Thingiverse

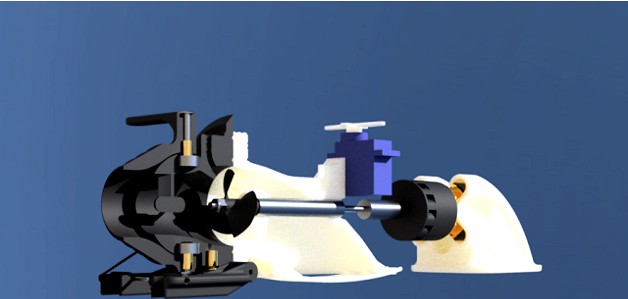

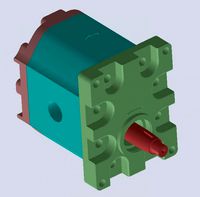

Pump Jet (32mm Prop) by N7_Cat

by Thingiverse

Last crawled date: 3 years, 3 months ago

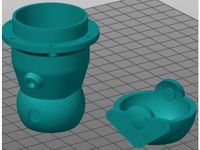

An offshoot of my project https://www.thingiverse.com/thing:4606971 RC Pump Jet boat, I modeled a stand alone water jet originally intending boat to be modular in design. After consideration I decided to just integrate the pump jet with the boat body rather than try to seal the modular parts against water ingress.

This model might still be useful for someone though. I've also kept the motor separate from the pump jet in case you want to model your own motor housing for different motors.

Note this design has inlet and outlets for water cooling, you will need to plug or remove these if not needed

BOM:

Motor: 2212 if using the provided mount https://www.aliexpress.com/item/32672300112.html

Prop: 32mm with 100 mm shaft (note get the 10 cm one with 3.18 motor as the 2212 shaft is 3.175 mm - I initially tried to model an axial flow impeller but I found this purchased item to be far more sturdy. Advantages are it has built in high speed bearings and replacement props can be purchased from here as well. I also added provisions for a diy 3mm shaft using 623 bearings) https://www.aliexpress.com/item/32714017489.html https://www.aliexpress.com/item/32528668718.html

Servo: sized for 9g servo (important you will want to waterproof or find an alternate waterproof servo) https://www.aliexpress.com/item/33005962141.html

M3 X 6 X 5.3 Embedded Nuts (old link no longer works - possible substitution M3 X D5 X L6) https://www.aliexpress.com/item/4000232858343.html

M3 Machine Screws (Button head and Flat head) https://www.aliexpress.com/item/32798146322.html or stainless https://www.aliexpress.com/item/32934186482.html

Thrust vector nozzle, stator and motor cooling impeller should be printed in TPU for layer adhesion qualities.

For post processing pics please go to https://www.thingiverse.com/thing:4606971

Note that the embedded nuts go on the inner side for this model while they go on the outer face for the boat project due to access issues. The boat model also has an alternate motor mount with base which might suit some builders better as well as a template for custom motors other than the 2212.

Josh at Flite Test did a good vid about waterproofing RC electronics with Peter Sripol (Flite Test | Waterproofing Electronics)

Enjoy >^.^< also let me know if there are any issues as my main focus for the near term will be the RC boat project and changes / improvements there may not make it here.

Updated 10/3/2020, removed the bar surrounding the servo to improve printability.

Updated 10/7/2020, improved printability by modifying the fillet around the shaft support

Update 10/9/2020, After a print failure of the protective grid on the intake as well as impact durability test failures I have replaced with a filament heat stake method as shown in my boat project post processing pics.

