Thingiverse

PSMD (Pololu Stepper Motor Driver) Triple Axis Driver by tinkerings

by Thingiverse

Last crawled date: 3 years ago

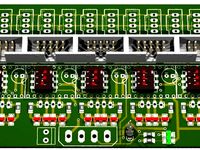

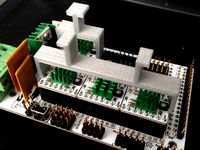

A drop-in replacement for the MakerBot stepper drivers that contains all three axes on one board.

You can order these from my web site: http://www.tinkerin.gs/p/psmd-pololu-stepper-motor-driver-triple.html

Now you can also order these from Seeed Studio!: http://www.seeedstudio.com/depot/psmd-triple-axis-driver-p-1029.html

Updated: Now smaller (same height as a Gen4 stepper driver and 1/4" wider for 3X the axes), and with dip switches to configure microstepping. Also now has a motor-power-in (or 12V out) screw terminal that can be used to drive the motors on up to 35V. I need to update the files an description.

See it in action here (with an early prototype): http://www.youtube.com/watch?v=8TEvwzTABEI&hd=1

And it's not mentioned or shown, but you can see it in action in this video: http://www.youtube.com/watch?v=2iGnlqBLn5s&hd=1

This board makes your steppers run at eight times higher resolution (1/16th steps instead of 1/2 steps), making it run smoother and way quieter.

I based the design on the MakerBot Stepper Driver v3.0 ( http://www.thingiverse.com/thing:760 ) but with a few notable exceptions:

•) I used the Pololu A4983/A4988 ( http://j.mp/pololu-smd2 ) stepper motor driver carrier board for each axis, so three of them are required for all three axes to work. (This was originally designed fo the A4983, but the replacement A4988 works great.)

•) Circuitry that is already on the Pololu board has been removed.

•) The CD-ROM-style connectors from the Gen4 electronics are used. I used a horizontal-mount connector instead of a vertical mount for mostly cosmetic reasons on the Cupcake, and that may have to be changed for the Thing-o-magic or a RepRap. I'll have to modify the layout to support vertical connectors if they are needed.

•) This board is etchable and hand-solderable. This means that, with the exception of the thru-hole capacitor leads, none of the lead holes are used as vias. Also, traces are reasonably far apart, all of the wiring of the thru-hole parts (except the caps) is on the back, and vias (and drilling) are avoided as much as possible. I have provided the PDF I used for toner transfer.

I placed the Pololu boards vertically and with nothing under them to provide a natural flow of hot air past them. This is why the capacitors are mounted on the back. If they still show signs of overheating, there are holes at the bottom to mount a 12v CPU fan to blow air up past them and provide cooling. So far, in my testing, the steppers overheat before the drivers.

More info about the RepRap testing with Pololu drivers (and my inspiration) here: http://www.reprap.org/wiki/Pololu_Electronics

Update 1: Oops, I forgot to post my machines.xml. Now it's up.

Update 2: I added a photo of this latest revision with the endstop connectors corrected and soldered in place. I'm working on the mechanical endstops as another thing. All of the other photos are of the previos revision of this board.

Update 3: I updated the eagle files with some minor cosmetic changes, mostly to clean up the silk screen. I didn't change the version because it's all cosmetic.

Update 4: I have partial build instructions up on Flickr. http://www.flickr.com/photos/giseburt/sets/72157625473951054/

Update 5: I have updated the design a little, and bumped the version number to 0.5. (I've left the 0.2 files here.) It now has 6-pin connectors that should be compatible with the Gen4 electronics. It also has a 12V in/out screw terminal, and I've added more silk-screen to help identify parts and pins. The down side is that the -pin connectors made the traces really tight, and it will be more difficult to solder a home-etched version, since some traces to the 6-pin headers are on the top side.

I'm sorry, I'm currently out of kits. I am in the process of having some professionally made, but I don't currently have an ETA. The good news is that they will be completely assembled, and the only soldering needed will be of the Pololu drivers.

You can order these from my web site: http://www.tinkerin.gs/p/psmd-pololu-stepper-motor-driver-triple.html

Now you can also order these from Seeed Studio!: http://www.seeedstudio.com/depot/psmd-triple-axis-driver-p-1029.html

Updated: Now smaller (same height as a Gen4 stepper driver and 1/4" wider for 3X the axes), and with dip switches to configure microstepping. Also now has a motor-power-in (or 12V out) screw terminal that can be used to drive the motors on up to 35V. I need to update the files an description.

