Thingiverse

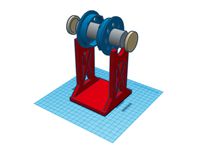

PseudoBot Filament Extruder by unotre

by Thingiverse

Last crawled date: 3 years ago

Inspired by http://www.extrusionbot.com

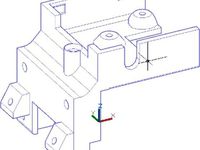

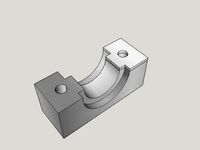

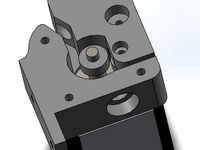

Auger barrel is 1" OD x .875" ID seamless 304 SS tubing and was single-point threaded on the bottom end. It, and the SS feed tube, were cupped with a 1" endmill @ 30 deg and welded together. The auger is a 7/8" "Jennings Pattern" screw bit, and its shank had to be trued and turned down on a lathe to 8mm to fit into an 8mm shaft collar and 8mm ball bearing. A thrust bearing stacked on top of the shat collar pushes against an aluminum plug that's been pinned to the auger barrel with a 5-40 screw. On the top end of the alu plug is a counter-bore to press fit the 8mm bearing into. On the bottom threaded portion of the barrel, an aluminum heat sink/hot-end with an internal 30 degree taper terminating to a 7/16-14 thread, screws on, and the brass extruder nozzle screws into the 7/16-14 thread. The heatsink is heated with a 1" 250w band heater. For the thermocouple, a 1/16" hole was drilled into the heatsink adjacent to the 7/16-14 thread and between where the band heater splits

Motor is the "BetaMotor" featured on filastruder.com. It was fastened to 4" x 1/4" aluminum angle with one leg milled down to 3", and the angle fastened to a 1/4" x 2" aluminum bar. The betamotor came with a square drive shaft, so I replaced the shaft with a 1/2" rod turned down to 3/8" on the drive end to fit into a 3/8" Lovejoy equipped w/ bronze spider.

The power supply for the motor (externally mounted on the left side) was a ~$25 12vdc10A LED power supply off Amazon.

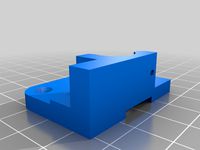

Housing dimensions: 6.5" width x 5" depth x 10" height.

I used a rotabroach to cut the 1" and 1.25" holes in what were to be the top and bottom before I bent it on a magnabend. All other holes, the PID, and window cut-outs were drilled or nipped after bending. After bending, the auger/motor brace assembly w/ spacers added was put into place, and the spacers were then traced around with a pencil to map where the housing mount holes should be. Six 1" pieces of 1/2"x1/8" angle were riveted to the rear housing to serve as attachment points for the front half of the housing.

Auger barrel is 1" OD x .875" ID seamless 304 SS tubing and was single-point threaded on the bottom end. It, and the SS feed tube, were cupped with a 1" endmill @ 30 deg and welded together. The auger is a 7/8" "Jennings Pattern" screw bit, and its shank had to be trued and turned down on a lathe to 8mm to fit into an 8mm shaft collar and 8mm ball bearing. A thrust bearing stacked on top of the shat collar pushes against an aluminum plug that's been pinned to the auger barrel with a 5-40 screw. On the top end of the alu plug is a counter-bore to press fit the 8mm bearing into. On the bottom threaded portion of the barrel, an aluminum heat sink/hot-end with an internal 30 degree taper terminating to a 7/16-14 thread, screws on, and the brass extruder nozzle screws into the 7/16-14 thread. The heatsink is heated with a 1" 250w band heater. For the thermocouple, a 1/16" hole was drilled into the heatsink adjacent to the 7/16-14 thread and between where the band heater splits

Motor is the "BetaMotor" featured on filastruder.com. It was fastened to 4" x 1/4" aluminum angle with one leg milled down to 3", and the angle fastened to a 1/4" x 2" aluminum bar. The betamotor came with a square drive shaft, so I replaced the shaft with a 1/2" rod turned down to 3/8" on the drive end to fit into a 3/8" Lovejoy equipped w/ bronze spider.