Insert 1.75 mm filaments into the slots and use a low temp soldering iron to melt the ends into the inlet - you could also use servo wire and glue in place...unless you like grinding baby fish into a pulp...u monster

Updated 10/11/2020, increased clearance for the prop shaft

Updated 10/15/2020, motor mount was a tight fit, increased clearances - note if print elephant foots you will still need to trim mount a bit

Updated 10/18/2020, Added a variable trim ride plate. A bent 1.5 mm servo wire serves as the retention and adjustment mechanism, backup retention provided by an embedded nut and M3 X 10 screw + spring. Joint held by filament joint. Note stator profile carried over from my boat project and outer gasket allowance missing :P caturday cat prefers to nap >^.^< it is a feature not a deficiency

Updated 10/20/2020, some weird artifacts were cropping up in cooling impeller during slicing, increased to high resolution stl and fixed wall width

Updated 10/21/2020 increased prop clearance on stator bowl

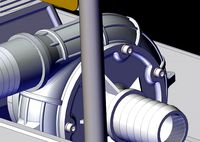

Updated 10/25/2020 improvements to trust vector nozzle to allow M3 X 5 X 6 mm embedded nuts to ride on the inner race of the 623zz bearing

Update 11/6/2020, feedback on my boat project suggest that a thrust vector nozzle with a slight pitch up would be beneficial - added a thrust vector nozzle with a 5 degree pitch up. If you find that your own boat is going nose down this new nozzle will help :). Added a 10 deg pitch nozzle if your CG/CB requires it

Update 11/18/2020, first functional test of the waterjet - I found that even with TPU gasket air and water would spray out thus sealing the stator bowl to inlet duct body with silicone or glue is necessary. I found an issue with air locking - I don't fully understand the cause but experimentally determined a way to resolve this via a pending modification to the thrust vector nozzle. Update uploaded (Thrust Vector Nozzle Variable Pitch) but untested - I'll hopefully get a chance to print and test by tmw. Testing confirms the air lock issue is resolved with this new nozzle - there is some loss of efficiency. I don't really know why this fixes the air lock but I suspect the stator bowl fins were not redirecting enough of the rotational energy generated by the prop resulting in an area of low pressure which would draw air in from behind the outlet...without high speed cameras or CFD I can't really say. N7 Cat says "wut he trying 2 say iz I putz mah paw ober da nozzle and dat fixes it"

11/21/2020 did some more study on propulsor units and updated the pitch and number of stator vanes - 5 vane stator uploaded - will test later and delete original if testing displays improvement. Test showed marked improvement in both trust and elimination of air lock using the 5 vane stator - original deleted. For anyone else designing or trouble shooting other pump jets on thingiverse the number of stator vanes needs to be a prime number and different than the number of prop blades otherwise a standing wave can develop. At some point in the future I might experiment with a properly designed axial flow prop and stator - salt sintering might be able to create a strong enough part for use as a prop.

11/25/2020 reverted thrust vector nozzle to neutral pitch

This model might still be useful for someone though. I've also kept the motor separate from the pump jet in case you want to model your own motor housing for different motors.

Note this design has inlet and outlets for water cooling, you will need to plug or remove these if not needed

BOM:

Motor: 2212 if using the provided mount https://www.aliexpress.com/item/32672300112.html

Prop: 32mm with 100 mm shaft (note get the 10 cm one with 3.18 motor as the 2212 shaft is 3.175 mm - I initially tried to model an axial flow impeller but I found this purchased item to be far more sturdy. Advantages are it has built in high speed bearings and replacement props can be purchased from here as well. I also added provisions for a diy 3mm shaft using 623 bearings) https://www.aliexpress.com/item/32714017489.html https://www.aliexpress.com/item/32528668718.html

Servo: sized for 9g servo (important you will want to waterproof or find an alternate waterproof servo) https://www.aliexpress.com/item/33005962141.html

M3 X 6 X 5.3 Embedded Nuts (old link no longer works - possible substitution M3 X D5 X L6) https://www.aliexpress.com/item/4000232858343.html

M3 Machine Screws (Button head and Flat head) https://www.aliexpress.com/item/32798146322.html or stainless https://www.aliexpress.com/item/32934186482.html

Thrust vector nozzle, stator and motor cooling impeller should be printed in TPU for layer adhesion qualities.

For post processing pics please go to https://www.thingiverse.com/thing:4606971

Note that the embedded nuts go on the inner side for this model while they go on the outer face for the boat project due to access issues. The boat model also has an alternate motor mount with base which might suit some builders better as well as a template for custom motors other than the 2212.