See it in action here (with an early prototype): http://www.youtube.com/watch?v=8TEvwzTABEI&hd=1

And it's not mentioned or shown, but you can see it in action in this video: http://www.youtube.com/watch?v=2iGnlqBLn5s&hd=1

This board makes your steppers run at eight times higher resolution (1/16th steps instead of 1/2 steps), making it run smoother and way quieter.

I based the design on the MakerBot Stepper Driver v3.0 ( http://www.thingiverse.com/thing:760 ) but with a few notable exceptions:

•) I used the Pololu A4983/A4988 ( http://j.mp/pololu-smd2 ) stepper motor driver carrier board for each axis, so three of them are required for all three axes to work. (This was originally designed fo the A4983, but the replacement A4988 works great.)

•) Circuitry that is already on the Pololu board has been removed.

•) The CD-ROM-style connectors from the Gen4 electronics are used. I used a horizontal-mount connector instead of a vertical mount for mostly cosmetic reasons on the Cupcake, and that may have to be changed for the Thing-o-magic or a RepRap. I'll have to modify the layout to support vertical connectors if they are needed.

•) This board is etchable and hand-solderable. This means that, with the exception of the thru-hole capacitor leads, none of the lead holes are used as vias. Also, traces are reasonably far apart, all of the wiring of the thru-hole parts (except the caps) is on the back, and vias (and drilling) are avoided as much as possible. I have provided the PDF I used for toner transfer.

I placed the Pololu boards vertically and with nothing under them to provide a natural flow of hot air past them. This is why the capacitors are mounted on the back. If they still show signs of overheating, there are holes at the bottom to mount a 12v CPU fan to blow air up past them and provide cooling. So far, in my testing, the steppers overheat before the drivers.

More info about the RepRap testing with Pololu drivers (and my inspiration) here: http://www.reprap.org/wiki/Pololu_Electronics

Update 1: Oops, I forgot to post my machines.xml. Now it's up.

Update 2: I added a photo of this latest revision with the endstop connectors corrected and soldered in place. I'm working on the mechanical endstops as another thing. All of the other photos are of the previos revision of this board.

Update 3: I updated the eagle files with some minor cosmetic changes, mostly to clean up the silk screen. I didn't change the version because it's all cosmetic.

Update 4: I have partial build instructions up on Flickr. http://www.flickr.com/photos/giseburt/sets/72157625473951054/

Update 5: I have updated the design a little, and bumped the version number to 0.5. (I've left the 0.2 files here.) It now has 6-pin connectors that should be compatible with the Gen4 electronics. It also has a 12V in/out screw terminal, and I've added more silk-screen to help identify parts and pins. The down side is that the -pin connectors made the traces really tight, and it will be more difficult to solder a home-etched version, since some traces to the 6-pin headers are on the top side.

I'm sorry, I'm currently out of kits. I am in the process of having some professionally made, but I don't currently have an ETA. The good news is that they will be completely assembled, and the only soldering needed will be of the Pololu drivers.

Similar models

thingiverse

free

Model for Pololu A4988 Stepper Motor Driver Carrier with Voltage Regulator by kdtop3

...n other designs when creating a part to hold this.

there are parameters to hide the pins, or show them above or below the board.

thingiverse

free

RepRap Stepper Driver G5 A4983 v0.1 by Fishedbear

...prap stepper driver g5 a4983 v0.1 by fishedbear

thingiverse

this board is for pololu a4983 driver.

board size is 5.6cm x 5.6cm.

thingiverse

free

Pololu A4983 heatsink by michthom

...modify some aluminium profile (bosch rexroth, but 80/20 is similar for use as a heatsink for 4x pololu stepper...

thingiverse

free

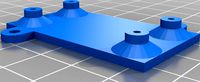

A4988 Stepper Motor Driver Spacer.

...ils out of the bottom of the board where they can be soldered.

this part was designed using the freeware version of emachineshop.

thingiverse

free

ccSD128 - A NEW MOTOR DRIVER FOR 3D PRINTERS by cccc_magicboy

...heet: http://www.onsemi.com/powersolutions/product.do?id=lv8728mr

order from here: https://world.taobao.com/item/538399988513.htm

thingiverse

free

One Stepper Driver for DRV8825/A4988 -OneStep Board by jasonmrc

... lines

led indicator for power on

decoupling cap next to driver .

