Thingiverse

Pull Switch Suite by bathrobotics

by Thingiverse

Last crawled date: 3 years, 1 month ago

Maybe I will do this.....

04/01/2016 Original Light Pull Switch Weight

05/01/2016 Scaled Up Light Pull Switch Weight

07/01/2016 LightBulb Motif Pull Switch Weight

08/01/2016 LighBulb Motif Pull Switch Weight (no thread)

11/01/2016 Extractor Fan Pull Switch Weight

This is a good little demo of how mass produced moulded design is different from 3D Printed Design.

in this case it isn't Injection moulds, most (UK) electrical polymer parts are made from Thermoset materials. Where Thermoplastic get softer when heated, Thermoset only polymerise once, when two reagents are pressurised and heated in the mould. This makes the parts safer for electrical usage, as if the parts where to get softer as they heat, they might deform and cause electrical contact.

So Thermosets are generally used to contain electrical connections for safety reasons. Please remember this when downloading electrical stuff: 3D PRINTERS USE THERMOPLASTICS.

Next up in my monologue: Angles of Draft. On 3D Prints, you don't have to remove the part from a complex (and expensive) tool, but on the Compression Moulding tools, you can't remove parts with undercut. Ideally designed parts would have no draft on them (for most parts) - it's only added on to make either Die Casting, Injection Moulding or Compression Moulding. 3D Printing allows us to make parts closer to the ideal form - in some instances. In Other ways, we need to add either Support Structure to be broken away or washed off, or design it to be self-supporting.

The original Pull Switch Weights are made from Thermoset polymer, simply to get parts from the same supplier who makes the other thermoset parts.

They don't have to be Thermoset.

I've designed these to be 3D printed replacements for the original Pull Switch Cords.

Enjoy.

-EUR ING. Andy Southern

aka BathRobotics.

04/01/2016 Original Light Pull Switch Weight

05/01/2016 Scaled Up Light Pull Switch Weight

07/01/2016 LightBulb Motif Pull Switch Weight

08/01/2016 LighBulb Motif Pull Switch Weight (no thread)

11/01/2016 Extractor Fan Pull Switch Weight

This is a good little demo of how mass produced moulded design is different from 3D Printed Design.

in this case it isn't Injection moulds, most (UK) electrical polymer parts are made from Thermoset materials. Where Thermoplastic get softer when heated, Thermoset only polymerise once, when two reagents are pressurised and heated in the mould. This makes the parts safer for electrical usage, as if the parts where to get softer as they heat, they might deform and cause electrical contact.

So Thermosets are generally used to contain electrical connections for safety reasons. Please remember this when downloading electrical stuff: 3D PRINTERS USE THERMOPLASTICS.

Next up in my monologue: Angles of Draft. On 3D Prints, you don't have to remove the part from a complex (and expensive) tool, but on the Compression Moulding tools, you can't remove parts with undercut. Ideally designed parts would have no draft on them (for most parts) - it's only added on to make either Die Casting, Injection Moulding or Compression Moulding. 3D Printing allows us to make parts closer to the ideal form - in some instances. In Other ways, we need to add either Support Structure to be broken away or washed off, or design it to be self-supporting.

The original Pull Switch Weights are made from Thermoset polymer, simply to get parts from the same supplier who makes the other thermoset parts.

They don't have to be Thermoset.

I've designed these to be 3D printed replacements for the original Pull Switch Cords.

Enjoy.

-EUR ING. Andy Southern

aka BathRobotics.

Similar models

grabcad

free

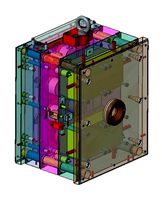

INJECTION MOULDING

... materials mainly including metals, glasses, elastomers, confections, and most commonly thermoplastic and thermosetting polymers.

grabcad

free

INJECTION MOULDING MACHINE

... materials mainly including metals, glasses, elastomers, confections, and most commonly thermoplastic and thermosetting polymers.

grabcad

free

matrix and punch

...do not melt during the injection moulding of some lower-temperature thermoplastics, can be used for some simple injection moulds.

cg_trader

$5

High Detailed 3D Injection Mould | 3D

...high detailed 3d injection mould | 3d

cg trader

complete 3d mould for thermoplastic injection

cg_trader

$3

Injected Plastic Cup

...injected plastic cup

cg trader

injected plastic cup ready to 3d print or make mould.

modeling includes draft angles and radii

grabcad

free

Lifter Motor Cover Set

...er motor cover set

grabcad

a two halves (rh/lh) motor cover set for electric lifter made in thermoplastics by injection moulding

grabcad

free

1by2 MCB Plastic injection moulding die

...1by2 mcb plastic injection moulding die

grabcad

1by2 mcb is a plastic electric part in which connection & switch place.

grabcad

free

pressure sensor

...ssure sensor

grabcad

oxygen pressure sensor( vacuum style), the product with parts made of polymer injected into simple moulds.

grabcad

free

plastic part Injection mould 2021

...plastic part injection mould 2021

grabcad

this mould is to make plastic parts

grabcad

free

Clothes Peg

...ompression spring is 14 mm.

the assemblies are available as step files (.stp) only.

all parts are available as stl files (.stl).

