&tag=neubeck-20&linkid=5c1adcf1e26e86d2a2323754efe7a0b7&language=en_us&ref_=as_li_ss_tl

thingiverse

free

RGB Youtube Play Button by KenMakesMistakes

...c=1&linkcode=sl1&tag=kenmakesmista-20&linkid=f2678d6d510fe6336c34cc36e0e6d247&language=en_us&ref_=as_li_ss_tl

thingiverse

free

Prusa Light Bar Simple Print by wbushee

...c=1&linkcode=sl1&tag=bluemonkeydev-20&linkid=4c12befa75c811732eb310b986c3f297&language=en_us&ref_=as_li_ss_tl

thingiverse

free

Buck Converter Case by jneubeck

...amp;psc=1&linkcode=sl1&tag=neubeck-20&linkid=01d25aa1e974a9096cd247acb9e6ac40&language=en_us&ref_=as_li_ss_tl

thingiverse

free

Seed organizer by reeseallen

...&psc=1&linkcode=sl1&tag=reeall-20&linkid=cfd0b80d7ba1f7ea99e5eb21ed0fb88f&language=en_us&ref_=as_li_ss_tl

thingiverse

free

Airsoft KWC Colt M1911 Improved Mag Follower by danielrama30

...39;s mag follower for kingarms 1911.

i recommend 100% infilll and 0,2 or 0,3 mm layer and use filaments like petg if you have it.

Proof10010

thingiverse

free

Proof AR-15 Magazine R20 by proof10010

... enhanced variant of the 20

round magazine created by barcamel of thingiverse. enhancement variant was completed

by proof10010.

thingiverse

free

Proof R20 prototype by proof10010

...a or pla+

nozzle temp: 220 c

bed temp: 55 c

nozzle speed: 50 mm/s

infill: 35 %

wall thickness: 4

supports: only for the follower.