The power supply for the motor (externally mounted on the left side) was a ~$25 12vdc10A LED power supply off Amazon.

Housing dimensions: 6.5" width x 5" depth x 10" height.

I used a rotabroach to cut the 1" and 1.25" holes in what were to be the top and bottom before I bent it on a magnabend. All other holes, the PID, and window cut-outs were drilled or nipped after bending. After bending, the auger/motor brace assembly w/ spacers added was put into place, and the spacers were then traced around with a pencil to map where the housing mount holes should be. Six 1" pieces of 1/2"x1/8" angle were riveted to the rear housing to serve as attachment points for the front half of the housing.

Similar models

thingiverse

free

8mm bar end mirror adapter by wingnut1000

... 2mm in abs.

update: replace model for bottom piece. original had error that made it too thick causing stock bolt to be short.

thingiverse

free

Heatbed Threaded Rod Support "Z" Axis by iMakebyDesign

...bearing, 10mm rod use a 6900zz bearing ( or similar ). locate the collars 19 - 20mm from end...

thingiverse

free

5mm to 8mm Z axis shaft coupler by mrice

...ible shaft couplers on z axis rods, for 5mm motor shafts and 8mm threaded rods. use two m3x10mm screws and nuts to tighten down.

thingiverse

free

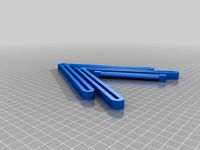

Aluminum extrusion acoustic panel bracket by realmakermods

...t; thickness.

screws are m3 screws, 3.4mm clearance holes in the print. 5.8mm head diameter for the countersunk front screw file.

thingiverse

free

V-Belt Pulley for Motor - 1 inch diameter, 0.5 inch shaft by circa1023

...

this is a 1" pulley for a motor with a notched 1/2" diameter drive shaft. the set screw is a 1/16" untapped hole.

thingiverse

free

Brackets for Drag chain by PCFlyer

...own" end piece. i had a difficult time getting to the lower holes once multiple wires were passing through it. this works.

thingiverse

free

NEMA17 motor to Acme lead screw shaft coupling by mrice

...ere are two versions of the stl, the original (3/8" lead screw) version shown in the photo, and a 1/4" version as well.

thingiverse

free

Coupling 12mm shaft with keyway to 7/16 hex by vaporsyndicate

...h keyway to 7/16 hex by vaporsyndicate

thingiverse

coupling for a 15:1 geared nema23 driving a 5/8 auger bit with a 7/16 shank.

thingiverse

free

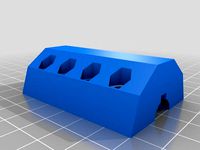

End Mill Set Holder by ril3y

... the last layer is the file that has the work "bottom" in it. it basically is only the outline and no end mill holes.

thingiverse

free

Shaft coupler from quarter inch (1/4") to 14mm by blaiseb

...mm shaft or threaded rod.

nuts and bolts used for assembly:

four 8-32 x 1"

two 8-32 x 1/2"

two 8-32 x 5/8"

Unotre

thingiverse

free

SLA Metallic Microlattice test by unotre

...sla metallic microlattice test by unotre

thingiverse

microtruss1 = imperial units

microtruss2 = metric units

thingiverse

free

Afinia UP! Extruder Cable Box by unotre

...anyone wanting to modify the extruder cable box on afinia / up! printers but can't because of the proprietary .up3 file type.

thingiverse

free

Afinia UP! Indicator Mount / Holder by unotre

... temp switch).

your indicator should have a 3/4" or 1" probe attached in order to take readings close to the nozzle.

thingiverse

free

10mm Keck by Bruta1ity

...10mm keck by bruta1ity thingiverse scaled down unotre#39;s 14mm keck clip to fit my 10mm...

thingiverse

free

14/20 Keck Clip - ST/NS Glassware Taper Joint Clip by unotre

... splitting.