Bathrobotics

thingiverse

free

Solar Cell from eBay by bathrobotics

...solar cell from ebay by bathrobotics

thingiverse

solar cell

thingiverse

free

A Test Piece by bathrobotics

...e by bathrobotics

thingiverse

see how accurately your printer can print this 210mm cube block.

remember to print at 100% fill.

thingiverse

free

hobbed drive (dummy) by bathrobotics

...rect modelling personal edition (which is free).

please also see my dummy stepper motor:https://www.thingiverse.com/thing:1757165

thingiverse

free

QR Pressure- Coupling by bathrobotics

...by bathrobotics

thingiverse

a sketch model, don't print, maybe use as a design aid or something to scare small animals with.

thingiverse

free

Clip for Batman Belt Buckle by bathrobotics

...ttp://www.thingiverse.com/thing:680736

enjoy.

-as,

ceng.

aka bath robotics.

http://www.thingiverse.com/bathrobotics/about

thingiverse

free

Bendy Straw Model (Do Not Print!) by bathrobotics

... attach to recent designs.

enjoy,

eur ing andy southern,

aka

bathrobotics

http://www.thingiverse.com/bathrobotics/about

thingiverse

free

Nokia_battery_holder_pepperpot_version by bathrobotics

...acetone to melt the abs to glue.

run the wires through the holes that are split in half.

nokia-batteryholder.

for a 5c battery(?)

thingiverse

free

Washer retainer by bathrobotics

...it's been made, used and proven.

it was designed for a very specific reason, in my own time, and printed on my own printer.

thingiverse

free

Ball Bearing 5x10x4 MR105ZZ by bathrobotics

...zz by bathrobotics

thingiverse

wednesday 22nd april 2015:

ball bearing 5x10x4 mr105zz.

specific for a design i wish to make.

thingiverse

free

Bamboo Flute End Piece by bathrobotics

...t'll be printed in red.

enjoy.

eur ing andy southern.

aka bath robotics

http://www.thingiverse.com/bathrobotics/about

Pull

3ddd

$1

Muuto Pull Lamp

...muuto pull lamp

3ddd

muuto , pull lamp

model of pull lamp, designed by muuto

3d_ocean

$24

Pull-down Machine

...n equipement gym gymnastic indoor machine pull pull-down silver sport workout

3d model of black and silver pull-down gym machine.

turbosquid

$19

Pull high

...rbosquid

royalty free 3d model pull high for download as ige on turbosquid: 3d models for games, architecture, videos. (1338664)

turbosquid

$9

Pull Rod

...urbosquid

royalty free 3d model pull rod for download as c4d on turbosquid: 3d models for games, architecture, videos. (1343200)

3ddd

$1

Pull and Bear Sneakers

...pull and bear sneakers

3ddd

обувь , кроссовки

pull and bear sneakers

turbosquid

$38

Pull Station

... free 3d model pull station for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1290796)

turbosquid

$20

Pouf with pulls

...ee 3d model pouf with pulls for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1186069)

turbosquid

$24

Pull Toy

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$8

Pull Saw

... 3d model pull saw for download as ma, max, obj, c4d, and fbx on turbosquid: 3d models for games, architecture, videos. (1178540)

turbosquid

$1

Pull Switch

...model pull switch for download as max, 3ds, fbx, obj, and dxf on turbosquid: 3d models for games, architecture, videos. (1649377)

Suite

3ddd

free

Suite

...suite

3ddd

suite

suite including detailed basin and camod with materials in max and fbx format

archibase_planet

free

Suit

...suit

archibase planet

suit clothing

suit n240308 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Suit

...suit

archibase planet

suit clothing

suit 2 n240308 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Suit

...suit

archibase planet

suit costume dress

suit n160211 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Suit

...suit

archibase planet

suit blouse jacket

suit n300713 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Suit

...suit

archibase planet

suit blouse jacket

suit n210813 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Suit

...suit

archibase planet

suit blouse jacket shirt-blouse

suit n140713 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Suit

...chibase planet

suit coat and skirt ladieswear outer clothing

suit n080713 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

design_connected

$29

Suite

...suite

designconnected

alivar suite computer generated 3d model. designed by bavuso, giuseppe.

3d_export

$15

3d hazmat worker hazmat suit body suit bio suit safety suit protective suit coverall safety wear

...suit coverall safety wear

3dexport

hazmat worker hazmat suit bodysuit bio-suit safety suit protective suit coverall safety wear

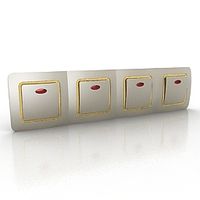

Switch

archibase_planet

free

Switch

...switch

archibase planet

switch cluster switch

light switch 1 - 3d model for interior 3d visualization.

archibase_planet

free

Switch

...switch

archibase planet

switches switch

switch 1 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Switch

...switch

archibase planet

closer button switch cluster switch

switch - 3d model (*.3ds) for interior 3d visualization.

archibase_planet

free

Switch

...switch

archibase planet

switch closer

light switch 2 - 3d model for interior 3d visualization.

archibase_planet

free

Switch

...switch

archibase planet

closer button switch

switch n300808 - 3d model (*.gsm+*.3ds) for interior 3d visualization

archibase_planet

free

Switch

...switch

archibase planet

closer button switch

switch n141108 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Switch

...switch

archibase planet

cluster switch closer

switch n260609 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Switch

...switch

archibase planet

button switch closer

switch 2 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Switch

...switch

archibase planet

button switch closer

switch n070510 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

$5

switch

...switch

3dexport

3d model of a low-poly switch