Josh at Flite Test did a good vid about waterproofing RC electronics with Peter Sripol (Flite Test | Waterproofing Electronics)

Enjoy >^.^< also let me know if there are any issues as my main focus for the near term will be the RC boat project and changes / improvements there may not make it here.

Updated 10/3/2020, removed the bar surrounding the servo to improve printability.

Updated 10/7/2020, improved printability by modifying the fillet around the shaft support

Update 10/9/2020, After a print failure of the protective grid on the intake as well as impact durability test failures I have replaced with a filament heat stake method as shown in my boat project post processing pics.

Insert 1.75 mm filaments into the slots and use a low temp soldering iron to melt the ends into the inlet - you could also use servo wire and glue in place...unless you like grinding baby fish into a pulp...u monster

Updated 10/11/2020, increased clearance for the prop shaft

Updated 10/15/2020, motor mount was a tight fit, increased clearances - note if print elephant foots you will still need to trim mount a bit

Updated 10/18/2020, Added a variable trim ride plate. A bent 1.5 mm servo wire serves as the retention and adjustment mechanism, backup retention provided by an embedded nut and M3 X 10 screw + spring. Joint held by filament joint. Note stator profile carried over from my boat project and outer gasket allowance missing :P caturday cat prefers to nap >^.^< it is a feature not a deficiency

Updated 10/20/2020, some weird artifacts were cropping up in cooling impeller during slicing, increased to high resolution stl and fixed wall width

Updated 10/21/2020 increased prop clearance on stator bowl

Updated 10/25/2020 improvements to trust vector nozzle to allow M3 X 5 X 6 mm embedded nuts to ride on the inner race of the 623zz bearing

Update 11/6/2020, feedback on my boat project suggest that a thrust vector nozzle with a slight pitch up would be beneficial - added a thrust vector nozzle with a 5 degree pitch up. If you find that your own boat is going nose down this new nozzle will help :). Added a 10 deg pitch nozzle if your CG/CB requires it

Update 11/18/2020, first functional test of the waterjet - I found that even with TPU gasket air and water would spray out thus sealing the stator bowl to inlet duct body with silicone or glue is necessary. I found an issue with air locking - I don't fully understand the cause but experimentally determined a way to resolve this via a pending modification to the thrust vector nozzle. Update uploaded (Thrust Vector Nozzle Variable Pitch) but untested - I'll hopefully get a chance to print and test by tmw. Testing confirms the air lock issue is resolved with this new nozzle - there is some loss of efficiency. I don't really know why this fixes the air lock but I suspect the stator bowl fins were not redirecting enough of the rotational energy generated by the prop resulting in an area of low pressure which would draw air in from behind the outlet...without high speed cameras or CFD I can't really say. N7 Cat says "wut he trying 2 say iz I putz mah paw ober da nozzle and dat fixes it"

11/21/2020 did some more study on propulsor units and updated the pitch and number of stator vanes - 5 vane stator uploaded - will test later and delete original if testing displays improvement. Test showed marked improvement in both trust and elimination of air lock using the 5 vane stator - original deleted. For anyone else designing or trouble shooting other pump jets on thingiverse the number of stator vanes needs to be a prime number and different than the number of prop blades otherwise a standing wave can develop. At some point in the future I might experiment with a properly designed axial flow prop and stator - salt sintering might be able to create a strong enough part for use as a prop.

11/25/2020 reverted thrust vector nozzle to neutral pitch

Similar models

thingiverse

free

RC Boat - Pump Jet Boat / 遥控船-喷射泵 by N7_Cat

...ntering might be able to create a strong enough part for use as a prop.