24/40 keck clip: http://www.thingiverse.com/thing:274563

19/22 keck clip: http://www.thingiverse.com/thing:275257

thingiverse

free

Torsen LSD - Limited Slip Differential by unotre

... the base plate should be printed lengthwise up so it has the lowest amount of contact area with the platform to prevent curling.

thingiverse

free

Torsen LSD SCALED by pachek

...this a remix of the torsen lsd designed by "unotrequot;. main change is that it is scaled by half...

thingiverse

free

Schmidt Coupling - Offset Coupling by unotre

...ed from the middle to prevent warping.

http://www.youtube.com/watch?v=04gz8nc38fu

https://www.youtube.com/watch?v=g2du1s2ukhq

thingiverse

free

24/40 Keck Clip - ST/NS Glassware Taper Joint Clip by unotre

..., no raft.

--

14/20 keck clip: http://www.thingiverse.com/thing:274395

19/22 keck clip: http://www.thingiverse.com/thing:275257

Extruder

thingiverse

free

Extruder

...extruder

thingiverse

extruder for 3dprinter

thingiverse

free

Linear extrude, rotation extrude by jtirado

...linear extrude, rotation extrude by jtirado

thingiverse

linear extrude, rotation extrude

thingiverse

free

extruder by brunoschoofs

...extruder by brunoschoofs

thingiverse

extruder

thingiverse

free

Extruder Catcher/Extruder Holder by Verdandi

...extruder catcher/extruder holder by verdandi

thingiverse

for holding extruder.

thx for clicking

designed on sketch up

thingiverse

free

extruder by nekro

...extruder by nekro

thingiverse

cooler extruder

thingiverse

free

Extruder by DViktor

...extruder by dviktor

thingiverse

extruder with three fans (1 unmanaged extruder and 2 managed to product) fans 20x20x10

thingiverse

free

Extruder Knob

...extruder knob

thingiverse

yet another extruder knob.

thingiverse

free

Extruder by ImHuman

...extruder by imhuman

thingiverse

my first extruder. my design.

thingiverse

free

BMG extruder

...bmg extruder

thingiverse

bmg extruder model : step, wrl, stl

thingiverse

free

Bowden Extruder

...bowden extruder

thingiverse

i have created bowden extruder for flsun delta 3d printer.

Filament

thingiverse

free

Filament holder for 1,75mm filament by Boschlike

...ent holder for 1,75mm filament by boschlike

thingiverse

filament holder for 1,75mm filament.

mountable on the prusa mk3s+ frame.

thingiverse

free

Filament Holder SUNLU Filament by TrisiT

...filament holder sunlu filament by trisit

thingiverse

remix for the sunlu filament rolls.

thingiverse

free

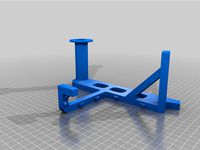

Filament stand

...filament stand

thingiverse

basic filament stand for filament coils with bigger diameter.

thingiverse

free

Filament Holder

...filament holder

thingiverse

this filament stand is to hold the filament without using the as-built location

thingiverse

free

Filament clip

... clip

really easy to print and use. no hole to insert the filament. the filament stay in place because pressed against the spool.

thingiverse

free

Filament hanger

...filament hanger

thingiverse

hanger for filaments. it helps you organize your filaments and work space.

thingiverse

free

filament holder

...filament holder

thingiverse

filament holder

thingiverse

free

Filament Cradle

...filament cradle

thingiverse

filament cradle

thingiverse

free

Filament Holder (Filament Spool) by herenkeskin

...filament holder (filament spool) by herenkeskin

thingiverse

this is a filament holder. i printed this part on my tevo tarantula.

thingiverse

free

Pyramid Filament Mount with Filament Sensor by wlbillmartin

...pyramid filament mount with filament sensor by wlbillmartin

thingiverse

pyramid filament mount with filament sensor

(9:30)