2 pin terminal for 12v input

idc 10 pin compatible with ramps !

grabcad

free

A4988 Stepper motor Driver

...a4988 stepper motor driver

grabcad

this is a a4988 stepper motor driver with heatsink

thingiverse

free

Pololu A4988 (RAMPS) by Vector_Mayhem

...a4988, the rest of the solidworks files are archistrong's. the step and stl files are the complete stack with 5 a4988's.

grabcad

free

Enclosure - CNC Shield For Arduino Nano

...8-stepper-motor-driver-electronics-mockup-1

-

https://grabcad.com/library/fan-3010-1

-

https://grabcad.com/library/usb-type-c-1

-

grabcad

free

A4988 - DRV8825 Stepstick Stepper Driver Mount Board

...a4988 - drv8825 stepstick stepper driver mount board

grabcad

a4988 - drv8825 stepstick stepper driver mount board

Psmd

thingiverse

free

PSMD (Pololu Stepper Motor Driver) Triple Axis Remix by bwevans

... the motors move smoothly and quietly. properly adjusted this thing is as quiet, well, as quiet as a resonant plywood box can be.

thingiverse

free

Quintuple Stepper Driver by CidVilas

...built one of these and only used the original psmd board as reference to try and make things fit....

Pololu

turbosquid

$5

A4988 Pololu driver

...r download as 3ds, dxf, obj, xsi, wrl, fbx, dwg, dae, and skp on turbosquid: 3d models for games, architecture, videos. (1366188)

thingiverse

free

Pololu by telefonche

...pololu by telefonche

thingiverse

print and place pololu usb avr programmer inside.

thingiverse

free

Soporte Motor Pololu by daveguevara

...soporte motor pololu by daveguevara

thingiverse

soporte de motor pololu con pernos de 3mm

thingiverse

free

Pololu extractor by Premium by Premium

...ololu extractor by premium by premium

thingiverse

save your pololu

forum français witbox et hephestos http://premium-forum.fr/

thingiverse

free

Pololu D24V90F5 tray mount by rpmwood

...pololu d24v90f5 tray mount by rpmwood

thingiverse

simple tray mount for a pololu d24v90f5

thingiverse

free

3pi Pololu Wall-e by rob0229

...3pi pololu wall-e by rob0229

thingiverse

this is designed to sit over a 3pi pololu.

thingiverse

free

Sprocket for Pololu track/wheel by Al_batarr

...rse

drive and idler spockets for pololu 22t/30t tracks and pololu wheel 42x19mm :

wheel diameter : 35mm

shaft diameter : 3mm

thingiverse

free

Pololu Relay Box by KikiTay

...f the pololu relay module

check out my other designs by clicking on my profile!

check out what i do at http://www.kikitayblog.com

thingiverse

free

Pololu 22T Custom Chassis by omerf

...pololu 22t custom chassis by omerf

thingiverse

created new chassis / frame for pololu 22t

thingiverse

free

Pololu Trex Jr Mount by isotope

...pololu trex jr mount by isotope

thingiverse

this is a simple mount for pololu trex jr motor controller board.

Tinkerings

thingiverse

free

TINKER CAP

...tinker cap

thingiverse

cap

thingiverse

free

Tinker obj elise

...tinker obj elise

thingiverse

tinker obj em lyon

thingiverse

free

Tinker Bot by DreadForgeMiniatures

...tinker bot by dreadforgeminiatures

thingiverse

tinker bot from dfm november 2019 pack.

thingiverse

free

Tinker Cad frame by nurcool99

...tinker cad frame by nurcool99

thingiverse

this is like a 3d picture of tinker cad

thingiverse

free

Tinker Sign by Mocha22

...tinker sign by mocha22

thingiverse

xxx

thingiverse

free

Tinker Thing by arrexender

...tinker thing by arrexender

thingiverse

this is a test model.

thingiverse

free

tinker toys by kpcampbell07

...tinker toys by kpcampbell07

thingiverse

made by ry

thingiverse

free

A tinker Toy by kpcampbell07

...a tinker toy by kpcampbell07

thingiverse

made by ry

thingiverse

free

Beet-Tinker by alithecat

...beet-tinker by alithecat

thingiverse

tinkercad sample - beetroot

thingiverse

free

Tinker CRAB by earnason

...tinker crab by earnason

thingiverse

crab designed in tinkercad

Triple

turbosquid

$10

Triple angle michael triple

...free 3d model triple angle michael triple for download as max on turbosquid: 3d models for games, architecture, videos. (1243156)

3d_export

$5

triple knob

...triple knob

3dexport

triple knob

3ddd

$1

flora triple

...flora triple

3ddd

slamp

подвес flora triple

3ddd

$1

Triple P!

...iple p!

3ddd

горшок , цветок , листья

triple p!

design_connected

$16

To triple sofa

...to triple sofa

designconnected

nurus to triple sofa computer generated 3d model. designed by ozelgin, tanju.