11/25/2020 reverted thrust vector nozzle to neutral pitch

grabcad

free

Atomstack air nozzle

...atomstack air nozzle

grabcad

nozzle from the atomstack air pump kit | https://aliexpress.ru/item/1005004561794589.html

thingiverse

free

RC boat by sergey2484

...:

nozzle: 0.8mm

extrusion width 0.92...0.93

layer hight: 0.4

perimeter shells: 2

inflll: 40...70%

inflll extrusion width 80...90%

thingiverse

free

Desktop Nozzle Tray by greensladenz

...nozzles i buy: https://www.aliexpress.com/item/4000414939069.html

nozzle tool: https://www.aliexpress.com/item/4001121556653.html

grabcad

free

24Volt mini air pump model DX524-2501-4000

...available here.

https://www.aliexpress.com/item/33016858930.html?spm=2114.12010612.8148356.21.1f417f92rakpgq

fusion 360 and step

grabcad

free

Jet Boat Impeller

...back and suggested. i used software from https://www.mitcalc.com/en/pr_shaftcon.htm to draw the profiles for the hub and shaft.

cg_trader

$3

A Pump-Jet | 3D

...with 4mm shaft and 34mm impeller for 500mm rc jet boat soon avable

nozzle diametre 16mm

shaft guide 4mm x 8mm

35° steering angle

thingiverse

free

Motor Bathtub Boat V5 by Kendler

...p boat to be motorized

use a simple motor like thishttps://www.aliexpress.com/item/33022320164.html

i recommend 300 rpm and above

thingiverse

free

4BDN jetunit stators and nozzles for 35mm impellor

...earing and a 10mm outer diameter grease seal, a 5mm stainless steel shaft.

if you download, please throw a ~like~ on the page :-)

thingiverse

free

Utility ship - one motor, two counter rotating propellers

...9042311.0.0.76474c4dw5ndyo

and two of theesehttps://www.aliexpress.com/item/32527501026.html?spm=a2g0s.9042311.0.0.76474c4dw5ndyo

N7

turbosquid

$10

N7 Pistol

...rbosquid

royalty free 3d model n7 pistol for download as fbx on turbosquid: 3d models for games, architecture, videos. (1472924)

3ddd

$1

Стол N7 от Casamania

...стол n7 от casamania

3ddd

casamania

футуристичный стол n7 от casamania

evermotion

$8

CASAMANIA N7 AM72

...nia design with all textures, shaders and materials. it is ready to use, just put it into your scene.. evermotion 3d models shop.

turbosquid

$70

Spaceship N7-1

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$60

Spaceship N7-3

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$50

Spaceship N7-2

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$12

Clothes n7

...tures are in png format and they are available in these dimensions:<br>dimensions of the 3d model: 0.402m x 0.324m x 0.912m

3d_sky

free

Table N7 from Casamania

...table n7 from casamania

3dsky

casamania

futuristic table n7 from casamania

3dbaza

$3

Coffe Table N7 (154932)

...coffe table n7 (154932)

3dbaza

coffe table 3d model<br>coffe table n7 wood metall

thingiverse

free

weapon-n7-valiant by Worffpack104TH

...on-n7-valiant by worffpack104th

thingiverse

weapon-n7-valiant is for mass effect 3 it is a good gun to use now u can . print it

32Mm

turbosquid

$20

wrench big collection from 8mm to 32mm

...llection from 8mm to 32mm for download as obj, fbx, and sldas on turbosquid: 3d models for games, architecture, videos. (1438111)

3d_export

$5

Spanner 6mm-32mm 10mm spanner vs nomber

... vs nomber

3dexport

spanner 3ds max 2021 model with textures all models, formats, textures, converted formats in 1 rar. archive.

3d_export

$6

Bases for miniatures

...bases for miniatures 3dexport 5 bases 32mm for...

3ddd

free

Radiant Screen

...baker -http://www.bakerfurniture.com - модель: radiant screen №8699 размеры: w-1540mm, d-32mm ...

3d_export

$5

golf cart wheel 265 mm

...width is 65mm center cross section of wheel is 32mm in which bearing are fitted very...

3d_export

$10

classic style carving rosette

...(l * h * d): 555 x 555 x 32mmlt;br>* polys: 153,712<br>* .stl file included<br>3d model of classical trim....

3d_export

$50

Knife phoenix

...phoenix 3dexport model dimensions:<br>total length - 180mm<br>maximum width - 32mmlt;br>blade thickness - 3mm<br>handle thickness - 6mm<br>multiformat: igs, obj, stl,...