3d_export

$5

Triple bars

...triple bars

3dexport

these are triple bars for outdoor training/gymnastics. suitable for push-ups on uneven bars

turbosquid

$10

Triple Window

...quid

royalty free 3d model triple window for download as 3ds on turbosquid: 3d models for games, architecture, videos. (1484877)

turbosquid

$5

Triple copper

...free 3d model triple copper for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1317753)

turbosquid

$3

TRIPLE SWITCH

...free 3d model triple switch for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1369504)

turbosquid

$3

Triple bench

...d model triple bench for download as sldpr, ige, stl, and obj on turbosquid: 3d models for games, architecture, videos. (1560286)

Stepper

turbosquid

$85

Stepper

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_ocean

$22

Mini Stepper

...gymnastic indoor legs machine mini silver sport stepper trainer workout

3d model of silver and black mini stepper with a counter.

turbosquid

$3

stepper deluxe

...osquid

royalty free 3d model stepper deluxe for download as on turbosquid: 3d models for games, architecture, videos. (1284335)

turbosquid

$49

Stepper Motor

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$5

Fitness Stepper

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$1

stepper motor driver

...stepper motor driver for download as , fbx, dae, obj, and stl on turbosquid: 3d models for games, architecture, videos. (1688860)

turbosquid

$1

Stepper motor driver

... model stepper motor driver for download as obj, stl, and ige on turbosquid: 3d models for games, architecture, videos. (1577811)

3d_export

$5

Stepper motor Nema17 17HS4401

...stepper motor nema17 17hs4401

3dexport

turbosquid

$1

Nema 17 Stepper motor

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$1

Nema 17 Stepper Motor 59Nm

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Driver

archibase_planet

free

At-At driver

...er

archibase planet

at-at driver pilot soldier imperial army

at-at driver - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

$5

screw driver

...screw driver

3dexport

small sized screw driver

3d_ocean

$5

Screw Driver

...river industrial machine mechanical screw tool

detailed model of screw driver. all materials are included. model is render ready.

archive3d

free

At-At driver 3D Model

...ilot soldier imperial army

at-at driver - 3d model (*.gsm+*.3ds) for interior 3d visualization.

turbosquid

$60

Street Drivers

...uid

royalty free 3d model street drivers for download as fbx on turbosquid: 3d models for games, architecture, videos. (1211321)

turbosquid

$25

SCREW DRIVERS

...quid

royalty free 3d model screw drivers for download as max on turbosquid: 3d models for games, architecture, videos. (1560558)

turbosquid

$15

DVD driver

...osquid

royalty free 3d model dvd driver for download as max on turbosquid: 3d models for games, architecture, videos. (1237955)

turbosquid

$2

Screw Driver

...squid

royalty free 3d model screw driver for download as max on turbosquid: 3d models for games, architecture, videos. (1208607)

turbosquid

free

Screw driver

...ree 3d model screw driver for download as blend, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1598537)

turbosquid

$118

Driver Seat

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Axis

3ddd

$1

Мария Axis

...

3ddd

кухня , классическая , axis

модель кухни.

3d_export

$22

Axis robot 6-axis robotic arm

...ing parts drawings, standard parts purchased parts list, can be produced directly according to the drawings, welcome to download!

3ddd

free

Versatile Axis

...ddd

nexus , плитка

http://bvtileandstone.com/ceramic-porcelain/versatile-axis/

3d_export

$19

robot 2 axis

...robot 2 axis

3dexport

robot 2 axis

turbosquid

$40

Axis R5F

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$40

Axis S5F

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$30

Axis Athlon

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

Linear Axis

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$15

drawing axis

...drawing axis

3dexport

simple rendering of the scene file

3ddd

$1

versatile axis ARC

...versatile axis arc

3ddd

versatile , плитка

versatile axis arc red dot design award

Motor

archibase_planet

free

Motor

...base planet

motor motor engine engine electric motor

motor wagner n250213 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Motor

...motor

archibase planet

motor motor engine engine

motor n151112 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Motor

...motor

archibase planet

motor motor engine engine

motor n150615 - 3d model (*.gsm+*.3ds+*.max) for interior 3d visualization.

turbosquid

$15

Motor

...otor

turbosquid

royalty free 3d model motor for download as on turbosquid: 3d models for games, architecture, videos. (1639404)

3d_ocean

$5

Electric motor

...electric motor

3docean

car electric engine industry motor phase train vehicle

an electric motor enjoy!

3d_ocean

$18

Electric Motor

...electric motor

3docean

electric motor engine machine mover parts

3d model electric motor for hoist crane

turbosquid

$29

Motor

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$5

Motor

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

electric motor

...electric motor

3dexport

electric motor use for industrial purposes

3d_export

$5

servo motor

...tor

3dexport

it's a simple part of servo motor 0.75kw for used in machines assembly to show specified motor in own project.