3dfindit

free

ENDCAP 32MM-32MM

...endcap 32mm-32mm

3dfind.it

catalog: a lex products

3dfindit

free

32MM-32MM PROFILE

...32mm-32mm profile

3dfind.it

catalog: a lex products

3dfindit

free

32MM-32MM CORNER PROF

...32mm-32mm corner prof

3dfind.it

catalog: a lex products

Pump

3d_export

$5

pump

...pump

3dexport

pump

archibase_planet

free

Pump

...pump

archibase planet

petrol pump petrol station gas station

pump - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_ocean

$8

Pumps

...ps

3docean

girls heels high kicks pumps shoes stilettos womens

womens high heels, pumps or stilettos. polygon model – no textures

3ddd

free

Pump

...ump

3ddd

pump , versus

производитель: versus

модель: pumphttp://www.versus.as/

turbosquid

$3

Pumps

...s

turbosquid

royalty free 3d model pumps for download as skp on turbosquid: 3d models for games, architecture, videos. (1275250)

3d_export

$5

pump

...pump

3dexport

turbosquid

$39

Realistic Water pump SYLLENT PUMP

...realistic water pump syllent pump for download as max and obj on turbosquid: 3d models for games, architecture, videos. (1312864)

turbosquid

$150

Pumpe

...yalty free 3d model pumpe for download as ige, blend, and stl on turbosquid: 3d models for games, architecture, videos. (1284318)

3d_export

$10

gear pump

...gear pump

3dexport

it is a gear pump in iges format

turbosquid

$19

Old Water Pumps Gas Pumps

...pumps gas pumps for download as 3ds, obj, fbx, blend, and dae on turbosquid: 3d models for games, architecture, videos. (1207997)

Jet

turbosquid

$1

jet

...jet

turbosquid

royalty free 3d model jet for download as fbx on turbosquid: 3d models for games, architecture, videos. (1659892)

3ddd

free

water jet

...water jet

3ddd

фонтан

water jet fountain

turbosquid

$65

JETS

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

jet

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

Jet

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$4

jet

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$1

Jet

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Jet

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

jet

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

jet engine

...jet engine

3dexport

this model is a fantasy on a jet engine and has no real prototype. enjoy !!!

Cat

3d_export

$26

Cat

...cat

3dexport

cat

3d_export

$6

Cat

...cat

3dexport

cat

3d_export

$6

cat

...cat

3dexport

this is a cat

3d_export

$5

Cat

...cat

3dexport

cat

3d_export

$5

Cat

...cat

3dexport

cat

3d_export

$5

cat

...cat

3dexport

low poly cat ball

archibase_planet

free

Cat

...cat

archibase planet

cats animals

cat n140208 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

$5

cat

...cat

3dexport

a cat that may look like a leopard because of its color.

turbosquid

free

Tidy Cats Cat Litter

...alty free 3d model tidy cats cat litter for download as blend on turbosquid: 3d models for games, architecture, videos. (1206013)

turbosquid

$15

The Battle Cats Cat Base

...odel the battle cats - eraser cat for download as max and ige on turbosquid: 3d models for games, architecture, videos. (1591322)

Prop

3ddd

$1

Props

...props

3ddd

props

3d_ocean

$10

Props

...ject you need this props design this 6 taype for props to get your design perfect and nice file include : 1 max 2 obj 3 3ds 4 zip

turbosquid

$15

Props

...s

turbosquid

royalty free 3d model props for download as max on turbosquid: 3d models for games, architecture, videos. (1249032)

turbosquid

$1

PROPS

...d model props for download as unitypackage, obj, fbx, and tga on turbosquid: 3d models for games, architecture, videos. (1627660)

turbosquid

$5

props

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

PROP

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

kids props

...kids props

3ddd

декоративный набор

kids props

3d_ocean

$8

Street props

...l barrier prop roads street street prop

street props game models barrel barrier roads aircos jerrycan models fbx obj and max file

turbosquid

$39

Apocalyptic Props

...uid

royalty free 3d model apocalyptic props for download as on turbosquid: 3d models for games, architecture, videos. (1380028)

turbosquid

$1

Bunker props

...rbosquid

royalty free 3d model bunker props for download as on turbosquid: 3d models for games, architecture, videos. (1196014)